Professional Documents

Culture Documents

Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing No

Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing No

Uploaded by

Vijaya Seharan NairOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing No

Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing No

Uploaded by

Vijaya Seharan NairCopyright:

Available Formats

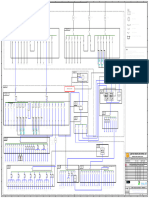

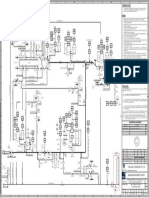

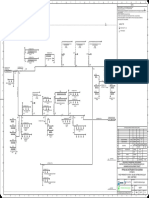

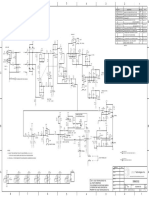

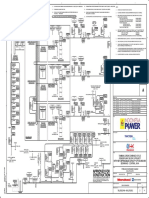

HAZOP ACTION SHEET

Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces

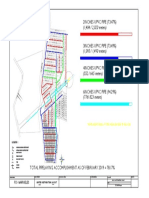

P&ID Drawing No 455-00-DT-M-10250 Sheet 11 of 15

70-GDB-MFB-001

71-GDB-MFB-001

HAZOP Title LP Steam Export

KKS No NAA

Item No: 001

Responsible Person:

Part of System/ Supply to brine heater More flow

Parameter:

Action Recommended: Clarify how turbine performance is determined and LP export steam is to be

controlled and method for maintenance of associated meter (10NAA35CP001).

Engineer Proposal: Clarification:

Alstom TCS maintains the IP exhaust pressure (MAC01CP001/2/3) which is

the terminal point for TCS control and maintains this pressure based on

relevant setpoint request from DCS.

Steam turbine is supplying steam export by IP bleeding (last stage of the IP

cylinder).

The steam export pressure is controlled by the Flap, installed on the crossover

pipe between outlet of the IP cylinder and the inlet of the LP cylinder.

If the pressure of the steam export decrease the flap will close.

Boiler load will increase to operate at stable MW load.

If the pressure increase on the steam export pipe the flap will open.

Final effect Boiler load will decrease, in order to respect the steam turbine load

set point.

To avoid any issue on the steam turbine, operation of the Flap is limited

according steam turbine criteria.

In the event the DESAL pressure need a back up based on steam turbine limits,

hot reheat steam back-up must be used.

On the other hand, the flowmeter (10NAA35CF001 renamed as

10NAA01CF002) has been relocated upstream the isolation valves to Package

D, therefore the flowmeter can be maintenance while the other power units

remains exporting steam to desalination plant header.

Final Clarification: Fichtner Hho 02.11.2015:

Noted, item closed.

Additional Comments:

Item Closed Signed Date

Engineer Technical Project Manager

Client Technical Project Manager

1 2 3 4 5 6 7 8 9 10 11 12

NOTE :

NOTE 1:

MINIMUM SLOPE 2‰ FOR STEAM PIPES

A LP EXPORT STEAM NOTE 2: A

DUAL SENSOR VORTEX FLOWMETER

UPSTREAM / DOWNSTREAM DISTANCE: 35Ø / 5Ø

NOTE 3:

FLOWMETERS TO BE INSTALLED AFTER PIPING STEAM BLOW. A SPOOL OF THE SAME

MATERIAL AS THE PIPE WILL BE INSTALLED DURING SUCH BLOW AND THE PREVIOUS

HYDRO TEST

NOTE 4:

STRAIGHT DISTANCE PENDING BY VALVE SUPPLIER

SCOPE OF SUPPLY PRELIMINARY

NOTE 5:

B DESUPERHEATING WATER LINE WILL CONNECT VERTICALLY TO THE DESUPERHEATER / B

BY-PASS VALVE, ENTERING THROUGH THE BOTTOM OF THE STEAM PIPE

NOTE 6:

COUNTERFLANGE WILL BE INCLUDED IN VALVE SUPPLIER SCOPE

NOTE 7:

FLANGE TO EASE RUPTURE DISC SUBSTITUTION / MAINTENANCE

NOTE 8:

DESIGN

DUAL SENSOR FLOWMETER

UPSTREAM / DOWNSTREAM DISTANCE: BRANCH

P T

15Ø / 5Ø barg ºC

NOTE 9: a 34 480

C C

VENT CONNECTIONS TO BE INSTALLED IN

HIGH POINTS FOR HYDRO-TEST A CAP WILL b 280 222

BE WELDED AND THE VALVES REMOVED

PI PI BR251-BA1e2-AP AFTER FINISHING THE HYDRO TEST c 68 380

PDTAI 10NAB10 CP015 10NAB10 CP020

10NAB10 CP005 NOTE 10: d 34/-1 280

10NAB10

10NAB10 10NAB10 SAFTY VALVE DISCHARGE CONFIGURATION

10NAB10 10NAB10 AA252

AA302 AA304 AA310 AA312 IS PRELIMINARY AND MAY BE MODIFIED e 21/-1 280

FTCAI FL AS A RESULT OF SUPPLIERS INFORMATION

10NAB10 CF001 10NAB10 EXHAUST LINE TO BE ROUTED AS SHORT f 4/-1 120

10NAB10 10NAB10 FO 10NAB10 H 10NAB10 AA251 AS POSSIBLE PIPELENGTH UPSTREAM

AA301 AA303 H AA309 O,C AA311

10NAB10 PS PS EXPANDER: g 6,5/-1 301

PS PS L.O. MAXIMUM ONE (1) 90º ELBOW

BR001-BA1e2-AH DN25 DN25

DN25 DN25 DN25

6240 Sheet 12, G-5 h 64 546

D NOTE 11: D

10NAB10 DN100 DN25

FROM 10NAB10 DN100 DN100 10NAB10 FOR MORE DETAIL INFORMATION ABOUT i 6,5/-1 200

DN25 AT001 NOTE 2 10NAB10 AA001

CONDENSATE AA101 SPECIAL FITINGS, SEE DOCUMENT Nº

10NAB10 AA203

RETURN 10NAB10 AA051 01-ZAA-MGA-002 j 6,5/-1 150

AA201

BR201-BA1e2-AP 10NAB10 NOTE 12:

k 43 120

BR203-BA1e2-AP AA204 VENT TO A SAFE AREA

10NAB10

AA202 l 5 200

m 3,5 200

n 43 200

10NAA18 o 3,5 60

E BS001 E

p 43 60

BR002-AA1re2-AP

q 6,5 532

DN25 r 32 120

10NAA04

BS001 s 3,5 120

GRADE

NOTE 7

i m 10NAA04 10NAA04

6,20 barg DN25 LEGEND

BR002-AA1e2-AP BR003-AA1e2-AP DN25

10NAA18

AA501 THIS DRAWING IS VALID FOR UNITS 1-2-3-4-5

DN250 DN350

DN350xDN250 10NAA35

F COMPONENT NUMBERS PRECEDED BY 10 SHOULD F

BR001-AA1re2-AH

10NAA04 AA251

NOTE 10

BR001-AA1re2-AH

AA501 BR201-AA1e2-AP NOTE 12 BE DUPLICATED AND PREFIXED BY

DN600

NOTE 12 10 FOR UNIT 1

BR001-AA1re2-AH

5,75 barg BR251-AA1re2-AP

BR001-AA1re2-AH

20 FOR UNIT 2

30 FOR UNIT 3

GRADE 40 FOR UNIT 4

10NAA18

PTCI TEI PI PI

10NAA04

PI PTCAI TEZCAI TEZCAI 50 FOR UNIT 5

10NAA01 CP006 10NAA01 CT007 10NAA01 CP004 10NAA01 CP005 NOTE 5

10NAA19

10NAA19

10NAA35 CP001 10NAA35 CP003 10NAA35 CT001 10NAA35 CT003

10NAA15

FC

DN200

10NAA15 AA101 TP-M01A

AA101

i k

FTCI

DN80

H TEZCAI NA P5/D1-1

10NAA01 10NAA01 O,C 10NAA01 10NAA35 10NAA35

AA305 DN80 AA306 AA307 10NAA35 CT002 10NAA35 CF001

AA301 AA303 j

10NAA01 PS PS PS PS i j

DN25 DN40 BR902 DN25 DN25 DN25 DN1900 DN40 DN40 DN40 NOTE 9

REF. 8

DN25 NOTE 4

5238 Sheet 9, C-9 5309 Sheet ,

G 10NAA01 DN1600 10NAA01 10NAA01 10NAA01 DN1600xDN1000 10NAA01 DN1000 10NAA01 10NAA35 BR001-AA1re2-AH DN25 10NAA35 10NAA35 TO MSF G

BR920 BR921 BR922 BR923 DN25 BR924 10NAA35 BR925 BR926 NOTE 8

BR004-AA1re2-AH AA051 10NAA01 BS001 PS 10NAA35 10NAA35 AA001 10NAA35 10NAA35

PS AA102

DESALINATION

AC002 AA302 AA101

BR001-AA1re2-AH

10NAA01

10NAA20

10NAA01 PLANTS

BR001-AA1re2-AH

10NAA17

AA201 NOTE 6 10NAA35 NOTE 6

DN600

BR005-AA1re2-AH DN25

DN500

AA202

10NAA01

PTCAI

BR201-AA1re2-AP BR202-AA1re2-AP

BR001-AA1re2-AH

10NAA21

10NAA35 CP002

DN600

10NAA20

BR002-AA1re2-AP

DN40

10NAA21 NA MAL

H 10NAA20 BR002-AA1re2-AP j H

AA001 10NAA20 DN50 DN50

10NAA20 10NAA17 DN40 REF. 2

AT002 AA801 AA301

10NAA20

10NAA20 AA002 10NAA17 6267 Sheet 3, B-5

AA303 LSSAI

BR003-AA1re2-AP 10NAA21 10NAA21 TO DRAINS

10NAA17 CL201 AA001 10NAA21 10NAA21 AA002

NA MAL LSSAI HEADER

AT002 AA801

DN40 i 10NAA17 CL202

10NAA20 DN50 10NAA21

AA003 REF. 2

10NAA17 BR004-AA1re2-AP

5301 Sheet 3, A-5 AA302

SWCC STAMP : CONTRACTOR'S STAMP :

TO DRAINS DN50 10NAA17 DN40

DN25 AA304 10NAA21

BR201-AA1re2-AP HEADER AA003

I DN25 I

BR201-AA1re2-AP

10NAA17

BR002-AA1re2-AP NA MAL

FO j

L.O. REF. 2

DN40

5305 Sheet 3, B-6

10NAA17 10NAA17 10NAA17 TO DRAINS

AA001 AA101 AA002 HEADER

A FOR APPROVAL CIV 14-06-02

J J

DN25 REV DESCRIPTION DRWN CHKD APPRD DATE

BR201-AA1re2-AP

Kingdom of Saudi Arabia

Saline Water Conversion Corporation

CLIENT

Project : CONSTRUCT OF DESALINATION

AND POWER PLANTS-YANBU PHASE 3

Contract No. : 20314

K K

ENGINEER

FICHTNER GmbH & Co. KG

CONTRACTOR

PROPRIETARY INFORMATION PROJECT Nº DRAWING TITLE P&ID

This document contains proprietary information of LOCATION YANBU STEAM EXPORT AND CONDENSATE

Empresarios Agrupados Internacional,S.A. and is to be used WEST COAST RETURN SYSTEM

solely for the Project and the purpose for which it is furnished. SCALE KKS DWG No. SHEET REV.

It may not be disclosed to others for a different use without the NONE 00-NA_-MFB-001

11 OF 15 A

L written permission of Empresarios Agrupados Internacional,S.A. L

SUBCONTRACTOR EAI DWG No. EAI REV.

CONTAINS INFORMATION FOR THE DESIGN OF STRUCTURES

SYSTEM OR COMPONENTS ................................ YES x NO

EMPRESARIOS AGRUPADOS 455-00-DT-M-10250 3

VERIFICATION: N/A SUP. x VERIFIER L1 L2

1 2 3 4 5 6 7 8 9 10 11 12

You might also like

- Schematic - BMW M50 ProDocument1 pageSchematic - BMW M50 ProEstang Da VieNo ratings yet

- Rumble 200 V3 Schematics-DiagramsDocument4 pagesRumble 200 V3 Schematics-DiagramsOrlandd Sanchezz100% (1)

- Cardinal 748Document47 pagesCardinal 748Juan MontufarNo ratings yet

- Virtual Memory Lab-2Document14 pagesVirtual Memory Lab-2Hafiz Muhammad Umar Aslam0% (1)

- Fender Rumble 100 V3 TDA8950-88534Document7 pagesFender Rumble 100 V3 TDA8950-88534Claudio Ariel Vera trussy100% (1)

- Classics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoFrom EverandClassics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoRating: 3.5 out of 5 stars3.5/5 (14)

- COPIER (B264/B265) Point To Point Diagram: Bicu PCB 1Document14 pagesCOPIER (B264/B265) Point To Point Diagram: Bicu PCB 1josdavisNo ratings yet

- Cxa VVVF 220Document1 pageCxa VVVF 220Mohamed ArefNo ratings yet

- 1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevA (2 OF 2)Document1 page1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevA (2 OF 2)mhazarath murariNo ratings yet

- A-19 - Electrical General Synoptics (Complete Motor List) - Layout1Document1 pageA-19 - Electrical General Synoptics (Complete Motor List) - Layout1Moez BorchaniNo ratings yet

- CB 1645 CombinedDocument7 pagesCB 1645 CombinedQuerubin RamirezNo ratings yet

- API PLAN "11" / "61" Api Plan "11" API PLAN 11/52: by VendorDocument1 pageAPI PLAN "11" / "61" Api Plan "11" API PLAN 11/52: by VendorTien Tran Kha Tien100% (1)

- Ae305 - Wall Section 3Document1 pageAe305 - Wall Section 3Omar ZakiNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Fluidics 5800Document1 pageFluidics 5800Héctor GarcíaNo ratings yet

- Fender Rumble 15 2010 Schematic Rev-ADocument2 pagesFender Rumble 15 2010 Schematic Rev-Abeytullah50% (2)

- 4 HydraulicsDocument51 pages4 Hydraulicsalexis aguirre espejoNo ratings yet

- LIPS-1: Power Board: Power, 42"Document2 pagesLIPS-1: Power Board: Power, 42"Rosario De CentralNo ratings yet

- J-DMS: Typical Floor ConnectionDocument1 pageJ-DMS: Typical Floor ConnectionMary DenizeNo ratings yet

- 7p23a PR Pid 1001 A2Document1 page7p23a PR Pid 1001 A2Aqib Khan VCSPNo ratings yet

- Preliminar: Va A CCM Lavar de Unilever Reserva No Equipada para 630 ADocument1 pagePreliminar: Va A CCM Lavar de Unilever Reserva No Equipada para 630 AfracevNo ratings yet

- Tidro 88Document2 pagesTidro 88dusan100% (1)

- Ed 0900 PRS Pid 000 09041CDocument1 pageEd 0900 PRS Pid 000 09041CMohamed ArafaNo ratings yet

- Hmc1031ms8e Eval PCB SchematicDocument3 pagesHmc1031ms8e Eval PCB SchematicbaymanNo ratings yet

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Document1 pagePiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Mohd KhaidirNo ratings yet

- SCH Srm450v2 Schematics Amp (0029446-Xx Revh00)Document5 pagesSCH Srm450v2 Schematics Amp (0029446-Xx Revh00)John CasasNo ratings yet

- 426-5051-00 - Turck Breakout & BoxRemote ModuleDocument6 pages426-5051-00 - Turck Breakout & BoxRemote ModulejNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- Water Intake Plant SLDDocument1 pageWater Intake Plant SLDali mohammedNo ratings yet

- Manifold Piping Requirements For Air Cooled Items: RDMP Ru V Balikpapan RDMP Balikpapan JoDocument2 pagesManifold Piping Requirements For Air Cooled Items: RDMP Ru V Balikpapan RDMP Balikpapan JoMichael RobinsonNo ratings yet

- Power Input: IN GND BS Comp EN SS SWDocument10 pagesPower Input: IN GND BS Comp EN SS SWjesurajanNo ratings yet

- Samyung Navis 2500/3000/3700Document33 pagesSamyung Navis 2500/3000/3700adavit73100% (1)

- Drawing DM1Document22 pagesDrawing DM1slamet haryadiNo ratings yet

- (2,020 / 2,020 Meters) : 2INCHES UPVC PIPE (100.00%)Document1 page(2,020 / 2,020 Meters) : 2INCHES UPVC PIPE (100.00%)VWSSI Technical TeamNo ratings yet

- 12AX7 Phono Tube Preamplifier User ManualDocument7 pages12AX7 Phono Tube Preamplifier User ManualmikelikespieNo ratings yet

- Fender Rumble 40 v3 SCHDocument7 pagesFender Rumble 40 v3 SCHCarlos ZaninNo ratings yet

- TELEMANN VIOLIN 2 IMSLP274959-PMLP264295-telemann - Ouverture - Violino2Document5 pagesTELEMANN VIOLIN 2 IMSLP274959-PMLP264295-telemann - Ouverture - Violino2liligueosNo ratings yet

- Brewery Ganzberg - Architectural design (thiết kế kiến trúc) - 18 June 2018- R6-TN-LAYOUT OF WWTPDocument1 pageBrewery Ganzberg - Architectural design (thiết kế kiến trúc) - 18 June 2018- R6-TN-LAYOUT OF WWTPsong1088No ratings yet

- Global - Shop Drawing Dry Wall 1st Floor - 2023.11.03Document11 pagesGlobal - Shop Drawing Dry Wall 1st Floor - 2023.11.03PasyaHumendruNo ratings yet

- Chiyuan Hdz2804-3a Rev.a Power Supply SCHDocument2 pagesChiyuan Hdz2804-3a Rev.a Power Supply SCHSaulvcr64 PorleyNo ratings yet

- Jalan: General Layout Gi 150 KV - Pltu Sampit General LayoutDocument1 pageJalan: General Layout Gi 150 KV - Pltu Sampit General LayoutNur Adi FirawanNo ratings yet

- Buje Bronce - 4256364-02-DDocument1 pageBuje Bronce - 4256364-02-Dcesar guerreroNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 16Document1 pageEpcc05 MDR 421 STR DWG 000 0072 16RANJEET PRATAP SINGHNo ratings yet

- P&ID CWP Rev 2Document1 pageP&ID CWP Rev 2Ajeng OctaviaNo ratings yet

- S-03710 P42118-Rev. 3-P18-Steam DrumDocument1 pageS-03710 P42118-Rev. 3-P18-Steam Drumwylie01No ratings yet

- 06 PRS - MASTER - STEAM - HEADERS - Latest One, Please Use ThisDocument11 pages06 PRS - MASTER - STEAM - HEADERS - Latest One, Please Use ThisPankaj SahuNo ratings yet

- Copia Controlada: ESP: 03101.T136Document1 pageCopia Controlada: ESP: 03101.T136Samuel MuñozNo ratings yet

- Delphi Wiring 66-2059-03Document1 pageDelphi Wiring 66-2059-03jose david Cardozo100% (2)

- HH45, HH55, HH65, and HH75 Harvester Heads Electrical SystemDocument2 pagesHH45, HH55, HH65, and HH75 Harvester Heads Electrical SystemGilvan JuniorNo ratings yet

- DN 40 - 1200 PN10/16: Large Tolerance Multimaterials Coupling Flanged AdaptorDocument4 pagesDN 40 - 1200 PN10/16: Large Tolerance Multimaterials Coupling Flanged Adaptorpablo gerardo gil cocaNo ratings yet

- Parte Di Controllo Digitale: Altri Componenti Presenti in Sm000097Document1 pageParte Di Controllo Digitale: Altri Componenti Presenti in Sm000097Hazim Samer0% (1)

- L&T Construction: B D F K N Q S CDocument1 pageL&T Construction: B D F K N Q S CPowerhouse ShaftNo ratings yet

- HCD-ECL77BT - ECL99BT DiagramaDocument14 pagesHCD-ECL77BT - ECL99BT DiagramaAmin Santana100% (1)

- P&ID For Inst Scope ReferenceDocument1 pageP&ID For Inst Scope Referenceprabudass pNo ratings yet

- 2INCHES UPVC PIPE (73.47%) : (1,484 / 2,020 Meters)Document1 page2INCHES UPVC PIPE (73.47%) : (1,484 / 2,020 Meters)Jhn Cbllr BqngNo ratings yet

- 01.102aed8 1 - ENDocument2 pages01.102aed8 1 - ENpablo gerardo gil cocaNo ratings yet

- Ed 0900 PRS Pid 000 09021HDocument1 pageEd 0900 PRS Pid 000 09021HMohamed ArafaNo ratings yet

- Panasonic tnp4g4572p Psu SCHDocument4 pagesPanasonic tnp4g4572p Psu SCHagesoporteNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- Hazardous (Classified) LocationsDocument24 pagesHazardous (Classified) LocationsVijaya Seharan NairNo ratings yet

- Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoDocument2 pagesHazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoVijaya Seharan NairNo ratings yet

- HAZOP STUDY REPORT-Latest Status List (2019-05-01)Document88 pagesHAZOP STUDY REPORT-Latest Status List (2019-05-01)Vijaya Seharan NairNo ratings yet

- Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoDocument2 pagesHazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoVijaya Seharan NairNo ratings yet

- Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoDocument2 pagesHazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoVijaya Seharan NairNo ratings yet

- Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoDocument2 pagesHazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoVijaya Seharan NairNo ratings yet

- Performance Metrics: For EMS Self Assessment & Management ReviewDocument24 pagesPerformance Metrics: For EMS Self Assessment & Management ReviewVijaya Seharan NairNo ratings yet

- Per Meas Pro WhsDocument5 pagesPer Meas Pro WhsVijaya Seharan NairNo ratings yet

- Working Near Utilities: Work Health and Safety ProcedureDocument31 pagesWorking Near Utilities: Work Health and Safety ProcedureVijaya Seharan NairNo ratings yet

- 8.2 HAZOP Study ProcedureDocument74 pages8.2 HAZOP Study ProcedureVijaya Seharan NairNo ratings yet

- Monitoring Measurement and Self-AssessmentDocument3 pagesMonitoring Measurement and Self-AssessmentVijaya Seharan NairNo ratings yet

- CAOAppraisalReport PanamaCanalExpansion C I R9 Y12 F159 ENGDocument19 pagesCAOAppraisalReport PanamaCanalExpansion C I R9 Y12 F159 ENGSumit SethNo ratings yet

- Mountain Passes of PakistanDocument3 pagesMountain Passes of PakistanMohsin Raza Maitla0% (2)

- Cazimi in Horary AstrologyDocument6 pagesCazimi in Horary AstrologyaiavenueNo ratings yet

- MonitersDocument25 pagesMonitersJaveed AhamedNo ratings yet

- Detecon Study Customer Experience Management in The Telecommunications Industry. Market Survey and Action Recommendations For The Optimal Design of Customer ExperiencesDocument58 pagesDetecon Study Customer Experience Management in The Telecommunications Industry. Market Survey and Action Recommendations For The Optimal Design of Customer ExperiencesDetecon InternationalNo ratings yet

- Newborn Studio Guide by Jessica G. PhotographyDocument13 pagesNewborn Studio Guide by Jessica G. PhotographyClau ppNo ratings yet

- 55-5-1 PhysicsDocument19 pages55-5-1 Physicsvikas aggarwalNo ratings yet

- Chapter 1 Introduction: 1.1 Purpose of The Manual For Micro-Hydro DevelopmentDocument7 pagesChapter 1 Introduction: 1.1 Purpose of The Manual For Micro-Hydro DevelopmentAde Y SaputraNo ratings yet

- Group-8 RRL Bes-107Document16 pagesGroup-8 RRL Bes-107bj30No ratings yet

- Rockwood January 1st 2015Document80 pagesRockwood January 1st 2015Security Lock DistributorsNo ratings yet

- TOS MAPEH 10-AutoRecoveredDocument4 pagesTOS MAPEH 10-AutoRecoveredAnne Kathria Bernadette GabrielNo ratings yet

- Mendiola ScriptDocument25 pagesMendiola ScriptAila Obrero MendiolaNo ratings yet

- Mining Equipment Maintenance PDFDocument93 pagesMining Equipment Maintenance PDFGanapati Hegde100% (1)

- Acute Coronary SyndromeDocument9 pagesAcute Coronary Syndromekimchi girlNo ratings yet

- 1 s2.0 S0196890417302509 MainDocument11 pages1 s2.0 S0196890417302509 MainCHELIN_2305No ratings yet

- BlusatranspassadaAriadne Top 123-1-3Document32 pagesBlusatranspassadaAriadne Top 123-1-3Nadiele MoraesNo ratings yet

- Dodds-Ancient Concept of Progress 4Document28 pagesDodds-Ancient Concept of Progress 4Trad AnonNo ratings yet

- 2003 Animal Rights AnswersDocument5 pages2003 Animal Rights AnswersVarshLokNo ratings yet

- Homeostasis Lab PDFDocument2 pagesHomeostasis Lab PDFSip BioNo ratings yet

- Algorithmic Fairness: From Social Good To A Mathematical FrameworkDocument2 pagesAlgorithmic Fairness: From Social Good To A Mathematical Frameworkjshen5No ratings yet

- GX71 GX51 PDFDocument18 pagesGX71 GX51 PDFRepresentaciones y Distribuciones FALNo ratings yet

- WHO IVB 11.09 Eng PDFDocument323 pagesWHO IVB 11.09 Eng PDFniaaseepNo ratings yet

- Analogy - Verbal Reasoning Questions and Answers Page 4Document2 pagesAnalogy - Verbal Reasoning Questions and Answers Page 4Palak JioNo ratings yet

- Semikron Datasheet SKT 551 01890270Document5 pagesSemikron Datasheet SKT 551 01890270Ga3ielNo ratings yet

- 4 - 0 Pex DW GBDocument8 pages4 - 0 Pex DW GBpushinluckNo ratings yet

- Southeast Asia Relationship Between Malaysia & SingaporeDocument34 pagesSoutheast Asia Relationship Between Malaysia & SingaporePavitra DrewNo ratings yet

- Notes of Cost (Microeconomics)Document10 pagesNotes of Cost (Microeconomics)Nishant DoshiNo ratings yet

- VMX User ManualDocument94 pagesVMX User ManualRoger M OlsonNo ratings yet