Professional Documents

Culture Documents

Calibracion Anti-Volteo

Calibracion Anti-Volteo

Uploaded by

HEARTBREAKER MALDONADO0 ratings0% found this document useful (0 votes)

49 views10 pages- The document provides instructions for calibrating an anti-tipping device on a diesel machine. It involves bypassing a connector, selecting load cell configurations, placing the machine in specific positions with and without a load, and saving calibration points by pressing a button. The goal is to correctly set tipping thresholds based on the machine's configuration and load capacity.

Original Description:

Original Title

Calibracion anti-volteo

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document- The document provides instructions for calibrating an anti-tipping device on a diesel machine. It involves bypassing a connector, selecting load cell configurations, placing the machine in specific positions with and without a load, and saving calibration points by pressing a button. The goal is to correctly set tipping thresholds based on the machine's configuration and load capacity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

49 views10 pagesCalibracion Anti-Volteo

Calibracion Anti-Volteo

Uploaded by

HEARTBREAKER MALDONADO- The document provides instructions for calibrating an anti-tipping device on a diesel machine. It involves bypassing a connector, selecting load cell configurations, placing the machine in specific positions with and without a load, and saving calibration points by pressing a button. The goal is to correctly set tipping thresholds based on the machine's configuration and load capacity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 10

ANTI-TIPPING DEVICE CALIBRATION PROCEDURE

- Turn off the diesel engine. Make a bypass on X123 connector

(see below photos).

- Turn on the diesel engine.

- Press the left button to select the load cell number (a machine

can have 1 load cell on back axle or 2 load cells on back axle and

on chassis).

- Press the right button to confirm.

- Note: in case of a problem, turn off the diesel engine and re-start

again.

- Place the machine as per below photo: boom completely up and

retracted, no load.

- On display you should have:

Stab H (it means outriggers up: H = High).

pointer on green zone.

- Press the right button: in so doing you save the first key point.

- Wait a few seconds: the system needs a little time to save data

(on display you see: CAL).

- The system is automatically suggesting us the second key point.

- Note: if H or L is blinking, it means that macine configuration is

not the correct one for the next step.

- If machine has the outriggers, lower them; if it hasn’t, skip this

page.

- Display should show:

Stab L (it means outriggers down: L = Low).

Pointer on green zone.

- Press the right button: in so doing you save the second key

point.

- Next step is to make calibration with a load and with outriggers

up (stab H on display): place the machine with boom down,

completely in and with a load on forks. We suggest to use a load

of about 50% of maximum load capacity for the machine. The load

must be known.

NB: for safety reasons forks must be kept close to ground (about

10-20 cm).

- Boom out till you reach the position for which boom extension

should be stopped by the anti-tipping device (refer to relevant load

chart).

- Wait a few seconds till boom oscillation ends.

- Press the right button: in so doing you save the third key point.

- Next step is to make calibration with a load and with outriggers

down (stab L on display): place the machine with boom down,

completely in and with a load on forks. We suggest to use a load

of about 50% of maximum load capacity for the machine. The load

must be known.

NB: for safety reasons forks must be kept close to ground (about

10-20 cm).

- Boom out till you reach the position for which boom extension

should be stopped by the anti-tipping device (refer to relevant load

chart).

- Wait a few seconds till boom oscillation ends.

- Press the right button: in so doing you save the fourth key point.

- If calibration procedure is successful, a buzzer will be on till the

bypass on connector X123 is removed.

- Check the anti-tipping system: is it working OK?

Note: we described the general procedure for a machine with two

load cells: the first one on back axle and the second one on

chassis.

In case the machine has one load cell only, the calibration

procedure must start by selecting “one load cell version”; then the

key point to be saved are the first one and the third one only.

You might also like

- Heacox Diane. - Differentiating Instruction in The Regular Classroom. How To Reach and Teach All Learners, Grades 3-12Document92 pagesHeacox Diane. - Differentiating Instruction in The Regular Classroom. How To Reach and Teach All Learners, Grades 3-12Gabriela BelenNo ratings yet

- 787 Full Flight Tutorial: 1. Route InformationDocument45 pages787 Full Flight Tutorial: 1. Route Informationmadyson12383% (6)

- 950DK 205Document18 pages950DK 205purushmicro100% (1)

- CNC 6040 User ManualDocument23 pagesCNC 6040 User ManualSeyton123100% (1)

- Direccion Asistida Megane 2Document56 pagesDireccion Asistida Megane 2Christiam Ortega100% (1)

- Flight Simulator 2004 - Eaglesoft Cessna Citation X ManualDocument53 pagesFlight Simulator 2004 - Eaglesoft Cessna Citation X ManualAngel Carrero100% (2)

- Visture TPMS ManualDocument11 pagesVisture TPMS ManualInd Sha100% (1)

- PMDG 737NXG Dark and Cold TutorialDocument23 pagesPMDG 737NXG Dark and Cold Tutorialluca26288% (17)

- Citation II POHDocument27 pagesCitation II POHCarlos Daniel Rodriguez50% (6)

- D6D TRACTOR 20X00001 A 03041Document107 pagesD6D TRACTOR 20X00001 A 03041andresfido123100% (2)

- Powergear 500456 Operations ManualDocument15 pagesPowergear 500456 Operations ManualKeith BurgnerNo ratings yet

- DIECI-SARL CalibracijaDocument2 pagesDIECI-SARL CalibracijaAnto BanašNo ratings yet

- Fadec Engineering LLC UMC10 ManualDocument23 pagesFadec Engineering LLC UMC10 ManualFadecEngineeringLLC100% (1)

- A380 Tutorial UKDocument16 pagesA380 Tutorial UKAntero GuerraNo ratings yet

- Star DiagnosticsDocument39 pagesStar DiagnosticsSirleh SalehNo ratings yet

- Clear Alarm ProgramDocument2 pagesClear Alarm Programpeco2002No ratings yet

- Renault ElectricDocument24 pagesRenault Electricjohn florosNo ratings yet

- Vag-Com Logging and Graphing PDFDocument21 pagesVag-Com Logging and Graphing PDFspiros23100% (3)

- JAC Light Truck HFC1040Document50 pagesJAC Light Truck HFC1040Jose Simonetti100% (1)

- TPS Calibration ProcessDocument3 pagesTPS Calibration ProcessCrimsonGloryCANo ratings yet

- Minor AnswersDocument30 pagesMinor AnswersLinux ThingsNo ratings yet

- Topcon X20 Monitor Instructions 2013Document35 pagesTopcon X20 Monitor Instructions 2013Chan TkfcNo ratings yet

- f185 Automatic CosDocument328 pagesf185 Automatic CosAnder FahriNo ratings yet

- Ce 12p Product ManualDocument36 pagesCe 12p Product ManualHrsDesingNo ratings yet

- BMW OBC ManualDocument13 pagesBMW OBC ManualblutinkerNo ratings yet

- Power On Off FadalDocument8 pagesPower On Off FadalDSunte WilsonNo ratings yet

- Quick Start TutorDocument3 pagesQuick Start TutorLucaNo ratings yet

- TroubleshootingDocument24 pagesTroubleshootingAamer Khawaja100% (1)

- DIY Quick Reference Guide - 3300Document5 pagesDIY Quick Reference Guide - 3300allbsforakNo ratings yet

- New Machine Installtion GuideDocument17 pagesNew Machine Installtion GuideJosé Ramón TorresNo ratings yet

- Meriva (Opel / Vauxhall) Quick Reference - 2006Document2 pagesMeriva (Opel / Vauxhall) Quick Reference - 2006lidodidoNo ratings yet

- H500D Realism Enhancement Mod ManualDocument6 pagesH500D Realism Enhancement Mod ManualElizabeth HernandezNo ratings yet

- MB W210 AC Diagnostics and Flap TestDocument4 pagesMB W210 AC Diagnostics and Flap TestStoica Daniel0% (1)

- Peugeot 107 Owners Manual 2005Document89 pagesPeugeot 107 Owners Manual 2005Kris WraggNo ratings yet

- PTS 916 Operating ManualDocument5 pagesPTS 916 Operating ManualtskumarNo ratings yet

- LX3122 S 3in1 Manual (自动保存的)Document178 pagesLX3122 S 3in1 Manual (自动保存的)alfredoNo ratings yet

- DC9 EssentialsDocument12 pagesDC9 EssentialsCyriac JoseNo ratings yet

- LCMS Starting ProcedureDocument7 pagesLCMS Starting ProceduremambojumbNo ratings yet

- 4 Wheel Steer CalibrationDocument8 pages4 Wheel Steer CalibrationFrancisco Santiago GallardoNo ratings yet

- 6040z User ManualDocument29 pages6040z User Manualscribd1-22No ratings yet

- 3 Button Controller English Manual 2022Document20 pages3 Button Controller English Manual 2022John FosterNo ratings yet

- Enabling of Tire Pressure Monitoring System On A4 A5 b8Document5 pagesEnabling of Tire Pressure Monitoring System On A4 A5 b8costeniucNo ratings yet

- TB037 (Rev2) - Measuring BacklashDocument2 pagesTB037 (Rev2) - Measuring BacklashCarlos RodriguezNo ratings yet

- Prusa - I3 - Rework - Rev1.5 - First Use InstructionsDocument40 pagesPrusa - I3 - Rework - Rev1.5 - First Use InstructionshipercortexNo ratings yet

- System Programming InstructionsDocument5 pagesSystem Programming InstructionsMervin PenneyNo ratings yet

- 2013 Volkswagen Golf 34525Document6 pages2013 Volkswagen Golf 34525Petar ObradovicNo ratings yet

- Dualogic NewBravoDocument22 pagesDualogic NewBravoCata StefanNo ratings yet

- Zoll M, E Defibrillator - Service GuidelineDocument3 pagesZoll M, E Defibrillator - Service GuidelinePaul Levi NkahNo ratings yet

- Manual Citation IIDocument27 pagesManual Citation IIjuanpepeNo ratings yet

- Quick Reference Guide: 1) 1) Z 16 LER OnlyDocument2 pagesQuick Reference Guide: 1) 1) Z 16 LER Onlynicoleta.lincaNo ratings yet

- Steps To Programming A Controller For A PaverDocument5 pagesSteps To Programming A Controller For A PaverCarlos FigueredoNo ratings yet

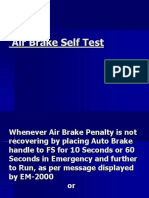

- Air Brake Self TestDocument24 pagesAir Brake Self TestAshoka SudharakaNo ratings yet

- Filzer db4lw Cyclometer InstructionsDocument1 pageFilzer db4lw Cyclometer Instructionsj sNo ratings yet

- As58 (Pfaff)Document16 pagesAs58 (Pfaff)jongaeckNo ratings yet

- 160Document2 pages160Luís FernandesNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- A Through Zs of Learning to Drive, Accident Free!: Drivers HandbookFrom EverandA Through Zs of Learning to Drive, Accident Free!: Drivers HandbookNo ratings yet

- Performance Analysis of Ber Vs SNR For BPSK and QPSK: A Project Based Lab Report OnDocument13 pagesPerformance Analysis of Ber Vs SNR For BPSK and QPSK: A Project Based Lab Report Onharika mandadapuNo ratings yet

- Note6 IntegerprogrammingDocument27 pagesNote6 Integerprogrammingアユ ギタNo ratings yet

- Indigo 36X3: Manual de UsuarioDocument4 pagesIndigo 36X3: Manual de UsuarioEliana Guzman PachecoNo ratings yet

- Conceptual FrameworkDocument3 pagesConceptual FrameworkChristoPher TorioNo ratings yet

- Labour Administration in A Changing World of WorkDocument160 pagesLabour Administration in A Changing World of WorkdomibrazilNo ratings yet

- FiiO M15 5Document9 pagesFiiO M15 5slobamsNo ratings yet

- What Is MulticulturalismDocument7 pagesWhat Is MulticulturalismamnahNo ratings yet

- CANDIDATE Instruction On Admit Cards: Srinagar, Kothi Bagh,,Srinagar, 190001Document1 pageCANDIDATE Instruction On Admit Cards: Srinagar, Kothi Bagh,,Srinagar, 190001AzImmNo ratings yet

- Clutches Brakes CtenDocument156 pagesClutches Brakes CtenRiz WanNo ratings yet

- Impact of Work Life Balance of Employees in Hospital Industry in India - A Case Study of Apollo Hospitals, VisakhapatnamDocument10 pagesImpact of Work Life Balance of Employees in Hospital Industry in India - A Case Study of Apollo Hospitals, Visakhapatnamindex PubNo ratings yet

- Acharya Bal KrishnahhDocument194 pagesAcharya Bal Krishnahhajay bhatnagarNo ratings yet

- Automated Plant Watering DeviceDocument31 pagesAutomated Plant Watering DeviceEdrei Jehezekel JavierNo ratings yet

- Sherif Lawal A.: Software Engineer-AndroidDocument2 pagesSherif Lawal A.: Software Engineer-AndroidLawal SherifNo ratings yet

- Art. MT Elliot - MatTAP A MATLAB Toolbox For The Control and Analysis of Movement Synchronisation ExperimentsDocument8 pagesArt. MT Elliot - MatTAP A MATLAB Toolbox For The Control and Analysis of Movement Synchronisation ExperimentsPaul RodrigoNo ratings yet

- ACS Publications 2018 UpdateDocument37 pagesACS Publications 2018 UpdateSeptian Perwira YudhaNo ratings yet

- Working Paper: Aeronautical Communications Panel (Acp) Twentyseventh Meeting of Working Group FDocument7 pagesWorking Paper: Aeronautical Communications Panel (Acp) Twentyseventh Meeting of Working Group FMark Angielo TrillanaNo ratings yet

- Unit-I - 4 StringDocument23 pagesUnit-I - 4 StringMochiNo ratings yet

- Module Programming and Reprogramming Service Tips September 2013 Update V4Document1 pageModule Programming and Reprogramming Service Tips September 2013 Update V4Mauri accattoliNo ratings yet

- Lesson Plan - PowerPoint PresentationDocument2 pagesLesson Plan - PowerPoint PresentationVicente CarandangNo ratings yet

- Solidification of Metals (To Be Completed) : Prof. H. K. Khaira Professor, Deptt. of MSME M.A.N.I.T., BhopalDocument62 pagesSolidification of Metals (To Be Completed) : Prof. H. K. Khaira Professor, Deptt. of MSME M.A.N.I.T., BhopalIndranil Bhattacharyya100% (1)

- EANTC CEWC2012 Whitepaper OnlineDocument9 pagesEANTC CEWC2012 Whitepaper OnlineijundiNo ratings yet

- Chapter 20 Sustainable Marketing: Social Responsibility and EthicsDocument45 pagesChapter 20 Sustainable Marketing: Social Responsibility and EthicsKAIVALYA PAINo ratings yet

- Mathematics Es1 Scope and Sequence Approach 1Document9 pagesMathematics Es1 Scope and Sequence Approach 1Jobelle De Vera TayagNo ratings yet

- Plumbing MaterialsDocument5 pagesPlumbing MaterialsJeany NoquilloNo ratings yet

- Program Schedule & Report - Research Methodology WorkshopDocument13 pagesProgram Schedule & Report - Research Methodology WorkshopDr. Vijaykumar BandalNo ratings yet

- EMI Intern Programme Brief For CandidatesDocument2 pagesEMI Intern Programme Brief For CandidatesKiizaNo ratings yet

- Critical Analysis of Folk MediaDocument3 pagesCritical Analysis of Folk MediaRaveel Qureshi100% (2)

- Zeroth Review TemplateDocument17 pagesZeroth Review TemplateJeffrey Dan OliverNo ratings yet