Professional Documents

Culture Documents

Scaffold Inspection Form: NO. Items To Be Checked Condition OK Observations / Comments

Scaffold Inspection Form: NO. Items To Be Checked Condition OK Observations / Comments

Uploaded by

Arshad MahmoodCopyright:

Available Formats

You might also like

- Lead Auditor 9001 Self AssessmentDocument5 pagesLead Auditor 9001 Self AssessmentArshad Mahmood76% (51)

- Caterpillar 3512b Operation and Maintenance Manual 56Document56 pagesCaterpillar 3512b Operation and Maintenance Manual 56Petro Osangiri100% (3)

- 9.8 Lockout & Tagout Inspection FormDocument1 page9.8 Lockout & Tagout Inspection FormArshad Mahmood100% (2)

- Westlake Lanes Case Analysis - EditedDocument5 pagesWestlake Lanes Case Analysis - EditedAditya DashNo ratings yet

- Tool Box Talk - Safe Use of Stanley KnivesDocument2 pagesTool Box Talk - Safe Use of Stanley KnivesGSI indonesia100% (2)

- Service Manual: P P P P PDocument87 pagesService Manual: P P P P PJialing Huang100% (1)

- Design of Brushless Permanent Magnet Machines-1Document2 pagesDesign of Brushless Permanent Magnet Machines-1harshalvikas50% (2)

- ICAPS Engineering Manual R3 10Document19 pagesICAPS Engineering Manual R3 10Arshad Mahmood100% (1)

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirNo ratings yet

- 14-03-00 Daily Pre-Task Plan (PTP)Document3 pages14-03-00 Daily Pre-Task Plan (PTP)JorgeNo ratings yet

- JHA Lifting-Moving Heavy Objects - ROMODocument5 pagesJHA Lifting-Moving Heavy Objects - ROMOSAMUEL POBRENo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Plywood Material Safety Data Sheet For MR Plywood PDFDocument4 pagesPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNo ratings yet

- Aramco HSE Roles & RespDocument16 pagesAramco HSE Roles & RespArshad Mahmood0% (1)

- Contractor Safety ManualDocument47 pagesContractor Safety ManualArshad Mahmood100% (4)

- Sds Gardoclean S 5070Document6 pagesSds Gardoclean S 5070Arshad MahmoodNo ratings yet

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Bhate & Raje Construction Co. Pvt. LTD: Electrical Work PermitDocument1 pageBhate & Raje Construction Co. Pvt. LTD: Electrical Work Permitvinayak salve100% (1)

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocument2 pagesSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherNo ratings yet

- 11 - Drilling Machine ChecklistDocument1 page11 - Drilling Machine ChecklistAfzal AkhtarNo ratings yet

- JSA Forklift PDFDocument2 pagesJSA Forklift PDFfauziNo ratings yet

- HSE Professionals - Fall Protection and PreventionDocument8 pagesHSE Professionals - Fall Protection and Preventionchinne046No ratings yet

- Night Shift FormDocument2 pagesNight Shift FormAnonymous kWfNFbNo ratings yet

- RB - HSE Daily Observation Report Dated 04.11.2021Document3 pagesRB - HSE Daily Observation Report Dated 04.11.2021Idris AdeniranNo ratings yet

- Jackhammer Inspection ChecklistDocument1 pageJackhammer Inspection ChecklistShahid BhattiNo ratings yet

- Daily Inspection Heck List: HSE General DepartmentDocument3 pagesDaily Inspection Heck List: HSE General DepartmentFaris WahedNo ratings yet

- Spill Kit ChecklistDocument1 pageSpill Kit Checklistmd rafiqueNo ratings yet

- Qusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistDocument1 pageQusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistJayaprakasan Koyadan KorothNo ratings yet

- Project Hse Notice Board: HSE Policy No Smoking Policy Permit To WorkDocument1 pageProject Hse Notice Board: HSE Policy No Smoking Policy Permit To WorkCristian Gil Gordillo100% (1)

- Fall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Document2 pagesFall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Lijo JohnNo ratings yet

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- F.e.& Scba InspectionDocument5 pagesF.e.& Scba InspectionAviects Avie JaroNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- DLF RCC HiraDocument8 pagesDLF RCC HiraskfahimuddinNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- Confined Space PlanDocument25 pagesConfined Space PlanPokiko MikotoNo ratings yet

- Earth Compactor Daily Check ListDocument2 pagesEarth Compactor Daily Check ListpjosesmNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Ladder-Safety-Inspection-Form-Editable - TemplateDocument2 pagesLadder-Safety-Inspection-Form-Editable - TemplateWayne McnaughtNo ratings yet

- 3.1 - CR 9 (1) Risk AssessorDocument1 page3.1 - CR 9 (1) Risk AssessorSusan LouwNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Electrical Work Checklist: Saline Water Desalination Plant On The West CoastDocument1 pageElectrical Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- Monthly Ladder Inspection ChecklistDocument1 pageMonthly Ladder Inspection ChecklistSalu BahiNo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- First Aid Kid ListDocument4 pagesFirst Aid Kid ListHairul Nizam Bin Mohd SalimNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Obie86 BahhierNo ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- Site Risk Register: Site Name: Rosebery ExDocument4 pagesSite Risk Register: Site Name: Rosebery ExvatasaNo ratings yet

- Rules For Electric SafetyDocument1 pageRules For Electric SafetyEmoji SquadNo ratings yet

- JSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Document3 pagesJSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Perwez21No ratings yet

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Self-Retracting Devices: Labels & MarkingsDocument1 pageSelf-Retracting Devices: Labels & Markingsghifariaghnia0% (1)

- JSA-Using A Type Ladder 2015Document1 pageJSA-Using A Type Ladder 2015nishanthNo ratings yet

- Permit To Work - Mobile CraneDocument2 pagesPermit To Work - Mobile CraneMIDWEST BUILDING DEMOLITIONS100% (1)

- Current Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryDocument3 pagesCurrent Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryAhsan MumtazNo ratings yet

- Manual Handling PosterDocument1 pageManual Handling PosterMacNo ratings yet

- JSO Slip, Trips & Fall (27 Aug.'07)Document1 pageJSO Slip, Trips & Fall (27 Aug.'07)Francis Enriquez TanNo ratings yet

- Reinforcement Cutting Bending JSA HSE ProfessionalsDocument1 pageReinforcement Cutting Bending JSA HSE ProfessionalsNoval FebriNo ratings yet

- Draft PTWDocument1 pageDraft PTWmohamad nur saufiNo ratings yet

- ZFP Sor 2022-9-20Document6 pagesZFP Sor 2022-9-20irfan shafiqueNo ratings yet

- MJ164 RIP SAW Operation ManualDocument36 pagesMJ164 RIP SAW Operation ManualEduardo Lopez CastilloNo ratings yet

- Cold Work PermitDocument2 pagesCold Work Permitimranul haqNo ratings yet

- PPE Matrix ExampleDocument2 pagesPPE Matrix ExampleVarun SharmaNo ratings yet

- TBT ExcavationsDocument2 pagesTBT ExcavationsJohn Vem BansagNo ratings yet

- Index of OP Project HIRA Activities ID No. Activities Remarks Format NoDocument7 pagesIndex of OP Project HIRA Activities ID No. Activities Remarks Format NoSameer JogasNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- Method Statement For Installation and Dismantling of Scaffolding at ACCDocument8 pagesMethod Statement For Installation and Dismantling of Scaffolding at ACCJethin SurendranNo ratings yet

- 9.5 Forklift Daily InspectionDocument1 page9.5 Forklift Daily InspectionArshad MahmoodNo ratings yet

- Storage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsDocument1 pageStorage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsArshad MahmoodNo ratings yet

- 9.7 Ladder Inspection ChecklistDocument1 page9.7 Ladder Inspection ChecklistArshad MahmoodNo ratings yet

- Qa/Qc Procedure Qcp-Painting - S 20Document1 pageQa/Qc Procedure Qcp-Painting - S 20Arshad MahmoodNo ratings yet

- Toyota Hilux Revo Brochure Saudi SpecificationsDocument6 pagesToyota Hilux Revo Brochure Saudi SpecificationsArshad MahmoodNo ratings yet

- 9.9 Power Tools Inspection FormDocument1 page9.9 Power Tools Inspection FormArshad MahmoodNo ratings yet

- Saudi Sadara Inspection Checklist CoverDocument1 pageSaudi Sadara Inspection Checklist CoverArshad MahmoodNo ratings yet

- Ergonomics & Hygiene Inspections Form: VAI Factory - HSE Audit ChecklistDocument1 pageErgonomics & Hygiene Inspections Form: VAI Factory - HSE Audit ChecklistArshad MahmoodNo ratings yet

- Case Study - Rooftop Multi Span LifelinesDocument2 pagesCase Study - Rooftop Multi Span LifelinesArshad MahmoodNo ratings yet

- Aerosol Can Safety: Be Aware of Extremely Flammable GasDocument1 pageAerosol Can Safety: Be Aware of Extremely Flammable GasArshad MahmoodNo ratings yet

- Alkifah Holding Company: Alkifah Contracting Company (KCC) Near Miss/Potential Hazard FormDocument2 pagesAlkifah Holding Company: Alkifah Contracting Company (KCC) Near Miss/Potential Hazard FormArshad MahmoodNo ratings yet

- Marafiq Risk Assessment 02Document5 pagesMarafiq Risk Assessment 02Arshad Mahmood50% (2)

- Clean Workspace PDFDocument1 pageClean Workspace PDFArshad MahmoodNo ratings yet

- Hand Tools Injury Prevention: DR Zehari DR Wahid TPC Hse TeamDocument23 pagesHand Tools Injury Prevention: DR Zehari DR Wahid TPC Hse TeamArshad MahmoodNo ratings yet

- Methane Fact SheetDocument6 pagesMethane Fact SheetArshad MahmoodNo ratings yet

- Pre Commissioning ChecklistsDocument13 pagesPre Commissioning ChecklistsMuhammad Akram100% (2)

- 0006 - 004 Near Miss Reporting Form PDFDocument1 page0006 - 004 Near Miss Reporting Form PDFArshad MahmoodNo ratings yet

- Overview of OHSAS 18001 and 18002Document10 pagesOverview of OHSAS 18001 and 18002Arshad MahmoodNo ratings yet

- Daily Obsrv Safety OfficersDocument1 pageDaily Obsrv Safety OfficersArshad MahmoodNo ratings yet

- How To Create Interactive PDFs With LibreOffice TechRepublicDocument6 pagesHow To Create Interactive PDFs With LibreOffice TechRepubliccastroNo ratings yet

- Unit Iv DabsDocument4 pagesUnit Iv Dabssanthini.tNo ratings yet

- GSE SCALE 350 Manual PDFDocument34 pagesGSE SCALE 350 Manual PDFSergio HernandezNo ratings yet

- Nominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe ChartDocument1 pageNominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe ChartakmlogaNo ratings yet

- Home AssignmentDocument2 pagesHome AssignmentSwastik GuptaNo ratings yet

- Combinatorics 17Document9 pagesCombinatorics 17Avani KumarNo ratings yet

- CIAYO Comics Logo Usages PDFDocument10 pagesCIAYO Comics Logo Usages PDFSyifa Putri YudianaNo ratings yet

- EMIS - Tamil Nadu Schools FOR HIGHER SECONDARYDocument9 pagesEMIS - Tamil Nadu Schools FOR HIGHER SECONDARYVelmurugan JeyavelNo ratings yet

- EjericiosDocument7 pagesEjericioskatherine FajardoNo ratings yet

- Consolidated Drained Tri AxialDocument15 pagesConsolidated Drained Tri AxialJemuel FloresNo ratings yet

- The Ultimate Guide To Audio Connectors and Cables - AudiostanceDocument17 pagesThe Ultimate Guide To Audio Connectors and Cables - Audiostancesabo6181No ratings yet

- Instructional Material FOR EETE 10013 Philippine Electrical CodeDocument58 pagesInstructional Material FOR EETE 10013 Philippine Electrical CodeRobert ApiladoNo ratings yet

- QB SYBBACA 304-Angular-JsDocument10 pagesQB SYBBACA 304-Angular-Jskastu0210No ratings yet

- 2022 - 002075129500003955742022 - CityEdge VAR Service Desk Go LiveDocument5 pages2022 - 002075129500003955742022 - CityEdge VAR Service Desk Go LiveMohamed HamdyNo ratings yet

- ExovoDocument357 pagesExovoreatonautoNo ratings yet

- 2 Days Artificial Intelligence Workshop For Students Without Any Charges by TechradianceDocument3 pages2 Days Artificial Intelligence Workshop For Students Without Any Charges by TechradianceDeadman ApexNo ratings yet

- National Institute of Technology: Communication Engineering Lab IIDocument11 pagesNational Institute of Technology: Communication Engineering Lab IIretgertreterNo ratings yet

- UENR2643UENR2643-05 - SIS Electrico Diagrama PDFDocument4 pagesUENR2643UENR2643-05 - SIS Electrico Diagrama PDFJaime LopezNo ratings yet

- DC Convolution CodesDocument136 pagesDC Convolution CodesARAVINDNo ratings yet

- How To Subtly Increase Your LinkedIn Visibility - HBR AscendDocument6 pagesHow To Subtly Increase Your LinkedIn Visibility - HBR AscendANDRES BERNALNo ratings yet

- Safeguard Properties Property Preservation Photos ManualDocument88 pagesSafeguard Properties Property Preservation Photos Manualnfirst965100% (1)

- Em03 - Machine LearningDocument14 pagesEm03 - Machine LearningVed Prakash SahNo ratings yet

- WebMoney Transfer Verification Application For A Personal PassportDocument1 pageWebMoney Transfer Verification Application For A Personal Passportnik.dymov100% (1)

- BD244CDocument2 pagesBD244CCarlosNo ratings yet

- The Art of Game Design A Book of Lenses Second EditionDocument61 pagesThe Art of Game Design A Book of Lenses Second Editioncarol.germann78195% (43)

- Havells-Switchgear 2010 BuildingDocument8 pagesHavells-Switchgear 2010 BuildingManpreet SinghNo ratings yet

Scaffold Inspection Form: NO. Items To Be Checked Condition OK Observations / Comments

Scaffold Inspection Form: NO. Items To Be Checked Condition OK Observations / Comments

Uploaded by

Arshad MahmoodOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scaffold Inspection Form: NO. Items To Be Checked Condition OK Observations / Comments

Scaffold Inspection Form: NO. Items To Be Checked Condition OK Observations / Comments

Uploaded by

Arshad MahmoodCopyright:

Available Formats

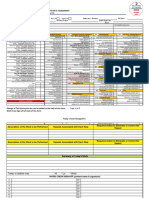

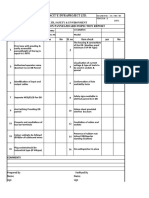

SCAFFOLD INSPECTION FORM

TYPE OF SCAFFOLD: □ FRAME □ TUBE & CLAMP □ SYSTEM LOCATION & DATE: ____________________________

ERECTOR/COMPETENT

MAXIMUM INTENDED LOAD: _____________________________ PERSON NAME:

CONDITION OBSERVATIONS /

NO. ITEMS TO BE CHECKED

OK COMMENTS

1 Scaffold components are in good condition?

2 Scaffold connections are secured?

3 Scaffold is level and plumb; resting on base plates (supported scaffols) and a

firm foundation?

4 Crossbracing is installed betweel scaffold legs?

5 Scaffold is contructed to support maximum intended load?

6 Wheel locks are operable on mobile scaffold (If any)?

Plank installation is correct and secure. Cleats are seated or planks are

7 properly extended (6 to 12 in. [15 to 30 cm]) beyond sill for lengths up to 10

ft (3.05 m)

8 Overlap is a minimum of 12 in. (30 cm) and extends 6 to

12 in. (15 to 30 cm) past the sill for the continuous run of planking.

Work platform fall protection:

* Fully planked within 9-1/2 in. (22.8 cm) of side rails

* Top rail (36 to 45 in. [ 91 to 1114 cm])

9 * Midrail (approximately centered)

* Toeboards

* Access

* Gate (or equal) where rails are missing

10 Loose hinges

11 Loose, broken or missing extension locks

12 Defective locks that do not seat properly when the ladder is extended

13 Deterioration of rope from exposure to weather or other destructive agents

Structure is stabilized against tipping if necessary. Secure at the nearest

horizontal bar as follows:

14 * Initially, secure at a height 4 times the minimum base dimension.

* Periodically, secure every 26 ft (7.9 m) unless the narrow dimension is 3 ft

(0.9 m) or less – then secure at 20-ft (6.1-m) increments.

* Secure at the nearest vertical bar every 30 ft (9.1 m) of length.

15 Minimum clearance from overhead power lines maintained as per applicable

legislation (750-150,000 Volts 10Ft)

16 Rolling scaffold wheel brakes locked and outriggers extended to maintain

maximum height of three times the smallest base dimension

17 Warning devices/signs provided if erected over walkways or roadways

(flashing lights, reflective tape streamers or area is roped off).

18 Scaffold status tag is completed and attached near the

access point.

Re-Approval Sunday Monday Tuesday Wednesday Thursday Saturday

Signature

Note:

1. This checklist shall be done every week by user prior to use of SCAFFOLD and be submitted to HSE Department on weekly basis.

2. Re-Approval / Inspection shall be done and signed on daily basis by user prior to use.

3. Any defects to the Scaffold must be reported and the Scaffold removed from use and marked with a label / tag to ensure further use is prohibited. All repair work to Scaffold may only be

carried out by a competent person.

REMARKS:

INSPECTOR NAME : ____________________________

DATE OF INSPECTION : __________________

INSPECTOR SIGNATURE

Form HS-INS-03

Revision 0 dated 09/01/217

You might also like

- Lead Auditor 9001 Self AssessmentDocument5 pagesLead Auditor 9001 Self AssessmentArshad Mahmood76% (51)

- Caterpillar 3512b Operation and Maintenance Manual 56Document56 pagesCaterpillar 3512b Operation and Maintenance Manual 56Petro Osangiri100% (3)

- 9.8 Lockout & Tagout Inspection FormDocument1 page9.8 Lockout & Tagout Inspection FormArshad Mahmood100% (2)

- Westlake Lanes Case Analysis - EditedDocument5 pagesWestlake Lanes Case Analysis - EditedAditya DashNo ratings yet

- Tool Box Talk - Safe Use of Stanley KnivesDocument2 pagesTool Box Talk - Safe Use of Stanley KnivesGSI indonesia100% (2)

- Service Manual: P P P P PDocument87 pagesService Manual: P P P P PJialing Huang100% (1)

- Design of Brushless Permanent Magnet Machines-1Document2 pagesDesign of Brushless Permanent Magnet Machines-1harshalvikas50% (2)

- ICAPS Engineering Manual R3 10Document19 pagesICAPS Engineering Manual R3 10Arshad Mahmood100% (1)

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirNo ratings yet

- 14-03-00 Daily Pre-Task Plan (PTP)Document3 pages14-03-00 Daily Pre-Task Plan (PTP)JorgeNo ratings yet

- JHA Lifting-Moving Heavy Objects - ROMODocument5 pagesJHA Lifting-Moving Heavy Objects - ROMOSAMUEL POBRENo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Plywood Material Safety Data Sheet For MR Plywood PDFDocument4 pagesPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNo ratings yet

- Aramco HSE Roles & RespDocument16 pagesAramco HSE Roles & RespArshad Mahmood0% (1)

- Contractor Safety ManualDocument47 pagesContractor Safety ManualArshad Mahmood100% (4)

- Sds Gardoclean S 5070Document6 pagesSds Gardoclean S 5070Arshad MahmoodNo ratings yet

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Bhate & Raje Construction Co. Pvt. LTD: Electrical Work PermitDocument1 pageBhate & Raje Construction Co. Pvt. LTD: Electrical Work Permitvinayak salve100% (1)

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocument2 pagesSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherNo ratings yet

- 11 - Drilling Machine ChecklistDocument1 page11 - Drilling Machine ChecklistAfzal AkhtarNo ratings yet

- JSA Forklift PDFDocument2 pagesJSA Forklift PDFfauziNo ratings yet

- HSE Professionals - Fall Protection and PreventionDocument8 pagesHSE Professionals - Fall Protection and Preventionchinne046No ratings yet

- Night Shift FormDocument2 pagesNight Shift FormAnonymous kWfNFbNo ratings yet

- RB - HSE Daily Observation Report Dated 04.11.2021Document3 pagesRB - HSE Daily Observation Report Dated 04.11.2021Idris AdeniranNo ratings yet

- Jackhammer Inspection ChecklistDocument1 pageJackhammer Inspection ChecklistShahid BhattiNo ratings yet

- Daily Inspection Heck List: HSE General DepartmentDocument3 pagesDaily Inspection Heck List: HSE General DepartmentFaris WahedNo ratings yet

- Spill Kit ChecklistDocument1 pageSpill Kit Checklistmd rafiqueNo ratings yet

- Qusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistDocument1 pageQusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistJayaprakasan Koyadan KorothNo ratings yet

- Project Hse Notice Board: HSE Policy No Smoking Policy Permit To WorkDocument1 pageProject Hse Notice Board: HSE Policy No Smoking Policy Permit To WorkCristian Gil Gordillo100% (1)

- Fall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Document2 pagesFall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Lijo JohnNo ratings yet

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- F.e.& Scba InspectionDocument5 pagesF.e.& Scba InspectionAviects Avie JaroNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- DLF RCC HiraDocument8 pagesDLF RCC HiraskfahimuddinNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- Confined Space PlanDocument25 pagesConfined Space PlanPokiko MikotoNo ratings yet

- Earth Compactor Daily Check ListDocument2 pagesEarth Compactor Daily Check ListpjosesmNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Ladder-Safety-Inspection-Form-Editable - TemplateDocument2 pagesLadder-Safety-Inspection-Form-Editable - TemplateWayne McnaughtNo ratings yet

- 3.1 - CR 9 (1) Risk AssessorDocument1 page3.1 - CR 9 (1) Risk AssessorSusan LouwNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Electrical Work Checklist: Saline Water Desalination Plant On The West CoastDocument1 pageElectrical Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- Monthly Ladder Inspection ChecklistDocument1 pageMonthly Ladder Inspection ChecklistSalu BahiNo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- First Aid Kid ListDocument4 pagesFirst Aid Kid ListHairul Nizam Bin Mohd SalimNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Obie86 BahhierNo ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- Site Risk Register: Site Name: Rosebery ExDocument4 pagesSite Risk Register: Site Name: Rosebery ExvatasaNo ratings yet

- Rules For Electric SafetyDocument1 pageRules For Electric SafetyEmoji SquadNo ratings yet

- JSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Document3 pagesJSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Perwez21No ratings yet

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Self-Retracting Devices: Labels & MarkingsDocument1 pageSelf-Retracting Devices: Labels & Markingsghifariaghnia0% (1)

- JSA-Using A Type Ladder 2015Document1 pageJSA-Using A Type Ladder 2015nishanthNo ratings yet

- Permit To Work - Mobile CraneDocument2 pagesPermit To Work - Mobile CraneMIDWEST BUILDING DEMOLITIONS100% (1)

- Current Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryDocument3 pagesCurrent Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryAhsan MumtazNo ratings yet

- Manual Handling PosterDocument1 pageManual Handling PosterMacNo ratings yet

- JSO Slip, Trips & Fall (27 Aug.'07)Document1 pageJSO Slip, Trips & Fall (27 Aug.'07)Francis Enriquez TanNo ratings yet

- Reinforcement Cutting Bending JSA HSE ProfessionalsDocument1 pageReinforcement Cutting Bending JSA HSE ProfessionalsNoval FebriNo ratings yet

- Draft PTWDocument1 pageDraft PTWmohamad nur saufiNo ratings yet

- ZFP Sor 2022-9-20Document6 pagesZFP Sor 2022-9-20irfan shafiqueNo ratings yet

- MJ164 RIP SAW Operation ManualDocument36 pagesMJ164 RIP SAW Operation ManualEduardo Lopez CastilloNo ratings yet

- Cold Work PermitDocument2 pagesCold Work Permitimranul haqNo ratings yet

- PPE Matrix ExampleDocument2 pagesPPE Matrix ExampleVarun SharmaNo ratings yet

- TBT ExcavationsDocument2 pagesTBT ExcavationsJohn Vem BansagNo ratings yet

- Index of OP Project HIRA Activities ID No. Activities Remarks Format NoDocument7 pagesIndex of OP Project HIRA Activities ID No. Activities Remarks Format NoSameer JogasNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- Method Statement For Installation and Dismantling of Scaffolding at ACCDocument8 pagesMethod Statement For Installation and Dismantling of Scaffolding at ACCJethin SurendranNo ratings yet

- 9.5 Forklift Daily InspectionDocument1 page9.5 Forklift Daily InspectionArshad MahmoodNo ratings yet

- Storage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsDocument1 pageStorage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsArshad MahmoodNo ratings yet

- 9.7 Ladder Inspection ChecklistDocument1 page9.7 Ladder Inspection ChecklistArshad MahmoodNo ratings yet

- Qa/Qc Procedure Qcp-Painting - S 20Document1 pageQa/Qc Procedure Qcp-Painting - S 20Arshad MahmoodNo ratings yet

- Toyota Hilux Revo Brochure Saudi SpecificationsDocument6 pagesToyota Hilux Revo Brochure Saudi SpecificationsArshad MahmoodNo ratings yet

- 9.9 Power Tools Inspection FormDocument1 page9.9 Power Tools Inspection FormArshad MahmoodNo ratings yet

- Saudi Sadara Inspection Checklist CoverDocument1 pageSaudi Sadara Inspection Checklist CoverArshad MahmoodNo ratings yet

- Ergonomics & Hygiene Inspections Form: VAI Factory - HSE Audit ChecklistDocument1 pageErgonomics & Hygiene Inspections Form: VAI Factory - HSE Audit ChecklistArshad MahmoodNo ratings yet

- Case Study - Rooftop Multi Span LifelinesDocument2 pagesCase Study - Rooftop Multi Span LifelinesArshad MahmoodNo ratings yet

- Aerosol Can Safety: Be Aware of Extremely Flammable GasDocument1 pageAerosol Can Safety: Be Aware of Extremely Flammable GasArshad MahmoodNo ratings yet

- Alkifah Holding Company: Alkifah Contracting Company (KCC) Near Miss/Potential Hazard FormDocument2 pagesAlkifah Holding Company: Alkifah Contracting Company (KCC) Near Miss/Potential Hazard FormArshad MahmoodNo ratings yet

- Marafiq Risk Assessment 02Document5 pagesMarafiq Risk Assessment 02Arshad Mahmood50% (2)

- Clean Workspace PDFDocument1 pageClean Workspace PDFArshad MahmoodNo ratings yet

- Hand Tools Injury Prevention: DR Zehari DR Wahid TPC Hse TeamDocument23 pagesHand Tools Injury Prevention: DR Zehari DR Wahid TPC Hse TeamArshad MahmoodNo ratings yet

- Methane Fact SheetDocument6 pagesMethane Fact SheetArshad MahmoodNo ratings yet

- Pre Commissioning ChecklistsDocument13 pagesPre Commissioning ChecklistsMuhammad Akram100% (2)

- 0006 - 004 Near Miss Reporting Form PDFDocument1 page0006 - 004 Near Miss Reporting Form PDFArshad MahmoodNo ratings yet

- Overview of OHSAS 18001 and 18002Document10 pagesOverview of OHSAS 18001 and 18002Arshad MahmoodNo ratings yet

- Daily Obsrv Safety OfficersDocument1 pageDaily Obsrv Safety OfficersArshad MahmoodNo ratings yet

- How To Create Interactive PDFs With LibreOffice TechRepublicDocument6 pagesHow To Create Interactive PDFs With LibreOffice TechRepubliccastroNo ratings yet

- Unit Iv DabsDocument4 pagesUnit Iv Dabssanthini.tNo ratings yet

- GSE SCALE 350 Manual PDFDocument34 pagesGSE SCALE 350 Manual PDFSergio HernandezNo ratings yet

- Nominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe ChartDocument1 pageNominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe ChartakmlogaNo ratings yet

- Home AssignmentDocument2 pagesHome AssignmentSwastik GuptaNo ratings yet

- Combinatorics 17Document9 pagesCombinatorics 17Avani KumarNo ratings yet

- CIAYO Comics Logo Usages PDFDocument10 pagesCIAYO Comics Logo Usages PDFSyifa Putri YudianaNo ratings yet

- EMIS - Tamil Nadu Schools FOR HIGHER SECONDARYDocument9 pagesEMIS - Tamil Nadu Schools FOR HIGHER SECONDARYVelmurugan JeyavelNo ratings yet

- EjericiosDocument7 pagesEjericioskatherine FajardoNo ratings yet

- Consolidated Drained Tri AxialDocument15 pagesConsolidated Drained Tri AxialJemuel FloresNo ratings yet

- The Ultimate Guide To Audio Connectors and Cables - AudiostanceDocument17 pagesThe Ultimate Guide To Audio Connectors and Cables - Audiostancesabo6181No ratings yet

- Instructional Material FOR EETE 10013 Philippine Electrical CodeDocument58 pagesInstructional Material FOR EETE 10013 Philippine Electrical CodeRobert ApiladoNo ratings yet

- QB SYBBACA 304-Angular-JsDocument10 pagesQB SYBBACA 304-Angular-Jskastu0210No ratings yet

- 2022 - 002075129500003955742022 - CityEdge VAR Service Desk Go LiveDocument5 pages2022 - 002075129500003955742022 - CityEdge VAR Service Desk Go LiveMohamed HamdyNo ratings yet

- ExovoDocument357 pagesExovoreatonautoNo ratings yet

- 2 Days Artificial Intelligence Workshop For Students Without Any Charges by TechradianceDocument3 pages2 Days Artificial Intelligence Workshop For Students Without Any Charges by TechradianceDeadman ApexNo ratings yet

- National Institute of Technology: Communication Engineering Lab IIDocument11 pagesNational Institute of Technology: Communication Engineering Lab IIretgertreterNo ratings yet

- UENR2643UENR2643-05 - SIS Electrico Diagrama PDFDocument4 pagesUENR2643UENR2643-05 - SIS Electrico Diagrama PDFJaime LopezNo ratings yet

- DC Convolution CodesDocument136 pagesDC Convolution CodesARAVINDNo ratings yet

- How To Subtly Increase Your LinkedIn Visibility - HBR AscendDocument6 pagesHow To Subtly Increase Your LinkedIn Visibility - HBR AscendANDRES BERNALNo ratings yet

- Safeguard Properties Property Preservation Photos ManualDocument88 pagesSafeguard Properties Property Preservation Photos Manualnfirst965100% (1)

- Em03 - Machine LearningDocument14 pagesEm03 - Machine LearningVed Prakash SahNo ratings yet

- WebMoney Transfer Verification Application For A Personal PassportDocument1 pageWebMoney Transfer Verification Application For A Personal Passportnik.dymov100% (1)

- BD244CDocument2 pagesBD244CCarlosNo ratings yet

- The Art of Game Design A Book of Lenses Second EditionDocument61 pagesThe Art of Game Design A Book of Lenses Second Editioncarol.germann78195% (43)

- Havells-Switchgear 2010 BuildingDocument8 pagesHavells-Switchgear 2010 BuildingManpreet SinghNo ratings yet