Professional Documents

Culture Documents

Semstone 110: Selection & Specification Data

Semstone 110: Selection & Specification Data

Uploaded by

skOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Semstone 110: Selection & Specification Data

Semstone 110: Selection & Specification Data

Uploaded by

skCopyright:

Available Formats

®

Semstone 110

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generic Type Modified Epoxy

Two part epoxy exhibiting superior adhesion to concrete and steel. Used primarily as a primer/

Description

sealer for concrete surfaces and top coated with a variety of chemically resistant toppings.

• Outstanding wetting properties

• Solvent-free

Features • Long working time

• Excellent adhesion

• Compatible with a variety of toppings

Color Amber

Dry Film Thickness 5 - 20 mils (125 - 500 microns) per coat

Solids Content By Volume 100% +/- 2%

1604 ft²/gal at 1.0 mil (39.4 m²/l at 25 microns)

Theoretical Coverage 321 ft²/gal at 5.0 mils (7.9 m²/l at 125 microns)

Rate 80 ft²/gal at 20.0 mils (2.0 m²/l at 500 microns)

Allow for loss in mixing and application.

VOC Values

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

Surfaces must be clean and dry. Employ adequate methods to remove dirt, dust, oil and all other

General

contaminants that could interfere with adhesion of the coating.

Concrete: Clean and dry. Remove all loose, unsound concrete. Do not apply coating unless

concrete has cured at least 28 days @ 70°F (21°C) and 50% RH or equivalent. Prepare surfaces in

Concrete

accordance with ASTM D4258 Surface Cleaning of Concrete and ASTM D4259 Abrading Concrete.

Voids in concrete may require filling/surfacing.

MIXING & THINNING

Mixing Mix Part A resin with Part B hardener until uniform in color and consistency.

Ratio A:B 2:1

Pot Life Approximately 60 minutes @ 75°F (24°C)

A P P L I C AT I O N P R O C E D U R E S

Apply to prepared surface using flat floor squeegee, paint roller, or brush. Apply in one even coat to

thoroughly wet and seal surface. Do not allow to puddle.

Note: To avoid potential outgassing problems, Carboline recommends applying Semstone 110

General while ambient temperature is descending. As common with all epoxies and novolacs, under certain

conditions such as low temperature and high humidity, this product may develop an oily film on its

surface known as “blush”. This blush should be removed by a soap and water wash prior to any re-

coating.

September 2017 Page 1 of 3

®

Semstone 110

PRODUCT DATA SHEET

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 50°F (10°C) 50°F (10°C) 50°F (10°C) 0%

Maximum 90°F (32°C) 110°F (43°C) 110°F (43°C) 90%

CURING SCHEDULE

Surface Temp. Dry to Touch Maximum Recoat Time

50°F (10°C) 24 Hours 4 Days

65°F (18°C) 10 Hours 3 Days

80°F (27°C) 6 Hours 48 Hours

95°F (35°C) 5 Hours 24 Hours

The surface of SEMSTONE 110 will be tackfree in 6-8 hours at 70°F/21°C.

*SEMSTONE 110 may be topped while still wet. Check specific topcoat data sheet or consult StonCor ME’s Technical

Service Department for specific instructions.

CLEANUP & SAFETY

Cleanup Toluene or Xylene solvents

Read and follow all caution statements on this product data sheet and on the SDS for this product.

Safety

Employ normal workmanlike safety precautions.

When used in enclosed areas, thorough air circulation must be used during and after application

until the coating is cured. The ventilation system should be capable of preventing the solvent vapor

Ventilation concentration from reaching the lower explosion limit for the solvents used. User should test and

monitor exposure levels to insure all personnel are below guidelines. If not able to monitor levels,

use MSHA / NIOSH approved respirator.

Fire and explosion hazards: This product contains less than 1% volatile components, however,

vapors are heavier than air and can travel long distances, ignite and flash back. Eliminate

all Ignitions sources. Keep away from sparks and open flames. All electrical equipment and

Caution

installations should be made and grounded in accordance with the National Electric Code. In areas

where explosion hazards exist, workers should be required to use non-ferrous tools and wear

conductive and non-sparking shoes.

PA C K A G I N G , H A N D L I N G & S T O R A G E

Shelf Life Part A & Part B: 24 months

Storage Store indoors, 50-90°F (10-32°C)

Shipping Weight 1.5 gallon unit: 15 lbs (7 kg)

(Approximate) 15 gallon unit: 146 lbs (67 kg)

Part A: 302°F (150°C)

Flash Point (Setaflash)

Part B: 230°F (110°C)

September 2017 Page 2 of 3

®

Semstone 110

PRODUCT DATA SHEET

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to

change without prior notice. User must contact StonCor ME to verify correctness before specifying or ordering. No guarantee of

accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance, injuries or damages resulting from use. StonCor ME's sole obligation, if any, is to replace or refund the

purchase price of the Carboline product(s) proven to be defective, at StonCor ME's option. StonCor ME shall not be liable for any

loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY STONCOR ME, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

September 2017 Page 3 of 3

You might also like

- Heating, Ventilation and Air Conditioning For Plant BuildingsDocument48 pagesHeating, Ventilation and Air Conditioning For Plant Buildingssk60% (5)

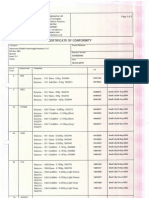

- Certificates For Belzona 1391 & Belzona 1511 PDFDocument2 pagesCertificates For Belzona 1391 & Belzona 1511 PDFskNo ratings yet

- Chimneys Selection, Design and Engineering (BASED ON EN 1992-1-1, EN 1993-3-2, EN 1443, EN 13084-PARTS 1, 2, 4, 5, 6, 7 AND 8)Document34 pagesChimneys Selection, Design and Engineering (BASED ON EN 1992-1-1, EN 1993-3-2, EN 1443, EN 13084-PARTS 1, 2, 4, 5, 6, 7 AND 8)skNo ratings yet

- Technowrap 2K PDFDocument1 pageTechnowrap 2K PDFskNo ratings yet

- Ficha Tecnica Carboline Semstone - 110 - PDSDocument3 pagesFicha Tecnica Carboline Semstone - 110 - PDSUlises Sanchez PavianNo ratings yet

- Phenoline 300: Selection & Specification DataDocument4 pagesPhenoline 300: Selection & Specification DataNicolas Montore RosNo ratings yet

- Semstone 145 SL: Selection & Specification DataDocument3 pagesSemstone 145 SL: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Flexane HP PuttyDocument2 pagesFlexane HP PuttyDivyanshu GuptaNo ratings yet

- Interzone 101Document4 pagesInterzone 101Trịnh Minh KhoaNo ratings yet

- Floor Patch Fast CureDocument2 pagesFloor Patch Fast CureStevenFerrelNo ratings yet

- Simacover EP Unicoat 2401-00 PDFDocument3 pagesSimacover EP Unicoat 2401-00 PDFAdnan FrrNo ratings yet

- Ceilcote-380 Primer - Vinyl EsterDocument4 pagesCeilcote-380 Primer - Vinyl EsterEspie SualogNo ratings yet

- Interzone 101: EpoxyDocument4 pagesInterzone 101: Epoxyjamjam75No ratings yet

- Interzone 101 Eng A4 20150205Document4 pagesInterzone 101 Eng A4 20150205Wale OyeludeNo ratings yet

- Semi-Hard Triflex ™: Technical Data SheetDocument2 pagesSemi-Hard Triflex ™: Technical Data SheetSantosh JayasavalNo ratings yet

- Ceilcote 180 Flakeline+ds+engDocument4 pagesCeilcote 180 Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 380 PrimerDocument4 pagesCeilcote 380 Primeryoonchankim0911No ratings yet

- Ceilcote 140 Flakeline+ds+engDocument4 pagesCeilcote 140 Flakeline+ds+englivefreakNo ratings yet

- Devcon Flexane-High-Performance-Putty - 15330Document2 pagesDevcon Flexane-High-Performance-Putty - 15330Yajaira ValdezNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSNguyễn Duy BiênNo ratings yet

- Ceilcote 282 Flakeline+ds+engDocument4 pagesCeilcote 282 Flakeline+ds+engMohamed NouzerNo ratings yet

- Plasite 7122 PDSDocument4 pagesPlasite 7122 PDSAdityo AgungNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- Thermaline 400 Primer PDSDocument3 pagesThermaline 400 Primer PDSQuy RomNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- Thermo-Lag 220 PDSDocument3 pagesThermo-Lag 220 PDSsbiplcc27No ratings yet

- Ceilcote 680 Primer AKZO PDFDocument4 pagesCeilcote 680 Primer AKZO PDFamitzalteNo ratings yet

- Corocrete Eng A4 20090807Document3 pagesCorocrete Eng A4 20090807andriNo ratings yet

- Carboguard 158 UP PDSDocument4 pagesCarboguard 158 UP PDSvihor94213No ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Thermaline 400 Finish PDSDocument3 pagesThermaline 400 Finish PDSQuy RomNo ratings yet

- Semi-Hard Flexible Ebonite: Technical Data SheetDocument2 pagesSemi-Hard Flexible Ebonite: Technical Data Sheethoangvubui4632No ratings yet

- White Semi-Hard Natural Rubber: Technical Data SheetDocument2 pagesWhite Semi-Hard Natural Rubber: Technical Data SheetSantosh JayasavalNo ratings yet

- Interline 984+ds+eng PDFDocument4 pagesInterline 984+ds+eng PDFMohamed NouzerNo ratings yet

- KCC DATASHEET KorepoxH.B.eh2560 (Two-Component) EngDocument2 pagesKCC DATASHEET KorepoxH.B.eh2560 (Two-Component) EngIsabelo AbaoNo ratings yet

- Thermaline 450 EP: Selection & Specification DataDocument3 pagesThermaline 450 EP: Selection & Specification DataGMSNo ratings yet

- Eh6280 (HS)Document2 pagesEh6280 (HS)anminsungNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Korepox Topcoat ET6572Document2 pagesKorepox Topcoat ET6572Isabelo AbaoNo ratings yet

- Semstone 6325 Sealant PDSDocument3 pagesSemstone 6325 Sealant PDSaleerossNo ratings yet

- Belzona 1391Document2 pagesBelzona 1391AsadAliNo ratings yet

- 770 UkDocument4 pages770 UkAhmed IbrahimNo ratings yet

- Transpoxy Masterbond 4.67N (FLOORING GRADE)Document3 pagesTranspoxy Masterbond 4.67N (FLOORING GRADE)Sami KahtaniNo ratings yet

- Interline 850+ds+eng PDFDocument4 pagesInterline 850+ds+eng PDFMohamed NouzerNo ratings yet

- Nitrile Rubber Lining: Technical Data SheetDocument2 pagesNitrile Rubber Lining: Technical Data SheetSenthil KumarNo ratings yet

- Tds CA1010 Mastinox PPGDocument2 pagesTds CA1010 Mastinox PPGAstari Putri NuarisaNo ratings yet

- Carboguard 1340 PDSDocument4 pagesCarboguard 1340 PDSSaefuddin OrtegaNo ratings yet

- Interline 984Document4 pagesInterline 984livefreakNo ratings yet

- 112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFDocument2 pages112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFFernando VittoNo ratings yet

- Interline 985+ds+eng PDFDocument4 pagesInterline 985+ds+eng PDFMohamed NouzerNo ratings yet

- Et5745 PDFDocument2 pagesEt5745 PDFSIMONNo ratings yet

- Penguard MidcoatDocument4 pagesPenguard MidcoatfirmanNo ratings yet

- Simacover EP Unicoat 2401-00: Product Data SheetDocument3 pagesSimacover EP Unicoat 2401-00: Product Data SheetParan baenNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- TDS - Tankguard Zinc - Issued 01.08.2014Document5 pagesTDS - Tankguard Zinc - Issued 01.08.2014Arya Kemal Pratama PutraNo ratings yet

- Flexane 80 CompoundDocument3 pagesFlexane 80 Compoundabh_omegaNo ratings yet

- HEMPADUR 47182 47182 en-GB PDFDocument3 pagesHEMPADUR 47182 47182 en-GB PDFwilfran villegasNo ratings yet

- Interzone 5140: Epoxy PrimerDocument4 pagesInterzone 5140: Epoxy PrimerTrịnh Minh KhoaNo ratings yet

- Interclene 175: TBT Free AntifoulingDocument4 pagesInterclene 175: TBT Free AntifoulingTrịnh Minh KhoaNo ratings yet

- 3. Splash Zone CoatDocument4 pages3. Splash Zone CoatDimas Bagus JarkhasihNo ratings yet

- Enviroline 2405: Hybrid EpoxyDocument4 pagesEnviroline 2405: Hybrid EpoxyMuthuKumarNo ratings yet

- Enviroline 199+ds+eng PDFDocument4 pagesEnviroline 199+ds+eng PDFMohamed NouzerNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Chemclad SC PDFDocument2 pagesChemclad SC PDFskNo ratings yet

- Onshore Ancillary Steel Structures: Dep SpecificationDocument19 pagesOnshore Ancillary Steel Structures: Dep Specificationsk100% (4)

- Carbothane 133 HB PDS PDFDocument5 pagesCarbothane 133 HB PDS PDFskNo ratings yet

- Thermo-Lag 3000-P PDS PDFDocument7 pagesThermo-Lag 3000-P PDS PDFskNo ratings yet

- METALCLAD CeramAlloy CLAC PDFDocument2 pagesMETALCLAD CeramAlloy CLAC PDFskNo ratings yet

- METALCLAD CeramAlloy CPAC PDFDocument2 pagesMETALCLAD CeramAlloy CPAC PDFskNo ratings yet

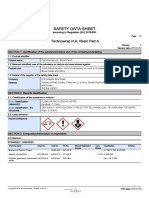

- Technowrap H.A. Hardener (Part B) PDFDocument6 pagesTechnowrap H.A. Hardener (Part B) PDFskNo ratings yet

- Technowrap H.A. Resin (Part A) PDFDocument6 pagesTechnowrap H.A. Resin (Part A) PDFskNo ratings yet

- World Class: Integrity & Maintenance SolutionsDocument2 pagesWorld Class: Integrity & Maintenance SolutionsskNo ratings yet

- Technowrap 2K Cloth CS PDFDocument2 pagesTechnowrap 2K Cloth CS PDFskNo ratings yet

- Loctite SDS PDFDocument15 pagesLoctite SDS PDFskNo ratings yet

- Plural Component XP70 Graco MachineDocument8 pagesPlural Component XP70 Graco MachineskNo ratings yet

- Enviroline 2405 Application Guidelines: Protective Coatings Technical SupportDocument12 pagesEnviroline 2405 Application Guidelines: Protective Coatings Technical SupportskNo ratings yet

- Garnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsDocument1 pageGarnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsskNo ratings yet

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetskNo ratings yet

- Details of AbrasivesDocument6 pagesDetails of AbrasivesskNo ratings yet

- Duqm Refinery Epc 2 - Utilities &offsites Contract No - CNT-1100-1000-007 Checklist For RAMDocument8 pagesDuqm Refinery Epc 2 - Utilities &offsites Contract No - CNT-1100-1000-007 Checklist For RAMskNo ratings yet

- Abrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaDocument1 pageAbrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaskNo ratings yet

- Semstone 145 PDS PDFDocument4 pagesSemstone 145 PDS PDFskNo ratings yet

- Garnet SpecificationDocument2 pagesGarnet SpecificationskNo ratings yet

- Semstone 145 PDS PDFDocument4 pagesSemstone 145 PDS PDFskNo ratings yet

- The Anatomy and Action of The Horse PDFDocument168 pagesThe Anatomy and Action of The Horse PDFstefm100% (1)

- Political Prisoner Profile: Su Su Nway@ Nwe Nwe WinDocument4 pagesPolitical Prisoner Profile: Su Su Nway@ Nwe Nwe WinAung Myo TheinNo ratings yet

- Labconco ManualDocument69 pagesLabconco ManualFredy Fernando Huarhua GarciaNo ratings yet

- Meniere' S Disease: (Endolymphatic Hydrops)Document9 pagesMeniere' S Disease: (Endolymphatic Hydrops)WillieNo ratings yet

- List of Hospital Performance Indicators For Accountability (Hpia)Document2 pagesList of Hospital Performance Indicators For Accountability (Hpia)Mohd syukri HashimNo ratings yet

- Exercise Labels and Procedure TextDocument3 pagesExercise Labels and Procedure TextivhaNo ratings yet

- New Microsoft PowerPoint PresentationDocument46 pagesNew Microsoft PowerPoint PresentationElizebethNo ratings yet

- NCP Tissue PerfusionDocument2 pagesNCP Tissue PerfusionNiña Montejo Ealdama100% (1)

- PEPA SummaryDocument6 pagesPEPA SummaryKhalid Masood GhaniNo ratings yet

- Conduct A Hazard Analysis What Does This Mean?Document5 pagesConduct A Hazard Analysis What Does This Mean?jujuNo ratings yet

- NURSING CARE PLAN - Impaired Urinary EliminationDocument2 pagesNURSING CARE PLAN - Impaired Urinary EliminationDaniel Andre S. SomorayNo ratings yet

- Jyothi Engineering College, Cheruthuruthy: S7 Civil Contact Class TimetableDocument1 pageJyothi Engineering College, Cheruthuruthy: S7 Civil Contact Class TimetableParthi PNo ratings yet

- Buletin Farmasi 02/2013Document19 pagesBuletin Farmasi 02/2013afiq83No ratings yet

- Ismenore: You Should Also DoDocument2 pagesIsmenore: You Should Also DoNurul Ilmi UtamiNo ratings yet

- Care PlanDocument3 pagesCare PlanMarlene Mathew100% (1)

- Dansville CSD Reopening Plan 073120Document107 pagesDansville CSD Reopening Plan 073120News 8 WROCNo ratings yet

- Case Study 3 (Eating Disorder)Document11 pagesCase Study 3 (Eating Disorder)Atul MishraNo ratings yet

- Weiss. LonelinessDocument4 pagesWeiss. Lonelinesssyifa rahimiNo ratings yet

- Neurology Physical Therapy Residency: The Johns Hopkins Hospital and University of DelawareDocument1 pageNeurology Physical Therapy Residency: The Johns Hopkins Hospital and University of Delawareapi-241031382No ratings yet

- Employee WelfareDocument12 pagesEmployee WelfareADITYA KHEITAN100% (1)

- Health Education Lesson PlanDocument22 pagesHealth Education Lesson Planapi-27198700633% (3)

- Rural Libraries, Village Knowledge Centre (VKC) and Concept of Rural Libraries and Knowledge Centre (RLKC) Bishnu Prasad Upadhaya, Ghanakanta Baruah College, Morigaon.Document3 pagesRural Libraries, Village Knowledge Centre (VKC) and Concept of Rural Libraries and Knowledge Centre (RLKC) Bishnu Prasad Upadhaya, Ghanakanta Baruah College, Morigaon.bishnupoudelNo ratings yet

- 11 Ways To Live A Happier LifeDocument5 pages11 Ways To Live A Happier LifeHannah Grace Tan GerminaNo ratings yet

- Latihan Soal Bahasa InggrisDocument2 pagesLatihan Soal Bahasa Inggriscilacapbarat999No ratings yet

- 952-Article Text-3024-1-10-20221113Document13 pages952-Article Text-3024-1-10-20221113Audi GaluhNo ratings yet

- Life Cycle Assessment of Defluoridation of Water Using Laterite Soil Based AdsorbentsDocument12 pagesLife Cycle Assessment of Defluoridation of Water Using Laterite Soil Based AdsorbentsVineet RathoreNo ratings yet

- Fifteen Effective Play Therapy TechniquesDocument28 pagesFifteen Effective Play Therapy TechniquesMark Avellanosa100% (1)

- Competency Assessment For Infection Control NurseDocument2 pagesCompetency Assessment For Infection Control Nursenseducation.mahgNo ratings yet

- Effect of Oral Vitamin E On Atopic DermatitisDocument4 pagesEffect of Oral Vitamin E On Atopic DermatitisYusufTaqwaMuladiNo ratings yet

- Soul Food JunkiesDocument7 pagesSoul Food JunkiesDennis GathuraNo ratings yet