Professional Documents

Culture Documents

Report .. Sima Darnal..

Report .. Sima Darnal..

Uploaded by

Roshan KejariwalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report .. Sima Darnal..

Report .. Sima Darnal..

Uploaded by

Roshan KejariwalCopyright:

Available Formats

Arun Rimal, P.E.

A Report on

Design of Residential Building

with

Rammed Earth Walls

Building Location: Shaibu, Lalitpur, ward no- 5

Owner: Sima Darnal

Prepared by: Arun Rimal, P.E.

Aashish Bhandari, Structural Engineer

September 2016

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Arun Rimal, P.E.

Table of Contents

1. Introduction ............................................................................................................................. 1

2. Building Description................................................................................................................ 1

3. Building Data ........................................................................................................................... 3

4. General Details ........................................................................................................................ 4

5. Footings ................................................................................................................................... 4

6. Rammed Earth walls ................................................................................................................ 6

7. Bond Beams ............................................................................................................................. 9

8. Structural Diaphragms (Floor Slabs & Roof) ........................................................................ 10

9. Conclusion and Recommendations ....................................................................................... 12

List of Figures

Figure 1: Building Plan ................................................................................................................... 1

Figure 2: Sectional Elevation of the Building................................................................................. 2

Figure 3: Exterior Elevation of the Building .................................................................................. 2

Figure 4: Wall Footing Section ....................................................................................................... 5

Figure 5: Footing Plan .................................................................................................................... 5

Figure 6: Footing Section at RCC Pads .......................................................................................... 5

Figure 7: Wall Reinforcements ....................................................................................................... 8

Figure 8: Wall Vertical Reinforcement in Plan .............................................................................. 8

Figure 9: Lintel/Sill band section .................................................................................................... 8

Figure 10: Reinforcement at Corner of Openings........................................................................... 8

Figure 11: Section of wall with Bond Beams. ............................................................................... 9

Figure 12: Floor Diaphragm Section ............................................................................................ 10

Figure 13: Roofing Section ........................................................................................................... 11

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Arun Rimal, P.E.

1. Introduction

This is a structural report on a design of a two-storied residential building to be constructed with a Rammed

Earth walls. The design of the building is done in compliance to NZS 4299: 1998 (Earthen Buildings not

requiring specific Design) and also to NBC 204: 1994 (Design of Earthen Buildings), wherever felt

necessary. The description of building and fulfillment of codal provisions are described in this report.

2. Building Description

Figure 1: Building Plan

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 1

Arun Rimal, P.E.

Figure 2: Sectional Elevation of the Building

Figure 3: Exterior Elevation of the Building

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 2

Arun Rimal, P.E.

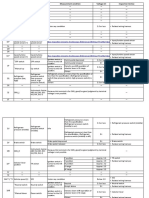

3. Building Data

Land Area in m2 1028.0

Ground floor Area in m2 79.41

First Floor Area in m2 60.5

Least base dimension of the structure (B) in m 7.010

Largest base dimension of the structure (L) in m 11.32

Ground Floor - Wall Height (in m) 2.67

Ground Floor - Wall thickness (in m) 0.45

Ground Floor - Maximum length between cross wall (in m) 4.32

First Floor - Wall Height (in m) 2.67

First Floor - Wall thickness (in m) 0.35

First Floor - Maximum length between cross wall (in m) 4.32

Seismic Zone Factor >0.6

Soil type Medium

Slab Thickness 0.125

Materials

Wall material Rammed Earth

Concrete M20 fck=20 Mpa

Reinforcement Fe500 fy=500 Mpa

Light timber floor with

Floor timber Joists

Rafter and Purlins in the roof Light timber

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 3

Arun Rimal, P.E.

4. General Details

Plinth Area in m2 79.41 <300m2 OK (As per Section 1.2 NZS 4299.1998

Max Floor wall height

(in m) 2.67 <2.75m OK (As per Section 1.2 C (ii) NZS 4299.1998)

Max. gable wall height

(in m) 0.81 <3.05 m Ok (As per Section 1.2 C (ii) NZS 4299.1998)

Wall thickness (in m) 0.35 >280mm OK (As per Section 1.2 e NZS 4299.1998)

Roof Slope 14.510 <450 OK (As per Section 1.2 f NZS 4299.1998)

Wind Speed (Approx.) 47 m/s <50 m/s OK (As per Section 2.4.3 NZS 4299.1998)

Snow Load - - No snow Load

1300 mm < 2000 mm

Rain Fall (Approx.) yearly yearly

Floor Live Load 1.5 Kpa As per Section 1.2 i NZS 4299.1998

Roof Type Light As per Section 1.2 m NZS 4299.1998

5. Footings

All the Rammed Earth walls are supported on the concrete tie beams rested on stone masonry

wall footings 1.0 m deep as shown in Figure 4: Wall Footing Section as per NBC 204: 1994

section 6.2. In addition to this, at each intersecting joint of the walls i.e. where vertical RCC

columns are provided a RCC footing is also provided as shown in figure below. Therefore the

vertical load of the building is transferred to the ground through both the wall footings and the

RCC footings. The RCC footings are of 1.5m x1.5m in size and 625mm deep and hence should

be good enough to withstand all kinds of vertical loads acting upon them. All footings, the RCC

pad footings and the stone masonry strip footings are symmetrical about the centerline of walls

in compliance to NZS 4299: 1998 section 4.1.2. The foundation bed is at same plane throughout

the foundation an hence in compliance with NZS 4299: 1998 section 4.1.2

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 4

Arun Rimal, P.E.

Figure 4: Wall Footing Section

Figure 5: Footing Plan Figure 6: Footing Section at RCC Pads

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 5

Arun Rimal, P.E.

Hence, the RCC beams rested on the stone masonry walls provide the foundation for the

Rammed Earth walls and have following properties.

Width of footing tie beams 500mm

Depth of footing tie beams 230 mm

Reinforcement in the footing 4-16dia+2-12 dia bars with 8 dia stirrups @ 150 mm

beams (6”) c/c

The vertical wall starter reinforcement bars are inserted

Vertical wall starter

into the footing tie beams and bent 900 with t least

reinforcements

200mm horizontal legs as per NZS 4299:1998 section

4.7.2

Damp Proof Course Damp Proof Course of two coats of bituminous paint on

top of the foundation at the underside of exterior and

interior earth walls as per NZS 4299:1998 Section 4.4.2

Top of the foundation Top of foundation is roughened to 5mm as per NZS

4299: 1998 Section 4.4.2

6. Rammed Earth walls

OK (As per Section 1.2 e NZS

Thickness of walls 350mm > 280 mm 4299.1998)

Openings on external walls from the

outside edge of an external (lowest OK (as per NZS 4299, section

dimension) 1090 mm >900mm 5.1.6)

Wall bracings provided to each walls

in each of two principal directions of OK (as per NZS 4299, section

the building at 900 to each other 5.3.1)

Max. Distance between centerlines of OK (as per NZS 4299, section

parallel bracing 4320 mm < 6000mm 5.3.3)

=Height of OK (as per NZS 4299, section

Height of Bracing 2.67mm walls 5.3.5)

OK (as per NZS 4299, section

Minimum Length of Bracing 2515 mm 5.3.5)

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 6

Arun Rimal, P.E.

Reinforcement in walls

Walls are provided with 2-12 dia. vertical reinforcing bar at each end of bracing walls at a distance

of 150 mm from the ends of the bracing wall as per NZS 4299, section 5.8.1

Walls are provided with 2-12 dia. bars as vertical at spacing of 450mm as vertical reinforcement and

hence shall be in compliance to NZS 4299, section 5.8.2.

Vertical concrete columns are provided at each corners and joints. The vertical column are

provided with 4-16mm dia. longitudinal bars and 8mm dia. stirrups@ 150mm c/c

Walls are provided with 2-12 dia. bars as at spacing of 300mm as horizontal reinforcement and

hence shall be in compliance to NZS 4299, section 5.8.3

The corners of openings (doors and windows) are provided with vertical reinforcement consisting

of 2-12 mm dia. bars.

RCC lintels and sill bands are provided above and below all openings in accordance with

NZS4299:1998, section 8.3.

The lintels are provided with 3-12mm dia. longitudinal bars tied with 7mm dia. binders provided @

150 mm c/c.

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 7

Arun Rimal, P.E.

Figure 7: Wall Reinforcements Figure 8: Wall Vertical Reinforcement in Plan

Figure 9: Lintel/Sill band section Figure 10: Reinforcement at Corner of Openings

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 8

Arun Rimal, P.E.

7. Bond Beams

RCC Bond beams are provided at the top of all earth walls in order to:

Assist in supporting lateral loads between adjacent transverse structural walls;

Provide anchorage of floor and roof members;

Tie the earth walls together.

As per NZS 4299: 1998 , section 7.3.2

The size of the Bond beams provided to comply with NZS 4299: 1998 section 7.3 and section

7.6

450 mm x 150 mm on the top of ground floor walls with 4-16mm dia. longitudinal tied

with 8mm dia. stirrups.

400 mm x 150 mm on the top of first floor walls with 4-16mm dia. longitudinal tied

with 8mm dia. stirrups.

Laps in the bond beams are to be provided at least 40 times the diameter of the longitudinal

bars as per NZS 4299:1998 section 7.5.

Reinforcement at concrete bond beam intersections are designed to be tied together with 16dia

longitudinal bars lapped 40 times the bar diameter as per NZS 4299:1998 section 7.7.

Figure 11: Section of wall with Bond Beams.

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 9

Arun Rimal, P.E.

8. Structural Diaphragms (Floor Slabs & Roof)

Floor slabs

All structural diaphragms supporting earth walls against horizontal is constructed as follows as

per NZS 4299: 1998, section 6.

The floor consists of the wooden beams/joists sized 100mm x 150mm placed @ 450 mm c/c

covered by a 25mm thick wooden flooring sheet.

Figure 12: Floor Diaphragm Section

Each sheet are to be fastened along each edge to boundary members with nails at 150 mm c/c

and be fastened to every intermediate framing member at 300 mm c/c and comply with NZS

4299: 1998 section 6.7 .

Joints in sheet material are to be made over supports.

Roof

A light weight roof is provided as per NZS 4299: 1998 section 1.2.The roof consists of wooden

rafter and purlins covered by PVC roof cover with aluminum sheet and a thermal insulation

sheet and a wooden plank in between.

The rafters are of size 75mm x 75mm and provided @ 600mm c/c while the purlins are of 50mm

x 50mm and provided @ 900mm c/c. Furthermore, where the rafter are joined an additional

purlin members are provided on each side of the joints. The rafters are rested and tied on 100mm

x 100mm wooden beams which are further rested and tied on bond beams.

The roof diaphragm is at an angle of 14.5 0 to the horizontal (< 250 ) and hence in compliance

to NZS 4299: 1998.section 6.2.

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 10

Arun Rimal, P.E.

The thickness of roofing sheet is 25mm > 18mm as required per NZS 4299: 1998 section 6.6.

The roof sheets are nailed to the purlins @ 150 mm c/c at the edges and @300mm c/c at other

parts as per NZS 4299: 1998 section

Figure 13: Roofing Section

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 11

Arun Rimal, P.E.

9. Conclusion and Recommendations

Hence, the building components are designed as per NZS 4299: 1998 and NBC 204: 1994. The

details of the design section and reinforcement are presented in the Structural Drawing Sheets.

Design and construction of the structure are inter – related jobs. A building behaves in a manner

how it has been built rather than what the intensions is during designing. A large percentage of

structural failures are attributed due to poor quality of construction. Quality assurance is needed in

both design and construction. Therefore, it is recommended that the construction of the building

be done under the supervision of skilled engineering manpower. Designer will not be responsible

for any faulty constructions at site.

310 Passaic Ave., Unit 406, Harrison, N.J. 07029

Ph. 212 414 4006 email:arun@osdengineering.com

Page | 12

You might also like

- BOQ-House Sri LankaDocument3 pagesBOQ-House Sri LankaTerornira Niranjan67% (39)

- Client:: Structural Analysis and Design Report StadiumDocument42 pagesClient:: Structural Analysis and Design Report StadiumRoshan KejariwalNo ratings yet

- BOQ - Proposed House For Mr. W. M. Chanaka UdayangaDocument8 pagesBOQ - Proposed House For Mr. W. M. Chanaka UdayangaNadun AthukoralaNo ratings yet

- Type of Slope Treatment PDFDocument103 pagesType of Slope Treatment PDFUmmi SurayaNo ratings yet

- Amrapali Project (Repaired)Document30 pagesAmrapali Project (Repaired)Goyal SagarNo ratings yet

- Client:: Structural Analysis and Design Report StadiumDocument39 pagesClient:: Structural Analysis and Design Report StadiumRoshan KejariwalNo ratings yet

- A Report On Structural Analysis and Design OF Industrial BuildingDocument20 pagesA Report On Structural Analysis and Design OF Industrial BuildingRoshan KejariwalNo ratings yet

- RFP - Procurement of Construction Works For AfDB Nigeria Field Office - Lot 3 - Electrical Works - Vol 3 - Bills of Quantities PDFDocument32 pagesRFP - Procurement of Construction Works For AfDB Nigeria Field Office - Lot 3 - Electrical Works - Vol 3 - Bills of Quantities PDFFelix IdeboghieNo ratings yet

- Guide: Mrs. P. Chithra (Lecturer)Document25 pagesGuide: Mrs. P. Chithra (Lecturer)Vicky RockNo ratings yet

- Protection PileDocument10 pagesProtection PilePrakash GuragainNo ratings yet

- ESTEEMDocument39 pagesESTEEMVictoria JungNo ratings yet

- Design CalculationsDocument76 pagesDesign Calculationsbometchilia27No ratings yet

- AuditoriumDocument8 pagesAuditoriumkamranNo ratings yet

- 102 02 000014 Engineer's ReportDocument7 pages102 02 000014 Engineer's ReportwestymNo ratings yet

- Main Building Structure ReportDocument65 pagesMain Building Structure ReportRoshan KejariwalNo ratings yet

- Street Lighting at Shirazi UnpricedDocument7 pagesStreet Lighting at Shirazi UnpricedKassim NderiNo ratings yet

- Gorhar-Khairatunda: Subject: Estimation of VUP at KM 1+330 DataDocument17 pagesGorhar-Khairatunda: Subject: Estimation of VUP at KM 1+330 Datanandu523No ratings yet

- 1994 Uniform Building Code Seismic Analysis ProcedureDocument26 pages1994 Uniform Building Code Seismic Analysis ProcedureNick OperarioNo ratings yet

- Bill of Quantity No Description Unit Quantity Unit Price Total PriceDocument5 pagesBill of Quantity No Description Unit Quantity Unit Price Total PriceSemNo ratings yet

- Copy-Proposed Fence WorkDocument12 pagesCopy-Proposed Fence WorkdillonperrymarieNo ratings yet

- fINAL Aruna Shrestha ANALYSIS REPORTDocument42 pagesfINAL Aruna Shrestha ANALYSIS REPORTer.praveenraj30100% (1)

- Structure Report RAINAS MUNICIPALITY BUILDING Revised.Document78 pagesStructure Report RAINAS MUNICIPALITY BUILDING Revised.Laxu Khanal100% (1)

- IT Park DesignDocument53 pagesIT Park DesignYashu YashuNo ratings yet

- Question Bank of DRCBMDocument11 pagesQuestion Bank of DRCBMrishinathnehruNo ratings yet

- DesignDocument18 pagesDesignSareesh ChandrawanshiNo ratings yet

- West Omo Meinit Goldia Woreda Bani Kebele Water SupplyDocument60 pagesWest Omo Meinit Goldia Woreda Bani Kebele Water SupplyReffisa JiruNo ratings yet

- Foundation Engineering Pile Foundation: Luthfi HasanDocument86 pagesFoundation Engineering Pile Foundation: Luthfi HasanYusron JamilNo ratings yet

- Pile Foundation#1Document86 pagesPile Foundation#1reza pahleviNo ratings yet

- Soil Nailing Design: Presenter Name: Su'aidi Bin Che Su Politeknik Tuanku Sultanah Bahiyah Geotechnical Forensic UnitsDocument44 pagesSoil Nailing Design: Presenter Name: Su'aidi Bin Che Su Politeknik Tuanku Sultanah Bahiyah Geotechnical Forensic Unitsjumapx100% (1)

- PR 02 Preparation of Structural Design CriteriaDocument15 pagesPR 02 Preparation of Structural Design CriteriaHans Metif LinaNo ratings yet

- Weekly Progress Pembangunan Jembatan HD 785 SMO Week 31Document28 pagesWeekly Progress Pembangunan Jembatan HD 785 SMO Week 31kalkulaNo ratings yet

- GBC 1 Notes-1Document39 pagesGBC 1 Notes-1Kenneth KimondoNo ratings yet

- Design Information: Unicorn Engineering Resources LimitedDocument2 pagesDesign Information: Unicorn Engineering Resources LimitedChristopher UcheNo ratings yet

- Client:: Structural Analysis and Design Report Official BuildingDocument53 pagesClient:: Structural Analysis and Design Report Official BuildingRoshan KejariwalNo ratings yet

- Project Planning and Reporting Assignment BSQ3523Document62 pagesProject Planning and Reporting Assignment BSQ3523ArdiniNo ratings yet

- Structural Analysis & Design: Structural Report On Dang ProjectDocument68 pagesStructural Analysis & Design: Structural Report On Dang ProjectNishan GajurelNo ratings yet

- Analysis Report: Residential Building, Thalidanchhi - 1, Kageshwori Manohara Municipality, KathmanduDocument8 pagesAnalysis Report: Residential Building, Thalidanchhi - 1, Kageshwori Manohara Municipality, KathmanduSunny Khagee100% (1)

- Technical Proposal For Pre Fab BuildingDocument3 pagesTechnical Proposal For Pre Fab BuildingFatima BushraNo ratings yet

- 1 - R-633 Structural Concept Report - Stage 2 - 2012-09-13Document19 pages1 - R-633 Structural Concept Report - Stage 2 - 2012-09-13Parth Daxini100% (1)

- P-142 King Post Shoring Design Report 18.11.2019Document31 pagesP-142 King Post Shoring Design Report 18.11.2019frog15No ratings yet

- Metals SuperstructureDocument6 pagesMetals SuperstructureAdnan IbrahimNo ratings yet

- PAGARDocument6 pagesPAGARTerick CarswellNo ratings yet

- Typical Beme For A Building ProjectDocument10 pagesTypical Beme For A Building Projectsayaya101No ratings yet

- Bill 1 BOQDocument9 pagesBill 1 BOQAaron AriifNo ratings yet

- Report-Metal Truss in Attic - FinalDocument43 pagesReport-Metal Truss in Attic - FinalManojNo ratings yet

- Append ADocument44 pagesAppend AVictor TorresNo ratings yet

- nrcs144p2 042170Document42 pagesnrcs144p2 042170Er. Hisham Ajmal PCNo ratings yet

- 10239036Document47 pages10239036Yazer ArafathNo ratings yet

- Equations UsedDocument6 pagesEquations Usedneeta rautelaNo ratings yet

- Final ProjectDocument53 pagesFinal ProjectManju Civil P100% (1)

- Reinforced Concrete DWGDocument11 pagesReinforced Concrete DWGAnonymous CPEha1db7UNo ratings yet

- CE2401-Design of Reinforced Concrete and Brick MasonryDocument12 pagesCE2401-Design of Reinforced Concrete and Brick MasonryJaga NathNo ratings yet

- Use of Different Depth of Footing To Determine Extra Number of Floor Required in Given SBC of SoilDocument9 pagesUse of Different Depth of Footing To Determine Extra Number of Floor Required in Given SBC of SoilIJRASETPublicationsNo ratings yet

- NagaDocument2 pagesNagaSancho AcbangNo ratings yet

- Assignment 2 Measurement 8Document2 pagesAssignment 2 Measurement 8Nurul IzzatiNo ratings yet

- Analysis & Design By:: Er. Shivaji Bhusal Civil Engineer NEC Regd. No. 4234 "A"Document40 pagesAnalysis & Design By:: Er. Shivaji Bhusal Civil Engineer NEC Regd. No. 4234 "A"er.praveenraj30No ratings yet

- Work Cost Estimate: 5. Brief Specification of The Construction To Be Made Is Given As UnderDocument3 pagesWork Cost Estimate: 5. Brief Specification of The Construction To Be Made Is Given As UnderCse312 B. PraveenNo ratings yet

- Karthi FinalDocument10 pagesKarthi Finalkarthikeyan100% (1)

- Structure Data File in TXT Format 67959Document25 pagesStructure Data File in TXT Format 67959SANDIP BUDHATHOKINo ratings yet

- Lokogoma BillDocument11 pagesLokogoma BillDear Lakes AyoNo ratings yet

- Structural Report - Type 4 Health PostDocument29 pagesStructural Report - Type 4 Health PostSaurav ShahNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- CV - SudeepDocument5 pagesCV - SudeepRoshan KejariwalNo ratings yet

- CV Ashish PDFDocument3 pagesCV Ashish PDFRoshan KejariwalNo ratings yet

- Sanjay Mehta - CV PDFDocument4 pagesSanjay Mehta - CV PDFRoshan KejariwalNo ratings yet

- Compounnd WallDocument70 pagesCompounnd WallRoshan KejariwalNo ratings yet

- Curriculum Vitae: A. Personal Details Civil/Structural EngineerDocument5 pagesCurriculum Vitae: A. Personal Details Civil/Structural EngineerRoshan KejariwalNo ratings yet

- Jyoti ResumeDocument2 pagesJyoti ResumeRoshan KejariwalNo ratings yet

- StructureDocument27 pagesStructureRoshan KejariwalNo ratings yet

- Gate Design PDFDocument1 pageGate Design PDFRoshan KejariwalNo ratings yet

- Pedestrain Bridge 25MDocument1 pagePedestrain Bridge 25MRoshan KejariwalNo ratings yet

- Required Data: HydrologyDocument104 pagesRequired Data: HydrologyRoshan KejariwalNo ratings yet

- Sanitary and Water Supply EstimateDocument100 pagesSanitary and Water Supply EstimateRoshan KejariwalNo ratings yet

- The Design of Seismic Reaction Block of BridgeDocument8 pagesThe Design of Seismic Reaction Block of BridgeRoshan KejariwalNo ratings yet

- SAP2000 Analysis Report: License #2B4FBDocument29 pagesSAP2000 Analysis Report: License #2B4FBRoshan KejariwalNo ratings yet

- Materials Unit Rate With TransporatationDocument29 pagesMaterials Unit Rate With TransporatationRoshan KejariwalNo ratings yet

- Load Calculation Football Stadium, GodawariDocument28 pagesLoad Calculation Football Stadium, GodawariRoshan KejariwalNo ratings yet

- Godavari Municipality: Bajarbarahi, LalitpurDocument317 pagesGodavari Municipality: Bajarbarahi, LalitpurRoshan KejariwalNo ratings yet

- r2 StadiumDocument69 pagesr2 StadiumRoshan KejariwalNo ratings yet

- Main Building Structure ReportDocument65 pagesMain Building Structure ReportRoshan KejariwalNo ratings yet

- Preparation of Standard Drawing of Pedestrian Bridge Span: 45 M Load CalculationsDocument13 pagesPreparation of Standard Drawing of Pedestrian Bridge Span: 45 M Load CalculationsRoshan KejariwalNo ratings yet

- Bill of Quantities: Prepared By: Checked By: Approved byDocument82 pagesBill of Quantities: Prepared By: Checked By: Approved byRoshan KejariwalNo ratings yet

- Final PTruss25m - 0122017Document195 pagesFinal PTruss25m - 0122017Roshan KejariwalNo ratings yet

- Preparation of Standard Drawing of Pedestrian Bridge Span: 25 M Load CalculationsDocument13 pagesPreparation of Standard Drawing of Pedestrian Bridge Span: 25 M Load CalculationsRoshan KejariwalNo ratings yet

- Preparation of Standard Drawing of Pedestrian Bridge Span: 60 M Load CalculationsDocument19 pagesPreparation of Standard Drawing of Pedestrian Bridge Span: 60 M Load CalculationsRoshan KejariwalNo ratings yet

- Avalanche DiodeDocument2 pagesAvalanche DiodevergilmustdieNo ratings yet

- Power Products Crompton Greaves Test Blocks PDFDocument2 pagesPower Products Crompton Greaves Test Blocks PDFMohammad Mahdi BozorgzadehNo ratings yet

- Elevator Pit FC Requirements CE017 - 1 - AppendicesABC - CodeDocument15 pagesElevator Pit FC Requirements CE017 - 1 - AppendicesABC - CodePj EstokNo ratings yet

- msd-6300 6320 frm243820Document12 pagesmsd-6300 6320 frm243820Hector KrrerasNo ratings yet

- MHP Electrical ComponentDocument60 pagesMHP Electrical ComponentSandip DeNo ratings yet

- ABB 1HDX580100en ELK04Document4 pagesABB 1HDX580100en ELK04vicesuza87No ratings yet

- NO Item No Description UOM RFI OLD NEW BOM QTYDocument8 pagesNO Item No Description UOM RFI OLD NEW BOM QTYNofie MNo ratings yet

- 3512B & 3516B Engines With Premium Electrical System Wiring Harness For Marine PropulsionDocument2 pages3512B & 3516B Engines With Premium Electrical System Wiring Harness For Marine PropulsionMehdi Chakroune100% (2)

- (See Inspection Using An Oscilloscope (Reference) (Without Throttle Valve Actuator) .)Document8 pages(See Inspection Using An Oscilloscope (Reference) (Without Throttle Valve Actuator) .)surajNo ratings yet

- Eds G 1101Document6 pagesEds G 1101aldairlopesNo ratings yet

- Data Sheets - Hs Series 72.5kV/31.5kA - 2000A: Page - 1Document4 pagesData Sheets - Hs Series 72.5kV/31.5kA - 2000A: Page - 1jurica_2006No ratings yet

- IC - Pd.600.2a.02 Solenoid CoilDocument23 pagesIC - Pd.600.2a.02 Solenoid CoilAldwinNo ratings yet

- UENR59580001232 DhidDocument15 pagesUENR59580001232 DhidHooldus BarranquillaNo ratings yet

- 2020 RAB PANTI ASUHAN (Englis G)Document3 pages2020 RAB PANTI ASUHAN (Englis G)LJ LJ rahmatNo ratings yet

- 500 ManualDocument44 pages500 ManualLeonardo Vinicio Olarte CarrilloNo ratings yet

- Wiper and Washer Systems: Symptom Related Diagnostic Procedures Windshield Wiper Washer System MalfunctionDocument5 pagesWiper and Washer Systems: Symptom Related Diagnostic Procedures Windshield Wiper Washer System MalfunctionJose GarciaNo ratings yet

- 5010-Re Rtre Reu - Imo - GBDocument2 pages5010-Re Rtre Reu - Imo - GBVrhovac RadenkoNo ratings yet

- Kia Code Retrieval: Accessing Diagnostic Trouble Codes Models Up To 95Document9 pagesKia Code Retrieval: Accessing Diagnostic Trouble Codes Models Up To 95mounir20No ratings yet

- TWA Assembly BrochureDocument2 pagesTWA Assembly BrochureNaqib FuadNo ratings yet

- Aries Brevia NewDocument2 pagesAries Brevia NewFaiz AzaharNo ratings yet

- DSC Lc105dgbDocument2 pagesDSC Lc105dgbImi Michał SmulskiNo ratings yet

- Electrical System G3500 Generator Set With EMCPII+Document2 pagesElectrical System G3500 Generator Set With EMCPII+Sam SamNo ratings yet

- Jazan Baseline ScheduleDocument4 pagesJazan Baseline ScheduleNoor MohdNo ratings yet

- 54-RE-46-E Instructions For Use 110207 PDFDocument52 pages54-RE-46-E Instructions For Use 110207 PDFanhdungro1986No ratings yet

- Fun Projects 12 Chapter PDFDocument4 pagesFun Projects 12 Chapter PDFtihomihoNo ratings yet

- SubstationsDocument33 pagesSubstationsTabi4every1100% (1)

- Philips Industrial LightingsDocument13 pagesPhilips Industrial Lightingsmn_sundaraamNo ratings yet

- Fittings For Outdoor FurnitureDocument68 pagesFittings For Outdoor FurnitureTEP DesignNo ratings yet

- OG Akım Gerilim TRF AK VK SerisiDocument19 pagesOG Akım Gerilim TRF AK VK SerisiGeorge Asuncion100% (1)