Professional Documents

Culture Documents

Valve Sizing and Selection: (Psia) (Inlet Pressure)

Valve Sizing and Selection: (Psia) (Inlet Pressure)

Uploaded by

pablolevrand0 ratings0% found this document useful (0 votes)

10 views1 pageOriginal Title

STEAM SIZING_PGPL

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views1 pageValve Sizing and Selection: (Psia) (Inlet Pressure)

Valve Sizing and Selection: (Psia) (Inlet Pressure)

Uploaded by

pablolevrandCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Valve Sizing and Selection

®®

Steam Application Considerations: For High Pressure (above 15 psi) Modulating

Applications - use h = 42% P1 (psia)

1 - Two position or proportional control

2 - 1/3 or 2/3 Steam Application Q = 4000 #/hr

2 - Inlet pressure of Steam Inlet psi = 20 psi

3 - Steam Flow (in #/hr steam)

4 - Pipe Size Q = Flow Rate Q = 4000 #/hr

5 - Media Temperature P1(psia) = psig (inlet pressure)+14.7 P1 = 20 psig+14.7 = 34.7 psia

6 - Ambient Temperature h = 42% P1 h = 0.42 (20+14.7) = 14.57

7 - Spring Return Actuation or Non-Spring Return Po = P1-h Po = (20+14.7)–14.57 = 20.13

Actuation Required

8 - Voltage Requirement

Cv = 4000

= 77.86

Cv = Valve coefficient of flow 3 x √14.57 x 20.13

Q = #/hr steam

h = pressure drop across open valve

Po = Outlet pressure in psia=P1-h For 1/3.. 2/3 Steam Application:

P1 = Absolute Inlet Pressure=Gauge Pressure (psig) + 14.7

For this application two valves will be used for the same coil.

Cv = Q The 1/3 valve will be modulated at low loads, and at medium

loads where more steam is required, the 2/3 valve is modulat-

3x √h x Po ed and the 1/3 valve is driven closed. At high loads, the 2/3

valve remains full open, and the 1/3 valve is modulated. This

produces high accuracy.

For On-Off Applications - use 10% of the inlet

pressure and line size For example: Low Pressure (15 psi and less)

Modulating Applications-

Cv = 1000

= 51.25 use h=80% P1, where P1 is inlet psi

3 x √1.5 x 28.2

The total Cv is divided into thirds. Two valves are selected

Q = FLOW RATE Q = 1000 #/hr based on 1/3 of the calculated Cv, and 2/3 of the calculat-

h = 10% (inlet psi) h = 0.10 (15) = 1.5 ed Cv.

I20707 - 03/07 - 10M - Subject to change. © Belimo Aircontrols (USA), Inc.

Po = (inlet psi + 14.7) – h Po = (15 + 14.7) – 1.5 = 28.2

Q = 10,000 #/hr

Q = 1000 #/hr Inlet psi = 10 psi

Inlet psi = 15 psi

Q = FLOW RATE Q = 10,000 #/hr

h = 80% ( inlet psi) h = 0.8 (10) =8

Po = (inlet psi + 14.7) – h Po = (10 + 14.7) – 8=16.7

For Low Pressure (15 psi and less) Modulating

Applications - use h=80% P1, where P1 is inlet psi

Cv = 10,000

= 288.35

Q=1000 #/hr 3 x √8 x 16.7

Inlet psi = 15 psi

Cv = 288.35

Q = FLOW RATE Q = 1000 #/hr So, Divide the Cv by 3:

h = 80% (inlet psi) h = 0.8 (15) = 12 288.35 / 3 = 96.12

Po = (inlet psi + 14.7) – h Po = (15 + 14.7) – 12 = 17.7 1/3 = 96.12

2/3 = 192.23

Cv = 1000 Valves would be selected based on these two Cv ratings.

= 22.7

3 x √12 x 17.7

Valve Sizing/Selection

Note: On high pressure steam valves, trim and linkage

material must be selected to meet the temperature

requirements of the initial steam pressure before

any pressure reducing solutions.

800-543-9038 (USA) • 866-805-7089 (Ontario) • 203-791-8396 (Latin America) 233

You might also like

- ch03 PDFDocument23 pagesch03 PDFAkash Thummar100% (2)

- Week 13 To 15 Hydroelectric Power PlantDocument11 pagesWeek 13 To 15 Hydroelectric Power PlantyellowP100% (1)

- Asano An Introduction To Mathematics For Economics PDFDocument284 pagesAsano An Introduction To Mathematics For Economics PDFAlina-Alexandra Poschină0% (1)

- Summary Major Changes 2017 NESCDocument4 pagesSummary Major Changes 2017 NESCmora287No ratings yet

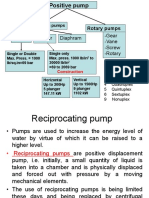

- Pump School - Basic Pump TheoryDocument47 pagesPump School - Basic Pump TheoryrezaNo ratings yet

- Pump School - Basic Pump TheoryDocument47 pagesPump School - Basic Pump TheoryHaji Muhammad AbushasaNo ratings yet

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document19 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- University of Perpetual Help System Dalta College of Engineering Electronics Engineering DepartmentDocument19 pagesUniversity of Perpetual Help System Dalta College of Engineering Electronics Engineering DepartmentFrenz VillasisNo ratings yet

- Pelton Wheel WriteupDocument10 pagesPelton Wheel Writeupbottomfragger993No ratings yet

- AD Lab ManualDocument33 pagesAD Lab ManualBasith AbbasNo ratings yet

- Mapúa University: Experiment No. 3Document20 pagesMapúa University: Experiment No. 3Eriane GarciaNo ratings yet

- Design of Expansion TankDocument4 pagesDesign of Expansion TankKELVIN100% (2)

- Vacuum TechnologyDocument15 pagesVacuum TechnologyRamal CooreyNo ratings yet

- Reciprocating Pump Test RigDocument7 pagesReciprocating Pump Test RigPurtain MENo ratings yet

- VE-101 ReportDocument2 pagesVE-101 ReportALAMEL MANZGHAI A/P GANESONNo ratings yet

- Expt No: Date:: Load Test On Francis TurbineDocument7 pagesExpt No: Date:: Load Test On Francis TurbineAlex ChollackalNo ratings yet

- TB8102.8 PGDocument8 pagesTB8102.8 PGAlberto LazzarettiNo ratings yet

- Air Receivers Volume CalculationDocument86 pagesAir Receivers Volume CalculationyoyoNo ratings yet

- Fluid Machinery: Hydraulic TurbinesDocument16 pagesFluid Machinery: Hydraulic Turbinesmathews munyumbeNo ratings yet

- Bypass Control Valve: Special Features and ControlsDocument13 pagesBypass Control Valve: Special Features and ControlsBrain J PérezNo ratings yet

- M7S1 Flood Gates and Pump StationsDocument19 pagesM7S1 Flood Gates and Pump StationsEunnice PanaliganNo ratings yet

- Performance Testing of A Centrifugal PumpDocument7 pagesPerformance Testing of A Centrifugal Pumppurushottam prajapatiNo ratings yet

- CalculationsDocument4 pagesCalculationsVinish HARIDAS NAIRNo ratings yet

- Fire Pump ChecklistDocument11 pagesFire Pump ChecklistLD Jr FrancisNo ratings yet

- 14 Hydro Electric Power PlantDocument31 pages14 Hydro Electric Power PlantYohan ManaligodNo ratings yet

- Pumps in Parallel or Series: Valves Intake DischargeDocument5 pagesPumps in Parallel or Series: Valves Intake Dischargeejzuppelli8036No ratings yet

- Operation of Centrifugal PumpDocument16 pagesOperation of Centrifugal PumpvenisamegaNo ratings yet

- Waste Water Piping and Vent SystemDocument8 pagesWaste Water Piping and Vent SystemGeraldine LaceaNo ratings yet

- Control System TemperatureDocument5 pagesControl System TemperatureGourav SharmaNo ratings yet

- Steam Sizing Chart-Technical Information PDFDocument2 pagesSteam Sizing Chart-Technical Information PDFgustavoNo ratings yet

- 663e0bd244269a00191dc6d8 - ## - Hydraulic Machine Short NotesDocument30 pages663e0bd244269a00191dc6d8 - ## - Hydraulic Machine Short NotesDknargesh 2003No ratings yet

- E12Document20 pagesE12Tadeo ChoqueNo ratings yet

- Automatic Fire Sprinkler CalcualtionDocument2 pagesAutomatic Fire Sprinkler CalcualtionKyaw HtayNo ratings yet

- Energy Conversion - II Lab ManualDocument33 pagesEnergy Conversion - II Lab ManualAshish VermaNo ratings yet

- Hydrodynamics Training-2Document143 pagesHydrodynamics Training-2Luis SudNo ratings yet

- F Luid Mec Hanic S: Week 3: Fluid Statics: Pressu ReDocument36 pagesF Luid Mec Hanic S: Week 3: Fluid Statics: Pressu ReAhmad RazaNo ratings yet

- Observations and Tabulation Table 1 Test For Single PumpDocument7 pagesObservations and Tabulation Table 1 Test For Single PumpadityaNo ratings yet

- 2 Way & 3 Way Modulating Valve Selection ProcedureDocument5 pages2 Way & 3 Way Modulating Valve Selection ProcedureJuan Altamirano RojasNo ratings yet

- Solenoid Valve SelectDocument3 pagesSolenoid Valve Selecttoddski1No ratings yet

- FRANCIS TURBINE - 1 KW - (Pipe 65 MM)Document7 pagesFRANCIS TURBINE - 1 KW - (Pipe 65 MM)manoj kumarNo ratings yet

- Procedure (ME Lab Report 2)Document2 pagesProcedure (ME Lab Report 2)MARREN JEIRELLE PENAFLORNo ratings yet

- Fluid Mechanics II (Chapter4)Document15 pagesFluid Mechanics II (Chapter4)حيدر محمدNo ratings yet

- 79 SeriesDocument12 pages79 SeriesUdayraj KawariNo ratings yet

- M12 PDFDocument22 pagesM12 PDFAdrian GuzmanNo ratings yet

- Reciprocating Pump AppDocument5 pagesReciprocating Pump Appmanoj kumarNo ratings yet

- Lecture Title-11Document45 pagesLecture Title-11Adel AshrafNo ratings yet

- Refrigeration Systems Lecture 2 Notes Bsme 3ADocument8 pagesRefrigeration Systems Lecture 2 Notes Bsme 3ARetro GamerNo ratings yet

- Series 160S "S" Type Pitot Tubes: Operating InstructionsDocument2 pagesSeries 160S "S" Type Pitot Tubes: Operating InstructionsDanteNo ratings yet

- FM & HM - Manual - 2019-2020Document34 pagesFM & HM - Manual - 2019-2020madhu sudhanNo ratings yet

- The Pitot Static TubeDocument2 pagesThe Pitot Static TubemvanoudenaardeNo ratings yet

- V1 001 PDFDocument20 pagesV1 001 PDFG100% (2)

- Pump - Design BahirisenDocument14 pagesPump - Design Bahirisenujjwal sapkotaNo ratings yet

- Experiment NoDocument33 pagesExperiment NoNandikaNo ratings yet

- Pump Performance: EAS 199A NotesDocument16 pagesPump Performance: EAS 199A Notesantopaul2No ratings yet

- For Turbine: For Pump & Compressor:: Design Parameter - NPH - NQH Specific Speed of TurbineDocument7 pagesFor Turbine: For Pump & Compressor:: Design Parameter - NPH - NQH Specific Speed of TurbineVirender SawaliyaNo ratings yet

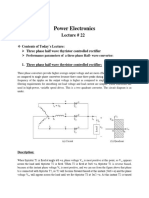

- Power Electronics: Lecture # 22Document3 pagesPower Electronics: Lecture # 22adnanNo ratings yet

- Air Receivers Volume CalculationDocument83 pagesAir Receivers Volume CalculationsudarwantoNo ratings yet

- ++flow Calculation For Gases PDFDocument1 page++flow Calculation For Gases PDFCarlos TarquinoNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- CH 20Document68 pagesCH 20BolWolNo ratings yet

- Pre Board CBRC Region 7 200 ItemsDocument215 pagesPre Board CBRC Region 7 200 ItemsMichelle Chale LumabaoNo ratings yet

- Semi Detailed Lesson Plan: (Finite Sequence) (Infinite Sequence)Document3 pagesSemi Detailed Lesson Plan: (Finite Sequence) (Infinite Sequence)Jayl 22100% (6)

- Packet Tracer - Configure Initial Switch Settings: ObjectivesDocument12 pagesPacket Tracer - Configure Initial Switch Settings: Objectiveszvezda dieslowNo ratings yet

- 1.2 FIBONACCI SEQUENCE TTH 12Document11 pages1.2 FIBONACCI SEQUENCE TTH 12Kris CruzNo ratings yet

- Composites ASTMDocument5 pagesComposites ASTMEirick Wayne Zuñigga De-ItzelNo ratings yet

- Heart Disease Prediction DocumentationDocument4 pagesHeart Disease Prediction DocumentationkhizrullahkhanNo ratings yet

- Short Notes On Kiln RefractoryDocument4 pagesShort Notes On Kiln RefractoryVijay BhanNo ratings yet

- SPE 71517 Decline Curve Analysis Using Type Curves - Evaluation of Well Performance Behavior in A Multiwell Reservoir SystemDocument15 pagesSPE 71517 Decline Curve Analysis Using Type Curves - Evaluation of Well Performance Behavior in A Multiwell Reservoir SystemGHIFFARI PARAMANTA ELBEESNo ratings yet

- Pump PutzmeisterDocument6 pagesPump PutzmeisterCamila AponteNo ratings yet

- How To Draw Basic Linear PerspectiveDocument16 pagesHow To Draw Basic Linear PerspectiveYao N'GoranNo ratings yet

- Bending of PlatesDocument72 pagesBending of PlatesPrajeesh Raj100% (1)

- 9.21 Pivot Table Slicer Chart DashboardDocument78 pages9.21 Pivot Table Slicer Chart DashboardrafaelsgNo ratings yet

- Sino Hydro Bureau 11 (1512-1520) PDFDocument6 pagesSino Hydro Bureau 11 (1512-1520) PDFCJNo ratings yet

- Write Python Instead of SQL!: An Introduction To SqlalchemyDocument10 pagesWrite Python Instead of SQL!: An Introduction To SqlalchemysxurdcNo ratings yet

- EM Notes For PrintingDocument268 pagesEM Notes For PrintingAnand PimpleNo ratings yet

- Data Sheets For Transmitters: Document ID JB0844-50710100-MIS-011Document3 pagesData Sheets For Transmitters: Document ID JB0844-50710100-MIS-011Vishnu PatidarNo ratings yet

- 8051MICROCONTROLLER BASED GAS AND FIRE ALARM SYSTEM+final RepDocument80 pages8051MICROCONTROLLER BASED GAS AND FIRE ALARM SYSTEM+final RepBhuwon Arjun83% (6)

- Identifying Salts LabDocument14 pagesIdentifying Salts LabSantiago Macías100% (1)

- Nutanix Collector User Guide v4 - 0Document48 pagesNutanix Collector User Guide v4 - 0Clement EbereNo ratings yet

- Registration of The Digital Signature of The Authorized Signatories of T...Document10 pagesRegistration of The Digital Signature of The Authorized Signatories of T...madhu chippalapallyNo ratings yet

- Testing of IEC 61850 Sampled Values Based Digital Substation Automation SystemsDocument5 pagesTesting of IEC 61850 Sampled Values Based Digital Substation Automation SystemsMikeyV03No ratings yet

- Synthesis of Vitamin B6Document3 pagesSynthesis of Vitamin B6Alejandro GRNo ratings yet

- Widi Pramesia Utami - 221015200088 (Pertemuan 10)Document2 pagesWidi Pramesia Utami - 221015200088 (Pertemuan 10)kedaicemilannnNo ratings yet

- SpaceClaim2017.1 SP0 ReleaseNotes PDFDocument47 pagesSpaceClaim2017.1 SP0 ReleaseNotes PDFKeerNo ratings yet

- John Deere Motor Grader 772a Manual de UsuarioDocument4 pagesJohn Deere Motor Grader 772a Manual de UsuarioEduardo ServínNo ratings yet

- Reconfigurable Intelligent Surfaces-Assisted Multiuser MIMO Uplink Transmission With Partial CSIDocument15 pagesReconfigurable Intelligent Surfaces-Assisted Multiuser MIMO Uplink Transmission With Partial CSIAgent NiharikaNo ratings yet