Professional Documents

Culture Documents

Cement Industry: Factor Endowments

Cement Industry: Factor Endowments

Uploaded by

gokul9rovOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Industry: Factor Endowments

Cement Industry: Factor Endowments

Uploaded by

gokul9rovCopyright:

Available Formats

[Author name]

CEMENT INDUSTRY

[DOCUMENT TITLE]

FACTOR ENDOWMENTS

Availability of raw material: Procurement of local raw materials forms the basis for the

manufacture of cement and represents an essential component of industrial value creation

chain. The most important base materials in cement include limestone and clay

Modern technology: With the successful adaption of the modern innovative technologies the

industry can reduce the cast and improve productivity. advanced process of automation

ensures that cement plants perform in a better way, which will be resulting in increased

stability and higher profitability.

Low salary: In developing nation such has India and China the cost of labour is low, and the

industry can benefit from this.

Legal, regulatory, and environmental scenario – The cement industry is affected by

regulatory norms. This is prominent in developed countries where environmental issues are

more stringent. This adds to the companies’ costs.

DEMAND CONDITIONS

Boom in the housing sector world-wide: In developing nation such as India and China the

income of the people is increasing, and this has led to the boom in the housing sector. India's

real estate market is expected to reach US$ 180 billion by 2020 from US$ 93.8 billion in

2014. Emergence of nuclear families, rapid urbanisation and rising household income are

likely to remain the key drivers for growth

Increased government spending on infrastructure and construction sector: The

development of physical infrastructure in India and, consequently, the construction sector has

been in focus during the last decade. It is well established that the influence of the construction

industry spans across several sub-sectors of the economy.

FIRM STRATEGY, STRUCTURE AND RIVALRY

Second-largest cement producer in the world: With 502 million tons per year of cement

production capacity as of 2018, India is the second-largest cement producer in the world. The

cement production capacity is estimated to touch 550 MT by 2020. Of the total capacity, 98

percent lies with the private sector and the rest with the public sector.

Top 20 companies account for around 70% of the total production: The Indian cement

industry is dominated by a few companies. The top 20 cement companies account for almost

70 per cent of the total cement production of the country. A total of 210 large cement plants

account for a cumulative installed capacity of over 410 million tonnes, with 350 small plants

accounting for the rest.

High entry barrier: The entry barriers to cement industry include high capital costs and long

gestation periods. Access to limestone reserves also acts as a significant entry barrier.

Licensing of coal and limestone reserves, supply of power from the state grid is all controlled

by the Government. Most of the Cement companies rely more on captive power for the need

of electricity.

RELATED AND SUPPORTING INDUSTRIES

Limestone mining industry: Limestone is the pre-requisite to make Clinker. Limestone is

extracted from Mines. A company that has its own mines is at an advantageous position than

the one which doesn’t have mines.

Coal Industry: Coal is one of the important related industry, Coal is used in large quantity to

achieve the required heat. Coal is generally procured from open market and company which

has is successful in getting coal at low cost has an advantage. Cheaper coal can be obtained

through Government tendering – government rations a quota of cheap coal to each industry

You might also like

- Porter's Five Forces Analysis of Cement IndustryDocument8 pagesPorter's Five Forces Analysis of Cement Industryjanvii rayani100% (2)

- Roll No 8 (PGDM - Comm) - Value Chain Analysis - Ultra Tech CementsDocument8 pagesRoll No 8 (PGDM - Comm) - Value Chain Analysis - Ultra Tech CementsanuragmahendraNo ratings yet

- Cement Industry and M&A PDFDocument5 pagesCement Industry and M&A PDFSourin SauNo ratings yet

- Cement Industry in IndiaDocument19 pagesCement Industry in IndiaShobhit Chandak100% (14)

- Porter's Value Chain: Primary ActivitiesDocument2 pagesPorter's Value Chain: Primary Activitiesgokul9rov100% (1)

- My Business PlanDocument24 pagesMy Business PlanZacchaeus BulukuNo ratings yet

- Cement Industry in India PDFDocument19 pagesCement Industry in India PDFVrushabh ShelkarNo ratings yet

- Cement Industry AmbujaDocument21 pagesCement Industry Ambujaakhil janjirala100% (1)

- Indian Cement Industry: Riding The High Tide Managerial Economics Case AnalysisDocument11 pagesIndian Cement Industry: Riding The High Tide Managerial Economics Case AnalysisVrushabh ShelkarNo ratings yet

- Ambuja Main FileDocument60 pagesAmbuja Main Filemicropoint2524No ratings yet

- Cement Industry and M&A PDFDocument5 pagesCement Industry and M&A PDFSourin SauNo ratings yet

- Group01 - End Term ProjectDocument35 pagesGroup01 - End Term ProjectSiddharth GuptaNo ratings yet

- Indian Cement IndustryDocument7 pagesIndian Cement IndustrymayankNo ratings yet

- Cement Industry of BangladeshDocument22 pagesCement Industry of BangladeshAfrin Tonni33% (3)

- 07 Ultratech CementDocument16 pages07 Ultratech Cementkohinoor_roy5447No ratings yet

- ChettinadDocument52 pagesChettinadVinodh KumarNo ratings yet

- LGB SY AV PerformanceoftheIndianCementIndustry TheCompetitiveLandscapeDocument34 pagesLGB SY AV PerformanceoftheIndianCementIndustry TheCompetitiveLandscapeNulu Gopi chandNo ratings yet

- A Report On Swot Analysis and Pest Analysis of Birla GroupDocument5 pagesA Report On Swot Analysis and Pest Analysis of Birla Groupjustinlanger4100% (5)

- Indian Cement IndustryDocument27 pagesIndian Cement IndustrySubhamay Biswas100% (1)

- Sector Report: Sector Report: CementDocument4 pagesSector Report: Sector Report: CementsunilbajaadNo ratings yet

- 9-12 Cement Dec11Document4 pages9-12 Cement Dec11Pankaj SawankarNo ratings yet

- Kafle Report 1Document71 pagesKafle Report 1arjun kafleNo ratings yet

- Cost Investment in Different Sectors in Any Cement Manufacturing IndustryDocument7 pagesCost Investment in Different Sectors in Any Cement Manufacturing Industry9098238509No ratings yet

- Literature Review of Indian Cement IndustryDocument8 pagesLiterature Review of Indian Cement Industryc5pgcqzv100% (1)

- Report On Cement Industry in India By: Shobhit ChandaDocument13 pagesReport On Cement Industry in India By: Shobhit ChandaPrasanta DebnathNo ratings yet

- The Cement Industry Is One of The Main Beneficiaries of The Infrastructure BoomDocument9 pagesThe Cement Industry Is One of The Main Beneficiaries of The Infrastructure BoomSyedFaisalHasanShahNo ratings yet

- TAPMI School of Business: Manipal University, JaipurDocument26 pagesTAPMI School of Business: Manipal University, Jaipurvivek guptaNo ratings yet

- Study of Indian MarketDocument5 pagesStudy of Indian Marketvipul099No ratings yet

- Roll No 8 PGDM Comm Value Chain Analysis Ultra Tech CementsDocument8 pagesRoll No 8 PGDM Comm Value Chain Analysis Ultra Tech CementsAkashNo ratings yet

- SWOT Analysis On Cement IndustryDocument8 pagesSWOT Analysis On Cement IndustryNitesh Kumar100% (2)

- SWOT Analysis On Cement IndustryDocument8 pagesSWOT Analysis On Cement Industryranjith134No ratings yet

- Industry Analysis Cement IndustryDocument13 pagesIndustry Analysis Cement IndustrySalma Pazhayillath50% (2)

- Megharaja CBS01Document89 pagesMegharaja CBS01Naveen S GNo ratings yet

- Cement IndustryDocument18 pagesCement Industryvasanthamsri100% (1)

- Cement Is A Key Infrastructure IndustryDocument2 pagesCement Is A Key Infrastructure Industryletter2lalNo ratings yet

- Prestige Institute of Management & Research, Indore: ETOP ProfileDocument48 pagesPrestige Institute of Management & Research, Indore: ETOP Profileruchi katareNo ratings yet

- 08 - Chapter 1 PDFDocument36 pages08 - Chapter 1 PDFAkash RastogiNo ratings yet

- Cement Industry in India and Its Contribution To Indian GDPDocument18 pagesCement Industry in India and Its Contribution To Indian GDPkoon00721100% (1)

- Indian Cement IndustryDocument10 pagesIndian Cement IndustryJovi Agoc100% (1)

- Arun Performance FinalDocument67 pagesArun Performance FinalumeshrathoreNo ratings yet

- Msearchcementindustryreportjuly2020 (1) - 2020 11 13 06 12 36Document15 pagesMsearchcementindustryreportjuly2020 (1) - 2020 11 13 06 12 36Prashanth TapseNo ratings yet

- Planning Comision SummaryDocument11 pagesPlanning Comision Summarykumud_nishadNo ratings yet

- Capital Structure Analysis of Cement Industry in BangladeshDocument19 pagesCapital Structure Analysis of Cement Industry in Bangladeshamanur rahmanNo ratings yet

- Analysis of The Indian Cement IndustryDocument19 pagesAnalysis of The Indian Cement Industryashish sawantNo ratings yet

- Cement Industry Word FileDocument10 pagesCement Industry Word FileAyush Sharma100% (1)

- Industry Analysis of CementDocument19 pagesIndustry Analysis of CementKajal SharmaNo ratings yet

- Cemen T: Key Points Financial Year '09 Prospects Sector Do's and Dont's Indian Cement IndustryDocument12 pagesCemen T: Key Points Financial Year '09 Prospects Sector Do's and Dont's Indian Cement IndustryshanmumuthuNo ratings yet

- An Environmental Scanning Report On Cement IndustryDocument20 pagesAn Environmental Scanning Report On Cement IndustrySatyajeet SumanNo ratings yet

- Infrastructure Today - Nov'19 PDFDocument2 pagesInfrastructure Today - Nov'19 PDFswarupkumarnayakNo ratings yet

- Binani Cement Research ReportDocument11 pagesBinani Cement Research ReportRinkesh25No ratings yet

- G-2 - IA - GA (Cement Industry)Document29 pagesG-2 - IA - GA (Cement Industry)AalokNo ratings yet

- India Symposium IBEF Sectoral Reports CementDocument32 pagesIndia Symposium IBEF Sectoral Reports CementRitesh TayalNo ratings yet

- RBSA Indian Cement Industry AnalysisDocument18 pagesRBSA Indian Cement Industry AnalysisPuneet Mathur100% (1)

- Tejas Shelke Cement 1Document12 pagesTejas Shelke Cement 1Shweta ShelkeNo ratings yet

- Internship Report 1Document21 pagesInternship Report 1Jamesalbert KingNo ratings yet

- CEMENT INDUSTRY REPORT - Viddhi and DiyaDocument38 pagesCEMENT INDUSTRY REPORT - Viddhi and DiyaViddhiNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Tales from the Development Frontier: How China and Other Countries Harness Light Manufacturing to Create Jobs and ProsperityFrom EverandTales from the Development Frontier: How China and Other Countries Harness Light Manufacturing to Create Jobs and ProsperityNo ratings yet

- MiS Yansha Report My PartDocument3 pagesMiS Yansha Report My Partgokul9rovNo ratings yet

- Session 20 Job Shop Scheduling OM 2019 Practice ProblemsDocument9 pagesSession 20 Job Shop Scheduling OM 2019 Practice Problemsgokul9rovNo ratings yet

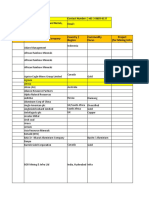

- Cost of Debt 2018-19: Wacc Weights Values (Rs. in Crores)Document3 pagesCost of Debt 2018-19: Wacc Weights Values (Rs. in Crores)gokul9rovNo ratings yet

- Essay On VideoDocument17 pagesEssay On Videogokul9rovNo ratings yet

- Supply Chain Management (SCM)Document4 pagesSupply Chain Management (SCM)gokul9rovNo ratings yet

- Proposal 2: The Progressive Research Group About The FirmDocument2 pagesProposal 2: The Progressive Research Group About The Firmgokul9rovNo ratings yet

- Leading Demand Aloe Vera Moisturizing CreamDocument1 pageLeading Demand Aloe Vera Moisturizing Creamgokul9rovNo ratings yet

- Cell ServiceDocument1 pageCell Servicegokul9rovNo ratings yet

- Q5,6 and RecommendationDocument3 pagesQ5,6 and Recommendationgokul9rovNo ratings yet

- Purpose and Context of SpeechDocument19 pagesPurpose and Context of Speechgokul9rovNo ratings yet

- Planning Processes - Project Management ExerciseDocument3 pagesPlanning Processes - Project Management Exercisegokul9rovNo ratings yet

- Vikram Talwar - Exl ServiceDocument9 pagesVikram Talwar - Exl Servicegokul9rovNo ratings yet

- Report On The Data AnalysisDocument2 pagesReport On The Data Analysisgokul9rovNo ratings yet

- International BusinessDocument5 pagesInternational Businessgokul9rovNo ratings yet

- Credit CardsDocument4 pagesCredit Cardsgokul9rovNo ratings yet

- Customer Day D - Mon D - Tue D - Wed D - Thu D - Fri D - SatDocument8 pagesCustomer Day D - Mon D - Tue D - Wed D - Thu D - Fri D - Satgokul9rovNo ratings yet

- Managerial Communication - I: Assignment Critiques of A SpeechDocument2 pagesManagerial Communication - I: Assignment Critiques of A Speechgokul9rovNo ratings yet

- Miles 32 33 28 n-1 37 Variance Is Unknown 29 30 25 27 39 40 26 26 27 30 25 30 31 29 24 36 25 37 37 20 22 35 23 28 30 36 40 41 30.5625Document9 pagesMiles 32 33 28 n-1 37 Variance Is Unknown 29 30 25 27 39 40 26 26 27 30 25 30 31 29 24 36 25 37 37 20 22 35 23 28 30 36 40 41 30.5625gokul9rovNo ratings yet

- Sustainability 11 02103 PDFDocument28 pagesSustainability 11 02103 PDFgokul9rovNo ratings yet

- Segmentation, Targeting and PositioningDocument2 pagesSegmentation, Targeting and Positioninggokul9rovNo ratings yet

- Colgate Max-Fresh: Marketing Management ProjectDocument21 pagesColgate Max-Fresh: Marketing Management Projectgokul9rovNo ratings yet

- Gratitude Journal: Name: Gokul Rov J PGDM NO: 19079 Section: BDocument1 pageGratitude Journal: Name: Gokul Rov J PGDM NO: 19079 Section: Bgokul9rovNo ratings yet

- Leather Industry of BangladeshDocument7 pagesLeather Industry of BangladeshAheen ImtiazNo ratings yet

- Supply Chain and Operations Management: Axelerom InternationalDocument16 pagesSupply Chain and Operations Management: Axelerom InternationalEmilio HlayelNo ratings yet

- Bugatti Shoes Q&A-Paper EnglishDocument5 pagesBugatti Shoes Q&A-Paper EnglishSajeer C Salim100% (1)

- IndustriesDocument3 pagesIndustriesaashna shirbhateNo ratings yet

- Chemical Manufacture and Industries Lahore Sheikhupura RoadDocument6 pagesChemical Manufacture and Industries Lahore Sheikhupura RoadEngr Muhammad Haider AliNo ratings yet

- Feeds and Speeds Titan Micro End MillsDocument1 pageFeeds and Speeds Titan Micro End MillsAngel Adan Llamas YañezNo ratings yet

- Ceftriaxone 1g InjectionDocument40 pagesCeftriaxone 1g InjectionNazia KabirNo ratings yet

- CRI - 2014 - LFS - Q - Variables NamesDocument19 pagesCRI - 2014 - LFS - Q - Variables Namessavan anvekarNo ratings yet

- Syrian Petroleum Company (SPC) : DescriptionDocument8 pagesSyrian Petroleum Company (SPC) : DescriptionAiham AltayehNo ratings yet

- Central Bank of India (Eco Project)Document2 pagesCentral Bank of India (Eco Project)Shivam TanejaNo ratings yet

- MTC Day 26 Jan 23Document5 pagesMTC Day 26 Jan 23irvan bustomiNo ratings yet

- DIA Project DescriptionDocument7 pagesDIA Project DescriptionDonnabelle AliwalasNo ratings yet

- Mutinta Siamuyoba Research Proposal 2020Document15 pagesMutinta Siamuyoba Research Proposal 2020Mutinta MubitaNo ratings yet

- Gold and Silver Policy BookletDocument40 pagesGold and Silver Policy BookletoxotosNo ratings yet

- ASN & Shipment FieldsDocument2 pagesASN & Shipment FieldsMuhammad NaumanNo ratings yet

- Agribusiness Magazine August 2019 EditionDocument42 pagesAgribusiness Magazine August 2019 EditiondowntopNo ratings yet

- 5.transportation ManagementDocument3 pages5.transportation ManagementAn Trần việtNo ratings yet

- India Uran 2005Document5 pagesIndia Uran 2005Akshay DidwaniyaNo ratings yet

- Mining Companies - GlobalDocument21 pagesMining Companies - Globalramesh50% (2)

- Urban and City Nodes - IreneDocument10 pagesUrban and City Nodes - IreneaayilliyaNo ratings yet

- Memorandum of Agreement ItcphhhDocument8 pagesMemorandum of Agreement ItcphhhHoward UntalanNo ratings yet

- Milling - ABC Hansen Africa Provides, Maize Mills and Stone Mills - 2 2Document30 pagesMilling - ABC Hansen Africa Provides, Maize Mills and Stone Mills - 2 2Nitty ChimpeloNo ratings yet

- Presentation On KnitwearDocument36 pagesPresentation On Knitweardssahadulal5483No ratings yet

- 3 Kigali Master Plan Transport PlanLowResDocument176 pages3 Kigali Master Plan Transport PlanLowResavinash kotaNo ratings yet

- 3 Shell and Tube Heat Exchanger Features That Affect Shell-Side Pressure DropDocument10 pages3 Shell and Tube Heat Exchanger Features That Affect Shell-Side Pressure DropRanjani J DeepakNo ratings yet

- Can Ethiopia's Coal Bonanza Substitute Imports - Ethiopian Business ReviewDocument2 pagesCan Ethiopia's Coal Bonanza Substitute Imports - Ethiopian Business ReviewsimenehNo ratings yet

- CIMAH Rules 2003Document20 pagesCIMAH Rules 2003Alpha StaturoryNo ratings yet

- Walmart in China: Strategic Business AnalysisDocument30 pagesWalmart in China: Strategic Business Analysisdilip504No ratings yet