Professional Documents

Culture Documents

Are Crystallization and Melting The Reverse Transformation of Each Other

Are Crystallization and Melting The Reverse Transformation of Each Other

Uploaded by

Angelo Mateo Garcia LopezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Are Crystallization and Melting The Reverse Transformation of Each Other

Are Crystallization and Melting The Reverse Transformation of Each Other

Uploaded by

Angelo Mateo Garcia LopezCopyright:

Available Formats

Research: Science and Education

Are Crystallization and Melting W

the Reverse Transformation of Each Other?

Hermínio P. Diogo

Centro de Química Estrutural, Complexo I, IST, Av. Rovisco Pais, 1049-001 Lisboa, Portugal

Joaquim J. Moura Ramos*

Centro de Química-Física Molecular, Complexo I, IST, Av. Rovisco Pais, 1049-001 Lisboa, Portugal; *mouraramos@ist.utl.pt

Despite the importance of crystal technology and of epi- tion of those bonds on heating prior to the melting point

layer fabrication, these topics are not addressed in the typi- can cause a broadening of the melting peak. The melting pro-

cal undergraduate curriculum. Chemistry students are usually cess, while not uncomplicated, is still much simpler than the

exposed to crystallization only as an equilibrium phase tran- crystallization process.

sition that is part of a phase diagram. Phase transitions oc- Crystallization is a combination of two processes: nucle-

See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles.

cur in nature and in technological processes under ation and crystal growth (2). Crystallization requires the pres-

Downloaded via UNIV NACIONAL DE COLOMBIA on October 27, 2019 at 03:00:19 (UTC).

nonequilibrium conditions, where crystallization is not sim- ence of a nucleus on which the crystal will subsequently grow.

ply the reverse of melting. For example, liquids can be cooled In the absence of nuclei, the material will form a glass upon

below their freezing point without crystallizing, and sub- cooling. The nucleus for crystallization may be either homo-

stances can crystallize when heated. In this article we will geneous (forming spontaneously in the melt) or heteroge-

show that crystallization is not simply the reverse of melt- neous (forming at a pre-existing surface of an impurity, for

ing, and we will explain apparently anomalous crystallization example). In this article, we are concerned only with homo-

behavior by examining crystallization as a two-step process: geneous nucleation.

nucleation and crystal growth.

Four Examples of Crystallization

Melting and Crystallization Process

Four substances (Figure 1) showing various crystalliza-

Melting is most often a single-step process determined tion properties are examined. The DSC thermograms are

solely by thermodynamic factors. The melting of a crystal shown in Figures 2 to 5. The background of the technique

may be a first-order thermodynamic transition according to of DSC and the significance of the information it provides

the Ehrenfest (1) classification. Such phase transitions are is clearly explained in several textbooks (3).

typical for low molecular weight crystals, they occur at a defi- Figure 2 shows caffeine with linear heating and cooling

nite temperature, and are accompanied by a discontinuous ramps of 2, 5, 10, and 15 ⬚C兾min. The endothermic peaks,

change in thermodynamic properties such as enthalpy and (downwards) obtained on heating, correspond to the melting

density. Sometimes, however, complex features may occur in process. The exothermic peaks, (upwards) obtained on cooling,

the melting peak obtained by differential scanning calorim- correspond to the crystallization process. The onset tempera-

etry (DSC). So-called “pre-melting” or surface melting can tures of the two processes are very similar (ton = 235–236 ⬚C),

occur several degrees below the melting point of the bulk solid they are not very dependent on the heating or cooling rate,

(1). For a hydrogen-bonded crystal, the progressive destruc- the peak shapes are similar, and thus the enthalpy changes

caffeine p-cresol

phenyl salicylate salicyl salicylate

Figure 2. Results of DSC experiments performed on caffeine. The

experimental protocol was a sequence of heating and cooling lin-

Figure 1. Chemical structures of the compounds. ear ramps with different rates: 2, 5, 10, and 15 ºC兾min.

www.JCE.DivCHED.org • Vol. 83 No. 9 September 2006 • Journal of Chemical Education 1389

Research: Science and Education

for crystallization and melting are equal in magnitude but the cooling rate, and the shapes of the peaks also vary. This

opposite in sign. Figure 2 corresponds to so-called normal shows supercooling (4) of p-cresol, where the melt enters a

behavior. metastable state at temperatures less than 25 ⬚C. This super-

Figure 3 shows p-cresol with the same experimental pro- cooled state persists for over 50 ⬚C, even at the lowest cool-

tocol as Figure 2. The results are decidedly different. The on- ing rate of 2 ⬚C兾min.

set of the melting peak (ton = 25 ⬚C) and of the crystallization The third sample is phenyl salicylate, which requires a

peak (ton from ᎑30 to ᎑25 ⬚C) are markedly displaced, the different procedure. Salol shows a lower tendency to crys-

onset of crystallization is variable in a way not dependent of tallize on cooling when compared to p-cresol. It is easily su-

percooled, and it is relatively easy to vitrify. After melting at

60 ⬚C, the melt is cooled to a glassy state at ᎑90 ⬚C. Figure

4 shows the subsequent heating and cooling cycle for three

different rates. All show three common features: (i) a glass-

transition temperature, Tg, at about ᎑52 ⬚C; (ii) an exother-

mic (upwards) signal occurring during heating over a

temperature interval from ᎑25 ⬚C to the melting point; and

(iii) the endothermic (downwards) signal located between

32 ⬚C and 42 ⬚C according to the heating rate. The variable

endothermic melting peak is the result of crystal polymor-

phism (5). The exothermic signal is the result of crystalliza-

tion occurring during the heating cycle, also called “cold

crystallization”. This counterintuitive phenomenon will be

discussed later.

A final example, salicyl salicylate, is examined in Figure

5. It melts over a wide range (139 ⬚C to 151 ⬚C) and cools

without crystallization to form a supercooled liquid that can

be molded and stress fractured. No normal means of induc-

ing crystallization, including crystal seeding, are effective in

Figure 3. Results of DSC experiments carried out on p-cresol. The

experimental protocol was a sequence of heating and cooling lin-

this material. Only dissolution and recrystallization yields the

ear ramps with different rates: 2, 5, 10, and 15 ºC兾min. crystalline solid (6). A glass-transition signal was observed at

about 6 ⬚C, but no cold crystallization is observed.

Description of the Nucleation Process

In any equilibrated macroscopic system, local variations

of the values of the macroscopic properties occur and are

called fluctuations. These fluctuations correspond to a lo-

cal increase of the thermodynamic potential, so that they

are less probable than the mean (macroscopic) state of the

system. In a homogeneous molecular system (liquid or va-

por) there are always small fluctuations of the density, that

is, small molecular aggregates that are well compatible with

the actual state of aggregation of the system. The concen-

tration of these fluctuations is higher near the conditions

of phase equilibrium, where the chemical potentials of the

two phases are equal. The fluctuations in an equilibrated

phase (the most stable phase at some specified temperature)

are ephemeral in the sense that their sizes are negligible and

they decay without revealing any tendency to grow. How-

ever, in a metastable phase (the supercooled liquid or the

superheated liquid, for example) the tendency of the clus-

ters of the most stable phase to grow prevails after exceed-

ing a certain critical size. These density fluctuations or

clusters are the so-called critical nuclei of the new phase,

and, as will be seen, some Gibbs energy must be expended

to form such clusters.

These clusters are continuously being formed and dis-

Figure 4. Results of DSC experiments performed on phenyl salicy- sociated in the liquid, and this molecular accretion process

late. The sample was heated from the glassy state at t = ᎑90 ⬚C to occurs based on localized energy fluctuations. Clustering is a

above the melting temperature. The heating rates were: (A) 2 random event where molecules come together, interact, and

ºC兾min; (B) 5 ºC兾min; (C) 20 ºC兾min. then dissociate again on some time scale. If conditions are

1390 Journal of Chemical Education • Vol. 83 No. 9 September 2006 • www.JCE.DivCHED.org

Research: Science and Education

correct (sufficient undercooling), the rate of association is

∆mS ∆ S ∆U

greater than the rate of dissociation, and a cluster of critical Jgr = a exp − m exp − ∆T (4)

size is formed that converts into a crystal lattice. k BT kB kBT

Thermodynamics of Nucleus Formation where a is a constant, ∆mS is the change in entropy for melt-

ing, ∆U is the energy barrier to flow owing to viscosity, and

The theory of homogeneous nucleation is presented in ∆T is the degree of undercooling, that is, the difference be-

several specialized books (7–9). As shown in the Supplemental tween T (the temperature of the supercooled melt) and Tm

Material,W the Gibbs energy change for Z monomeric liquid

molecules aggregating to form a spherical cluster (nucleus)

is given by

4 3

∆G = π r ∆GV + 4π r 2 σ (1)

3

where ∆GV is the Gibbs energy of formation of the solid phase

per unit volume, σ is the surface tension between the solid

and the liquid, and r is the radius of the cluster. A graphical

solution of ∆G as a function of r is shown in Figure 6.

The maximum in Figure 6 corresponds to the critical

size of the nucleus, rc, above which crystal growth is spon-

taneous. The value of the Gibbs energy change making a

cluster of this critical size, ∆Gc, is the nucleation thermo-

dynamic barrier. Since the entropy change of liquid mol-

ecules becoming the critical-sized cluster, ∆Sc, is negative,

the magnitude of ∆Gc decreases with a decrease in tempera-

ture; that is,

∂

∆G c Figure 5. Results of DSC experiments performed on salicyl salicy-

= −∆Sc (2) late. The crystalline sample was heated at a rate of 10 ºC兾min

∂

T P and the endothermic melting peak was observed at ton = 144 ºC.

Subsequently, the melt was cooled at 10 ºC兾min to t = ᎑50 ºC: no

W

The Supplemental Material shows in more detail how ∆Gc, crystallization is observed but the fingerprint of the glass transition

and rc both decrease with decrease in temperature. Thus, from on cooling is clearly shown. Finally, the sample was heated from

a thermodynamic viewpoint, nucleation is more efficient at the glassy state at 10 ºC兾min: the glass-transition signal is again

low temperatures. observed (onset at ton = 6 ºC), and no cold crystallization takes

place.

Kinetics of Nucleus Formation

As shown in the Supplemental Material,W the kinetic rate

of nucleus formation is given by a Boltzmann distribution:

NV kB T ∆Gc

Jnucl = 3

exp − (3)

3 πη λ k BT

where NV is the number density of molecules in the nucleus,

η is the viscosity coefficient, and λ is the mean free path

length (approximated as the molecular diameter). At a tem-

perature approaching the glass-transition temperature, Tg, the

viscosity is too high and the resulting motion of molecules is

too sluggish for a reasonable kinetic rate of aggregate cluster

formation. At a temperature approaching the melting point,

the thermodynamics become unfavorable for nucleus forma-

tion. Thus there is an inevitable tradeoff between nucleation

at a lower temperature (thermodynamically favored via a

lower ∆Gc) and a nucleation at a higher temperature (kineti-

cally favored via a lower viscosity). Figure 6. Representation of the Gibbs energy change associated

with the formation of a stable nucleus, ∆G, as a function of the

Crystal Growth radius of the nucleus, r. The increasing and decreasing curves cor-

respond respectively to the second and first term in the right hand

As shown in the Supplemental Material,W the kinetic rate side of eq 1. The critical radius, rc, and the barrier ∆Gc are indi-

of crystal growth is given by (7): cated.

www.JCE.DivCHED.org • Vol. 83 No. 9 September 2006 • Journal of Chemical Education 1391

Research: Science and Education

clei have been formed. At yet lower temperatures, nuclei be-

gin to form, but crystal growth has become kinetically im-

practical. In the case of Figure 4, the melt was quenched to

temperatures below Tg. On heating, the nuclei are formed

first and, if thermally stable, survive up to a temperature range

where crystal growth can occur. This explains the anomalous

result of cold crystallization, the phenomenon of crystals

forming in an exothermic process while heating the super-

cooled melt. For salicyl salicylate in Figure 5, we see a strong

resistance to crystallization both on heating as well as cool-

ing; there is no cold crystallization. This could be the result

of the nuclei formed at lower temperatures not having suffi-

cient thermal stability to reach the temperatures required for

crystal growth. Alternatively, one could propose very restric-

Figure 7. Schematic representation of the nucleation rate, Jnucl, and tive stereochemical requirements that make crystallization

of the rate of crystal growth, Jgr, as a function of the temperature. inefficient.

The rate units are arbitrary. Tg is the glass-transition temperature

and Tm is the melting temperature. The gray area, where the curves

overlap, defines the temperature range where both nucleation and Summary

growth can occur with significant probability.

In teaching phase transitions, we should avoid giving stu-

dents the impression that crystallization is simply the reverse

of melting. While melting is a single-step process controlled

(the normal melting point). Here again we see a dual role by thermodynamics, crystallization is a two-step process

of temperature in the rate expression. For a melt that is sig- (nucleation and crystal growth) of which both steps reflect

nificantly supercooled, ∆T is large, and the crystal growth thermodynamic and kinetic control.

rate increases proportionately. But this also implies a low

absolute value of T, which in the second exponential term W

Supplemental Material

will make for a more negative exponent, and thus a smaller

rate of crystal growth. Like the nucleus formation, crystal- A more complete presentation of classical nucleation and

lization will occur between Tg and Tm. Equations 3 and 4 crystal growth theories is available in this issue of JCE Online.

show that the optimum temperature for nucleus formation

and the optimum temperature for crystal growth are not Literature Cited

necessarily the same. One version of this is shown graphi-

cally in Figure 7. 1. Papon, P.; Leblond, J.; Meijer, P. H. E. The Physics of Phase

Transitions: Concepts and Applications; Springer–Verlag: Ber-

Qualitative Interpretations of the Four Examples lin, 2002.

2. Shelby, J. E. Introduction to Glassy Science and Applications;

Development of structured clusters is recognized to be Royal Society of Chemistry: Cambridge, United Kingdom,

more enhanced as the temperature is decreased down to the 1997.

glass-transition temperature. The maximum rate of growth 3. Principles of Thermal Analysis and Calorimetry; Haines, P. J.,

process, on the other hand, has been observed for many sys- Ed.; Royal Society of Chemistry: Cambridge, United King-

tems rather in the middle of the interval between Tg and Tm, dom, 2002.

or at temperatures closer to Tm. The maximum rates of the 4. Debenedetti, P. G. Metastable Liquids: Concepts and Principles;

homogeneous nucleation and of the crystal growth are ex- Princeton University Press: Princeton, NJ, 1996.

pected to appear, in many cases, at considerably different tem- 5. Moura Ramos, J. J.; Correia, N. T.; Diogo, H. P. Phys. Chem.

peratures (10). Chem. Phys. 2004, 6, 793–798.

For caffeine in Figure 2, the rate of nucleation and the 6. Greener, B.; Archibal, S. J.; Hodkinson, M. Angew. Chem. Int.

rate of crystal growth must both be efficient at a tempera- Educ. 2000, 39, 3601–3604.

ture very near Tm (i.e., the two curves in Figure 7 signifi- 7. Markov, I. V. Crystal Growth for Beginners: Fundamentals of

cantly overlap and are shifted to the right-hand extreme of Nucleation, Crystal Growth and Epitaxi; World Scientific Pub-

Tm). For p-cresol in Figure 3, the crystallization peak was lishing Co.: Singapore, 1998.

strongly displaced to temperatures below Tm. This indicates 8. Hartel, R. W. Crystallization in Foods; Aspen Publishers, Inc.:

that the nucleation curve and crystal growth curve overlap Gaithersburg, MD, 2001.

only at a temperature shifted left from Tm in Figure 7. For 9. Gutzow, I.; Schmelzer, J. The Vitreous State: Thermodynamics,

phenyl salicylate, the normal cooling curve results in no over- Structure, Rheology and Crystallization; Springer–Verlag: Ber-

lap between the nucleation curve and the crystal growth lin, 1995.

curve. As temperature is lowered from Tm, a temperature 10. Hikima, T.; Hanaya, N.; Oguni, M. Solid State Comm. 1995,

range is reached where crystal growth is efficient, but no nu- 93, 713–717.

1392 Journal of Chemical Education • Vol. 83 No. 9 September 2006 • www.JCE.DivCHED.org

You might also like

- Protein Synthesis Guided Practice: by Laney LeeDocument10 pagesProtein Synthesis Guided Practice: by Laney LeeRebecca HardeeNo ratings yet

- General Chemistry 2: ElectrochemistryDocument12 pagesGeneral Chemistry 2: ElectrochemistrySteinerNo ratings yet

- CrystallizationDocument7 pagesCrystallizationKhaqan AminNo ratings yet

- Transportation Engineering I Lab ReportsDocument22 pagesTransportation Engineering I Lab ReportsSushrut0% (1)

- MSDS - Cs137Document3 pagesMSDS - Cs137Juliano Strassburg50% (2)

- Crystallization - MCE 203Document31 pagesCrystallization - MCE 203samuelodeyemi3000No ratings yet

- Types of CrystalsDocument29 pagesTypes of CrystalsPratap TanariNo ratings yet

- Cristalizacion EnfriamientoDocument9 pagesCristalizacion EnfriamientoHector Joel Chaname RodriguezNo ratings yet

- On Calcium Carbonates: From Fundamental Research To ApplicationDocument18 pagesOn Calcium Carbonates: From Fundamental Research To ApplicationAna RosaNo ratings yet

- 2008 LibDocument17 pages2008 LibTest Test2No ratings yet

- Introduction To Nonlinear Optics and Crystal Growth Techniques ProcessDocument9 pagesIntroduction To Nonlinear Optics and Crystal Growth Techniques ProcessInternational Journal of Engineering and TechniquesNo ratings yet

- Rheological Behavior of Crystallizing Palm OilDocument7 pagesRheological Behavior of Crystallizing Palm OilMarcela Hernandez SehuanesNo ratings yet

- Hulliger 1994Document20 pagesHulliger 1994Tatiana TrujilloNo ratings yet

- Crystallization From The Amorphous State: Nucleation-Growth Decoupling, Polymorphism Interplay, and The Role of InterfacesDocument14 pagesCrystallization From The Amorphous State: Nucleation-Growth Decoupling, Polymorphism Interplay, and The Role of InterfacesMartín MaciasNo ratings yet

- Modeling of Crystallization Processes FinalDocument18 pagesModeling of Crystallization Processes FinalSunil HansdaNo ratings yet

- Crystallization Under Nanoscale ConfinementDocument14 pagesCrystallization Under Nanoscale ConfinementJonatas LopesNo ratings yet

- Crystal IzationDocument8 pagesCrystal Izationahmed.khallaf1962No ratings yet

- J Jnoncrysol 2015 08 027Document9 pagesJ Jnoncrysol 2015 08 027Itamar JuniorNo ratings yet

- Mass Transfer Operation 1 (2150501) : Crystallization Concept, Techniques and ProcessesDocument18 pagesMass Transfer Operation 1 (2150501) : Crystallization Concept, Techniques and Processesvashu patelNo ratings yet

- Chapter 10 - Grain Growth, Sintering and VitrificationDocument34 pagesChapter 10 - Grain Growth, Sintering and VitrificationYuri Noskenko SchklerenovNo ratings yet

- 489Document16 pages489yasirsshah261No ratings yet

- Isotope Effects Reveal The Template Influence On The Crystal Growth of A Metal-Halide NetworkDocument11 pagesIsotope Effects Reveal The Template Influence On The Crystal Growth of A Metal-Halide NetworkGold MochaNo ratings yet

- Acta Crystallographica F - 2014 - Vekilov - Nucleation Precursors in Protein CrystallizationDocument12 pagesActa Crystallographica F - 2014 - Vekilov - Nucleation Precursors in Protein CrystallizationspkanaujiaNo ratings yet

- Engineering Materials and Metallurgy Questions For Campus Interviews - SanfoundryDocument9 pagesEngineering Materials and Metallurgy Questions For Campus Interviews - SanfoundryGopinathan MNo ratings yet

- Re Tten May Rint Mater Rev 2009Document17 pagesRe Tten May Rint Mater Rev 2009alirafiqNo ratings yet

- Cry Equi 2Document13 pagesCry Equi 2Shreya JoshiNo ratings yet

- Crystallization MechanismsDocument20 pagesCrystallization MechanismsZayra OrtizNo ratings yet

- Sakamoto 2010Document11 pagesSakamoto 2010tin.huynhdac6994No ratings yet

- Spherulitic Growth TheoryDocument13 pagesSpherulitic Growth Theoryクマール ヴァンツNo ratings yet

- Rystallization: Instructor: Zafar ShakoorDocument41 pagesRystallization: Instructor: Zafar ShakoorMALIK ZARYABBABARNo ratings yet

- Theory of GlassesDocument54 pagesTheory of GlassesRolando Herrera100% (1)

- 1 s2.0 S2211812814010529 MainDocument12 pages1 s2.0 S2211812814010529 MainJhonny Rotciv FerroNo ratings yet

- Unesco - Eolss Sample Chapters: Heat ND Mass Transfer Operations - CrystallizationDocument10 pagesUnesco - Eolss Sample Chapters: Heat ND Mass Transfer Operations - Crystallizationkaviyas.21chemNo ratings yet

- Seeding in Crystal Lisa Tion Book ChapterDocument13 pagesSeeding in Crystal Lisa Tion Book ChapterTyokNo ratings yet

- Ligand Binding Assays in The 21Document9 pagesLigand Binding Assays in The 21Bagoes AsNo ratings yet

- Structure Property Relations in Soft Matter Session 2Document106 pagesStructure Property Relations in Soft Matter Session 2EricNo ratings yet

- Mechanisms of Nucleation and Growth of Nanoparticles in SolutionDocument21 pagesMechanisms of Nucleation and Growth of Nanoparticles in SolutionMathar BashirNo ratings yet

- Optometry: A-Crystallin: A Review of Its Structure and FunctionDocument11 pagesOptometry: A-Crystallin: A Review of Its Structure and FunctionSritapa Basu MallickNo ratings yet

- CrystalProcessDev A4 PDFDocument16 pagesCrystalProcessDev A4 PDFJonathan C MontealegreNo ratings yet

- Crystallization PDFDocument74 pagesCrystallization PDFMohammed Akif ShaikhNo ratings yet

- Sorokina 2021Document20 pagesSorokina 2021Martin VárhegyiNo ratings yet

- Industrial Crystallization: Seppo Palosaari, Marjatta Louhi-Kultanen, and Zuoliang ShaDocument22 pagesIndustrial Crystallization: Seppo Palosaari, Marjatta Louhi-Kultanen, and Zuoliang ShaNoel GatbontonNo ratings yet

- 2015 Lib 2Document18 pages2015 Lib 2Test Test2No ratings yet

- Polymer Ageing: Physics, Chemistry or Engineering? Time To ReflectDocument13 pagesPolymer Ageing: Physics, Chemistry or Engineering? Time To ReflectDEEPSHIKA DUTTANo ratings yet

- Principles of SolidificationDocument2 pagesPrinciples of SolidificationKhairul MuzafarNo ratings yet

- CrystallizationDocument6 pagesCrystallizationPulok HasanNo ratings yet

- (2008) From Crystal Structure Prediction To Polymorph Prediction (Interpreting The Crystal Energy Landscape) - Sarah L. PriceDocument14 pages(2008) From Crystal Structure Prediction To Polymorph Prediction (Interpreting The Crystal Energy Landscape) - Sarah L. PricewalterNo ratings yet

- Crystal Growth PHD ThesisDocument5 pagesCrystal Growth PHD Thesisendulrave1986100% (2)

- The Descent Into Glass Formation in Polymer Fluids: ConspectusDocument10 pagesThe Descent Into Glass Formation in Polymer Fluids: ConspectusJuanesVascoNo ratings yet

- Bridging The Cost BarrierDocument5 pagesBridging The Cost Barriercklcat1437No ratings yet

- Tech Tip 7 - Epoxy CrystallizationDocument2 pagesTech Tip 7 - Epoxy CrystallizationflavioferiNo ratings yet

- Presence of A Translucent Stage of Super Cooled Fluid or A Supersaturated DissolvableDocument2 pagesPresence of A Translucent Stage of Super Cooled Fluid or A Supersaturated DissolvableHas SimNo ratings yet

- Crystallisation - Faculty LectureDocument24 pagesCrystallisation - Faculty Lecturesoumitra hazraNo ratings yet

- 2015, McPherson - Microgravity Protein CrystallizationDocument20 pages2015, McPherson - Microgravity Protein Crystallizationjeffrey EellisNo ratings yet

- Crystallization - Wikipedia, The Free EncyclopediaDocument26 pagesCrystallization - Wikipedia, The Free EncyclopediaAvinash SumanNo ratings yet

- CrystallizationDocument7 pagesCrystallizationReggie DueñasNo ratings yet

- Disappearing Polymorphs Acc Chem Res 1995Document8 pagesDisappearing Polymorphs Acc Chem Res 1995Divyesh KuduvaNo ratings yet

- Acta Crystallographica F - 2014 - McPherson - Mechanisms Kinetics Impurities and Defects Consequences in MacromolecularDocument20 pagesActa Crystallographica F - 2014 - McPherson - Mechanisms Kinetics Impurities and Defects Consequences in MacromolecularspkanaujiaNo ratings yet

- Theory Copolymer Crystallization: Vol. NODocument8 pagesTheory Copolymer Crystallization: Vol. NOGersón JácomeNo ratings yet

- Mass CrystallizationDocument15 pagesMass Crystallizationمعاذ المجيولNo ratings yet

- Crystallisation ThesisDocument4 pagesCrystallisation Thesisxxsfomwff100% (2)

- Structural Glasses and Supercooled Liquids: Theory, Experiment, and ApplicationsFrom EverandStructural Glasses and Supercooled Liquids: Theory, Experiment, and ApplicationsNo ratings yet

- HT 2Document49 pagesHT 2JATIN DALMIANo ratings yet

- Case Study of Cement Industry To EnvorementDocument9 pagesCase Study of Cement Industry To Envorementshamen AmarasekaraNo ratings yet

- ადამიანის ფიზიოლოგია 1Document377 pagesადამიანის ფიზიოლოგია 1giorgi borcvaZeNo ratings yet

- Photochemical Reactions: Laws of PhotochemistryDocument2 pagesPhotochemical Reactions: Laws of Photochemistryمحمد عامر الحكيميNo ratings yet

- ElizabethRISETeacher Orlearner CentredDocument25 pagesElizabethRISETeacher Orlearner CentredhanniemaelimonNo ratings yet

- Physical and Chemical Changes Makeup LabDocument4 pagesPhysical and Chemical Changes Makeup Labkatiemc124No ratings yet

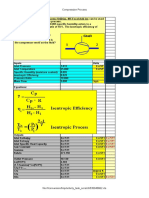

- Compression Process CalculationsDocument2 pagesCompression Process CalculationsRahul ChandrawarNo ratings yet

- Alcolin Fire Stop Neutral Silicone: Technical Data SheetDocument6 pagesAlcolin Fire Stop Neutral Silicone: Technical Data SheetTonyNo ratings yet

- Archivetemp01 Modul A + Kimia Tg5 - Bab 1Document54 pagesArchivetemp01 Modul A + Kimia Tg5 - Bab 1DOROTHY LING YU CHANG Moe0% (1)

- Author's Accepted Manuscript: Ipomoea BatatasDocument28 pagesAuthor's Accepted Manuscript: Ipomoea BatatasLuqman MileNo ratings yet

- Notes Percent PPM PPBDocument3 pagesNotes Percent PPM PPBeashelNo ratings yet

- USP 660 - Containers - GlassDocument4 pagesUSP 660 - Containers - Glasskunalkp88100% (1)

- Enthalpy of SolutionDocument41 pagesEnthalpy of SolutionTrishaNo ratings yet

- Corrosion Science: Surendra Singh, Saibal Basu, A.K. Poswal, R.B. Tokas, S.K. GhoshDocument6 pagesCorrosion Science: Surendra Singh, Saibal Basu, A.K. Poswal, R.B. Tokas, S.K. GhoshAlexander Escobar MoralesNo ratings yet

- WeldDocument7 pagesWeldMuhammad Akbar Faereza NugrahaNo ratings yet

- Seminar On Carnot Cycle and Its EfficiencyDocument10 pagesSeminar On Carnot Cycle and Its EfficiencyUjjal DasNo ratings yet

- Chapter 1 - Automotive Batteries ConstructionDocument62 pagesChapter 1 - Automotive Batteries ConstructionMsaiful MiyoshiNo ratings yet

- Wahlco Aqueous Ammonia Systems For Denox ApplicationsDocument4 pagesWahlco Aqueous Ammonia Systems For Denox ApplicationsObed IrwantoNo ratings yet

- Master Flow 648Document4 pagesMaster Flow 648gazwang478No ratings yet

- Acta Mechanica JournalDocument10 pagesActa Mechanica JournalVikram C KNo ratings yet

- TP 2000 210186Document26 pagesTP 2000 210186Anthony SimonaitisNo ratings yet

- Science 10 Q4 SLM5Document14 pagesScience 10 Q4 SLM5Kennedy Fieldad Vagay80% (5)

- Icsm2010 BookDocument827 pagesIcsm2010 Bookicsm2010100% (1)

- Cambridge IGCSE Chemistry Topic 7: Chemical ReactionsDocument3 pagesCambridge IGCSE Chemistry Topic 7: Chemical ReactionsayaanNo ratings yet

- (BS 1016-106.4.1-1993) - Methods For Analysis and Testing of Coal and Coke. Ultimate Analysis of Coal and Coke. Determination of Total Sulfur Content. Eschka Method PDFDocument14 pages(BS 1016-106.4.1-1993) - Methods For Analysis and Testing of Coal and Coke. Ultimate Analysis of Coal and Coke. Determination of Total Sulfur Content. Eschka Method PDFaufal Riswan100% (2)

- CTAB DNA ExtractionDocument2 pagesCTAB DNA ExtractionHumam-bmNo ratings yet