Professional Documents

Culture Documents

Recommended Belt Tensions

Recommended Belt Tensions

Uploaded by

Antonio UgartecheaCopyright:

Available Formats

You might also like

- Ecolife PDFDocument2 pagesEcolife PDFAntonio Ugartechea100% (5)

- Modern Physics SyllabusDocument10 pagesModern Physics Syllabusjhen bautista100% (1)

- Penske 7800 Technical ManualDocument12 pagesPenske 7800 Technical ManualgeorgeNo ratings yet

- Schémas Électriques XJ6 Service Manual Vol 5 PDFDocument695 pagesSchémas Électriques XJ6 Service Manual Vol 5 PDFTACHONNo ratings yet

- Belt Tension Recommendations Rev. 4.18.13 PDFDocument2 pagesBelt Tension Recommendations Rev. 4.18.13 PDFrfffffNo ratings yet

- Belt Tension RecommendationsDocument2 pagesBelt Tension RecommendationsW MoralesNo ratings yet

- Desch KB 16 GB Lutex LKBDocument6 pagesDesch KB 16 GB Lutex LKBchodgemNo ratings yet

- Torque Values For Standard Hardware: Imperial BoltsDocument5 pagesTorque Values For Standard Hardware: Imperial BoltsHugh O'Brien GwazeNo ratings yet

- AP EngDocument34 pagesAP EngNail KayaNo ratings yet

- 24 Roller Gate: Standard Assembly Unit Installation DataDocument1 page24 Roller Gate: Standard Assembly Unit Installation DataIulian Florin PeşuNo ratings yet

- Capscrew Markings and Torqure ValuesDocument4 pagesCapscrew Markings and Torqure ValuesNaing Min HtunNo ratings yet

- Common Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsDocument1 pageCommon Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsNazar AlrodainyNo ratings yet

- Flange Bolt-Up Bolting Torque Table 4 PDFDocument4 pagesFlange Bolt-Up Bolting Torque Table 4 PDFddarioxavier80No ratings yet

- Zeetex PCR US - IND+Ch PDFDocument32 pagesZeetex PCR US - IND+Ch PDFSnaps RoadNo ratings yet

- Aksa Master Pricelist 2014Document1 pageAksa Master Pricelist 2014Wissam JarmakNo ratings yet

- SCN Magnetic ContactorsDocument8 pagesSCN Magnetic ContactorsSyed Abrar HussainNo ratings yet

- Parker-VOAC Motor PilyDocument16 pagesParker-VOAC Motor PilyHarwesterNo ratings yet

- Flow Coefficients CV Values: Bolted Bonnet Globe Valves API 623 & B 16.34 Class: 150 - 2500 Size: 2" - 18"Document1 pageFlow Coefficients CV Values: Bolted Bonnet Globe Valves API 623 & B 16.34 Class: 150 - 2500 Size: 2" - 18"Mohamed NabilNo ratings yet

- Balmoral RWH HH Direct ManualDocument2 pagesBalmoral RWH HH Direct ManualAlberto DiazNo ratings yet

- SC and SW Series Specifications: Magnetic Contactors and StartersDocument5 pagesSC and SW Series Specifications: Magnetic Contactors and StartersMohsin LatifNo ratings yet

- Keppel Piping Hand BookDocument21 pagesKeppel Piping Hand BooktinzarmoeNo ratings yet

- HTD Unc Unf Bolt Tightening TorqueDocument2 pagesHTD Unc Unf Bolt Tightening Torqueelmfp7774676No ratings yet

- Oil Consumption-Cummins - DG QSM 11 DMDocument5 pagesOil Consumption-Cummins - DG QSM 11 DMzubrs77No ratings yet

- Energy Efficient MotorsDocument6 pagesEnergy Efficient MotorsRoumya Darshan RayNo ratings yet

- Denyo Dca Specifications-6128914Document1 pageDenyo Dca Specifications-6128914siva ramakrishnanNo ratings yet

- Denyo - DCADocument1 pageDenyo - DCAvicky beastNo ratings yet

- Technical Specifications - Three Phase MotorsDocument1 pageTechnical Specifications - Three Phase MotorsNirmal mehtaNo ratings yet

- DIN FlangesDocument1 pageDIN FlangesAnonymous N0VcjC1ZoNo ratings yet

- Guia Parafusos, Arruelas E Porcas 1Document156 pagesGuia Parafusos, Arruelas E Porcas 1Adrian VerattiNo ratings yet

- 170M 6809Document2 pages170M 6809bernaNo ratings yet

- Squirrel Cage Induction Motors: 7AAC63-90 7AACC63-100Document8 pagesSquirrel Cage Induction Motors: 7AAC63-90 7AACC63-100Isuru DharmasiriNo ratings yet

- Denyo DCA 150-600kva Specification TableDocument1 pageDenyo DCA 150-600kva Specification TablejerryNo ratings yet

- Installation and Operating Manual For Dab 4" Submersible Pumps S4A - S4B - S4C - S4D - S4E - S4FDocument14 pagesInstallation and Operating Manual For Dab 4" Submersible Pumps S4A - S4B - S4C - S4D - S4E - S4Fbagus saputraNo ratings yet

- DW1020 - Capscrew Torque Chart & InstructionsDocument4 pagesDW1020 - Capscrew Torque Chart & InstructionsAlex RamirezNo ratings yet

- The Best Solution in VentilationDocument8 pagesThe Best Solution in VentilationKanjeng Raden Aryo SaifuNo ratings yet

- Haitima Single Acting Aluminium Pneumatic Actuator: FeaturesDocument1 pageHaitima Single Acting Aluminium Pneumatic Actuator: FeaturesRiswanda HimawanNo ratings yet

- Flexible Joint TWFDocument5 pagesFlexible Joint TWFAhmad FauziNo ratings yet

- m1tr SS Anchor BoltDocument1 pagem1tr SS Anchor BoltLeo SerasingheNo ratings yet

- Metallic Gaskets - Installation & Torque - October 2020Document6 pagesMetallic Gaskets - Installation & Torque - October 2020Alberto CaveroNo ratings yet

- Book 1Document8 pagesBook 1PUNDLIK RATHODNo ratings yet

- TC Coolant Pump Userguide - 2020 - V2Document10 pagesTC Coolant Pump Userguide - 2020 - V2Luc DuchesneNo ratings yet

- ss500Document11 pagesss500dekyun49No ratings yet

- SLG274 US Cut SheetDocument4 pagesSLG274 US Cut SheetMehdi MolavianNo ratings yet

- DenyoCatalog DCA Series 150 KVADocument1 pageDenyoCatalog DCA Series 150 KVAkemas biruNo ratings yet

- TECHNICAL Lowara EHM-td-En 50 HZ Part44Document1 pageTECHNICAL Lowara EHM-td-En 50 HZ Part44Alberto GutierrezNo ratings yet

- R2000iB Specs Bolt PaternDocument4 pagesR2000iB Specs Bolt Paternto0984903132No ratings yet

- Torque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsDocument2 pagesTorque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsPranpath NarupantawartNo ratings yet

- Size of CB Protecting of MotorDocument4 pagesSize of CB Protecting of MotorjigarNo ratings yet

- Technical Bulletin: Hydraulic SnubbersDocument5 pagesTechnical Bulletin: Hydraulic SnubbersDavid Luna MolinaNo ratings yet

- Willcox HosesDocument6 pagesWillcox Hosesbunyamin.bangbenNo ratings yet

- Series 1500 EngineeringDocument5 pagesSeries 1500 EngineeringroychabNo ratings yet

- SAE SAEL Heavy Duty Face Fix HangersDocument8 pagesSAE SAEL Heavy Duty Face Fix HangersBerl MNo ratings yet

- GIW Technical Series: Pipe Flange BoltsDocument4 pagesGIW Technical Series: Pipe Flange BoltsTravis SkinnerNo ratings yet

- Built-In Freewheels: P-7426-SC-A4 10/18Document2 pagesBuilt-In Freewheels: P-7426-SC-A4 10/18Silviu DochiaNo ratings yet

- D-CKFG Series Cast Iron Three Phase Asymchronous MotorDocument4 pagesD-CKFG Series Cast Iron Three Phase Asymchronous MotorNaveed AhmedNo ratings yet

- Tipscontrol: Script SLDocument9 pagesTipscontrol: Script SLRajesh Chowdary ParaNo ratings yet

- Mechanical Pinch Valves of OV SeriesDocument5 pagesMechanical Pinch Valves of OV SeriesDaniel SanNo ratings yet

- Ficha Técnica de Productos: Tone Model STC - MultipliersDocument2 pagesFicha Técnica de Productos: Tone Model STC - MultipliersRichards Salvatierra ArimanaNo ratings yet

- Bombas Milton Roy Series - Milroyal-BDocument12 pagesBombas Milton Roy Series - Milroyal-BMarvin Zapa BohorquezNo ratings yet

- Posible Orden Lacey 01 ComplDocument5 pagesPosible Orden Lacey 01 ComplComunidad GnosticaNo ratings yet

- Specifications: Limitorque MX Selection DataDocument18 pagesSpecifications: Limitorque MX Selection DatamarklaforestNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- KKK MinDocument118 pagesKKK MinAntonio UgartecheaNo ratings yet

- MITSUBISHI MinDocument78 pagesMITSUBISHI MinAntonio UgartecheaNo ratings yet

- Puebla c8r Masa-VolvoDocument1 pagePuebla c8r Masa-VolvoAntonio UgartecheaNo ratings yet

- Exfo - Ftb-7600e-0034b Ftb-7000 Series Otdr For Ftb-200 v2 - User Guide-9234 2Document339 pagesExfo - Ftb-7600e-0034b Ftb-7000 Series Otdr For Ftb-200 v2 - User Guide-9234 2Bilal GayretliNo ratings yet

- 43BDocument13 pages43BJamie Schultz100% (1)

- Pile Driving EquipmentsDocument23 pagesPile Driving EquipmentsAbhishek BhushanNo ratings yet

- Notice Mhouse Moovo GTX4Document8 pagesNotice Mhouse Moovo GTX4BAKOnlineNo ratings yet

- Paper192046 2050 PDFDocument5 pagesPaper192046 2050 PDFPrateek KesarwaniNo ratings yet

- Jntu Anan Civil 2 2 HHM Set 4Document8 pagesJntu Anan Civil 2 2 HHM Set 4Kalisetti AnilNo ratings yet

- Ingliz Tili 10 DarslikDocument224 pagesIngliz Tili 10 DarslikMiryunusov MirabbosNo ratings yet

- Cold Facts Vol 33 No 3 (2017)Document48 pagesCold Facts Vol 33 No 3 (2017)Binh Thanh LeNo ratings yet

- Abonacci Trading: Credit: Bobi Abonacci ContactDocument4 pagesAbonacci Trading: Credit: Bobi Abonacci ContactUjangNo ratings yet

- Apluslift HW 10kbpDocument17 pagesApluslift HW 10kbpGBNo ratings yet

- 100 Fractions: Great For You If You Are Returning To SchoolDocument6 pages100 Fractions: Great For You If You Are Returning To SchoolOlan ElraiNo ratings yet

- Component Identification ElectronicsDocument23 pagesComponent Identification ElectronicsManjunatha Swamy VNo ratings yet

- Questions About Reverse OsmosisDocument6 pagesQuestions About Reverse OsmosisManjunath HrmNo ratings yet

- SAP ABAP Code For DR ReportDocument3 pagesSAP ABAP Code For DR ReporthallarmemonNo ratings yet

- Tongs Adler Dong 04 S PM RefDocument14 pagesTongs Adler Dong 04 S PM ReflfklasNo ratings yet

- CD110/CD110X SERIES: Aluminum Electrolytic CapacitorsDocument2 pagesCD110/CD110X SERIES: Aluminum Electrolytic CapacitorsPi PonyNo ratings yet

- Galvanizing Defects & RectificationsDocument28 pagesGalvanizing Defects & RectificationsSreedhar Patnaik.M90% (10)

- IMM - Write UpDocument5 pagesIMM - Write UpvanmanNo ratings yet

- Gravimetric Analysis of A Chloride SaltDocument9 pagesGravimetric Analysis of A Chloride SaltDorien Villafranco0% (1)

- HKOH SNDL Int ReqDocument2 pagesHKOH SNDL Int ReqMuhammad AsfandyarNo ratings yet

- Cash Flow Estimation: Tugas 7 Accounting and FinanceDocument5 pagesCash Flow Estimation: Tugas 7 Accounting and FinanceJessy SeptalistaNo ratings yet

- Oracle Inventory Module-APLDocument207 pagesOracle Inventory Module-APLRavi Kumar Reddy KalikiriNo ratings yet

- Actuarial ScienceDocument45 pagesActuarial SciencejinnymistNo ratings yet

- Ahts Stability 130926173935 Phpapp01 PDFDocument30 pagesAhts Stability 130926173935 Phpapp01 PDFJl RuMbOsNo ratings yet

- Isometries of The Plane - BoswellDocument7 pagesIsometries of The Plane - BoswellGuido 125 LavespaNo ratings yet

- Samia PDFDocument7 pagesSamia PDFMohamed Sayed AbdoNo ratings yet

- LRDI Puzzle - 18, 19, 20, 21Document5 pagesLRDI Puzzle - 18, 19, 20, 21anshuno247No ratings yet

- Repair Manual Hydrostatic Pump Motor PDFDocument112 pagesRepair Manual Hydrostatic Pump Motor PDFВячеслав Шапочка100% (3)

Recommended Belt Tensions

Recommended Belt Tensions

Uploaded by

Antonio UgartecheaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recommended Belt Tensions

Recommended Belt Tensions

Uploaded by

Antonio UgartecheaCopyright:

Available Formats

RECOMMENDED BELT TENSIONS

Improperly tensioned belts can cause slippage, squealing, heat build-up, and

premature failure. Dayco® engineers recommend specific guidelines be followed when

tensioning new and/or used drive belts. When installing new drive belts, it is important to

tension the belt to its specified tension, then after 3 to 5 minutes of engine “run-in,” retension

the belt to compensate for the loss of tension due to the belt “seating” into the pulleys. The

guidelines for the new belt installation tension and retension amounts are given below.

NOTE: The chart below shows the recommended installation tension and retension amounts

for locked-center drive applications. For automatic tensioner applications, NO tension

recommendations are required, as the tensioner designed for the drive will supply the

proper amount of tension.

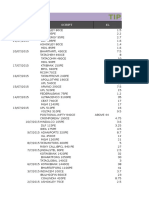

Recommended Tensioning Levels for Locked-Center Drive Applications

Belt Size New Belt Retension Amount Used Belt Tension

SAE / Dayco® Series Installation Tension (after 3-5 min run-in) (measured after belt cools)

IN METRIC DAYCO Lbs. Lbs. Lbs.

1/4 6A 09 90 70 45

5/16 8A 11 110 90 50

3/8 10A 13 140 112 65

7/16 11A 15 150 120 70

1/2 13A 17 160 128 75

11/16 15A 22 175 140 80

3/4 17A 24 190 152 90

7/8 20A 28 200 160 90

3K 3PK 105 90 45

4K 4PK 140 120 60

5K 5PK 175 150 75

6K 6PK 210 180 90

7K 7PK 245 210 105

8K 8PK 280 240 120

• The used belt tension is the amount of tension that would be maintained under normal drive conditions by the

given belt size. If the tension drops below the used belt tension, the belt should be re-tensioned according to

the retension amount. If the belt is shown to be worn, either caused by excessive slipping or long term

operation, it is recommended that the belt be replaced.

• It is important that the belt completely cools prior to measuring and retensioning the belt.

• If a “run-in” is not feasible, a minimum of 3 belt revolutions is required to “seat” the belt into the pulleys.

Once seated, retension the belt to the recommended amount.

• For “banded belts”, the recommended tension is found by multiplying the new belt installation tension value provided

above of the same belt type, by the number of belts banded together.

www.DaycoAftermarket.com

BELTTENREC_DOC001 © 2019 Dayco Products, LLC

You might also like

- Ecolife PDFDocument2 pagesEcolife PDFAntonio Ugartechea100% (5)

- Modern Physics SyllabusDocument10 pagesModern Physics Syllabusjhen bautista100% (1)

- Penske 7800 Technical ManualDocument12 pagesPenske 7800 Technical ManualgeorgeNo ratings yet

- Schémas Électriques XJ6 Service Manual Vol 5 PDFDocument695 pagesSchémas Électriques XJ6 Service Manual Vol 5 PDFTACHONNo ratings yet

- Belt Tension Recommendations Rev. 4.18.13 PDFDocument2 pagesBelt Tension Recommendations Rev. 4.18.13 PDFrfffffNo ratings yet

- Belt Tension RecommendationsDocument2 pagesBelt Tension RecommendationsW MoralesNo ratings yet

- Desch KB 16 GB Lutex LKBDocument6 pagesDesch KB 16 GB Lutex LKBchodgemNo ratings yet

- Torque Values For Standard Hardware: Imperial BoltsDocument5 pagesTorque Values For Standard Hardware: Imperial BoltsHugh O'Brien GwazeNo ratings yet

- AP EngDocument34 pagesAP EngNail KayaNo ratings yet

- 24 Roller Gate: Standard Assembly Unit Installation DataDocument1 page24 Roller Gate: Standard Assembly Unit Installation DataIulian Florin PeşuNo ratings yet

- Capscrew Markings and Torqure ValuesDocument4 pagesCapscrew Markings and Torqure ValuesNaing Min HtunNo ratings yet

- Common Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsDocument1 pageCommon Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsNazar AlrodainyNo ratings yet

- Flange Bolt-Up Bolting Torque Table 4 PDFDocument4 pagesFlange Bolt-Up Bolting Torque Table 4 PDFddarioxavier80No ratings yet

- Zeetex PCR US - IND+Ch PDFDocument32 pagesZeetex PCR US - IND+Ch PDFSnaps RoadNo ratings yet

- Aksa Master Pricelist 2014Document1 pageAksa Master Pricelist 2014Wissam JarmakNo ratings yet

- SCN Magnetic ContactorsDocument8 pagesSCN Magnetic ContactorsSyed Abrar HussainNo ratings yet

- Parker-VOAC Motor PilyDocument16 pagesParker-VOAC Motor PilyHarwesterNo ratings yet

- Flow Coefficients CV Values: Bolted Bonnet Globe Valves API 623 & B 16.34 Class: 150 - 2500 Size: 2" - 18"Document1 pageFlow Coefficients CV Values: Bolted Bonnet Globe Valves API 623 & B 16.34 Class: 150 - 2500 Size: 2" - 18"Mohamed NabilNo ratings yet

- Balmoral RWH HH Direct ManualDocument2 pagesBalmoral RWH HH Direct ManualAlberto DiazNo ratings yet

- SC and SW Series Specifications: Magnetic Contactors and StartersDocument5 pagesSC and SW Series Specifications: Magnetic Contactors and StartersMohsin LatifNo ratings yet

- Keppel Piping Hand BookDocument21 pagesKeppel Piping Hand BooktinzarmoeNo ratings yet

- HTD Unc Unf Bolt Tightening TorqueDocument2 pagesHTD Unc Unf Bolt Tightening Torqueelmfp7774676No ratings yet

- Oil Consumption-Cummins - DG QSM 11 DMDocument5 pagesOil Consumption-Cummins - DG QSM 11 DMzubrs77No ratings yet

- Energy Efficient MotorsDocument6 pagesEnergy Efficient MotorsRoumya Darshan RayNo ratings yet

- Denyo Dca Specifications-6128914Document1 pageDenyo Dca Specifications-6128914siva ramakrishnanNo ratings yet

- Denyo - DCADocument1 pageDenyo - DCAvicky beastNo ratings yet

- Technical Specifications - Three Phase MotorsDocument1 pageTechnical Specifications - Three Phase MotorsNirmal mehtaNo ratings yet

- DIN FlangesDocument1 pageDIN FlangesAnonymous N0VcjC1ZoNo ratings yet

- Guia Parafusos, Arruelas E Porcas 1Document156 pagesGuia Parafusos, Arruelas E Porcas 1Adrian VerattiNo ratings yet

- 170M 6809Document2 pages170M 6809bernaNo ratings yet

- Squirrel Cage Induction Motors: 7AAC63-90 7AACC63-100Document8 pagesSquirrel Cage Induction Motors: 7AAC63-90 7AACC63-100Isuru DharmasiriNo ratings yet

- Denyo DCA 150-600kva Specification TableDocument1 pageDenyo DCA 150-600kva Specification TablejerryNo ratings yet

- Installation and Operating Manual For Dab 4" Submersible Pumps S4A - S4B - S4C - S4D - S4E - S4FDocument14 pagesInstallation and Operating Manual For Dab 4" Submersible Pumps S4A - S4B - S4C - S4D - S4E - S4Fbagus saputraNo ratings yet

- DW1020 - Capscrew Torque Chart & InstructionsDocument4 pagesDW1020 - Capscrew Torque Chart & InstructionsAlex RamirezNo ratings yet

- The Best Solution in VentilationDocument8 pagesThe Best Solution in VentilationKanjeng Raden Aryo SaifuNo ratings yet

- Haitima Single Acting Aluminium Pneumatic Actuator: FeaturesDocument1 pageHaitima Single Acting Aluminium Pneumatic Actuator: FeaturesRiswanda HimawanNo ratings yet

- Flexible Joint TWFDocument5 pagesFlexible Joint TWFAhmad FauziNo ratings yet

- m1tr SS Anchor BoltDocument1 pagem1tr SS Anchor BoltLeo SerasingheNo ratings yet

- Metallic Gaskets - Installation & Torque - October 2020Document6 pagesMetallic Gaskets - Installation & Torque - October 2020Alberto CaveroNo ratings yet

- Book 1Document8 pagesBook 1PUNDLIK RATHODNo ratings yet

- TC Coolant Pump Userguide - 2020 - V2Document10 pagesTC Coolant Pump Userguide - 2020 - V2Luc DuchesneNo ratings yet

- ss500Document11 pagesss500dekyun49No ratings yet

- SLG274 US Cut SheetDocument4 pagesSLG274 US Cut SheetMehdi MolavianNo ratings yet

- DenyoCatalog DCA Series 150 KVADocument1 pageDenyoCatalog DCA Series 150 KVAkemas biruNo ratings yet

- TECHNICAL Lowara EHM-td-En 50 HZ Part44Document1 pageTECHNICAL Lowara EHM-td-En 50 HZ Part44Alberto GutierrezNo ratings yet

- R2000iB Specs Bolt PaternDocument4 pagesR2000iB Specs Bolt Paternto0984903132No ratings yet

- Torque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsDocument2 pagesTorque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsPranpath NarupantawartNo ratings yet

- Size of CB Protecting of MotorDocument4 pagesSize of CB Protecting of MotorjigarNo ratings yet

- Technical Bulletin: Hydraulic SnubbersDocument5 pagesTechnical Bulletin: Hydraulic SnubbersDavid Luna MolinaNo ratings yet

- Willcox HosesDocument6 pagesWillcox Hosesbunyamin.bangbenNo ratings yet

- Series 1500 EngineeringDocument5 pagesSeries 1500 EngineeringroychabNo ratings yet

- SAE SAEL Heavy Duty Face Fix HangersDocument8 pagesSAE SAEL Heavy Duty Face Fix HangersBerl MNo ratings yet

- GIW Technical Series: Pipe Flange BoltsDocument4 pagesGIW Technical Series: Pipe Flange BoltsTravis SkinnerNo ratings yet

- Built-In Freewheels: P-7426-SC-A4 10/18Document2 pagesBuilt-In Freewheels: P-7426-SC-A4 10/18Silviu DochiaNo ratings yet

- D-CKFG Series Cast Iron Three Phase Asymchronous MotorDocument4 pagesD-CKFG Series Cast Iron Three Phase Asymchronous MotorNaveed AhmedNo ratings yet

- Tipscontrol: Script SLDocument9 pagesTipscontrol: Script SLRajesh Chowdary ParaNo ratings yet

- Mechanical Pinch Valves of OV SeriesDocument5 pagesMechanical Pinch Valves of OV SeriesDaniel SanNo ratings yet

- Ficha Técnica de Productos: Tone Model STC - MultipliersDocument2 pagesFicha Técnica de Productos: Tone Model STC - MultipliersRichards Salvatierra ArimanaNo ratings yet

- Bombas Milton Roy Series - Milroyal-BDocument12 pagesBombas Milton Roy Series - Milroyal-BMarvin Zapa BohorquezNo ratings yet

- Posible Orden Lacey 01 ComplDocument5 pagesPosible Orden Lacey 01 ComplComunidad GnosticaNo ratings yet

- Specifications: Limitorque MX Selection DataDocument18 pagesSpecifications: Limitorque MX Selection DatamarklaforestNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- KKK MinDocument118 pagesKKK MinAntonio UgartecheaNo ratings yet

- MITSUBISHI MinDocument78 pagesMITSUBISHI MinAntonio UgartecheaNo ratings yet

- Puebla c8r Masa-VolvoDocument1 pagePuebla c8r Masa-VolvoAntonio UgartecheaNo ratings yet

- Exfo - Ftb-7600e-0034b Ftb-7000 Series Otdr For Ftb-200 v2 - User Guide-9234 2Document339 pagesExfo - Ftb-7600e-0034b Ftb-7000 Series Otdr For Ftb-200 v2 - User Guide-9234 2Bilal GayretliNo ratings yet

- 43BDocument13 pages43BJamie Schultz100% (1)

- Pile Driving EquipmentsDocument23 pagesPile Driving EquipmentsAbhishek BhushanNo ratings yet

- Notice Mhouse Moovo GTX4Document8 pagesNotice Mhouse Moovo GTX4BAKOnlineNo ratings yet

- Paper192046 2050 PDFDocument5 pagesPaper192046 2050 PDFPrateek KesarwaniNo ratings yet

- Jntu Anan Civil 2 2 HHM Set 4Document8 pagesJntu Anan Civil 2 2 HHM Set 4Kalisetti AnilNo ratings yet

- Ingliz Tili 10 DarslikDocument224 pagesIngliz Tili 10 DarslikMiryunusov MirabbosNo ratings yet

- Cold Facts Vol 33 No 3 (2017)Document48 pagesCold Facts Vol 33 No 3 (2017)Binh Thanh LeNo ratings yet

- Abonacci Trading: Credit: Bobi Abonacci ContactDocument4 pagesAbonacci Trading: Credit: Bobi Abonacci ContactUjangNo ratings yet

- Apluslift HW 10kbpDocument17 pagesApluslift HW 10kbpGBNo ratings yet

- 100 Fractions: Great For You If You Are Returning To SchoolDocument6 pages100 Fractions: Great For You If You Are Returning To SchoolOlan ElraiNo ratings yet

- Component Identification ElectronicsDocument23 pagesComponent Identification ElectronicsManjunatha Swamy VNo ratings yet

- Questions About Reverse OsmosisDocument6 pagesQuestions About Reverse OsmosisManjunath HrmNo ratings yet

- SAP ABAP Code For DR ReportDocument3 pagesSAP ABAP Code For DR ReporthallarmemonNo ratings yet

- Tongs Adler Dong 04 S PM RefDocument14 pagesTongs Adler Dong 04 S PM ReflfklasNo ratings yet

- CD110/CD110X SERIES: Aluminum Electrolytic CapacitorsDocument2 pagesCD110/CD110X SERIES: Aluminum Electrolytic CapacitorsPi PonyNo ratings yet

- Galvanizing Defects & RectificationsDocument28 pagesGalvanizing Defects & RectificationsSreedhar Patnaik.M90% (10)

- IMM - Write UpDocument5 pagesIMM - Write UpvanmanNo ratings yet

- Gravimetric Analysis of A Chloride SaltDocument9 pagesGravimetric Analysis of A Chloride SaltDorien Villafranco0% (1)

- HKOH SNDL Int ReqDocument2 pagesHKOH SNDL Int ReqMuhammad AsfandyarNo ratings yet

- Cash Flow Estimation: Tugas 7 Accounting and FinanceDocument5 pagesCash Flow Estimation: Tugas 7 Accounting and FinanceJessy SeptalistaNo ratings yet

- Oracle Inventory Module-APLDocument207 pagesOracle Inventory Module-APLRavi Kumar Reddy KalikiriNo ratings yet

- Actuarial ScienceDocument45 pagesActuarial SciencejinnymistNo ratings yet

- Ahts Stability 130926173935 Phpapp01 PDFDocument30 pagesAhts Stability 130926173935 Phpapp01 PDFJl RuMbOsNo ratings yet

- Isometries of The Plane - BoswellDocument7 pagesIsometries of The Plane - BoswellGuido 125 LavespaNo ratings yet

- Samia PDFDocument7 pagesSamia PDFMohamed Sayed AbdoNo ratings yet

- LRDI Puzzle - 18, 19, 20, 21Document5 pagesLRDI Puzzle - 18, 19, 20, 21anshuno247No ratings yet

- Repair Manual Hydrostatic Pump Motor PDFDocument112 pagesRepair Manual Hydrostatic Pump Motor PDFВячеслав Шапочка100% (3)