Professional Documents

Culture Documents

Infrared CO2 Sensor Module (Model: MH-Z19B) : User's Manual

Infrared CO2 Sensor Module (Model: MH-Z19B) : User's Manual

Uploaded by

sine summsun PradhanCopyright:

Available Formats

You might also like

- Acronis #CyberFit Cloud Tech Fundamentals 2022-Comprimido (1) - 1-150Document150 pagesAcronis #CyberFit Cloud Tech Fundamentals 2022-Comprimido (1) - 1-150Soportech RDNo ratings yet

- HRM - Thomas CookDocument52 pagesHRM - Thomas CookSabrish Nair50% (2)

- Dubai World Ehs - 2007 Regulations & StandardsDocument106 pagesDubai World Ehs - 2007 Regulations & StandardsSAYED100% (10)

- Infrared CO2 Sensor Module (Model: MH-Z19B) : User's ManualDocument9 pagesInfrared CO2 Sensor Module (Model: MH-Z19B) : User's ManualhebersbNo ratings yet

- Infrared CO2 Sensor Module (Model: MH-Z19B) : User's ManualDocument9 pagesInfrared CO2 Sensor Module (Model: MH-Z19B) : User's ManualAvs ElectronNo ratings yet

- MH z19b Co2 Ver1 - 0 PDFDocument9 pagesMH z19b Co2 Ver1 - 0 PDFMacovei Lucian FlorinNo ratings yet

- Infrared CO2 Sensor Module (Model: MH-Z19C) : User's ManualDocument7 pagesInfrared CO2 Sensor Module (Model: MH-Z19C) : User's ManualrerlgakkbuqysmavtmNo ratings yet

- MH Z19Document9 pagesMH Z19Simone PolinesiNo ratings yet

- MH-Z19C-DZ-terminal Type CO2 Manual (Ver1.21) - 202103Document9 pagesMH-Z19C-DZ-terminal Type CO2 Manual (Ver1.21) - 202103testNo ratings yet

- ZE16B-CO Module Manual V1.1Document5 pagesZE16B-CO Module Manual V1.1Mehdi MehdiNo ratings yet

- Ze03 Electrochemical Module Manualv2 - 5Document7 pagesZe03 Electrochemical Module Manualv2 - 5Ильнур ТагировNo ratings yet

- ms1022 gp22 EquivalentDocument60 pagesms1022 gp22 Equivalentdbm100% (1)

- Techincal Specifications With DetailsDocument11 pagesTechincal Specifications With Detailsruturaj v delekarNo ratings yet

- Datasheet Electromagnetic Flow Meter Sup-Ldg: Committed To Process Automation Solutions Tel: 86-15158063876 FDocument16 pagesDatasheet Electromagnetic Flow Meter Sup-Ldg: Committed To Process Automation Solutions Tel: 86-15158063876 FAink Dak bageur theaNo ratings yet

- ZPH01 DustDocument8 pagesZPH01 DustGhiban ConstantinNo ratings yet

- CO2 Box Product Specification: Parameter TableDocument3 pagesCO2 Box Product Specification: Parameter TableJoséNo ratings yet

- SDS011 Laser PM2.5 Sensor Specification-V1.3Document13 pagesSDS011 Laser PM2.5 Sensor Specification-V1.3Divjot SinghNo ratings yet

- Mainstream ETCO2 Module CM2200 Technical SpecificationDocument13 pagesMainstream ETCO2 Module CM2200 Technical SpecificationEmilio CánepaNo ratings yet

- Dso tc2 Oscilloscope Transistor Tester ManualDocument8 pagesDso tc2 Oscilloscope Transistor Tester ManualLuciano FerreiraNo ratings yet

- SDS011 Laser PM2.5 Sensor Specification-V1.4Document13 pagesSDS011 Laser PM2.5 Sensor Specification-V1.4Jürgen KircherNo ratings yet

- Dyp - ds1309Document11 pagesDyp - ds1309alaska112No ratings yet

- Laser PM2.5 Sensor Specification: Product Model: SDS011Document13 pagesLaser PM2.5 Sensor Specification: Product Model: SDS011Fredrik LingNo ratings yet

- MHS-5200A ManualDocument25 pagesMHS-5200A ManualAndrey VoroninNo ratings yet

- Multi Vision™: Multivariable TransmitterDocument10 pagesMulti Vision™: Multivariable TransmitterRaja RamNo ratings yet

- A1350 Flyer eDocument2 pagesA1350 Flyer eBojan IlievNo ratings yet

- Intelligent Infrared Carbon Dioxide Module (Model: MH-Z14A) : Issue Date. May 5, 2019Document10 pagesIntelligent Infrared Carbon Dioxide Module (Model: MH-Z14A) : Issue Date. May 5, 2019udara11No ratings yet

- Brochure Dew Point Sensors - ENDocument12 pagesBrochure Dew Point Sensors - ENosmanyildirim85No ratings yet

- v130 33 Ta24 - Dts v130 Ta24 - 10 07Document6 pagesv130 33 Ta24 - Dts v130 Ta24 - 10 07Ecaterina IrimiaNo ratings yet

- Modicon M171 - M172 - TM172PDG28RDocument7 pagesModicon M171 - M172 - TM172PDG28RPhaniNo ratings yet

- Carbon Monoxide DM-100-CO PDSDocument2 pagesCarbon Monoxide DM-100-CO PDSroyvindasNo ratings yet

- Ultrasonic Oxygen Sensor Module Gasboard7500EDocument6 pagesUltrasonic Oxygen Sensor Module Gasboard7500ECarlos Julián Muñoz QuirogaNo ratings yet

- Parallel Beam Line Sensor Z4Lc: Ordering InformationDocument17 pagesParallel Beam Line Sensor Z4Lc: Ordering InformationDjoNo ratings yet

- Selina Product CatalogDocument19 pagesSelina Product Catalogdondon correNo ratings yet

- DE550016 BA 3 Select 01Document4 pagesDE550016 BA 3 Select 01seve1No ratings yet

- Inclinometer Lca326t PDFDocument10 pagesInclinometer Lca326t PDFManasi NaikNo ratings yet

- Greisinger OXY 3690 MP User ManualDocument4 pagesGreisinger OXY 3690 MP User ManualesatpehlivanNo ratings yet

- Operating Manual: MHS-5200A Dual-Channel DDS Signal GeneratorDocument28 pagesOperating Manual: MHS-5200A Dual-Channel DDS Signal GeneratorwijilestarikhasannahNo ratings yet

- Gekko: Portable PAUT For NDTDocument2 pagesGekko: Portable PAUT For NDTManuel AvilaNo ratings yet

- Manual CU 1106 Rev1Document17 pagesManual CU 1106 Rev1Jose Maria PerezNo ratings yet

- SCM-W Datasheet v41Document10 pagesSCM-W Datasheet v41nguyenam2008No ratings yet

- Detector de Gas - TGas-1031Document6 pagesDetector de Gas - TGas-1031Fernando BonillaNo ratings yet

- CO-T1 SpecDocument2 pagesCO-T1 SpecvicairmasterNo ratings yet

- Isweek SprintIR CO2 SensorDocument2 pagesIsweek SprintIR CO2 SensorindustrialNo ratings yet

- Specification: Product Name: Laser Particle Sensor Module Item No.: PM2008 Date: February 27, 2019Document24 pagesSpecification: Product Name: Laser Particle Sensor Module Item No.: PM2008 Date: February 27, 2019MIN GU KIMNo ratings yet

- BS03 Fixed Gas Detector-VOCDocument1 pageBS03 Fixed Gas Detector-VOCtruongNo ratings yet

- Analog Input/output Modules - EM 231 Analog Input ModulesDocument11 pagesAnalog Input/output Modules - EM 231 Analog Input ModulesLượng TrầnNo ratings yet

- SDS011 Laser PM2.5 Sensor Specification-V1.5Document13 pagesSDS011 Laser PM2.5 Sensor Specification-V1.5SearcherNo ratings yet

- MH Z14jjjjjknjkDocument3 pagesMH Z14jjjjjknjkBabu DharmarajNo ratings yet

- Ultrasonic Fuel Sensor User Manual - 181129Document11 pagesUltrasonic Fuel Sensor User Manual - 181129Carlos MontalvanNo ratings yet

- DS0073rev14 OXY Flex-1590383Document5 pagesDS0073rev14 OXY Flex-1590383Jorge Morales CerónNo ratings yet

- Zh03b Laser Dust Module v2 1Document11 pagesZh03b Laser Dust Module v2 1Hoan PhamNo ratings yet

- Ultra1000 IR CombustibleDocument2 pagesUltra1000 IR Combustiblececilia aguilarNo ratings yet

- Sensor CO2 para El 20% KCD - HP - en - 110602 PDFDocument5 pagesSensor CO2 para El 20% KCD - HP - en - 110602 PDFAngelica MarulandaNo ratings yet

- FT2 Flow Temperature Thermal Mass TransmitterDocument4 pagesFT2 Flow Temperature Thermal Mass TransmitterJulian GaleanoNo ratings yet

- Janitza-Especificaciones Técnicas-UMG604Document18 pagesJanitza-Especificaciones Técnicas-UMG604Pablo RodaNo ratings yet

- XGZP161 Pressure Sensor-V2Document8 pagesXGZP161 Pressure Sensor-V2samsularief03No ratings yet

- OCS-3F 2.1data SheetDocument5 pagesOCS-3F 2.1data SheetGONZALO ENRIQUE MARTINEZ OJEDA100% (1)

- TP-624D H2S Mos PDS PDFDocument2 pagesTP-624D H2S Mos PDS PDFkaleeswaranNo ratings yet

- Company ProfileDocument36 pagesCompany Profileyoussouf ismaNo ratings yet

- Mechanical Compact Meter: ApplicationDocument7 pagesMechanical Compact Meter: ApplicationVelimir MilovanovicNo ratings yet

- Final Report 2020Document26 pagesFinal Report 2020Siva BadrinathNo ratings yet

- Automatic Pattern Classification by Unsupervised Learning Using Dimensionality Reduction of Data With Mirroring Neural NetworksDocument5 pagesAutomatic Pattern Classification by Unsupervised Learning Using Dimensionality Reduction of Data With Mirroring Neural Networkssine summsun PradhanNo ratings yet

- Rar PDFDocument254 pagesRar PDFsine summsun PradhanNo ratings yet

- Phys 6.1 and 6.2 Ant Pituitary GH and Post Pituitary NOTESDocument7 pagesPhys 6.1 and 6.2 Ant Pituitary GH and Post Pituitary NOTESsine summsun PradhanNo ratings yet

- Powerful English Speaking PDFDocument14 pagesPowerful English Speaking PDFsine summsun PradhanNo ratings yet

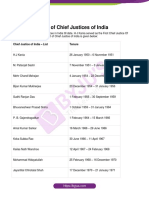

- List of Chief Justices of IndiaDocument4 pagesList of Chief Justices of Indiasine summsun PradhanNo ratings yet

- Mil STD 461eDocument288 pagesMil STD 461ech.navnNo ratings yet

- U3A5 Practitioner's Handbook Organizing ChartDocument3 pagesU3A5 Practitioner's Handbook Organizing Chartkael9010 kael9010No ratings yet

- Janus MV FM200 BrochureDocument22 pagesJanus MV FM200 BrochurenoisNo ratings yet

- Omkar TrustDocument156 pagesOmkar TrustAveline Dsouza100% (2)

- Recreationalactivities 140317203039 Phpapp01 PDFDocument27 pagesRecreationalactivities 140317203039 Phpapp01 PDFRodjan MoscosoNo ratings yet

- Lesson 1.4 Literary Genres: Genres of Drama: Arellano UniversityDocument21 pagesLesson 1.4 Literary Genres: Genres of Drama: Arellano UniversityKing TadlasNo ratings yet

- Advanced Drilling Engineering Final TOCDocument10 pagesAdvanced Drilling Engineering Final TOCbrayanconin0% (1)

- FOR Approval Specification: Title 32.0" Wuxga TFT LCDDocument36 pagesFOR Approval Specification: Title 32.0" Wuxga TFT LCDСергій НестеровичNo ratings yet

- Es - Chatta Bakhtawar-Shaheen ColonyDocument3 pagesEs - Chatta Bakhtawar-Shaheen ColonyNida NazNo ratings yet

- Autoclaves For Sterilisation "Presoclave II" - ManualDocument12 pagesAutoclaves For Sterilisation "Presoclave II" - ManualMariaNo ratings yet

- Prayer For The Elderly and GrandparentsDocument2 pagesPrayer For The Elderly and GrandparentsRomain Garry Evangelista LazaroNo ratings yet

- CAMLIFE 2023 ProspectusDocument16 pagesCAMLIFE 2023 Prospectusboydilinh012No ratings yet

- The Automated Battlefield Brief NotesDocument3 pagesThe Automated Battlefield Brief NotesEddie GerminoNo ratings yet

- Case 10 (Post-Operative Pain Management & Complication)Document10 pagesCase 10 (Post-Operative Pain Management & Complication)ReddyNo ratings yet

- Digital BankingDocument3 pagesDigital BankingDPC Gym100% (1)

- Chatrapati Shivaji TurminusDocument6 pagesChatrapati Shivaji TurminusshrutiNo ratings yet

- Aqua Starter BookletDocument13 pagesAqua Starter BookletPartha NathNo ratings yet

- Challenges in The Collection and Processing of Physical Evidence For Sexual Offences Cases in Gauteng ProvinceDocument10 pagesChallenges in The Collection and Processing of Physical Evidence For Sexual Offences Cases in Gauteng ProvinceleseditjaleNo ratings yet

- Cambridge Checkpoint: Overview and PreparationDocument50 pagesCambridge Checkpoint: Overview and PreparationIrishMujNo ratings yet

- LeafletsDocument2 pagesLeafletsAmir FarajiNo ratings yet

- Sprinkler System Design GuidelinesDocument2 pagesSprinkler System Design GuidelinesaneeshNo ratings yet

- A Report On The Internship Training Undergone at "Madhura Fire Works, Sivakasi"Document44 pagesA Report On The Internship Training Undergone at "Madhura Fire Works, Sivakasi"Naresh Kumar100% (4)

- The Significance of Yoga TantraDocument358 pagesThe Significance of Yoga TantraAnurag Chand100% (3)

- SensION1 ManualDocument40 pagesSensION1 ManualMaria Victoria GuarinNo ratings yet

- Co2 Lesson PlanDocument5 pagesCo2 Lesson PlanMAY RACHEL NARRAGANo ratings yet

- Intern Project MBADocument102 pagesIntern Project MBAuiuxdesigneramitNo ratings yet

- Profil Company 2017Document10 pagesProfil Company 2017Eno Ronaldfrank OguriNo ratings yet

Infrared CO2 Sensor Module (Model: MH-Z19B) : User's Manual

Infrared CO2 Sensor Module (Model: MH-Z19B) : User's Manual

Uploaded by

sine summsun PradhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Infrared CO2 Sensor Module (Model: MH-Z19B) : User's Manual

Infrared CO2 Sensor Module (Model: MH-Z19B) : User's Manual

Uploaded by

sine summsun PradhanCopyright:

Available Formats

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.

com

Infrared CO2 Sensor Module

(Model: MH-Z19B)

User’s Manual

(Version: 1.5)

Valid from: 2019.09.23

Zhengzhou Winsen Electronics Technology Co., Ltd

ISO9001 certificated company

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.com

Statement

This manual’s copyright belongs to Zhengzhou Winsen Electronics Technology Co., LTD. Without

the written permission, any part of this manual shall not be copied, translated, stored in database

or retrieval system, also can’t spread through electronic, copying, record ways.

Thanks for purchasing our product. In order to let customers use it better and reduce the faults

caused by misuse, please read the manual carefully and operate it correctly in accordance with the

instructions. If users disobey the terms or remove, disassemble, change the components inside of

the sensor, we shall not be responsible for the loss.

The specific such as color, appearance, sizes &etc., please in kind prevail.

We are devoting ourselves to products development and technical innovation, so we reserve the

right to improve the products without notice. Please confirm it is the valid version before using this

manual. At the same time, users’ comments on optimized using way are welcome.

Please keep the manual properly, in order to get help if you have questions during the usage in the

future.

Zhengzhou Winsen Electronics Technology CO., LTD.

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.com

MH-Z19B NDIR CO2 Module

1. Profile

MH-Z19B NDIR infrared gas module is a common type, small size sensor, using non-dispersive infrared (NDIR)

principle to detect the existence of CO 2 in the air, with good selectivity, non-oxygen dependent and long

life. Built-in temperature compensation; and it has UART output and PWM output. It is developed by the

tight integration of mature infrared absorbing gas detection technology, precision optical circuit design and

superior circuit design.

2. Applications

*HVAC refrigeration *Air cleaner device *Indoor air quality monitoring

*Smart home *Ventilation system *School

3. Main Features

Chamber is gold plated, water-proof and anti-corrosion

High sensitivity, low power consumption

Good stability

Temperature compensation, excellent linear output

Multiple output modes: UART, DAC, PWM

Long lifespan

Anti-water vapor interference, anti-poisoning

4. Structure

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.com

Terminal connection type:

Unit: mm

Pins connection type:

Pins connection type:

Pin Pin Definition

Vin Positive pole of power (Vin)

GND Negative pole of power (GND)

Vo Analog output(0.4~2V)

PWM PWM

HD(zero point calibration, low level

Hd

lasting for over 7s is effective)

Rx UART(RXD)TTL Level data input

Tx UART(TXD)TTL Level data output

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.com

Terminal connection type:

Pin Terminal pin Definition

Pin 1 Anolog Output Vo (0.4~2V)

Pin 2 None

Pin 3 Negtive Pole(GND)

Pin 4 Positive Pole(Vin)

Pin 5 UART(RXD)TTL Level data input

UART(TXD)TTL Level data

Pin 6

output

Pin 7 None

Note: The analog output Vo has a default output range of 0.4V~ 2V. It is configurable from 0V to 3V.

5. Detection range and accuracy

Detection Gas Formula Detection Range Accuracy

0~2000ppm

Carbon Dioxide CO2 0~5000ppm ± (50ppm+5% reading value)

0~10000ppm

6. Main parameters

Model No. MH-Z19B

Detection Gas CO2

Working voltage 4.5 ~ 5.5 V DC

Average current < 20mA (@5V power supply)

Peak current 150mA (@5V power supply)

Interface level 3.3 V (Compatible with 5V)

Detection Range 0~2000/5000/10000ppm(optional)

Serial Port (UART) (TTL level 3.3V)

PWM

Output signal

Analog output(DAC) (default 0.4~2V)

(0~3V range could be customized)

Preheat time 3 min

Response Time T90 < 120 s

Working temperature -10 ~ 50 ℃

Working humidity 0 ~ 90% RH (No condensation)

Weight 5g

Lifespan > 5 years

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.com

7. Output

PWM output

Take 0~2000ppm for example

CO2 output range 0~2000ppm

Cycle 1004ms±5%

Cycle start high level output 2ms(theoretical value)

The middle cycle 1000ms±5%

cycle end low level output 2ms(theoretical value)

CO2 concentration: Cppm=2000×(TH-2ms)/(TH+TL-4ms)

Cppm: CO2 concentration could be calculated by PWM output

TH high level output time during cycle

TL low level output time during cycle

Serial port output (UART)

Hardware connection

Connect module’s Vin-GND-RXD-TXD to users’ 5V-GND-TXD-RXD.

(Users must use TTL level. If RS232 level, it must be converted.)

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.com

Software setting

Set serial port baud rate be 9600, data bit 8 bytes, stop bit 1byte, parity bit null.

Commands

0x86 Read CO2 concentration

0x87 Calibrate Zero Point (ZERO)

0x88 Calibrate Span Point (SPAN)

0x79 ON/OFF Self-calibration function for zero point

0x99 Detection range setting

0x86- Read CO2 concentration

Sending command

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7 Byte8

Start Byte Reserved Command - - - - - Checksum

0xFF 0x01 0x86 0x00 0x00 0x00 0x00 0x00 0x79

Return value

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7 Byte8

Start Byte Comman Concentration Concentration - - - - Checksum

d (High 8 Byte) (Low 8 Byte)

0xFF 0x86 HIGH LOW - - - - Checksum

CO2 concentration = HIGH * 256 + LOW

For example:

Send command FF 01 86 00 00 00 00 00 79, Return value FF 86 02 20 00 00 00 00 58

How to calculate concentration: convert hexadecimal 02 into decimal 2, hexadecimal 20 into decimal 32, then 2*256+32=544ppm

0x79- On/Off Self-calibration for Zero Point

Send command-No return value

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7 Byte8

Start Byte Reserved Command - - - - - Checksum

0xFF 0x01 0x79 0xA0/0x00 0x00 0x00 0x00 0x00 Checksum

For example:

ON this function, send command: FF 01 79 A0 00 00 00 00 E6

OFF this function, send command: FF 01 79 00 00 00 00 00 86

NOTE: This function is on when Byte3 is 0xA0 while this function is off when Byte3 is 0x00.

Default status is “this function is on”.

0x99- Detection range setting

Send command-No return value

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7 Byte8

Start Reserved Command Reserved Detection range Detection range Detection Detection Check

Byte 24~32 bit 16~23 bit range 8~15 bit range 0~7 bit sum

0xFF 0x01 0x99 0x00 Data 1 Data 2 Data 3 Data 4 Check

sum

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.com

Note: Detection range should be 0~2000, 0~5000, or 0~10000ppm.

For example: set 0~2000ppm detection range, send command: FF 01 99 00 00 00 07 D0 8F

set 0~10000ppm detection range, send command: FF 01 99 00 00 00 27 10 2F

Analog Voltage Output(Vo)

Conversion between analog voltage output and concentration, take 0.4V~2V as an example:

Vo(V)=0.4V+(2.0V-0.4V)*C(concentration ppm) / detection range(ppm)

1. Checksum calculation method

Checksum = (Negative (Byte1+Byte2+Byte3+Byte4+Byte5+Byte6+Byte7))+1

For example:

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7 Byte8

Start Byte Reserved Command - - - - - Check

sum

0xFF 0x01 0x86 0x00 0x00 0x00 0x00 0x00 Check

sum

Calculating Checksum:

1、Add Byte 1 to Byte 7: 0x01 + 0x86 + 0x00 + 0x00 + 0x00 + 0x00 + 0x00 = 0x87

2、Negative: 0xFF - 0x87 = 0x78

3、Then+1:0x78 + 0x01 = 0x79

C language

char getCheckSum(char *packet)

{

char i, checksum;

for( i = 1; i < 8; i++)

{

checksum += packet[i];

}

checksum = 0xff – checksum;

checksum += 1;

return checksum;

}

8.Zero Point Calibration

About zero point calibration:

This module has three methods for zero point calibration: hand-operated method, sending command method

and self-calibration. All the zero point is at 400ppm CO2.

Hand-operated method: Connect module’s HD pin to low level(0V), lasting for 7 seconds at least. Before

calibrating the zero point, please ensure that the sensor is stable for more than 20 minutes at 400ppm ambient

environment.

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.com

Sending command method:

Zero and Span point calibration can be achieved by sending a calibration command to the sensor via the serial

port (URAT). Zero and SPAN point calibration commands are as follows:

Self-calibration:

After the module works for some time, it can judge the zero point intelligently and do the zero calibration

automatically. The calibration cycle is every 24 hours since the module is power on. The zero point is 400ppm.

This method is suitable for office and home environment, not suitable for agriculture greenhouse, farm,

refrigerator, etc.. If the module is used in latter environment, please turn off this function.

9. Notes

9.1 Please avoid the pressure of its gilded plastic chamber from any direction, during welding, installation, and

use.

9.2 When placed in small space, the space should be well ventilated, especially for diffusion window.

9.3 The module should be away from heat, and avoid direct sunlight or other heat radiation.

9.4 The module should be calibrated termly, the suggested period is not longer than 6 months.

9.5 Do not use the sensor in the high dusty environment for long time.

9.6 To ensure the normal work, the power supply must be among 4.5V~5.5V DC rang, the power current must be

not less than 150mA. Out of this range, it will result in the failure of the sensor. (The concentration output is low,

or the sensor can not work normally.)

9.7 During the zero point calibration procedure by manual, the sensor must work in stable gas environment

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

Zhengzhou Winsen Electronics Technology Co., Ltd www.winsen-sensor.com

(400ppm) for over 20 minutes. Connect the HD pin to low level (0V) for over 7 seconds.

9.8 Forbid using wave soldering for the sensor.

9.9 When soldering with soldering iron, set the temperature to be (350 ± 5) °C, and soldering time must be

within 3 seconds.

9.0 As for pin version sensor, it is recommended to use soldering socket to directly insert or remove sensors for

convenient maintenance.

Tel: 86-371-67169097/67169670 Fax: 86-371-60932988 Email: sales@winsensor.com

Leading gas sensing solutions supplier in China!

You might also like

- Acronis #CyberFit Cloud Tech Fundamentals 2022-Comprimido (1) - 1-150Document150 pagesAcronis #CyberFit Cloud Tech Fundamentals 2022-Comprimido (1) - 1-150Soportech RDNo ratings yet

- HRM - Thomas CookDocument52 pagesHRM - Thomas CookSabrish Nair50% (2)

- Dubai World Ehs - 2007 Regulations & StandardsDocument106 pagesDubai World Ehs - 2007 Regulations & StandardsSAYED100% (10)

- Infrared CO2 Sensor Module (Model: MH-Z19B) : User's ManualDocument9 pagesInfrared CO2 Sensor Module (Model: MH-Z19B) : User's ManualhebersbNo ratings yet

- Infrared CO2 Sensor Module (Model: MH-Z19B) : User's ManualDocument9 pagesInfrared CO2 Sensor Module (Model: MH-Z19B) : User's ManualAvs ElectronNo ratings yet

- MH z19b Co2 Ver1 - 0 PDFDocument9 pagesMH z19b Co2 Ver1 - 0 PDFMacovei Lucian FlorinNo ratings yet

- Infrared CO2 Sensor Module (Model: MH-Z19C) : User's ManualDocument7 pagesInfrared CO2 Sensor Module (Model: MH-Z19C) : User's ManualrerlgakkbuqysmavtmNo ratings yet

- MH Z19Document9 pagesMH Z19Simone PolinesiNo ratings yet

- MH-Z19C-DZ-terminal Type CO2 Manual (Ver1.21) - 202103Document9 pagesMH-Z19C-DZ-terminal Type CO2 Manual (Ver1.21) - 202103testNo ratings yet

- ZE16B-CO Module Manual V1.1Document5 pagesZE16B-CO Module Manual V1.1Mehdi MehdiNo ratings yet

- Ze03 Electrochemical Module Manualv2 - 5Document7 pagesZe03 Electrochemical Module Manualv2 - 5Ильнур ТагировNo ratings yet

- ms1022 gp22 EquivalentDocument60 pagesms1022 gp22 Equivalentdbm100% (1)

- Techincal Specifications With DetailsDocument11 pagesTechincal Specifications With Detailsruturaj v delekarNo ratings yet

- Datasheet Electromagnetic Flow Meter Sup-Ldg: Committed To Process Automation Solutions Tel: 86-15158063876 FDocument16 pagesDatasheet Electromagnetic Flow Meter Sup-Ldg: Committed To Process Automation Solutions Tel: 86-15158063876 FAink Dak bageur theaNo ratings yet

- ZPH01 DustDocument8 pagesZPH01 DustGhiban ConstantinNo ratings yet

- CO2 Box Product Specification: Parameter TableDocument3 pagesCO2 Box Product Specification: Parameter TableJoséNo ratings yet

- SDS011 Laser PM2.5 Sensor Specification-V1.3Document13 pagesSDS011 Laser PM2.5 Sensor Specification-V1.3Divjot SinghNo ratings yet

- Mainstream ETCO2 Module CM2200 Technical SpecificationDocument13 pagesMainstream ETCO2 Module CM2200 Technical SpecificationEmilio CánepaNo ratings yet

- Dso tc2 Oscilloscope Transistor Tester ManualDocument8 pagesDso tc2 Oscilloscope Transistor Tester ManualLuciano FerreiraNo ratings yet

- SDS011 Laser PM2.5 Sensor Specification-V1.4Document13 pagesSDS011 Laser PM2.5 Sensor Specification-V1.4Jürgen KircherNo ratings yet

- Dyp - ds1309Document11 pagesDyp - ds1309alaska112No ratings yet

- Laser PM2.5 Sensor Specification: Product Model: SDS011Document13 pagesLaser PM2.5 Sensor Specification: Product Model: SDS011Fredrik LingNo ratings yet

- MHS-5200A ManualDocument25 pagesMHS-5200A ManualAndrey VoroninNo ratings yet

- Multi Vision™: Multivariable TransmitterDocument10 pagesMulti Vision™: Multivariable TransmitterRaja RamNo ratings yet

- A1350 Flyer eDocument2 pagesA1350 Flyer eBojan IlievNo ratings yet

- Intelligent Infrared Carbon Dioxide Module (Model: MH-Z14A) : Issue Date. May 5, 2019Document10 pagesIntelligent Infrared Carbon Dioxide Module (Model: MH-Z14A) : Issue Date. May 5, 2019udara11No ratings yet

- Brochure Dew Point Sensors - ENDocument12 pagesBrochure Dew Point Sensors - ENosmanyildirim85No ratings yet

- v130 33 Ta24 - Dts v130 Ta24 - 10 07Document6 pagesv130 33 Ta24 - Dts v130 Ta24 - 10 07Ecaterina IrimiaNo ratings yet

- Modicon M171 - M172 - TM172PDG28RDocument7 pagesModicon M171 - M172 - TM172PDG28RPhaniNo ratings yet

- Carbon Monoxide DM-100-CO PDSDocument2 pagesCarbon Monoxide DM-100-CO PDSroyvindasNo ratings yet

- Ultrasonic Oxygen Sensor Module Gasboard7500EDocument6 pagesUltrasonic Oxygen Sensor Module Gasboard7500ECarlos Julián Muñoz QuirogaNo ratings yet

- Parallel Beam Line Sensor Z4Lc: Ordering InformationDocument17 pagesParallel Beam Line Sensor Z4Lc: Ordering InformationDjoNo ratings yet

- Selina Product CatalogDocument19 pagesSelina Product Catalogdondon correNo ratings yet

- DE550016 BA 3 Select 01Document4 pagesDE550016 BA 3 Select 01seve1No ratings yet

- Inclinometer Lca326t PDFDocument10 pagesInclinometer Lca326t PDFManasi NaikNo ratings yet

- Greisinger OXY 3690 MP User ManualDocument4 pagesGreisinger OXY 3690 MP User ManualesatpehlivanNo ratings yet

- Operating Manual: MHS-5200A Dual-Channel DDS Signal GeneratorDocument28 pagesOperating Manual: MHS-5200A Dual-Channel DDS Signal GeneratorwijilestarikhasannahNo ratings yet

- Gekko: Portable PAUT For NDTDocument2 pagesGekko: Portable PAUT For NDTManuel AvilaNo ratings yet

- Manual CU 1106 Rev1Document17 pagesManual CU 1106 Rev1Jose Maria PerezNo ratings yet

- SCM-W Datasheet v41Document10 pagesSCM-W Datasheet v41nguyenam2008No ratings yet

- Detector de Gas - TGas-1031Document6 pagesDetector de Gas - TGas-1031Fernando BonillaNo ratings yet

- CO-T1 SpecDocument2 pagesCO-T1 SpecvicairmasterNo ratings yet

- Isweek SprintIR CO2 SensorDocument2 pagesIsweek SprintIR CO2 SensorindustrialNo ratings yet

- Specification: Product Name: Laser Particle Sensor Module Item No.: PM2008 Date: February 27, 2019Document24 pagesSpecification: Product Name: Laser Particle Sensor Module Item No.: PM2008 Date: February 27, 2019MIN GU KIMNo ratings yet

- BS03 Fixed Gas Detector-VOCDocument1 pageBS03 Fixed Gas Detector-VOCtruongNo ratings yet

- Analog Input/output Modules - EM 231 Analog Input ModulesDocument11 pagesAnalog Input/output Modules - EM 231 Analog Input ModulesLượng TrầnNo ratings yet

- SDS011 Laser PM2.5 Sensor Specification-V1.5Document13 pagesSDS011 Laser PM2.5 Sensor Specification-V1.5SearcherNo ratings yet

- MH Z14jjjjjknjkDocument3 pagesMH Z14jjjjjknjkBabu DharmarajNo ratings yet

- Ultrasonic Fuel Sensor User Manual - 181129Document11 pagesUltrasonic Fuel Sensor User Manual - 181129Carlos MontalvanNo ratings yet

- DS0073rev14 OXY Flex-1590383Document5 pagesDS0073rev14 OXY Flex-1590383Jorge Morales CerónNo ratings yet

- Zh03b Laser Dust Module v2 1Document11 pagesZh03b Laser Dust Module v2 1Hoan PhamNo ratings yet

- Ultra1000 IR CombustibleDocument2 pagesUltra1000 IR Combustiblececilia aguilarNo ratings yet

- Sensor CO2 para El 20% KCD - HP - en - 110602 PDFDocument5 pagesSensor CO2 para El 20% KCD - HP - en - 110602 PDFAngelica MarulandaNo ratings yet

- FT2 Flow Temperature Thermal Mass TransmitterDocument4 pagesFT2 Flow Temperature Thermal Mass TransmitterJulian GaleanoNo ratings yet

- Janitza-Especificaciones Técnicas-UMG604Document18 pagesJanitza-Especificaciones Técnicas-UMG604Pablo RodaNo ratings yet

- XGZP161 Pressure Sensor-V2Document8 pagesXGZP161 Pressure Sensor-V2samsularief03No ratings yet

- OCS-3F 2.1data SheetDocument5 pagesOCS-3F 2.1data SheetGONZALO ENRIQUE MARTINEZ OJEDA100% (1)

- TP-624D H2S Mos PDS PDFDocument2 pagesTP-624D H2S Mos PDS PDFkaleeswaranNo ratings yet

- Company ProfileDocument36 pagesCompany Profileyoussouf ismaNo ratings yet

- Mechanical Compact Meter: ApplicationDocument7 pagesMechanical Compact Meter: ApplicationVelimir MilovanovicNo ratings yet

- Final Report 2020Document26 pagesFinal Report 2020Siva BadrinathNo ratings yet

- Automatic Pattern Classification by Unsupervised Learning Using Dimensionality Reduction of Data With Mirroring Neural NetworksDocument5 pagesAutomatic Pattern Classification by Unsupervised Learning Using Dimensionality Reduction of Data With Mirroring Neural Networkssine summsun PradhanNo ratings yet

- Rar PDFDocument254 pagesRar PDFsine summsun PradhanNo ratings yet

- Phys 6.1 and 6.2 Ant Pituitary GH and Post Pituitary NOTESDocument7 pagesPhys 6.1 and 6.2 Ant Pituitary GH and Post Pituitary NOTESsine summsun PradhanNo ratings yet

- Powerful English Speaking PDFDocument14 pagesPowerful English Speaking PDFsine summsun PradhanNo ratings yet

- List of Chief Justices of IndiaDocument4 pagesList of Chief Justices of Indiasine summsun PradhanNo ratings yet

- Mil STD 461eDocument288 pagesMil STD 461ech.navnNo ratings yet

- U3A5 Practitioner's Handbook Organizing ChartDocument3 pagesU3A5 Practitioner's Handbook Organizing Chartkael9010 kael9010No ratings yet

- Janus MV FM200 BrochureDocument22 pagesJanus MV FM200 BrochurenoisNo ratings yet

- Omkar TrustDocument156 pagesOmkar TrustAveline Dsouza100% (2)

- Recreationalactivities 140317203039 Phpapp01 PDFDocument27 pagesRecreationalactivities 140317203039 Phpapp01 PDFRodjan MoscosoNo ratings yet

- Lesson 1.4 Literary Genres: Genres of Drama: Arellano UniversityDocument21 pagesLesson 1.4 Literary Genres: Genres of Drama: Arellano UniversityKing TadlasNo ratings yet

- Advanced Drilling Engineering Final TOCDocument10 pagesAdvanced Drilling Engineering Final TOCbrayanconin0% (1)

- FOR Approval Specification: Title 32.0" Wuxga TFT LCDDocument36 pagesFOR Approval Specification: Title 32.0" Wuxga TFT LCDСергій НестеровичNo ratings yet

- Es - Chatta Bakhtawar-Shaheen ColonyDocument3 pagesEs - Chatta Bakhtawar-Shaheen ColonyNida NazNo ratings yet

- Autoclaves For Sterilisation "Presoclave II" - ManualDocument12 pagesAutoclaves For Sterilisation "Presoclave II" - ManualMariaNo ratings yet

- Prayer For The Elderly and GrandparentsDocument2 pagesPrayer For The Elderly and GrandparentsRomain Garry Evangelista LazaroNo ratings yet

- CAMLIFE 2023 ProspectusDocument16 pagesCAMLIFE 2023 Prospectusboydilinh012No ratings yet

- The Automated Battlefield Brief NotesDocument3 pagesThe Automated Battlefield Brief NotesEddie GerminoNo ratings yet

- Case 10 (Post-Operative Pain Management & Complication)Document10 pagesCase 10 (Post-Operative Pain Management & Complication)ReddyNo ratings yet

- Digital BankingDocument3 pagesDigital BankingDPC Gym100% (1)

- Chatrapati Shivaji TurminusDocument6 pagesChatrapati Shivaji TurminusshrutiNo ratings yet

- Aqua Starter BookletDocument13 pagesAqua Starter BookletPartha NathNo ratings yet

- Challenges in The Collection and Processing of Physical Evidence For Sexual Offences Cases in Gauteng ProvinceDocument10 pagesChallenges in The Collection and Processing of Physical Evidence For Sexual Offences Cases in Gauteng ProvinceleseditjaleNo ratings yet

- Cambridge Checkpoint: Overview and PreparationDocument50 pagesCambridge Checkpoint: Overview and PreparationIrishMujNo ratings yet

- LeafletsDocument2 pagesLeafletsAmir FarajiNo ratings yet

- Sprinkler System Design GuidelinesDocument2 pagesSprinkler System Design GuidelinesaneeshNo ratings yet

- A Report On The Internship Training Undergone at "Madhura Fire Works, Sivakasi"Document44 pagesA Report On The Internship Training Undergone at "Madhura Fire Works, Sivakasi"Naresh Kumar100% (4)

- The Significance of Yoga TantraDocument358 pagesThe Significance of Yoga TantraAnurag Chand100% (3)

- SensION1 ManualDocument40 pagesSensION1 ManualMaria Victoria GuarinNo ratings yet

- Co2 Lesson PlanDocument5 pagesCo2 Lesson PlanMAY RACHEL NARRAGANo ratings yet

- Intern Project MBADocument102 pagesIntern Project MBAuiuxdesigneramitNo ratings yet

- Profil Company 2017Document10 pagesProfil Company 2017Eno Ronaldfrank OguriNo ratings yet