Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

18 viewsAn Alternative To Neutral Unbalance Protection

An Alternative To Neutral Unbalance Protection

Uploaded by

bansalrCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Cache Dirt 5700Document5 pagesCache Dirt 5700David LynxNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Protection of Wind Electric Plants: PSRC Working Group C25Document82 pagesProtection of Wind Electric Plants: PSRC Working Group C25bansalrNo ratings yet

- Impact - of - Transformer - Inrush - Currents S PDFDocument1 pageImpact - of - Transformer - Inrush - Currents S PDFbansalrNo ratings yet

- MTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsDocument4 pagesMTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsbansalrNo ratings yet

- Earthing Transformer Protection Fail AnalysisDocument7 pagesEarthing Transformer Protection Fail AnalysisbansalrNo ratings yet

- 2 Harmonic Analysis Knowing The Basics Is Essential Presented by NEPSIDocument52 pages2 Harmonic Analysis Knowing The Basics Is Essential Presented by NEPSIbansalrNo ratings yet

- Cost Per KvarDocument3 pagesCost Per KvarbansalrNo ratings yet

- Generator Transformer Backup ProtectionDocument7 pagesGenerator Transformer Backup ProtectionbansalrNo ratings yet

- +LJK, Pshgdqfh'Liihuhqwldo3Urwhfwlrq8Vlqj 2Yhufxuuhqw5Hod/V: Application Guide Volume V AG98-09Document6 pages+LJK, Pshgdqfh'Liihuhqwldo3Urwhfwlrq8Vlqj 2Yhufxuuhqw5Hod/V: Application Guide Volume V AG98-09bansalrNo ratings yet

- Iron Core Vs Air CoreDocument5 pagesIron Core Vs Air CorebansalrNo ratings yet

- actiVAR - Performance in Mitigating Voltage Sags Associated With Motor StartingDocument9 pagesactiVAR - Performance in Mitigating Voltage Sags Associated With Motor StartingbansalrNo ratings yet

- b313-80 Technical Manual v5.2Document81 pagesb313-80 Technical Manual v5.2bansalrNo ratings yet

- 1 Detuned Shunt Capacitor Banks: Rating Capacitor Bank ComponentsDocument2 pages1 Detuned Shunt Capacitor Banks: Rating Capacitor Bank ComponentsbansalrNo ratings yet

- RMC20 Hardware-Installation-Guide ENDocument36 pagesRMC20 Hardware-Installation-Guide ENbansalrNo ratings yet

- Capacitor Discharge Times: Optimised NetworkDocument1 pageCapacitor Discharge Times: Optimised NetworkbansalrNo ratings yet

- Zero Power Harmonic Filters: EquipmentDocument3 pagesZero Power Harmonic Filters: EquipmentbansalrNo ratings yet

- RS910 Hardware-Installation-Guide ENDocument52 pagesRS910 Hardware-Installation-Guide ENbansalrNo ratings yet

- Design Aspects of Medium Voltage Capacitor Banks: Marius Jansen, Optimised Network Equipment, AustraliaDocument6 pagesDesign Aspects of Medium Voltage Capacitor Banks: Marius Jansen, Optimised Network Equipment, AustraliabansalrNo ratings yet

- Common Units of Measure: EquipmentDocument1 pageCommon Units of Measure: EquipmentbansalrNo ratings yet

- 3rd Round Wise GATE Cut Off of All Round AY 2024-25 v555 - Copy (1) (1) - RemovedDocument2 pages3rd Round Wise GATE Cut Off of All Round AY 2024-25 v555 - Copy (1) (1) - RemovedAgony SinghNo ratings yet

- UAS General English-2-2021Document12 pagesUAS General English-2-2021Putri Pradnya DewantiNo ratings yet

- Compass Estonia Startup Ecosystem Report v1.0Document8 pagesCompass Estonia Startup Ecosystem Report v1.0Jovan PetronijevićNo ratings yet

- HMS Talent (S92)Document4 pagesHMS Talent (S92)rbnaoNo ratings yet

- Health 5 Lamp V3Document6 pagesHealth 5 Lamp V3Jul Lester CastilloNo ratings yet

- WaterproofingDocument14 pagesWaterproofingAfzal MohamedNo ratings yet

- Conformity Compliance and ObedienceDocument14 pagesConformity Compliance and ObedienceUjjwalBansalNo ratings yet

- Isolve Sata: Product Features and BenefitsDocument2 pagesIsolve Sata: Product Features and BenefitsShah DhavalNo ratings yet

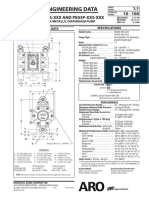

- Sales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1Document4 pagesSales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1jarosNo ratings yet

- 2021 Main Residency Match® by The Numbers: PositionsDocument1 page2021 Main Residency Match® by The Numbers: Positionsyogitha dadiNo ratings yet

- Essay Service UkDocument7 pagesEssay Service Ukb6zm3pxh100% (2)

- Activity Based Costing-A Tool To Aid Decision MakingDocument54 pagesActivity Based Costing-A Tool To Aid Decision MakingSederiku KabaruzaNo ratings yet

- Understanding OTDRDocument10 pagesUnderstanding OTDRAnonymous 6PurzyegfXNo ratings yet

- Kumpulan Soal-Soal Asli SMM/SMPD Usu 2021 Bidang: Bahasa InggrisDocument2 pagesKumpulan Soal-Soal Asli SMM/SMPD Usu 2021 Bidang: Bahasa InggrisCaestonentiels MarcoponencialNo ratings yet

- Low Power RegulatorDocument28 pagesLow Power RegulatorSagarNo ratings yet

- Data Warehouse DefinitionDocument12 pagesData Warehouse DefinitionRoni StiawanNo ratings yet

- Hygienic Process ConnectionsDocument22 pagesHygienic Process Connectionsabcdario666No ratings yet

- Internship Report FormatDocument8 pagesInternship Report FormatThushar DNo ratings yet

- Dezasamblare Cutie Viteze Lada NivaDocument13 pagesDezasamblare Cutie Viteze Lada NivaCatalinSSNo ratings yet

- Operation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsDocument20 pagesOperation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsMarcelo Elói De Amorim SilvaNo ratings yet

- Cabinet MedicalDocument5 pagesCabinet MedicalDavid BarikaNo ratings yet

- CAN2 Power-Train (Engine Control and Pump Control) CAN2 Power-Train (Engine Control and Pump Control)Document18 pagesCAN2 Power-Train (Engine Control and Pump Control) CAN2 Power-Train (Engine Control and Pump Control)Boran CarmonaNo ratings yet

- Updated Standard Vendor Application Form - 202112Document2 pagesUpdated Standard Vendor Application Form - 202112kamenriders637No ratings yet

- EKKO ProjectDocument2 pagesEKKO ProjectGeofisica GusZavNo ratings yet

- EdtDocument10 pagesEdtjagruthimsNo ratings yet

- Corporate PPT Template 20Document10 pagesCorporate PPT Template 20Mustafa RahmanNo ratings yet

- Autoflame Sensors Guide: Combustion Management SystemsDocument41 pagesAutoflame Sensors Guide: Combustion Management SystemsFAROUKNo ratings yet

- 2.2 Psychological PerspectiveDocument17 pages2.2 Psychological PerspectiveMaica LagareNo ratings yet

- Practicum Narrative Report FormatDocument8 pagesPracticum Narrative Report FormatJC GAMINGNo ratings yet

An Alternative To Neutral Unbalance Protection

An Alternative To Neutral Unbalance Protection

Uploaded by

bansalr0 ratings0% found this document useful (0 votes)

18 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views2 pagesAn Alternative To Neutral Unbalance Protection

An Alternative To Neutral Unbalance Protection

Uploaded by

bansalrCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

66 Carey Road Queensbury, NY 12804

Ph: (518) 792-4776 Fax: (518) 792-5767

www.nepsi.com sales@nepsi.com

AN ALTERNATIVE TO NEUTRAL VOLTAGE UNBALANCE PROTECTION

SYSTEMS IN UN-GROUNDED WYE CAPACITOR BANKS

Metal-Enclosed Capacitor Banks and Harmonic Filter

Banks are normally equipped with blown fuse

detection systems. The primary purpose of this

detection is as follows:

To prevent capacitor damage on the

remaining capacitors on the stage with the

blown fuse. This problem occurs on

ungrounded banks with less than 4

capacitors per phase.

To alert plant personnel of a blown fuse

condition.

To prevent unbalance var support that can

lead to system voltage unbalance. Figure 2 – Alternate Blown Fuse

Detection System Use Direct Sensing

BACKGROUND ON NEUTRAL VOLTAGE UNBALANCE

PROTECTION SYSTEMS

A Neutral Voltage Unbalance Protection System normally consists of a neutral voltage sensor

and an over-voltage relay. Figure 1 below shows a three line-diagram of a 3-stage capacitor

bank that is equipped with a neutral voltage sensor on each stage. Under normal operation, the

neutral voltage of each capacitor stage will be near zero volts as each capacitor has nearly the

same capacitive reactance (assuming healthy capacitors and balanced system voltage).

During and after fuse operation, the neutral voltage will shift in accordance with the impedance

unbalance caused by the failing or

failed capacitor. The neutral

voltage sensor (either a resistive

voltage divider or a transformer)

output is monitored by an over-

voltage-relay that trips when the

voltage exceeds the relay trip value

for a prescribed length of time.

Typically the over-voltage relay has

a definite time characteristic and is

equipped with one or two relay

outputs. Larger banks having stages

consisting of 5 or more capacitors

can operate with a blown fuse. For

these banks, the first set-point is

used for alarm, while the second is

used for tripping under conditions

where the bank can be damaged.

Northeast Power Fuse

Figure 1 – Blown Systems, Inc. System Utilizing Neutral Unbalance

Detection Page 1 of 2

Voltage Detection

SHORT-COMINGS TO BLOWN FUSE

Fuse-Failure Due to Over-Heating

DETECTION UTILIZING NEUTRAL

VOLTAGE UNBALANCE Unlike low-voltage fuses, medium-

voltage current limiting fuses do

For metal-enclosed banks with four or less

not protect against over-load. The

capacitors per stage, blown fuse detection using

medium voltage fuse standard

False trips due to line-to-ground faults only require a general purpose

where ground fault clearing times current limiting fuse to properly

exceed the delay time of the unbalance

protection relay. clear for currents that melt their

elements in 1-hour or less.

Fuse failure due to overheating cannot

be detected (See Fuse Failure Side Note Fuse melting times greater than an

Below). hour result in excessive fuse tube

temperatures (greater than 400C)

Fuse operation is detected by indirect

sensing and relies upon the proper and result in fuse housing damage

operation and setting of the relay and and improper clearing. Improper

control system clearing normally results in flash-

over and total bank shut-down.

ALTERNATE BLOWN FUSE DETECTION SYSTEM

Fuse over-heating is more prevalent in

As an alternate to using a conventional neutral voltage unbalance protection system, NEPSI can

ungrounded banks consists of 1 to 4

provide a system in which each fuse is equipped with a fuse failure sensor. This blown fuse sensor

capacitors

will operate when the fuse reaches 130C or when it operates dueper

to stage as aUpon

a fault. faulted

operation of

the fuse sensor, the stage associated with the blown fuse is tripped

capacitor willoff-line and

result in locked

a fuse outof

current until it

is checked over by the owner. three times the load current rating of the

stage/bank. This current is relatively low

The combination of the thermal sensor in addition to the direct fuse sensing offers the following

in comparison

advantages over blown fuse detection using neutral voltage sensing: to the Time-Current

Characteristic Curve and is more likely to

False trips will not occur due to line-to-ground faults

result in fuse failure.

Fuse failure will not occur as the blown fuse sensor will actuate when the

fuse temperature reaches 130C and trip the stage off-line.

Fuse operation is detected by direct sensing and therefore is more

reliable.

CONCLUSION

Engineers specifying blown fuse detection systems on metal-enclosed banks

consisting of 4 or less capacitors per stage should consider the merits of using

NEPSI’s blown fuse sensors as an alternative to indirect sensing using neutral

voltage unbalance detection. This document presents compelling reasons to

consider the alternate design.

Figure 3 – Picture of a Failed

Fuse Due to Over-Heating

Northeast Power Systems, Inc. Page 2 of 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Cache Dirt 5700Document5 pagesCache Dirt 5700David LynxNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Protection of Wind Electric Plants: PSRC Working Group C25Document82 pagesProtection of Wind Electric Plants: PSRC Working Group C25bansalrNo ratings yet

- Impact - of - Transformer - Inrush - Currents S PDFDocument1 pageImpact - of - Transformer - Inrush - Currents S PDFbansalrNo ratings yet

- MTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsDocument4 pagesMTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsbansalrNo ratings yet

- Earthing Transformer Protection Fail AnalysisDocument7 pagesEarthing Transformer Protection Fail AnalysisbansalrNo ratings yet

- 2 Harmonic Analysis Knowing The Basics Is Essential Presented by NEPSIDocument52 pages2 Harmonic Analysis Knowing The Basics Is Essential Presented by NEPSIbansalrNo ratings yet

- Cost Per KvarDocument3 pagesCost Per KvarbansalrNo ratings yet

- Generator Transformer Backup ProtectionDocument7 pagesGenerator Transformer Backup ProtectionbansalrNo ratings yet

- +LJK, Pshgdqfh'Liihuhqwldo3Urwhfwlrq8Vlqj 2Yhufxuuhqw5Hod/V: Application Guide Volume V AG98-09Document6 pages+LJK, Pshgdqfh'Liihuhqwldo3Urwhfwlrq8Vlqj 2Yhufxuuhqw5Hod/V: Application Guide Volume V AG98-09bansalrNo ratings yet

- Iron Core Vs Air CoreDocument5 pagesIron Core Vs Air CorebansalrNo ratings yet

- actiVAR - Performance in Mitigating Voltage Sags Associated With Motor StartingDocument9 pagesactiVAR - Performance in Mitigating Voltage Sags Associated With Motor StartingbansalrNo ratings yet

- b313-80 Technical Manual v5.2Document81 pagesb313-80 Technical Manual v5.2bansalrNo ratings yet

- 1 Detuned Shunt Capacitor Banks: Rating Capacitor Bank ComponentsDocument2 pages1 Detuned Shunt Capacitor Banks: Rating Capacitor Bank ComponentsbansalrNo ratings yet

- RMC20 Hardware-Installation-Guide ENDocument36 pagesRMC20 Hardware-Installation-Guide ENbansalrNo ratings yet

- Capacitor Discharge Times: Optimised NetworkDocument1 pageCapacitor Discharge Times: Optimised NetworkbansalrNo ratings yet

- Zero Power Harmonic Filters: EquipmentDocument3 pagesZero Power Harmonic Filters: EquipmentbansalrNo ratings yet

- RS910 Hardware-Installation-Guide ENDocument52 pagesRS910 Hardware-Installation-Guide ENbansalrNo ratings yet

- Design Aspects of Medium Voltage Capacitor Banks: Marius Jansen, Optimised Network Equipment, AustraliaDocument6 pagesDesign Aspects of Medium Voltage Capacitor Banks: Marius Jansen, Optimised Network Equipment, AustraliabansalrNo ratings yet

- Common Units of Measure: EquipmentDocument1 pageCommon Units of Measure: EquipmentbansalrNo ratings yet

- 3rd Round Wise GATE Cut Off of All Round AY 2024-25 v555 - Copy (1) (1) - RemovedDocument2 pages3rd Round Wise GATE Cut Off of All Round AY 2024-25 v555 - Copy (1) (1) - RemovedAgony SinghNo ratings yet

- UAS General English-2-2021Document12 pagesUAS General English-2-2021Putri Pradnya DewantiNo ratings yet

- Compass Estonia Startup Ecosystem Report v1.0Document8 pagesCompass Estonia Startup Ecosystem Report v1.0Jovan PetronijevićNo ratings yet

- HMS Talent (S92)Document4 pagesHMS Talent (S92)rbnaoNo ratings yet

- Health 5 Lamp V3Document6 pagesHealth 5 Lamp V3Jul Lester CastilloNo ratings yet

- WaterproofingDocument14 pagesWaterproofingAfzal MohamedNo ratings yet

- Conformity Compliance and ObedienceDocument14 pagesConformity Compliance and ObedienceUjjwalBansalNo ratings yet

- Isolve Sata: Product Features and BenefitsDocument2 pagesIsolve Sata: Product Features and BenefitsShah DhavalNo ratings yet

- Sales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1Document4 pagesSales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1jarosNo ratings yet

- 2021 Main Residency Match® by The Numbers: PositionsDocument1 page2021 Main Residency Match® by The Numbers: Positionsyogitha dadiNo ratings yet

- Essay Service UkDocument7 pagesEssay Service Ukb6zm3pxh100% (2)

- Activity Based Costing-A Tool To Aid Decision MakingDocument54 pagesActivity Based Costing-A Tool To Aid Decision MakingSederiku KabaruzaNo ratings yet

- Understanding OTDRDocument10 pagesUnderstanding OTDRAnonymous 6PurzyegfXNo ratings yet

- Kumpulan Soal-Soal Asli SMM/SMPD Usu 2021 Bidang: Bahasa InggrisDocument2 pagesKumpulan Soal-Soal Asli SMM/SMPD Usu 2021 Bidang: Bahasa InggrisCaestonentiels MarcoponencialNo ratings yet

- Low Power RegulatorDocument28 pagesLow Power RegulatorSagarNo ratings yet

- Data Warehouse DefinitionDocument12 pagesData Warehouse DefinitionRoni StiawanNo ratings yet

- Hygienic Process ConnectionsDocument22 pagesHygienic Process Connectionsabcdario666No ratings yet

- Internship Report FormatDocument8 pagesInternship Report FormatThushar DNo ratings yet

- Dezasamblare Cutie Viteze Lada NivaDocument13 pagesDezasamblare Cutie Viteze Lada NivaCatalinSSNo ratings yet

- Operation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsDocument20 pagesOperation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsMarcelo Elói De Amorim SilvaNo ratings yet

- Cabinet MedicalDocument5 pagesCabinet MedicalDavid BarikaNo ratings yet

- CAN2 Power-Train (Engine Control and Pump Control) CAN2 Power-Train (Engine Control and Pump Control)Document18 pagesCAN2 Power-Train (Engine Control and Pump Control) CAN2 Power-Train (Engine Control and Pump Control)Boran CarmonaNo ratings yet

- Updated Standard Vendor Application Form - 202112Document2 pagesUpdated Standard Vendor Application Form - 202112kamenriders637No ratings yet

- EKKO ProjectDocument2 pagesEKKO ProjectGeofisica GusZavNo ratings yet

- EdtDocument10 pagesEdtjagruthimsNo ratings yet

- Corporate PPT Template 20Document10 pagesCorporate PPT Template 20Mustafa RahmanNo ratings yet

- Autoflame Sensors Guide: Combustion Management SystemsDocument41 pagesAutoflame Sensors Guide: Combustion Management SystemsFAROUKNo ratings yet

- 2.2 Psychological PerspectiveDocument17 pages2.2 Psychological PerspectiveMaica LagareNo ratings yet

- Practicum Narrative Report FormatDocument8 pagesPracticum Narrative Report FormatJC GAMINGNo ratings yet