Professional Documents

Culture Documents

Technical Specification BIBO 2102.041: Product Material Rating

Technical Specification BIBO 2102.041: Product Material Rating

Uploaded by

Sebastian Amézaga ZegarraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specification BIBO 2102.041: Product Material Rating

Technical Specification BIBO 2102.041: Product Material Rating

Uploaded by

Sebastian Amézaga ZegarraCopyright:

Available Formats

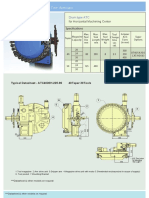

Technical specification BIBO 2102.

041

50 Hz

Shaft Power [hp] / [kW]

10

8 6

231, MT

6

4 233, HT

4 234, HT 242, MT

2

2

0 0

Head [ft] / [m]

140

40

120

655 – 35

725 mm 100 30

80 25

20

60

15

40

10 231, MT

233, HT

20 5

242, MT

234, HT

0 0

0 5 10 15 20 25 30 35

335 – 510 mm 0 100 200 300 400 500 600

Capacity [l/s] / [usgpm]

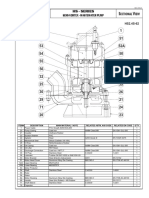

Product Material Rating

Submersible pump for dewatering build- Outer casing ________________ Aluminium 3~

ing yards, draining water in flooded areas, Impeller,alt.1 _____ Alloyed white cast iron Rated output ___________________ 5.2 kW

and other similar applications. The pump alt.2 ____________ Stainless steel Speed of rotation _____________ 2850 rpm

can handle water containing relatively Wear parts _______________ Nitrile rubber Rated Starting

abrasive solids. Stator housing _______________ Aluminium Voltage current current

Strainer _______________ Galvanized steel V A A

Denomination Shaft ___________________ Stainless steel

220 19 133

Product code _________________ 2102.041 O-rings __________________ Nitrile rubber

230 18 128

Installation ___________________________ S

Impeller characteristic __________ MT, HT

Mechanical face seals 380 11 77

400 10 71

Discharge connection _____________ 3", 4" Inner _________________ Tungsten carbide

415 10 69

Outer ________________ Tungsten carbide

Process data 440 9.4 73

Liquid temperature _________ max +40° C

Weight 500 8.3 54

550 7.6 59

Depth of immersion __________ max 20 m Total (excl. cable) ____________ 48 - 50 kg

660 6.3 45

pH of the pumped liquid _______ pH 5 - 8

Liquid density __________ max 1100 kg/m3 Options 1000 4.2 30

Strainer hole size ________ 7 mm x 40 mm Polyurethane-lined wear parts _ POLY-LIFE

3~

Impeller (MT, HT) ________ Stainless steel

Motor data Warm water version

Rated output ___________________ 3.7 kW

Speed of rotation _____________ 2850 rpm

Squirrel cage 3-phase induction motor. Starters

Frequency ________________________ 50 Hz Plug contact 3-phase Rated Starting

Insulation class _____________ H (+180° C) Various cable sizes Voltage current current

V A A

Voltage variation Zinc anodes

- continuously running ______ max ± 5% Tandem connection 220 13 80

- intermittent running _____ max ± 10% 230 13 77

Voltage imbalance between phases max 2% Accessories 380 7.8 46

No. of starts/hour _______________ max 15 Adapters, hose connections and other me- 400 7.4 44

chanical accessories. 415 7.1 41

Cable Electrical accessories such as pump control- 440 6.7 44

Direct-on-line and Y/D start _____ SUBCAB ler, control panels, starters, monitoring re- 500 6.0 32

lays, cables. 550 5.4 32

Monitoring equipment 660 4.5 27

Thermal contacts. 1000 2.9 20

You might also like

- STIHL 021 023 025 Parts DiagramDocument23 pagesSTIHL 021 023 025 Parts DiagramTodd Lukes100% (6)

- Dk294j-Parts ManualDocument4 pagesDk294j-Parts ManualJorge Alonso Fernandez50% (2)

- DPWH Cost Estimate GuidelinesDocument101 pagesDPWH Cost Estimate GuidelinesJohn80% (5)

- Campbell Hausfeld 70 Amp Stick WelderDocument36 pagesCampbell Hausfeld 70 Amp Stick Welderb0beiii100% (1)

- VW TL 217 2009-08 enDocument7 pagesVW TL 217 2009-08 enjoaopedrosousaNo ratings yet

- Technical Specification BIBO 2201.320: Product Material RatingDocument1 pageTechnical Specification BIBO 2201.320: Product Material RatingNaw AzNo ratings yet

- BHR 35 - 30 4 Stg.Document3 pagesBHR 35 - 30 4 Stg.Maknan SteelNo ratings yet

- Bevel Gear DatasheetDocument7 pagesBevel Gear Datasheetmohammad khoraminiaNo ratings yet

- Product Datasheet - Helical Gear ReducerDocument7 pagesProduct Datasheet - Helical Gear ReducerTrisna RamadhanNo ratings yet

- Application Deep Well Turbine Pumps: Product Introduction 2361.1x/01-10G3Document4 pagesApplication Deep Well Turbine Pumps: Product Introduction 2361.1x/01-10G3FawadNo ratings yet

- 40GKX Cassette DX OldDocument18 pages40GKX Cassette DX OldinkblueNo ratings yet

- SC hp15T2Document2 pagesSC hp15T2carolina fuentesNo ratings yet

- Engineering Data: Bare Pump Detailed SpecificationsDocument4 pagesEngineering Data: Bare Pump Detailed SpecificationsJimy Percy Villa SuazoNo ratings yet

- Hydraulic Bow and Stern ThrustersDocument2 pagesHydraulic Bow and Stern ThrustersginanjarNo ratings yet

- FLYGTDocument1 pageFLYGTChamparret SosaNo ratings yet

- Ingersoll Rand Compressor - 2545 Engineering DataDocument4 pagesIngersoll Rand Compressor - 2545 Engineering DataJNo ratings yet

- Yuvraj L Bamane: Rall .No:2026Document3 pagesYuvraj L Bamane: Rall .No:2026Rocky JNo ratings yet

- PR 1Document3 pagesPR 1Rocky JNo ratings yet

- Etech EH SeriesDocument16 pagesEtech EH SeriesZeina FarhatNo ratings yet

- Presion Neumaticos 931Document1 pagePresion Neumaticos 931kathy fernandezNo ratings yet

- Suggested Torque Values For Use With Teadit 905 Metalbest Gaskets / Standard ASME B16.5 Raised Face Pipe FlangesDocument10 pagesSuggested Torque Values For Use With Teadit 905 Metalbest Gaskets / Standard ASME B16.5 Raised Face Pipe FlangesronfaNo ratings yet

- Product Datasheet: HelicalbevelgearedDocument7 pagesProduct Datasheet: Helicalbevelgeared손선호No ratings yet

- Tds - 25 LPS, Head-150 MTRDocument4 pagesTds - 25 LPS, Head-150 MTRmukherjeemohul25No ratings yet

- 28 V3307dit 26Document2 pages28 V3307dit 26أبو خالد الأثرىNo ratings yet

- Drum Type HMCDocument1 pageDrum Type HMCEliane SouzaNo ratings yet

- Drum Type HMC PDFDocument1 pageDrum Type HMC PDFSweta GajjarNo ratings yet

- Гідромотор 304Document1 pageГідромотор 304sanches.avgNo ratings yet

- Pump GAD For Vertical TurbineDocument9 pagesPump GAD For Vertical TurbineVijay Rama RajuNo ratings yet

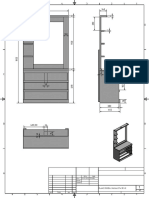

- Plano Comoda Minimalista de 90Document1 pagePlano Comoda Minimalista de 90danielNo ratings yet

- Pocincani Limovi, Teh - KarakteristikeDocument10 pagesPocincani Limovi, Teh - KarakteristikeEko LuftNo ratings yet

- RAV Mercedes RAV8055.2.54MB 01Document2 pagesRAV Mercedes RAV8055.2.54MB 01Gabriel LaureanoNo ratings yet

- RAV Mercedes RAV8055.2.54MB 01 PDFDocument2 pagesRAV Mercedes RAV8055.2.54MB 01 PDFGabriel LaureanoNo ratings yet

- Honda 5 Speed FWD: Miscellaneous ComponentsDocument1 pageHonda 5 Speed FWD: Miscellaneous Componentsวรพงษ์ กอชัชวาลNo ratings yet

- 15ppm - Bilge Separator PDFDocument2 pages15ppm - Bilge Separator PDFCodruţ ErașcuNo ratings yet

- 96 1345 1 PBDocument2 pages96 1345 1 PBPanji Setya LaksonoNo ratings yet

- Dimensional DrawingDocument9 pagesDimensional DrawingHery MukhlisNo ratings yet

- Irjet V4i590Document2 pagesIrjet V4i590Abhiman KokateNo ratings yet

- Ilovepdf MergedDocument4 pagesIlovepdf Mergedvince baconsNo ratings yet

- 29 V3800dit 26Document2 pages29 V3800dit 26Hector Dongo ArrayanNo ratings yet

- کاتالوگ ولوو پنتاDocument2 pagesکاتالوگ ولوو پنتامحمد محمدNo ratings yet

- BHR 28 - 30 3 Stg.Document3 pagesBHR 28 - 30 3 Stg.Maknan SteelNo ratings yet

- Md310 Quick ManualDocument55 pagesMd310 Quick ManualHitesh PanigrahiNo ratings yet

- LMD-600Hx2500L (CL2) KT - DBFY16123R0Document1 pageLMD-600Hx2500L (CL2) KT - DBFY16123R0Datumuseng SabdullahNo ratings yet

- ExhaustDepot Catalog WebDocument130 pagesExhaustDepot Catalog WebSaif MshahNo ratings yet

- C - 1486 Cooler Assembly-ModelDocument1 pageC - 1486 Cooler Assembly-ModelKrupal PatelNo ratings yet

- Stihl ms-210 ms-230 Ms-250.iplDocument17 pagesStihl ms-210 ms-230 Ms-250.iplfire campNo ratings yet

- Typical Edge Section E-E: 4Ø12 Stø8C/C250 L-740 400 2Ø14 +2Ø12 2Ø14 +2 Ø12Document1 pageTypical Edge Section E-E: 4Ø12 Stø8C/C250 L-740 400 2Ø14 +2Ø12 2Ø14 +2 Ø12metsihafeNo ratings yet

- 03 - Dqa451-144316enDocument4 pages03 - Dqa451-144316enkevin.loyola.donosoNo ratings yet

- Desdeporfolio CorporativoDocument4 pagesDesdeporfolio CorporativoRaul FuentesNo ratings yet

- Commercial Gas Service Parts List: A.O. Smith Water Heater Parts FulfillmentDocument8 pagesCommercial Gas Service Parts List: A.O. Smith Water Heater Parts Fulfillmentisaias ramirezNo ratings yet

- Manual Domiproject DDocument6 pagesManual Domiproject DDavid CadeloNo ratings yet

- Byg Mining-EnDocument36 pagesByg Mining-EnMartin HendersonNo ratings yet

- CP Submersible Solid Handling PumpDocument8 pagesCP Submersible Solid Handling PumpSid Esterico SestosoNo ratings yet

- SE266E40 Performance Characteristic: According ISO 8665 Standard Max. Accaptable Exhaust Backpressure 150mbarDocument1 pageSE266E40 Performance Characteristic: According ISO 8665 Standard Max. Accaptable Exhaust Backpressure 150mbarSebastian GonzalezNo ratings yet

- North American Industrial Buyer's Guide: RittalDocument2 pagesNorth American Industrial Buyer's Guide: Rittalingdimitriospino_110No ratings yet

- Tsurumi HS2.4S-62 Sectional ViewDocument1 pageTsurumi HS2.4S-62 Sectional ViewYoutube For EducationNo ratings yet

- EL 60 A B DRAGFLOW-schede-EL-50Hz-ENGDocument2 pagesEL 60 A B DRAGFLOW-schede-EL-50Hz-ENGCarlos Picaluga CerveiraNo ratings yet

- Rebar Steel Weight CalculatorDocument2 pagesRebar Steel Weight CalculatorGohar ZamanNo ratings yet

- Instruction Manual - NB124 - Order No 262919,262920 - 4H100-1250HS+VSDocument71 pagesInstruction Manual - NB124 - Order No 262919,262920 - 4H100-1250HS+VSOscar AlexandersonNo ratings yet

- Nema Nomenclature RolesDocument9 pagesNema Nomenclature RolesRicardo LaraNo ratings yet

- HM 350-4Document12 pagesHM 350-4Mohan CharanchathNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Mineral Processing A DasDocument36 pagesMineral Processing A DasYallarling NagureNo ratings yet

- Gravimetric AnalysisDocument11 pagesGravimetric AnalysisLUISA YALILA RODRIGUEZ GALVIZNo ratings yet

- Assignment 2 (Archit Todi 17 - 274)Document15 pagesAssignment 2 (Archit Todi 17 - 274)chemical todiNo ratings yet

- ViewDocument398 pagesViewRodrique KazambaNo ratings yet

- PPSC Exams Past Paper 10Document9 pagesPPSC Exams Past Paper 10Muhammad RawasNo ratings yet

- NDT and Tpi Control1Document87 pagesNDT and Tpi Control1KyNo ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityDocument8 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityRuy AlvesNo ratings yet

- Irc Code ListDocument6 pagesIrc Code Listmoondonoo7No ratings yet

- Webinar FX Supartono HAKI BALANG 2021-04-20Document261 pagesWebinar FX Supartono HAKI BALANG 2021-04-20FX SupartonoNo ratings yet

- E SkinDocument29 pagesE SkinThanvithaNo ratings yet

- Notes of ClassDocument9 pagesNotes of ClassRishi PrakashNo ratings yet

- Fabrication of Semi-Automatic Drainage Cleaner For Floating MaterialsDocument5 pagesFabrication of Semi-Automatic Drainage Cleaner For Floating MaterialsVikram KedambadiNo ratings yet

- NORSOK Structural Steel Fabrication M-101Document67 pagesNORSOK Structural Steel Fabrication M-101Agnes Chong80% (5)

- Summer Internship Project Report TTTTDocument60 pagesSummer Internship Project Report TTTTAnonymous Ut4ourcNo ratings yet

- 3 MEP SMP Negeri 2 Satap Parigi SelatanDocument31 pages3 MEP SMP Negeri 2 Satap Parigi Selatanrezhalengkong tulipNo ratings yet

- MCQ Question Bank For Unit 1: A Is Lattice Parameter) Is (B) A/2Document14 pagesMCQ Question Bank For Unit 1: A Is Lattice Parameter) Is (B) A/2Shubham MagarNo ratings yet

- Steel Lecture Notes 1 PDFDocument6 pagesSteel Lecture Notes 1 PDFMary Grace BorinagaNo ratings yet

- Service & Operating Manual: 1/2" Elima-Matic Bolted MetalDocument14 pagesService & Operating Manual: 1/2" Elima-Matic Bolted MetalCalNo ratings yet

- Knock Out Drums and SeparatorsDocument2 pagesKnock Out Drums and SeparatorsAhmed RedaNo ratings yet

- Rtps Unit # 7 Boiler Water ChemistryDocument16 pagesRtps Unit # 7 Boiler Water ChemistryharimadhavareddyNo ratings yet

- Standard Electrode PotentialDocument14 pagesStandard Electrode PotentialFahrur RoziNo ratings yet

- (Download PDF) Anticorrosive Rubber Lining A Technical Know How For Process Engineers Chandrasekaran Full Chapter PDFDocument69 pages(Download PDF) Anticorrosive Rubber Lining A Technical Know How For Process Engineers Chandrasekaran Full Chapter PDFscythepticek100% (7)

- Tutorial 1Document41 pagesTutorial 1Ellen SentovichNo ratings yet

- Crack Width MeasurementDocument5 pagesCrack Width MeasurementKlLeeNo ratings yet

- Francisco Oringo, Sr. Elementary SchoolDocument3 pagesFrancisco Oringo, Sr. Elementary SchoolprecillaugartehalagoNo ratings yet

- Carbon DioxideDocument2 pagesCarbon DioxidevicentNo ratings yet

- What Are the Main Properties of Shengyi SP175M PCB Material - 副本Document5 pagesWhat Are the Main Properties of Shengyi SP175M PCB Material - 副本jackNo ratings yet