Professional Documents

Culture Documents

Fork Lift Truck-Risk Assessment - Date: R A - S A /S

Fork Lift Truck-Risk Assessment - Date: R A - S A /S

Uploaded by

Jalagandeeswaran KalimuthuCopyright:

Available Formats

You might also like

- Critical Care Nursing A Holistic Approach 10th Edition Morton Test Bank PDFDocument6 pagesCritical Care Nursing A Holistic Approach 10th Edition Morton Test Bank PDFa806088253No ratings yet

- JHA - Unloading of Sheet PileDocument3 pagesJHA - Unloading of Sheet PileJensen Sunga100% (1)

- 1.0 Driver Induction, Agreements & ChecklistDocument10 pages1.0 Driver Induction, Agreements & Checklistdave.muir.25No ratings yet

- PPE Request Form (New)Document1 pagePPE Request Form (New)Syafrial AnasNo ratings yet

- Miss Alli Model Nude Sets Mega PDFDocument4 pagesMiss Alli Model Nude Sets Mega PDFSeanNo ratings yet

- Background Checking Requirements Undertaking: Name: PositionDocument2 pagesBackground Checking Requirements Undertaking: Name: PositionANTHONNETTE DELA TORRENo ratings yet

- Suspended Load SafetyDocument3 pagesSuspended Load Safetymy_agautamNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Health & Safety Management Plan 2014-2019 Annual Key Performance IndicatorsDocument3 pagesHealth & Safety Management Plan 2014-2019 Annual Key Performance Indicatorsmohit67% (3)

- Risk Assessment For Erection of Steel GirderDocument11 pagesRisk Assessment For Erection of Steel GirderNirajan MarwaitNo ratings yet

- Bill Starr - Sets, Reps and Getting StrongDocument2 pagesBill Starr - Sets, Reps and Getting StrongTomSusNo ratings yet

- Fork Lift - Risk Assessment - ExampleDocument4 pagesFork Lift - Risk Assessment - Exampleعلي المرزوقNo ratings yet

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- General Risk Assessment FormDocument8 pagesGeneral Risk Assessment FormmkmusaNo ratings yet

- Safety ProgramDocument21 pagesSafety ProgramSits RdddNo ratings yet

- TOPIC: Personal Protective Equipment ChecklistDocument1 pageTOPIC: Personal Protective Equipment ChecklistMd ShNo ratings yet

- Risk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.Document2 pagesRisk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.salauddin0mohammedNo ratings yet

- Toolbox Talk Slips Trips and FallsDocument2 pagesToolbox Talk Slips Trips and FallsrajNo ratings yet

- How To Document Accident ReportDocument5 pagesHow To Document Accident Reportcristina23No ratings yet

- Gsa Generic Office Risk Assessment Health and Safety OfficeDocument7 pagesGsa Generic Office Risk Assessment Health and Safety Officetest fypNo ratings yet

- Generic RA Gas CylindersDocument6 pagesGeneric RA Gas CylindersShahid RazaNo ratings yet

- Issue-Based Risk Assessment Sub-Contractor ITS Filters CleaningDocument5 pagesIssue-Based Risk Assessment Sub-Contractor ITS Filters CleaningAhmed AbdulmajeedNo ratings yet

- Safety Campaign-Energy Isolation-April 2022Document7 pagesSafety Campaign-Energy Isolation-April 2022HSE99 BHDCNo ratings yet

- Toolbox Talks - Near Miss ReportingDocument1 pageToolbox Talks - Near Miss ReportinganaNo ratings yet

- Task Risk AssesmentDocument3 pagesTask Risk Assesmentafsalkareem100% (1)

- Belt & Orbital Sander PDFDocument2 pagesBelt & Orbital Sander PDFcityofdarwingisNo ratings yet

- Lone Working PolicyDocument22 pagesLone Working PolicyVictor TasieNo ratings yet

- 04, Use of Hand ToolsDocument2 pages04, Use of Hand ToolsFrancis K BonfulNo ratings yet

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoNo ratings yet

- Toolbox Talk FormDocument4 pagesToolbox Talk FormPrem Preetham DsouzaNo ratings yet

- JSA #28 - Use of Hand ToolsDocument1 pageJSA #28 - Use of Hand ToolsSubham SohalNo ratings yet

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocument2 pagesSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherNo ratings yet

- 10 - Safety Harness InspectorDocument1 page10 - Safety Harness InspectorSusan LouwNo ratings yet

- SWMS Loading and Unloading Vehicles WHS.127 V002.1Document18 pagesSWMS Loading and Unloading Vehicles WHS.127 V002.1Amit BhattNo ratings yet

- Warehouse Risk Assessment Aldir II IWPPDocument25 pagesWarehouse Risk Assessment Aldir II IWPPMadhu MohanNo ratings yet

- Unloading of EWPs From ContainersDocument10 pagesUnloading of EWPs From ContainersPirashanth SathananthanNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- SWP - LifelinesDocument7 pagesSWP - LifelinesREHOBOTH YAMBO KAHILUNo ratings yet

- Working at Height Risk AssessmentDocument9 pagesWorking at Height Risk AssessmentBasky0% (1)

- TCB Work at Height WEBDocument5 pagesTCB Work at Height WEBFaraaz MohammadNo ratings yet

- 11 Construction of Kill LineDocument9 pages11 Construction of Kill LinePangky AbasoloNo ratings yet

- Work at Heights PermitDocument4 pagesWork at Heights PermitFerdinand M. TurbanosNo ratings yet

- 2.4 Attachments - Risk Assessment and Method StatementDocument10 pages2.4 Attachments - Risk Assessment and Method StatementFahad MaqsoodNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- Earthmoving Attachment Maintenance: Safe Operational ProcedureDocument3 pagesEarthmoving Attachment Maintenance: Safe Operational ProcedureJamesNo ratings yet

- Confined Space Risk Assessment WHSFOR-009BDocument3 pagesConfined Space Risk Assessment WHSFOR-009BvictorNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- 1 ST Quater Drill ScenarioDocument2 pages1 ST Quater Drill ScenarioSk MehbobNo ratings yet

- Concrete WorkDocument3 pagesConcrete WorkAbdul Ghaffar100% (1)

- Day5 Delivery WAH Management Training.Document88 pagesDay5 Delivery WAH Management Training.MarthaNo ratings yet

- Generic Risk Assessment - General Lathe Use v.1Document7 pagesGeneric Risk Assessment - General Lathe Use v.1Darus YasunNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

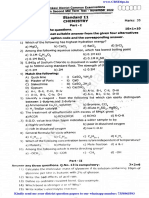

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- Accident Incident Report SampleDocument4 pagesAccident Incident Report SampleNgoua CalixNo ratings yet

- Night Work PermitDocument3 pagesNight Work PermitArmando AballeNo ratings yet

- Risk Assessment/Management FormDocument4 pagesRisk Assessment/Management FormNazriNo ratings yet

- Lifting Fixing of GI SheetDocument1 pageLifting Fixing of GI SheetJack PNo ratings yet

- Working at Height Risk Assessment Mar 21Document2 pagesWorking at Height Risk Assessment Mar 21tariq1987No ratings yet

- WHS-SOP-046 Fuel Storage and Handling 2022Document2 pagesWHS-SOP-046 Fuel Storage and Handling 2022MUKODWA NAJIB100% (1)

- Rules For Electric SafetyDocument1 pageRules For Electric SafetyEmoji SquadNo ratings yet

- Cuplock ScaffoldDocument155 pagesCuplock ScaffoldKailash PandeyNo ratings yet

- Env Governance ArchitectureDocument32 pagesEnv Governance ArchitectureJalagandeeswaran KalimuthuNo ratings yet

- Kalviseithi - 6,7,8 Lesson Plan Term 2 - All Subject PDFDocument220 pagesKalviseithi - 6,7,8 Lesson Plan Term 2 - All Subject PDFJalagandeeswaran KalimuthuNo ratings yet

- 11th Computer Science Chapter 10 Study Material emDocument16 pages11th Computer Science Chapter 10 Study Material emJalagandeeswaran KalimuthuNo ratings yet

- 11th Physics English Medium Full Study Material 2022-23Document195 pages11th Physics English Medium Full Study Material 2022-23Jalagandeeswaran KalimuthuNo ratings yet

- 11th Maths Chap 9Document23 pages11th Maths Chap 9Jalagandeeswaran KalimuthuNo ratings yet

- 11th Computer Science Don Guide em 219517Document26 pages11th Computer Science Don Guide em 219517Jalagandeeswaran KalimuthuNo ratings yet

- 11th Maths Chap 10-1Document16 pages11th Maths Chap 10-1Jalagandeeswaran KalimuthuNo ratings yet

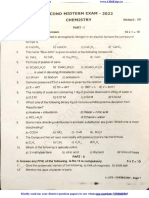

- 11th Chemistry EM Quarterly Exam 2022 Original Question Paper Tenkasi District English Medium PDF DownloadDocument2 pages11th Chemistry EM Quarterly Exam 2022 Original Question Paper Tenkasi District English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- 11th Chemistry Volume 1 English Medium Full Study Guide Download PDFDocument106 pages11th Chemistry Volume 1 English Medium Full Study Guide Download PDFJalagandeeswaran KalimuthuNo ratings yet

- 11th Computer Science Chapter 11 Study Material emDocument7 pages11th Computer Science Chapter 11 Study Material emJalagandeeswaran KalimuthuNo ratings yet

- 11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Kallakurichi District English Medium PDF DownloadDocument2 pages11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Kallakurichi District English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- Notification Retrofitting 7422Document2 pagesNotification Retrofitting 7422Jalagandeeswaran KalimuthuNo ratings yet

- Industry: The Environment (Protection) Rules, 1986Document1 pageIndustry: The Environment (Protection) Rules, 1986Jalagandeeswaran KalimuthuNo ratings yet

- 11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Thenkasi District English Medium PDF DownloadDocument2 pages11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Thenkasi District English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- 11th Chemistry - Second Mid Term 2019 Question Paper - English Medium PDF DownloadDocument4 pages11th Chemistry - Second Mid Term 2019 Question Paper - English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- 7 Tank ProcessDocument4 pages7 Tank ProcessJalagandeeswaran Kalimuthu100% (1)

- 11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Tirupattur District English Medium PDF DownloadDocument2 pages11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Tirupattur District English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- Provisional Peer-Reviewed Toxicity Values For 1,1,1,2-TetrachloroethaneDocument14 pagesProvisional Peer-Reviewed Toxicity Values For 1,1,1,2-TetrachloroethaneJalagandeeswaran KalimuthuNo ratings yet

- Vapor Intrusion Screening Level (Visl) Calculator User'S GuideDocument9 pagesVapor Intrusion Screening Level (Visl) Calculator User'S GuideJalagandeeswaran KalimuthuNo ratings yet

- R.A - Section 2Document7 pagesR.A - Section 2Jalagandeeswaran KalimuthuNo ratings yet

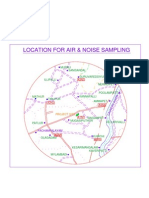

- Spac Sample Location 2Document1 pageSpac Sample Location 2Jalagandeeswaran KalimuthuNo ratings yet

- 2021 Volatile Organic Compounds Inhalation Toxicity Value ReviewDocument4 pages2021 Volatile Organic Compounds Inhalation Toxicity Value ReviewJalagandeeswaran KalimuthuNo ratings yet

- Risk Assessment Form: JalagandeeswaranDocument3 pagesRisk Assessment Form: JalagandeeswaranJalagandeeswaran KalimuthuNo ratings yet

- Time TableDocument1 pageTime TableJalagandeeswaran KalimuthuNo ratings yet

- Risk Assessment Form: I. PrabaharanDocument3 pagesRisk Assessment Form: I. PrabaharanJalagandeeswaran KalimuthuNo ratings yet

- Walani 2020 Global Burden of Preterm BirthDocument3 pagesWalani 2020 Global Burden of Preterm BirthHelyana DíazNo ratings yet

- Towards Water Sustainability: Ias Prelims Exam How To Command Polity Topics WDocument40 pagesTowards Water Sustainability: Ias Prelims Exam How To Command Polity Topics WMohaideen SubaireNo ratings yet

- ToxicokineticsDocument17 pagesToxicokineticsAshwin Ben JamesNo ratings yet

- Daftar Peserta UNEP Mop25-ProvisionalDocument80 pagesDaftar Peserta UNEP Mop25-Provisionalyoeneka ConsultingNo ratings yet

- Ati RN Community Health Proctored Exam 7 Versions Latest 2020 21 All Correct AnswersDocument35 pagesAti RN Community Health Proctored Exam 7 Versions Latest 2020 21 All Correct Answersolgahuntr827o100% (17)

- CRISC Exam - Secrets of Passing Exam in First AttemptDocument13 pagesCRISC Exam - Secrets of Passing Exam in First AttemptPractise-Test57% (7)

- Pre Kinder Parent OrientationDocument60 pagesPre Kinder Parent OrientationSandell SequenaNo ratings yet

- NSW Decision Making TreeDocument2 pagesNSW Decision Making TreeAyesha ahmedNo ratings yet

- Applied Pharmacology For The Dental Hygienist 7th Edition Haveles Solutions ManualDocument34 pagesApplied Pharmacology For The Dental Hygienist 7th Edition Haveles Solutions Manualatop.remiped25zad100% (16)

- Lab Exercise 9 Respiratory System PhysiologyDocument5 pagesLab Exercise 9 Respiratory System PhysiologySophia Nicole RosalesNo ratings yet

- Alteraciones Cromosomicas Molecular GeneticsDocument14 pagesAlteraciones Cromosomicas Molecular GeneticsChristian AguirreNo ratings yet

- Flyers Speaking PracticeDocument7 pagesFlyers Speaking PracticeIoana RadutaNo ratings yet

- HYPERLIGHT - A Breakthrough in MedicineDocument12 pagesHYPERLIGHT - A Breakthrough in MedicinePeter CsalloNo ratings yet

- Survival Guide To O LevelsDocument25 pagesSurvival Guide To O Levelszelaismail218No ratings yet

- Edited Risk For MaternalDocument2 pagesEdited Risk For MaternalElisha100% (1)

- StrongLifts 5×5 Workout Program For Beginners - StrongLiftsDocument94 pagesStrongLifts 5×5 Workout Program For Beginners - StrongLiftsAdalberto GomesNo ratings yet

- Cancer Cells Can Exhibit A Sparing FLASH Effect atDocument9 pagesCancer Cells Can Exhibit A Sparing FLASH Effect atMohamed El-AgamyNo ratings yet

- OEKO-TEX Quality Assurance SystemDocument3 pagesOEKO-TEX Quality Assurance Systemzman99No ratings yet

- Research Proposal Form DraFT 1Document10 pagesResearch Proposal Form DraFT 1minoli fernandoNo ratings yet

- Workplace Safety Word SearchDocument1 pageWorkplace Safety Word SearchSwaraj KadamNo ratings yet

- Nejmoa 2304146Document13 pagesNejmoa 2304146Njeodo VignyNo ratings yet

- Social Identity - Erik Erikson TheoryDocument2 pagesSocial Identity - Erik Erikson TheoryHolySmoly100% (3)

- Stok Tanggal 25 Mei 2022Document8 pagesStok Tanggal 25 Mei 2022dewi lestariNo ratings yet

- Environmental AND Social Management Plan: Nepal Electricity AuthorityDocument113 pagesEnvironmental AND Social Management Plan: Nepal Electricity AuthoritySubesh JoshiNo ratings yet

- July MCQ-2023 - 230922 - 091408Document55 pagesJuly MCQ-2023 - 230922 - 091408Maria SiddiquiNo ratings yet

Fork Lift Truck-Risk Assessment - Date: R A - S A /S

Fork Lift Truck-Risk Assessment - Date: R A - S A /S

Uploaded by

Jalagandeeswaran KalimuthuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fork Lift Truck-Risk Assessment - Date: R A - S A /S

Fork Lift Truck-Risk Assessment - Date: R A - S A /S

Uploaded by

Jalagandeeswaran KalimuthuCopyright:

Available Formats

Fork lift truck- Risk Assessment- date

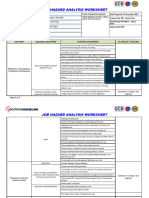

RISK ASSESSMENT – SPECIFIC ACTIVITY/SITUATION

WORKPLACE / ACTIVITY / Fork Lift Truck Operations – REVIEW

Annually

EQUIPMENT BEING ASSESSED: Unloading area TIMESCALE:

FLT drivers, any employees,

PERSONS AT RISK- AFFECTED

BY ACTIVITY:

contractors, members of public in the NUMBER 1 – 20

vicinity

OTHER VULNERABLE

PERSONS AFFECTED BY None NUMBER

ACTIVITY:

POTENTIAL HAZARDS Assessment of Risk

REF. Low Med High

1 Pedestrian/vehicle collision causing impact injury √

2 Falling loads, dropping onto pedestrians in work area √

Adverse weather conditions causing poor visibility, impact √

3

injury

4 Sliding or skidding on wet/contaminated/ icy floor surfaces √

Electric shock from touching live terminals of battery causing √

5

severe burning to the hands

6 Overloading of the forklift causing load failure, falling objects √

7 Unsecured loads falling from height – crushing injury √

8 Fire /explosion caused by LPG leaks – burns etc √

9 Forklift falling when unloading on the slope √

10 Overturning vehicle travelling at speed, driver crush injury √

EXISTING CONTROL MEASURES

Daily pre us driver inspection of vehicle – checklist maintained

Checking of all pallets are sound condition prior to use – Driver training – Load checks

Restricted use in adverse weather conditions – management control

Protective footwear worn by forklift truck drivers and another personnel in unloading areas

Salt available and applied during icy conditions.

Lighting is provided and maintained.

Marked pedestrian access areas and temporary barriers to restrict access in non routine work

Statutory LOLER inspections of vehicle chains – SWL marked in drivers area

Trained and competent drivers operating vehicles – Authorised to drive – Site Induction

Routine vehicle maintenance – D A C Handling – Records of maintenance maintained

Restrict forklift use in customer areas during peak times

Forklift must be used on the flattest ground possible

FLT Operating sign to front of work area – restricted access

INITIAL ASSESSMENT OF OVERALL RISK LOW MEDIUM √ HIGH

RISK = SEVERITY x LIKELIHOOD

Rating SEVERITY of injury/disease LIKELIHOOD of occurrence

Frame-putting you in the picture

Fork lift truck- Risk Assessment- date

HIGH Fatality; major injury or illness causing long term disability Certain or near certain to occur

MEDIUM Injury or illness causing short term disability Reasonably likely to occur

LOW Other injury or illness Very seldom or never occurs

COMPLETION

ADDITIONAL CONTROL MEASURES - (IF APPLICABLE) RESPONSIBLE PERSON

DATE

Train personnel on the installation of the LPG

cylinder, refuelling and include daily checks within the

maintenance regime.

Provide drivers with fluorescent jackets

Provide barriers to unloading area

Carry out and record familiarisation training for

drivers.

Introduce formal recorded weekly inspection of traffic

routes/work area

Flashing beacons should be fitted to all forklift trucks.

RESIDUAL ASSESSMENT OF OVERALL RISK LOW √ MEDIUM HIGH

Note: Re-Assessment Required if Overall Residual Risk Remains High

ADDITIONAL INFORMATION:

(Notes, comments, further details, outline procedures, safe systems of work, standards, drawings, etc.)

Risk Assessment Circulation list (tick box)

Employees √ Management √ Contractors

Other – Specify:

Signature of person primarily accountable: Date:

Assessor: Signature:

Review

Date Assessed: 1 year

Timescale:

Notes: Control measures that already exist or additional control measures that will reduce the risks further

require to be noted. The additional control measures noted will also have to have the completion date for

each measure indicated

Frame-putting you in the picture

You might also like

- Critical Care Nursing A Holistic Approach 10th Edition Morton Test Bank PDFDocument6 pagesCritical Care Nursing A Holistic Approach 10th Edition Morton Test Bank PDFa806088253No ratings yet

- JHA - Unloading of Sheet PileDocument3 pagesJHA - Unloading of Sheet PileJensen Sunga100% (1)

- 1.0 Driver Induction, Agreements & ChecklistDocument10 pages1.0 Driver Induction, Agreements & Checklistdave.muir.25No ratings yet

- PPE Request Form (New)Document1 pagePPE Request Form (New)Syafrial AnasNo ratings yet

- Miss Alli Model Nude Sets Mega PDFDocument4 pagesMiss Alli Model Nude Sets Mega PDFSeanNo ratings yet

- Background Checking Requirements Undertaking: Name: PositionDocument2 pagesBackground Checking Requirements Undertaking: Name: PositionANTHONNETTE DELA TORRENo ratings yet

- Suspended Load SafetyDocument3 pagesSuspended Load Safetymy_agautamNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Health & Safety Management Plan 2014-2019 Annual Key Performance IndicatorsDocument3 pagesHealth & Safety Management Plan 2014-2019 Annual Key Performance Indicatorsmohit67% (3)

- Risk Assessment For Erection of Steel GirderDocument11 pagesRisk Assessment For Erection of Steel GirderNirajan MarwaitNo ratings yet

- Bill Starr - Sets, Reps and Getting StrongDocument2 pagesBill Starr - Sets, Reps and Getting StrongTomSusNo ratings yet

- Fork Lift - Risk Assessment - ExampleDocument4 pagesFork Lift - Risk Assessment - Exampleعلي المرزوقNo ratings yet

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- General Risk Assessment FormDocument8 pagesGeneral Risk Assessment FormmkmusaNo ratings yet

- Safety ProgramDocument21 pagesSafety ProgramSits RdddNo ratings yet

- TOPIC: Personal Protective Equipment ChecklistDocument1 pageTOPIC: Personal Protective Equipment ChecklistMd ShNo ratings yet

- Risk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.Document2 pagesRisk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.salauddin0mohammedNo ratings yet

- Toolbox Talk Slips Trips and FallsDocument2 pagesToolbox Talk Slips Trips and FallsrajNo ratings yet

- How To Document Accident ReportDocument5 pagesHow To Document Accident Reportcristina23No ratings yet

- Gsa Generic Office Risk Assessment Health and Safety OfficeDocument7 pagesGsa Generic Office Risk Assessment Health and Safety Officetest fypNo ratings yet

- Generic RA Gas CylindersDocument6 pagesGeneric RA Gas CylindersShahid RazaNo ratings yet

- Issue-Based Risk Assessment Sub-Contractor ITS Filters CleaningDocument5 pagesIssue-Based Risk Assessment Sub-Contractor ITS Filters CleaningAhmed AbdulmajeedNo ratings yet

- Safety Campaign-Energy Isolation-April 2022Document7 pagesSafety Campaign-Energy Isolation-April 2022HSE99 BHDCNo ratings yet

- Toolbox Talks - Near Miss ReportingDocument1 pageToolbox Talks - Near Miss ReportinganaNo ratings yet

- Task Risk AssesmentDocument3 pagesTask Risk Assesmentafsalkareem100% (1)

- Belt & Orbital Sander PDFDocument2 pagesBelt & Orbital Sander PDFcityofdarwingisNo ratings yet

- Lone Working PolicyDocument22 pagesLone Working PolicyVictor TasieNo ratings yet

- 04, Use of Hand ToolsDocument2 pages04, Use of Hand ToolsFrancis K BonfulNo ratings yet

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoNo ratings yet

- Toolbox Talk FormDocument4 pagesToolbox Talk FormPrem Preetham DsouzaNo ratings yet

- JSA #28 - Use of Hand ToolsDocument1 pageJSA #28 - Use of Hand ToolsSubham SohalNo ratings yet

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocument2 pagesSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherNo ratings yet

- 10 - Safety Harness InspectorDocument1 page10 - Safety Harness InspectorSusan LouwNo ratings yet

- SWMS Loading and Unloading Vehicles WHS.127 V002.1Document18 pagesSWMS Loading and Unloading Vehicles WHS.127 V002.1Amit BhattNo ratings yet

- Warehouse Risk Assessment Aldir II IWPPDocument25 pagesWarehouse Risk Assessment Aldir II IWPPMadhu MohanNo ratings yet

- Unloading of EWPs From ContainersDocument10 pagesUnloading of EWPs From ContainersPirashanth SathananthanNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- SWP - LifelinesDocument7 pagesSWP - LifelinesREHOBOTH YAMBO KAHILUNo ratings yet

- Working at Height Risk AssessmentDocument9 pagesWorking at Height Risk AssessmentBasky0% (1)

- TCB Work at Height WEBDocument5 pagesTCB Work at Height WEBFaraaz MohammadNo ratings yet

- 11 Construction of Kill LineDocument9 pages11 Construction of Kill LinePangky AbasoloNo ratings yet

- Work at Heights PermitDocument4 pagesWork at Heights PermitFerdinand M. TurbanosNo ratings yet

- 2.4 Attachments - Risk Assessment and Method StatementDocument10 pages2.4 Attachments - Risk Assessment and Method StatementFahad MaqsoodNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- Earthmoving Attachment Maintenance: Safe Operational ProcedureDocument3 pagesEarthmoving Attachment Maintenance: Safe Operational ProcedureJamesNo ratings yet

- Confined Space Risk Assessment WHSFOR-009BDocument3 pagesConfined Space Risk Assessment WHSFOR-009BvictorNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- 1 ST Quater Drill ScenarioDocument2 pages1 ST Quater Drill ScenarioSk MehbobNo ratings yet

- Concrete WorkDocument3 pagesConcrete WorkAbdul Ghaffar100% (1)

- Day5 Delivery WAH Management Training.Document88 pagesDay5 Delivery WAH Management Training.MarthaNo ratings yet

- Generic Risk Assessment - General Lathe Use v.1Document7 pagesGeneric Risk Assessment - General Lathe Use v.1Darus YasunNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- Accident Incident Report SampleDocument4 pagesAccident Incident Report SampleNgoua CalixNo ratings yet

- Night Work PermitDocument3 pagesNight Work PermitArmando AballeNo ratings yet

- Risk Assessment/Management FormDocument4 pagesRisk Assessment/Management FormNazriNo ratings yet

- Lifting Fixing of GI SheetDocument1 pageLifting Fixing of GI SheetJack PNo ratings yet

- Working at Height Risk Assessment Mar 21Document2 pagesWorking at Height Risk Assessment Mar 21tariq1987No ratings yet

- WHS-SOP-046 Fuel Storage and Handling 2022Document2 pagesWHS-SOP-046 Fuel Storage and Handling 2022MUKODWA NAJIB100% (1)

- Rules For Electric SafetyDocument1 pageRules For Electric SafetyEmoji SquadNo ratings yet

- Cuplock ScaffoldDocument155 pagesCuplock ScaffoldKailash PandeyNo ratings yet

- Env Governance ArchitectureDocument32 pagesEnv Governance ArchitectureJalagandeeswaran KalimuthuNo ratings yet

- Kalviseithi - 6,7,8 Lesson Plan Term 2 - All Subject PDFDocument220 pagesKalviseithi - 6,7,8 Lesson Plan Term 2 - All Subject PDFJalagandeeswaran KalimuthuNo ratings yet

- 11th Computer Science Chapter 10 Study Material emDocument16 pages11th Computer Science Chapter 10 Study Material emJalagandeeswaran KalimuthuNo ratings yet

- 11th Physics English Medium Full Study Material 2022-23Document195 pages11th Physics English Medium Full Study Material 2022-23Jalagandeeswaran KalimuthuNo ratings yet

- 11th Maths Chap 9Document23 pages11th Maths Chap 9Jalagandeeswaran KalimuthuNo ratings yet

- 11th Computer Science Don Guide em 219517Document26 pages11th Computer Science Don Guide em 219517Jalagandeeswaran KalimuthuNo ratings yet

- 11th Maths Chap 10-1Document16 pages11th Maths Chap 10-1Jalagandeeswaran KalimuthuNo ratings yet

- 11th Chemistry EM Quarterly Exam 2022 Original Question Paper Tenkasi District English Medium PDF DownloadDocument2 pages11th Chemistry EM Quarterly Exam 2022 Original Question Paper Tenkasi District English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- 11th Chemistry Volume 1 English Medium Full Study Guide Download PDFDocument106 pages11th Chemistry Volume 1 English Medium Full Study Guide Download PDFJalagandeeswaran KalimuthuNo ratings yet

- 11th Computer Science Chapter 11 Study Material emDocument7 pages11th Computer Science Chapter 11 Study Material emJalagandeeswaran KalimuthuNo ratings yet

- 11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Kallakurichi District English Medium PDF DownloadDocument2 pages11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Kallakurichi District English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- Notification Retrofitting 7422Document2 pagesNotification Retrofitting 7422Jalagandeeswaran KalimuthuNo ratings yet

- Industry: The Environment (Protection) Rules, 1986Document1 pageIndustry: The Environment (Protection) Rules, 1986Jalagandeeswaran KalimuthuNo ratings yet

- 11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Thenkasi District English Medium PDF DownloadDocument2 pages11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Thenkasi District English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- 11th Chemistry - Second Mid Term 2019 Question Paper - English Medium PDF DownloadDocument4 pages11th Chemistry - Second Mid Term 2019 Question Paper - English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- 7 Tank ProcessDocument4 pages7 Tank ProcessJalagandeeswaran Kalimuthu100% (1)

- 11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Tirupattur District English Medium PDF DownloadDocument2 pages11th Chemistry 2nd Mid Term Exam 2022 Original Question Paper Tirupattur District English Medium PDF DownloadJalagandeeswaran KalimuthuNo ratings yet

- Provisional Peer-Reviewed Toxicity Values For 1,1,1,2-TetrachloroethaneDocument14 pagesProvisional Peer-Reviewed Toxicity Values For 1,1,1,2-TetrachloroethaneJalagandeeswaran KalimuthuNo ratings yet

- Vapor Intrusion Screening Level (Visl) Calculator User'S GuideDocument9 pagesVapor Intrusion Screening Level (Visl) Calculator User'S GuideJalagandeeswaran KalimuthuNo ratings yet

- R.A - Section 2Document7 pagesR.A - Section 2Jalagandeeswaran KalimuthuNo ratings yet

- Spac Sample Location 2Document1 pageSpac Sample Location 2Jalagandeeswaran KalimuthuNo ratings yet

- 2021 Volatile Organic Compounds Inhalation Toxicity Value ReviewDocument4 pages2021 Volatile Organic Compounds Inhalation Toxicity Value ReviewJalagandeeswaran KalimuthuNo ratings yet

- Risk Assessment Form: JalagandeeswaranDocument3 pagesRisk Assessment Form: JalagandeeswaranJalagandeeswaran KalimuthuNo ratings yet

- Time TableDocument1 pageTime TableJalagandeeswaran KalimuthuNo ratings yet

- Risk Assessment Form: I. PrabaharanDocument3 pagesRisk Assessment Form: I. PrabaharanJalagandeeswaran KalimuthuNo ratings yet

- Walani 2020 Global Burden of Preterm BirthDocument3 pagesWalani 2020 Global Burden of Preterm BirthHelyana DíazNo ratings yet

- Towards Water Sustainability: Ias Prelims Exam How To Command Polity Topics WDocument40 pagesTowards Water Sustainability: Ias Prelims Exam How To Command Polity Topics WMohaideen SubaireNo ratings yet

- ToxicokineticsDocument17 pagesToxicokineticsAshwin Ben JamesNo ratings yet

- Daftar Peserta UNEP Mop25-ProvisionalDocument80 pagesDaftar Peserta UNEP Mop25-Provisionalyoeneka ConsultingNo ratings yet

- Ati RN Community Health Proctored Exam 7 Versions Latest 2020 21 All Correct AnswersDocument35 pagesAti RN Community Health Proctored Exam 7 Versions Latest 2020 21 All Correct Answersolgahuntr827o100% (17)

- CRISC Exam - Secrets of Passing Exam in First AttemptDocument13 pagesCRISC Exam - Secrets of Passing Exam in First AttemptPractise-Test57% (7)

- Pre Kinder Parent OrientationDocument60 pagesPre Kinder Parent OrientationSandell SequenaNo ratings yet

- NSW Decision Making TreeDocument2 pagesNSW Decision Making TreeAyesha ahmedNo ratings yet

- Applied Pharmacology For The Dental Hygienist 7th Edition Haveles Solutions ManualDocument34 pagesApplied Pharmacology For The Dental Hygienist 7th Edition Haveles Solutions Manualatop.remiped25zad100% (16)

- Lab Exercise 9 Respiratory System PhysiologyDocument5 pagesLab Exercise 9 Respiratory System PhysiologySophia Nicole RosalesNo ratings yet

- Alteraciones Cromosomicas Molecular GeneticsDocument14 pagesAlteraciones Cromosomicas Molecular GeneticsChristian AguirreNo ratings yet

- Flyers Speaking PracticeDocument7 pagesFlyers Speaking PracticeIoana RadutaNo ratings yet

- HYPERLIGHT - A Breakthrough in MedicineDocument12 pagesHYPERLIGHT - A Breakthrough in MedicinePeter CsalloNo ratings yet

- Survival Guide To O LevelsDocument25 pagesSurvival Guide To O Levelszelaismail218No ratings yet

- Edited Risk For MaternalDocument2 pagesEdited Risk For MaternalElisha100% (1)

- StrongLifts 5×5 Workout Program For Beginners - StrongLiftsDocument94 pagesStrongLifts 5×5 Workout Program For Beginners - StrongLiftsAdalberto GomesNo ratings yet

- Cancer Cells Can Exhibit A Sparing FLASH Effect atDocument9 pagesCancer Cells Can Exhibit A Sparing FLASH Effect atMohamed El-AgamyNo ratings yet

- OEKO-TEX Quality Assurance SystemDocument3 pagesOEKO-TEX Quality Assurance Systemzman99No ratings yet

- Research Proposal Form DraFT 1Document10 pagesResearch Proposal Form DraFT 1minoli fernandoNo ratings yet

- Workplace Safety Word SearchDocument1 pageWorkplace Safety Word SearchSwaraj KadamNo ratings yet

- Nejmoa 2304146Document13 pagesNejmoa 2304146Njeodo VignyNo ratings yet

- Social Identity - Erik Erikson TheoryDocument2 pagesSocial Identity - Erik Erikson TheoryHolySmoly100% (3)

- Stok Tanggal 25 Mei 2022Document8 pagesStok Tanggal 25 Mei 2022dewi lestariNo ratings yet

- Environmental AND Social Management Plan: Nepal Electricity AuthorityDocument113 pagesEnvironmental AND Social Management Plan: Nepal Electricity AuthoritySubesh JoshiNo ratings yet

- July MCQ-2023 - 230922 - 091408Document55 pagesJuly MCQ-2023 - 230922 - 091408Maria SiddiquiNo ratings yet