Professional Documents

Culture Documents

US9199855-Chemical Treatment To Improve Red Mud Separation and Washing in The Bayer Process

US9199855-Chemical Treatment To Improve Red Mud Separation and Washing in The Bayer Process

Uploaded by

Galih Dyah0 ratings0% found this document useful (0 votes)

20 views7 pagesThis patent describes a method for improving the separation of red mud from Bayer process liquor. The method involves adding both a flocculant and a cross-linked polysaccharide to the liquor. This combination allows for dense amounts of red mud to form but prevents it from becoming too thick, allowing for high recovery rates of alumina and caustic from the red mud while still enabling easy handling.

Original Description:

Chemical Treatment to Improve Red Mud Separation

Original Title

US9199855-Chemical Treatment to Improve Red Mud Separation and Washing in the bayer process

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a method for improving the separation of red mud from Bayer process liquor. The method involves adding both a flocculant and a cross-linked polysaccharide to the liquor. This combination allows for dense amounts of red mud to form but prevents it from becoming too thick, allowing for high recovery rates of alumina and caustic from the red mud while still enabling easy handling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

20 views7 pagesUS9199855-Chemical Treatment To Improve Red Mud Separation and Washing in The Bayer Process

US9199855-Chemical Treatment To Improve Red Mud Separation and Washing in The Bayer Process

Uploaded by

Galih DyahThis patent describes a method for improving the separation of red mud from Bayer process liquor. The method involves adding both a flocculant and a cross-linked polysaccharide to the liquor. This combination allows for dense amounts of red mud to form but prevents it from becoming too thick, allowing for high recovery rates of alumina and caustic from the red mud while still enabling easy handling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

US009 199855B2

(12) United States Patent (10) Patent No.: US 9,199,855 B2

Urbani et al. (45) Date of Patent: *Dec. 1, 2015

(54) CHEMICAL TREATMENT TO IMPROVE RED 5,049,612 A 9, 1991 Bulatovic

MUD SEPARATION AND WASHING IN THE 5,091,159 A 3. 1992 Connelly et al.

BAYER PROCESS 33-3A Si Sioneyeat.

5,346,628 A 9, 1994 Sommese et al.

(71) Applicant: NALCO COMPANY, Naperville, IL 5,387.405 A 2/1995 Connelly et al.

(US) 5,478.477 A 12/1995 Ramesh et al.

5,534,235 A 7, 1996 Reed et al.

(72) Inventors: Carl Urbani. Forrestfield (AU); John D 3. 39 A

w--

3.E. Sing: t al.

WOS 3.

Kildea, Baldivis (AU): Ryan Chester, 6,033,579 A 3/2000 Riemer et al.

Heathrisge (AU); Jing Wang, Aurora, IL 6,048,463 A 4/2000 Selvarajan et al.

(US) 6,365,116 B1 4/2002 Barham et al.

6,605,674 B1 8/2003 Whipple et al.

(73) Assignee: Nalco Company, Naperville, IL (US) 6,726,845 B1 4/2004 Barham et al.

6,740,249 B1 5, 2004 Barham

(*) Notice: Subject to any disclaimer, the term of this so R: 39. SE" et al.

patent is extended or adjusted under 35 2007,0173405. A 7/2007 Liu

U.S.C. 154(b) by 209 days. 2008/0107578 A1 5/2008 Wang et al.

2008/0257827 A1 10, 2008 Dai et al.

This patent is Subject to a terminal dis- 2012.0034142 A1 2, 2012 WA et al.

claimer.

FOREIGN PATENT DOCUMENTS

(21) Appl. No.: 13/729,744

AU 5310690 A 10, 1990

(22) Filed: Dec. 28, 2012 AU T37191 B2 8, 2001

WO WO97-41064 A1 11, 1997

O O WO WO992962.6 A1 6, 1999

(65) Prior Publication Data WO WO2009085514 A2 7, 2009

US 2013/01 12627 A1 May 9, 2013 WO WO2O1203131.6 A1 3f2012

OTHER PUBLICATIONS

Related U.S. Application Data

(63) Continuation-in-part of application No. 13/662.964, B.J Gladman

2006 p et al., “Understanding

inderstanding the

une Thickening

1 nickening PProcess Past

Faste

filed on Oct. 29, 2012, which is a continuation-in-part Step change improvements in underflow rheology by Berger A. et al.,

of application No. 12/852.910, filed on Aug. 9, 2010, Proceedings of the 14th International Seminar on Paste and Thick

now Pat. No. 8,298,508. ened Tailings, pp. 135-141 (2011).

Effect off Surfactants

Surf on Bauxite Residues Suspensions

S ions Vi ity by

Viscosity b

(51) Int. Cl. Frost, R. etal, Colloids and Surfaces A: Physicochemical and Engi

neering Aspects, 292(1), pp. 21-26 (2007).

BOID 37/03 (2006.01) Kapusniak, Janusz et al., “Starch Based Depressors for Selective

Ot iW: 3:08: Flotation of Metal Sulfide Ores.” Starch, vol. 51, No. 11-12, 2000, pp.

416-421.

COIF 7/4 (2006.01) Termes, S.C. et al., “Insoluble crosslinked starch Xanthate as a selec

COIF 7/06 (2006.01) tive flocculant for sulfide minerals.” Transactions of the American

COIF 7/47 (2006.01) Institute of Mining, Metallurgical, and Petroleum Engineers, Society

(52) U.S. Cl of Mining Engineers of AIME, vol. 274, 1983, pp. 1971-1977.

CPC .............. COIF 7/0653 (2013.01); B0ID 21/01 * cited b

(2013.01); B0ID 37/03 (2013.01); B01D 37/04 c1ted by examiner

(2013.01); COIF 7/145 (2013.01); COIF 7/148 Primary Examiner — Anthony J Zimmer

(58) Field of Classificati Sh COIF 7/47 (2013.01)

OSSO Sea

Assistant Examiner — Justin Bova

74). Att

CPC ........ SSSI so pop soo (74) Attorney, Agent,

Agent, oror Firm

Firm — B

Benjamin Carl

Carlsen

B01D 67/0006; B01D 69/125; COIF 7/148 (57) ABSTRACT

See application file for complete search history.

The invention provides methods and compositions for

(56) References Cited improving the rheology of red mud removed from Bayer

Process liquor. The method includes adding a flocculant and

U.S. PATENT DOCUMENTS a cross-linked polysaccharide to the liquor. This combination

3,085,853. A 4, 1963 Lesinski et al.

separates the red mud from the liquor but also prevents the red

3,397.953 A 8, 1968 Galvin et al. mud from becoming toothick. By preventing excessive thick

3,445,187 A 5, 1969 Siebert ness, the method allows for the formation of extremely dense

3,541,009 A 11, 1970 Arendt et al. amounts of red mud even in primary settlers because the

3,681,012 A 8, 1972 Siebert et al. dense red mud can still flow. As a result a user can simulta

4,339,331 A 7, 1982 Lim neously enjoy both easy handling of red mud and also high

4,478,795 A 10, 1984 Hereda et al.

4,737,352 A 4, 1988 Owen recovery rates of valuable alumina and caustic from the red

4,767,540 A 8/1988 Spitzer et al. mud.

5,008,089 A 4/1991 Moody et al.

5,041,269 A 8/1991 Moody et al. 10 Claims, No Drawings

US 9,199,855 B2

1. 2

CHEMICAL TREATMENT TO IMPROVE RED this section should not be construed to mean that a search has

MUD SEPARATION AND WASHING IN THE been made or that no other pertinent information as defined in

BAYER PROCESS 37 CFRS1.56(a) exists.

CROSS-REFERENCE TO RELATED BRIEF SUMMARY OF THE INVENTION

APPLICATIONS

At least one embodiment of the invention is directed

This application is a continuation in part of co-pending towards improving the process of separating and washing

U.S. patent application Ser. No. 13/662.964 filed on Oct. 29, insoluble red mud solids in the Bayer process by addition of

2012 which in turn is a continuation in part of U.S. patent 10 cross-linked polysaccharides in combination with flocculants

application Ser. No. 12/852.91.0 filed on Aug. 9, 2010 and in the primary settling and washing stages of the process.

which has issued as U.S. Pat. No. 8,298,508.

DETAILED DESCRIPTION OF THE INVENTION

STATEMENT REGARDING FEDERALLY

SPONSORED RESEARCH ORDEVELOPMENT 15 The following definitions are provided to determine how

terms used in this application, and in particular how the

Not Applicable. claims, are to be construed. The organization of the defini

tions is for convenience only and is not intended to limit any

BACKGROUND OF THE INVENTION of the definitions to any particular category.

“Clarifier” means a separation device used for red mud

The invention relates to compositions, methods, and appa clarification including: a thickener, a settler, or a washer.

ratuses for improving the performance of primary settlers and “Consisting Essentially of means that the methods and

washer circuits for red mud in a Bayer Process. As described compositions may include additional steps, components,

for example in U.S. Pat. Nos. 6,814,873, 6,033,579, 6,048, ingredients or the like, but only if the additional steps, com

463, and US Published Patent Application 2008/0257827, in 25 ponents and/or ingredients do not materially alter the basic

the Bayer Process alumina trihydrate is extracted from baux and novel characteristics of the claimed methods and compo

ite ore. Bauxite ore is pulverized then goes through a diges sitions.

tion stage (where it is slurried in a caustic liquor medium and “Dextran” is a polysaccharide characterized as being an

is heated under pressure), a clarification stage, a precipitation C-D-1,6 glucose-linked glucan with side chains 1-3 linked to

stage, a classification stage, and finally a calcination stage 30 the backbone units of the polysaccharide.

from which the final product is recovered. “Distal' is the opposite of “Proximal’ and means subse

In the clarification stage red mud is separated from the quent to a particular step in a sequential process.

alumina in the ore. Red mud is the large percentage of the ore “Flocculant’ means a composition of matter which when

that remains insoluble after digestion with caustic medium. added to a liquid containing finely divided Suspended par

This insoluble traction must be removed prior to the alumina 35 ticles, destabilizes and aggregates the Solids through the

trihydrate recovery step in the process so as to avoid contami mechanism of interparticle bridging, it may have a low charge

nating the final Bayer Process product. The digestion slurry density and/or may have a high molecular weight (in excess of

consists of finely Suspended mud particles which are com 1,000,000).

monly removed by the addition of flocculants in large sepa “Green Liquor means the alumina containing liquor that

ration vessels called thickeners or settlers. The flocculantacts 40 has passed through a Security Filtration stage and no longer

to bind the mud particles increasing their rate of settling in the contains red mud.

thickener. The overflow liquor then typically reports to filters, "Liquor or “Bayer liquor means a caustic, liquid medium

often referred to as Security Filtration, to remove any remain that has run through a Bayer process in an industrial facility.

ing insoluble material prior to alumina trihydrate recovery. “Polysaccharide' means a polymeric carbohydrate having

The red mud slurry from the thickener underflow contains 45 a plurality of repeating units comprised of simple Sugars, the

valuable alumina and caustic in Solution that is recovered in C O—C linkage formed between two such joined simple

the Red Mud Washer Circuit otherwise known as a counter Sugar units in a polysaccharide chain is called a glycosidic

current decantation (CCD) circuit. Over several stages, mud linkage, and continued condensation of monosaccharide

slurry is mixed with progressively more dilute (lower in valu units will result in polysaccharides, common polysaccharides

able alumina and caustic) wash water. The advancing wash 50 are amylase and cellulose, both made up of glucose mono

water progressively increases in caustic and alumina content mers, polysaccharides can have a straight chain or branched

as it recovers the valuables from the mud slurry, then ulti polymer backbone including one or more Sugar monomers,

mately exits as a dilution stream for use back into the process common Sugar monomers in polysaccharides include glu

at an appropriate point. The resulting red mud is sent to cose, galactose, arabinose, mannose, fructose, rahmnose, and

disposal. Some examples of red mud clarification are 55 Xylose.

described in U.S. Pat. Nos. 3,085,853, 3,397,953, 3,445,187, “Primary Settler Feed' means Bayer process digested

3,541,009, 3,681,012, 4,767,540, and 5,008,089. slurry as charged to the first Solids/liquid separation stage, it

Because of the cost associated with each additional filtra may be an admixture of the digested slurry plus dilution

tion and dilution step, large savings and efficiencies can be liquor, and the dilution liquor is routinely the counter current

realized from reducing the number or intensity of the required 60 technique wash water from the red mud washing stages, the

filtration and dilution steps. As a result, there is clear utility in primary settler feed differs from the liquors or slurries sub

novel methods of more effectively flocculating and separat jected to clarification and/or separation in the Subsequent

ing red mud from the red mud-containing liquors. clarification stage or the red mud washing stages by compo

The art described in this section is not intended to consti sition as to the Solids content, dissolved sodium alum mate

tute an admission that any patent, publication or other infor 65 content, and total alkalinity, in addition, the primary settler

mation referred to herein is “prior art” with respect to this feed also differs from the liquors or slurries subjected to

invention, unless specifically designated as such. In addition, clarification and/or separation in the Subsequent clarification

US 9,199,855 B2

3 4

stage or the red mud washing stages in that no insoluble yield stress of the slurry will also increase and consequently

fraction thereofhas received an earlier flocculation treatment. this reduces the ability of the underflow to actually flow

“Proximal' is the opposite of “Distal and means prior to a through the equipment used in the clarification process. As a

particular step in a sequential process. result, in practice the underflow density must be kept below a

"RedMud' means the insoluble solid material which is a degree of thickness even though this means that valuable

residual product from the Bayer liquor that does not freely alumina and caustic remain within the underflow. This is a

dissolve during the digestion stage, or which precipitates as costly practice which reduces the amount of actual alumina

part of the digestion process. Red mud can comprise ferric that can be recovered from a given sample of ore to an amount

oxide (from which the mud typically derives its red-brown significantly below its theoretical yield.

color), alumina, silica, Silicon oxide, calcium oxide, sodium 10 Additionally, by reducing the level of suspended solids that

alumino-silicates, and/or titanium oxides (depending on the remain in the supernatant above the flocculated slurry formed

specific compositions of the ore input into the Bayer process) in the primary settler liquor, the Solids to be removed during

as well as caustic and other materials from the digestion the subsequent clarification of the overflow by filtration are

liquor that may be part of the liquid phase of the Bayer diminished.

process red mud slurry. 15 In at least one embodiment the method alters the rheology

“Rheology’ means the interrelatedness of the flow rate and (viscosity, elasticity, and/or plasticity) of the underflow that

the elastic, viscousand/or plastic properties offlowing matter. passes through washer(s) and/or settler(s) such that the under

"Slurry' means a mixture comprising a liquid medium flow has properties that would otherwise be associated with

within which fine solid particles are dispersed or suspended. an underflow slurry of lower solids density. This allows

"Thickener” or “Settler” means a vessel used to effect a operators to increase the underflow density in one, Some, or

solid-liquid separation of a slurry, often with the addition of all of the vessels of the circuit, resulting in better extraction

flocculants, the vessel constructed and arranged to receive a efficiency of alumina and caustic and increased throughput.

slurry, retain the slimy for a period of time sufficient to allow In at least one embodiment the underflow passing through

solid portions of the slurry to settle downward (underflow) at least a portion of the circuit has a density so high that for the

away from a more liquid portion of the slurry (overflow), 25 method, it would not be capable of passing through the wash

decant the overflow, and remove the underflow. Thickener er(s) and/or settler(s) or would only be able to do so with the

underflow and thickener overflow are often passed on to fil input of a significant amount of energy, effort, and/or cost.

ters to further separate solids from liquids. Suitable flocculants generally have molecular weights in

“Washer means a vessel used to effect a solid-liquid sepa excess of 1,000,000 and often in excess of 5,000,000. The

ration of red mud from liquid by utilizing counter current, 30 flocculants may be anionic, cationic and/or Zwitterionic. The

decantation separating the material into an underflow (a dose of flocculant depends on the properties of the slurry

highly concentrated suspension typically at the bottom of the being treated and can be empirically determined by one of

washer), and an overflow (a clarified liquid stream typically at skill in the art. In general, the flocculant polymer dose

the top of the equipment), the liquid used to effect the counter required depends on both the nature of the feed slurry (settler

current may be water, liquor a mixture of water and liquor or 35 or washer) and the type offlocculant used. However, typically

overflow from elsewhere in the Bayer Process. dose rates are generally within the range of 10-500 g/T based

In the event, that the above definitions or a description on polymer Solids, per ton of red mud and more preferably

stated elsewhere in this application is inconsistent with a 30-400 g/T.

meaning (explicit or implicit) which is commonly used, in a In at least one embodiment the flocculant is selected from

dictionary, or stated in a source incorporated by reference into 40 the group consisting of: (i) homopolymers of acrylic acid, (ii)

this application, the application and the claim terms in par copolymers of acrylic acid and acrylamide, (iii) copolymers

ticular are understood to be construed according to the defi of acrylic acid and acrylamide modified to contain a hydrox

nition or description in this application, and not according to amic acid moiety; and (iv) copolymers of acrylic acid and

the common definition, dictionary definition, or the definition acrylamide modified to contain and comprise ammonium

that was incorporated by reference. In light of the above, in 45 acrylate. In at least one embodiment the flocculant has a

the event that a term can only be understood if it is construed molecular weight greater than 10 million.

by a dictionary, if the term is defined by the Kirk-Othmer Similarly, while anionic polymer flocculants may be

Encyclopedia of Chemical Technology, 5th Edition, (2005), formed using anionic monomers, it is also possible to modify

(Published by Wiley, John & Sons, Inc.) this definition shall certain nonionic vinyl addition polymers to form anionically

control how the term is to be defined in the claims. 50 charged polymers. Polymers of this type include, for

At least one embodiment of the invention is directed example, those prepared by the hydrolysis of polyacrylamide.

towards a method of treating Bayer Process red mud slurry to The flocculant may be prepared in the solid form, as an

enhance the recovery of caustic and alumina. The treatment aqueous solution, as a water-in-oil emulsion, or as a disper

can occur in settlers and In washer circuits. The method sion in water. Representative anionic polymers include

comprises contacting primary settler feed or washer feed 55 copolymers of acrylamide with sodium acrylate and/or

slurry with a flocculant in combination with a modified 2-acryiamido 2-methylpropane sulfonic acid (AMPS) or an

polysaccharide. The method modulates the theology of thick acrylamide homopolymer that has been hydrolyzed to con

ened red mud allowing higher underflow densities to be tar Vert a portion of the acrylamide groups to acrylic acid.

geted in each vessel of the Wash Circuit or in the primary In at least one embodiment the polysaccharide is cross

settlers. 60 linked. The cross linking may beachieved with a crosslinking

Red mud slurry flow in the clarification stage suffers from agent. In at least one embodiment the cross-linking is accom

a number of contradictory properties. Ideally the underflow of plished by an the interaction with a cross linking agent on an

a settler or washer should have a very high density. Such a ethylenically unsaturated monomer either containing at least

high density results from highly effective removal of soluble two sites of ethylenic unsaturation or containing one site of

caustic and alumina from the red mud underflow, so effective 65 ethylenic unsaturation and one site of a reactive group Such as

in fact that the red mud comprises only insoluble materials. an epoxide or an aldehyde. Representative Cross-Linking

However as solids density in the underflow increases, the Agents include N,N-methylenebisacrylamide, N.N-methyl

US 9,199,855 B2

5 6

enebismethacrylamide, polyethylene glycol diacrylate, eth latex flocculant and a 13% solution of a modified (cross

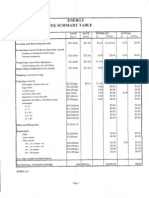

ylene glycol dimethacrylate, diethylene glycol dimethacry linked) polysaccharide. In this case the modified polysaccha

late, triethylene glycol dimethacrylate, polyethylene glycol ride was dextran. Table 1 details the overflow solids for red

dimethacrylate, polypropylene glycol dimethacrylate, N-vi mud slurry flocculated with (i) anionic flocculant and (ii) a

nyl acrylamide, divinyl benzene, triallyl ammonium salts, combination of anionic flocculant and the cross-linked

N-methyl allylacrylamide, glycidyl acrylate, acrolein, polysaccharide. Addition of modified polysaccharide to the

methylolacrylamide, glyoxal, epihalohydrins, dialdehydes

diglycidyl ethers, and the like, and any combination thereof. slurry, at a dose rate in the order of 30 ppm, resulted in

In at least one embodiment the crosslinking agent is added to approximately 50% reduction in overflow solids. A substan

the cross-linked polymers at a dosage of from about 0.0001 to tial reduction in overflow solids was achieved over the floc

10

about 10, preferably from about 0.0001 to about 0.2 weight culant dose range of 40-130 g/T.

percent based on the weight of the polymers.

In at least one embodiment, upon flocculation of a primary TABLE 1

settler feed, a clear liquor/mud interface will form, and will

gradually settle, providing a clear liquor Supernatant layer Overflow solids measured from red mud settling tests

overlying a mud layer. The lower mud layer contains the 15 using a standard anionic flocculant with and without

flocculated material. The overlying Supernatant is the liquor additional treatment with modified polysaccharide.

that is separated for Subsequent filtration and contains only a Dose Anionic Flocc Dose MPS Overflow Solids

minimal amount of mud Solids. The invention diminishes the Treatment (gT) (ppm active) (gL)

amount of Suspended solids in Such Supernatant, and hence AF 43 O 1.28

decreases the extent of filtration required to obtain a given AF - MPS 43 3.6 O.S4

purity of sodium aluminate Solution. AF 85 O 1.19

In at least one embodiment, the solids captured by the AF - MPS 85 4.2 O45

combination of the flocculant and modified polysaccharide AF

AF - MPS

128

128

O

4.4

O.71

0.44

contain more of the minerals and solids comprised of silica

and potassium Such that the Solids reporting to the overflow of 25 AF = Anionic Flocculant

the clarifier contain a lower amount of Such materials, result MPS = Modified polysaccharide (cross-linked dextran)

ing in selective flocculation and settling of Such materials.

In at least one embodiment, the polymeric flocculant and

the polysaccharide are both added to the primary settler feed Example 2

as aqueous solutions to facilitate rapid dispersion of each 30

agent within the primary settler feed. The method of application of the modified polysaccharide

In at least one embodiment the method Is conducted was assessed by addition of a modified polysaccharide prior

according to and/or in conjunction with some or all of one or to, with or after the flocculant addition. The anionic flocculant

more of the: compositions, apparatuses, and methods used in and modified polysaccharide were the same as those used in

the Bayer Process described in one or more of U.S. Pat. Nos. 35

example 1 as was the test method. Slurry used was again plant

6,365,116, 6,726,845, 5,217,620, 5,478,477, 5,387,405, settler feed, Table 2 details the overflow solids when the

International Patent Application WO99/29626, and scientific modified polysaccharide was pre-dosed, and co-dosed with

papers: Step change improvements in underflow rheology by the anionic flocculant in one set of tests and when it was

Berger A. et al., Proceedings of the 14" International Seminar co-dosed and post-dosed with the anionic flocculant in a

on Paste and Thickened Tailings, pp. 135-141 (2011), and second set of tests. The modified polysaccharide was effec

40

Effect of Surfactants on Bauxite Residues Suspensions Vis tive in all methods of application, reducing the overflow sol

cosity by Frost, R, et al. Colloids and Surfaces A: Physico ids when compared to the same dose of anionic flocculant

chemical and Engineering Aspects, 292(1), pp. 21-26 (2007). applied without additional modified polysaccharide.

EXAMPLES

45

TABLE 2

The foregoing may be better understood by reference to the Overflow data from settling tests comparing the method

following examples, which are presented for purposes of of application of a modified polysaccharide when

illustration and are not intended to limit the scope of the applied with a conventional anionic flocculant.

invention. Dose Anionic Flocc Dose MPS MPS added relative Overflow

Red mud settling tests were performed in order to evaluate 50 (gT) (ppm active) to flocculant Solids (g/L)

the effect on liquor overflow clarity and settling rate with and 73 O O.63

without addition of a cross-linked polysaccharide to a stan 73 5.7 Pre-dose O.29

dard anionic flocculant treatment. These tests involved mix 73 5.7 Co-dose O.31

ing a known amount of flocculant solution (and polysaccha 73 O O.69

ride where appropriate) into a cylinder containing Bayer 55 73

73

5.7

5.7

Post-dose

Co-dose

O.32

0.37

process red mud slurry. After mixing, the cylinders were left

to settle and after a given period of time the liquor at the

surface of the cylinder was sampled, filtered and the filtered

residue weighed. The clarity of the liquor is described in Example 3

terms of overflow solids with units of gram per litre (essen 60

tially the lower the overflow solids the more effective the The use of polysaccharides Such as dextran has previously

chemical treatment strategy). been identified and used in combination with anionic floccu

lants as a clarity aid in red mud settlers (as described, for

Example 1 example, in U.S. Pat. No. 3,085,853). Red mud settling tests,

65 as described above, were conducted to assess the relative

Samples of plant settler feed slurry were treated using a efficacy of a modified (cross-linked) polysaccharide com

0.1% solution of a commercially available 100% anionic pared to the same unmodified polysaccharide. The anionic

US 9,199,855 B2

7 8

flocculant and modified polysaccharide were the same as TABLE 5

those used in example 1. The modified and unmodified

polysaccharide solutionsS contained the same amount of Concentration of product (expressed as ppm

or ng of analyte per litre of overflow

polysaccharide in each treatment. Table 3 details the overflow

solids of red mud treated with a combination of (i) anionic % Reduction in

flocculant and cross-linked dextran and (ii) anionic flocculant component from

MPS treatment

with dextran. In this example a commercially available, 100% Flocc Flocc + Flocc + Flocc + (3.5 ppm) vs

anionic flocculant was again used but it was a different prod treatment MPS MPS MPS Flocc Only

uct to that used in examples 1 and 2. Analyte only (1 ppm) (2 ppm) (3.5 ppm) treatment (%)

10

Fe2O3 39.3 31.4 25.4 19.4 SO.6

TABLE 3 KO 2.69 1.75 1.28 O.81 69.9

SiO2 18.6 12.5 9.7 5.8 68.8

Overflow solids from red mud testing with modified CaO 1.34 1.08 O.90 0.73 45.5

polysaccharide and unmodified polysaccharide TiO2 5.65 4.70 3.89 3.09 45.4

combinations with anionic flocculant. 15

Anionic Polysaccharide

Red Mud Treatment Flocculant Dose (ppm Overflow Example 5

Regime Dose (gT) active) Solids (g/L)

Anionic Flocculant 75 O O43 Raked settling tests conducted in an Imhoff cone were

Anionic Flocculant + 75 O.60 O.34 performed to evaluate the effect of a flocculant/modified

Polysaccharide 120 O.33

Anionic Flocculant + 75 O.78 O.31 polysaccharide combination on the flow characteristics and

Modified 1.56 O.29 rheology of flocculated red mud. These tests involved mixing

Polysaccharide one litre of Bayer plant final washer feed red mud slurry

25

together with a known amount of conventional flocculant

Solution and modified polysaccharide solution in a cylinder.

The data demonstrates that addition of modified polysaccha After mixing, the slurry was Immediately transferred to an

ride is Surprisingly more effective at reducing overflow solids Imhoff cone and the slurry was then raked to a specific mud

compared with the use of unmodified polysaccharide. bed volume (bed underflow density was calculated from the

30

bed volume and known feed solids concentration). The

Example 4 Imhoff cone plug was then released and the time takentor the

thickened slurry to discharge from the cone was measured.

The time required for discharge of the entire slurry is a mea

Analysis of the Solids obtained from settling tests con sure of mud flow-ability (or rheology). This discharge time

ducted as described in the previous examples was completed was compared with feed slurry treated with flocculant alone

35

to determine the nature of the solids removed by the applica (the normal process for the settler and washer circuit). The

tion of modified polysaccharide. Red mud settling tests were faster the discharge rate the better the mud underflow rheol

completed using a combination of commercially available ogy and ultimately properties for pumping from the thickener

underflow.

hydroxamated anionic flocculant both with and without addi Table 6 details the average discharge rate of the thickened

tional application of a cross linked polysaccharide. The treat 40 red mud slurry from the raked Imhoff cone after treatment

ment and overflow solids obtained is listed in table 4.

with flocculant and after treatment with the combination of

TABLE 4 flocculant and modified polysaccharide. The flocculant dose

was kept constant at 100 g/T while the dose of modified

Overflow solids from red mud settling tests using a hydroxamated polysaccharide (when applied) was 3.75 ppm. In this case, the

anionic flocculant and modified polysaccharide. 45 modified polysaccharide used was a cross-linked dextran.

Dose Anionic Flocculant Dose MPS Overflow Solids

The flocculant used was a conventional polyacrylate/poly

(gT) (ppm active) (mg/L) acrylamide flocculant commercially available and typically

used for red mud settling in washers.

150 O 112

150 1 72

150 2 62

50 TABLE 6

150 3.5 45

Average time taken to discharge consolidated red mud

slurry from an Imhoff cone across a range of average

bed underflow densities. Flocculant dose was constant

Additionally, samples of the overflow solids were collected, at 100 g/T. Polysaccharide dose was 3.75 ppm.

dried and Subjected to X-ray fluorescence spectroscopy 55

(XRF) to determine the elemental components present in the Average Underflow Average

Treatment Density Discharge Time Discharge

overflow. Table 5 shows the amount and relative change in a Regime (g/100 mL) Recorded (sec) Rate (mL/sec)

range of elements analyzed in the treated Samples. Surpris

ingly treatment with the cross-linked polysaccharide results Flocculant 2O.O 10 100

21.3 60 17

in significantly less silica and potassium containing materials 60

21.4 >300 O

reporting in the overflow solids. When compared to the reduc 22.9 >300 O

tion in the relative amounts of other elements such as iron, 2S.O >300 O

34.O >300 O

titanium and calcium, there is a lot less silica and potassium in Flocculant + 21.3 10 100

the treated samples. This indicates that the modified polysac Modified 22.5 10 100

charide is selective in removing insoluble minerals which 65 Polysaccharide 2S.O 10 100

may be high in silica and potassium content. Examples of

Such minerals would be muscovite or mica.

US 9,199,855 B2

10

Raking of slurry treated with conventional flocculant to an All ranges and parameters disclosed herein are understood

average underflow density of greater than 21%, resulted In to encompass any and all Subranges Subsumed therein, and

effectively no flow when the plug was removed. Effectively every number between the endpoints. For example, a stated

the slurry did not discharge from the Imhoff cone due to the range of 1 to 10 should be considered to include any and all

poor flow characteristics of the raked, consolidated mud at the Subranges between (and inclusive of) the minimum value of 1

base of the cone. and the maximum value of 10; that is, all Subranges beginning

This was compared to the results obtained after raking with a minimum value of 1 or more, (e.g. 1 to 6.1), and ending

with a maximum value of 10 or less, (e.g. 2.3 to 9.4, 3 to 8, 4

slurry that was treated with the same dose of conventional to 7), and finally to each number 1, 2,3,4,5,6,7,8,9, and 10

flocculant together with modified polysaccharide (3.75 ppm). 10 contained within the range. All percentages, ratios and pro

Across a similar range of high average underflow densities, portions herein are by weight unless otherwise specified.

slurry discharged from the cone without restriction (~100 This completes the description of the preferred and alter

mL/sec). This is a significant increase in the flow properties of nate embodiments of the invention, Those skilled in the art

the red mud when compared to the control test (flocculant may recognize other equivalents to the specific embodiment

only treatment). 15

described herein which equivalents are intended to be encom

In a separate test mud was treated in a similar manner (the passed by the claims attached hereto.

The invention claimed is:

same flocculant at the same dose) but the modified polysac 1. A method of treating a Bayer Process slurry containing

charide dose was reduced to 0.75 ppm, When consolidated to comprising liquor and red mud, the method comprising: (a)

an average underflow density of 23.8/100 mL a discharge adding to the slurry a flocculant and a cross-linked polysac

time of 19 seconds was recorded (average discharge rate of 53

ml/sec). Comparing this to the data from Table 1, consolida charide and (b) removing flocculated red mud contained in

tion of mud to this concentration without addition of modified the slurry by at least one of sedimentation, centrifugation,

polysaccharide would be expected to result in no flow, while filtration, washing, and settling.

a higher dose of modified polysaccharide (3.75) clearly 2. The method of claim 1, wherein the cross-linked

results in substantially higher flow rates. 25

polysaccharide is added to the slurry prior to the addition of

The results of these tests indicate that addition of flocculant the flocculant to the slurry.

and polysaccharide in combination to a red mud washer cir 3. The method of claim 1, wherein the cross-linked

cuit or primary settler would enable the targeted underflow polysaccharide is added to the slurry after the addition of the

density to be substantially increased while fluid characteris flocculant to the slurry.

tics of the underflow solids could be maintained or enhanced. 30

4. The method of claim 1, wherein the cross-linked

While this invention may be embodied in many different polysaccharide is added to the slurry at the same time as the

forms, there are described in detail herein specific preferred addition of the flocculant to the slurry.

embodiments of the invention. The present disclosure is an 5. The method of claim 1, wherein the flocculant red mud

exemplification of the principles of the invention and is not is removed by at least one of a primary settler and a red mud

washer.

intended to limit the invention to the particular embodiments 35

6. The method of claim 1, wherein the flocculant is selected

illustrated. All patents, patent applications, scientific papers, from the group consisting of: (i) homopolymers of acrylic

and any other referenced materials mentioned herein are acid, (ii) copolymers of acrylic acid and acrylamide, (iii)

incorporated by reference in their entirety. Furthermore, the copolymers of acrylic acid and acrylamide modified to con

invention encompasses any possible combination of some or tain a hydroxamic acid moiety, (iv) copolymers of acrylic acid

all of the various embodiments described herein and/or incor 40

porated herein. In addition the invention encompasses any and acrylamide modified to contain an ammonium acrylate,

possible combination that also specifically excludes any one and (v) combinations thereof.

or some of the various embodiments described herein and/or 7. The method of claim 1, wherein the cross-linked

incorporated herein. polysaccharide comprises two or more different types of

The above disclosure is intended to be illustrative and not polysaccharide polymers.

45

exhaustive. This description will suggest many variations and 8. The method of claim 1, wherein the cross-linked

alternatives to one of ordinary skill in this art. All these polysaccharide is cross-linked dextran.

alternatives and variations are intended to be included within 9. The method of claim 1, wherein the flocculant has a

the scope of the claims where the term "comprising” means molecular weight of greater than 10 million daltons.

“including, but not limited to’. Those familiar with the art 50

10. The method of claim 1, further comprising raking the

may recognize other equivalents to the specific embodiments slurry after the addition of the flocculant and a cross-linked

described herein which equivalents are also intended to be polysaccharide.

encompassed by the claims.

UNITED STATES PATENT AND TRADEMARK OFFICE

CERTIFICATE OF CORRECTION

PATENT NO. : 9,199,855 B2 Page 1 of 1

APPLICATION NO. 13/729744

DATED : December 1, 2015

INVENTOR(S) : Carl Urbani et al.

It is certified that error appears in the above-identified patent and that said Letters Patent is hereby corrected as shown below:

In the Claims - Col 10 line 17 - “A method of treating a Bayer Process slurry containing

comprising... should read “A method of treating a Bayer Process slurry comprising...’

Signed and Sealed this

Eighth Day of November, 2016

74-4-04- 2% 4 Michelle K. Lee

Director of the United States Patent and Trademark Office

You might also like

- Ipc J-Std-030a-2014Document48 pagesIpc J-Std-030a-2014vahid hajihasaniNo ratings yet

- Movie Recommendation SystemDocument41 pagesMovie Recommendation SystemSowmya Srinivasan100% (3)

- The Challenges of Managerial Accounting 2Document5 pagesThe Challenges of Managerial Accounting 2therhine100% (2)

- United States Patent (10) Patent No.: US 9,302,974 B1Document11 pagesUnited States Patent (10) Patent No.: US 9,302,974 B1masood kblNo ratings yet

- United States Patent (10) Patent No.: US 8,803,766 B2Document20 pagesUnited States Patent (10) Patent No.: US 8,803,766 B2Roberto AbregoNo ratings yet

- United States Patent (10) Patent No.: US 8,096,525 B2Document26 pagesUnited States Patent (10) Patent No.: US 8,096,525 B2ismail hakkıNo ratings yet

- Floor Dust Cleaner 2Document25 pagesFloor Dust Cleaner 2topguitarNo ratings yet

- US8357795Document24 pagesUS8357795Rhelvis1No ratings yet

- Us9598594 PDFDocument16 pagesUs9598594 PDFAPEX SONNo ratings yet

- Fast Demould Extended Cream Time Pu Formulations US8618014Document9 pagesFast Demould Extended Cream Time Pu Formulations US8618014Gagan JainNo ratings yet

- Cleaning of Packed ColumnDocument4 pagesCleaning of Packed ColumnDipesh ParekhNo ratings yet

- US8721984Document17 pagesUS8721984Hangzhou Zhu Tai Trading Co.,LtdNo ratings yet

- Film ExtrusionDocument16 pagesFilm ExtrusionhatharasingheNo ratings yet

- US7380220Document62 pagesUS7380220Bonn QianNo ratings yet

- United States Patent (10) Patent No.: US 8,822,176 B2Document93 pagesUnited States Patent (10) Patent No.: US 8,822,176 B2M FNo ratings yet

- United States Patent (10) Patent No.: US 7473.462 B2: Coggio Et Al. (45) Date of Patent: Jan. 6, 2009Document14 pagesUnited States Patent (10) Patent No.: US 7473.462 B2: Coggio Et Al. (45) Date of Patent: Jan. 6, 2009AtulNo ratings yet

- United States Patent2019 - Isotachophoresis For Purification of Nucleic AcidsDocument102 pagesUnited States Patent2019 - Isotachophoresis For Purification of Nucleic AcidsHassan AbdelmoamenNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument19 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentUmar OmarNo ratings yet

- US8663494Document21 pagesUS8663494nhbhrdwj7_881625693No ratings yet

- United States Patent (10) Patent No.: US 9.273,221 B2Document6 pagesUnited States Patent (10) Patent No.: US 9.273,221 B2Sameer AhmedNo ratings yet

- US9415270Document14 pagesUS9415270sagnik ghoshNo ratings yet

- Apple 1Document45 pagesApple 1Choo Wei shengNo ratings yet

- PatentDocument15 pagesPatentOya ÜsküpNo ratings yet

- U.S. Pat. 7,179,841, Skinceuticals - Com Invention, 2007.Document19 pagesU.S. Pat. 7,179,841, Skinceuticals - Com Invention, 2007.Duane BlakeNo ratings yet

- 5c29 PDFDocument15 pages5c29 PDFGraciaVelitarioNo ratings yet

- US8425837Document16 pagesUS8425837Hangzhou Zhu Tai Trading Co.,LtdNo ratings yet

- US8449695 chromeIIIDocument5 pagesUS8449695 chromeIIIKute Lele BeanNo ratings yet

- PatentDocument8 pagesPatentRikyNo ratings yet

- Patent MethanolDocument12 pagesPatent MethanolBahrulUlumNo ratings yet

- US8388345Document13 pagesUS8388345dent appNo ratings yet

- USdsdasdsdsdDocument11 pagesUSdsdasdsdsdDat TanNo ratings yet

- United States Patent: (75) Inventors: Prashant Anil Tatake, Mumbai (IN)Document8 pagesUnited States Patent: (75) Inventors: Prashant Anil Tatake, Mumbai (IN)angsalcautzarNo ratings yet

- US8034246 PatentDocument9 pagesUS8034246 PatentCatalina SarriaNo ratings yet

- Us 7988883Document16 pagesUs 7988883AXIS LUBRIFICANTESNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument19 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentUmar OmarNo ratings yet

- United States Patent: Anderson Et Al. (45) Date of Patent: Feb. 22, 2005Document19 pagesUnited States Patent: Anderson Et Al. (45) Date of Patent: Feb. 22, 2005santosh mhetreNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,356,857 B2Document10 pagesUlllted States Patent (10) Patent N0.: US 8,356,857 B2maulik_20_8No ratings yet

- Us7648340 PDFDocument18 pagesUs7648340 PDFZeeshan HameedNo ratings yet

- United States Patent: (10) Patent No .: US 10, 174, 276 B2Document35 pagesUnited States Patent: (10) Patent No .: US 10, 174, 276 B213sandipNo ratings yet

- FERTILIZERSUSPENSIONDocument12 pagesFERTILIZERSUSPENSIONMohamed GamingNo ratings yet

- United States Patent (10) Patent No.: US 8,284.833 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,284.833 B2David HoffmanNo ratings yet

- United States Patent (10) Patent No.: US 7,774,911 B2: Sun Et Al. (45) Date of Patent: Aug. 17, 2010Document13 pagesUnited States Patent (10) Patent No.: US 7,774,911 B2: Sun Et Al. (45) Date of Patent: Aug. 17, 2010Keval KamaniNo ratings yet

- United States Patent (10) Patent No.: US 7,875,163 B2: Gilliam Et Al. (45) Date of Patent: Jan. 25, 2011Document26 pagesUnited States Patent (10) Patent No.: US 7,875,163 B2: Gilliam Et Al. (45) Date of Patent: Jan. 25, 2011Ruchita PoilkarNo ratings yet

- US7385068Document7 pagesUS7385068Mohamed SalemNo ratings yet

- United States Patent (10) Patent No.: US 7.969,673 B2Document29 pagesUnited States Patent (10) Patent No.: US 7.969,673 B2ja2ja1No ratings yet

- United States Patent (10) Patent No.: US 9.255,753 B2Document31 pagesUnited States Patent (10) Patent No.: US 9.255,753 B2Anonymous VNu3ODGavNo ratings yet

- United States Patent (10) Patent No.: US 8,076,507 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,076,507 B2Manuel Gonzalez GalvezNo ratings yet

- Method For Parachute Reefing ControlDocument9 pagesMethod For Parachute Reefing ControlgabrielmolloNo ratings yet

- synnotch大法 PDFDocument261 pagessynnotch大法 PDFTianliang GuoNo ratings yet

- US8376928Document17 pagesUS8376928Ator VastatinNo ratings yet

- US8833331-Repaired Engine Block and Repair MethodDocument7 pagesUS8833331-Repaired Engine Block and Repair MethodMahnoosh0% (1)

- United States Patent (10) Patent No.: US 8,131.205 B2Document9 pagesUnited States Patent (10) Patent No.: US 8,131.205 B2CORAL ALONSO JIMÉNEZNo ratings yet

- United States Patent: Rio Elit, PL, San PS 9/7007 (2013.01)Document67 pagesUnited States Patent: Rio Elit, PL, San PS 9/7007 (2013.01)M FNo ratings yet

- United States Patent (10) Patent No.: US 8,529,561 B2Document20 pagesUnited States Patent (10) Patent No.: US 8,529,561 B2rhkolte8881No ratings yet

- Us 9376582Document22 pagesUs 9376582Mary VettoriNo ratings yet

- United States Patent (10) Patent No.: US 8.439,531 B2Document19 pagesUnited States Patent (10) Patent No.: US 8.439,531 B2pmurphNo ratings yet

- "Rige.") Assistant Examiner Viet Le: (12) United States Patent (10) Patent No.: Us 9,108,738 B1Document24 pages"Rige.") Assistant Examiner Viet Le: (12) United States Patent (10) Patent No.: Us 9,108,738 B1SaraNo ratings yet

- Paten Kimia BenerDocument20 pagesPaten Kimia BenerRehan AshariNo ratings yet

- Dispensable Cured ResnDocument9 pagesDispensable Cured ResnFADIA PRIYANSHNo ratings yet

- Us9453128 PDFDocument57 pagesUs9453128 PDFVansala GanesanNo ratings yet

- Us7772966Document48 pagesUs7772966smcorporation23No ratings yet

- US9708475Document25 pagesUS9708475خبر عاجل وتحليلاتNo ratings yet

- Jumping Through HoopsDocument4 pagesJumping Through HoopsCharles RusnellNo ratings yet

- A Hybrid Intrution Detection Approach Based On Deep LearningDocument16 pagesA Hybrid Intrution Detection Approach Based On Deep LearningVictor KingbuilderNo ratings yet

- 3l/epublit of Tbe Bilippine9': Supreme !courtDocument15 pages3l/epublit of Tbe Bilippine9': Supreme !courtCesar ValeraNo ratings yet

- Ema Emits: UndergraduateDocument7 pagesEma Emits: UndergraduateJanineNo ratings yet

- Sylvania Lumalux Ordering Guide 1986Document2 pagesSylvania Lumalux Ordering Guide 1986Alan MastersNo ratings yet

- Q PapersDocument53 pagesQ PapersTanu RdNo ratings yet

- Chapter 11Document9 pagesChapter 11Joshua GuerreroNo ratings yet

- Dwnload Full Organization Development The Process of Leading Organizational Change 4th Edition Anderson Test Bank PDFDocument35 pagesDwnload Full Organization Development The Process of Leading Organizational Change 4th Edition Anderson Test Bank PDFliamhe2qr8100% (15)

- Gyrator - Wikipedia PDFDocument44 pagesGyrator - Wikipedia PDFRishabh MishraNo ratings yet

- Unit 1 - Identifying A Problem PDFDocument16 pagesUnit 1 - Identifying A Problem PDFZanko FitnessNo ratings yet

- Nguyễn Triệu Anh: Education And Degree Work ExperiencesDocument1 pageNguyễn Triệu Anh: Education And Degree Work ExperiencesQuach Manh ThuongNo ratings yet

- 3admin - 7Document13 pages3admin - 7JMXNo ratings yet

- Module 3 Notes (1) - 1Document18 pagesModule 3 Notes (1) - 1PARZIVAL GAMINGNo ratings yet

- CursorDocument7 pagesCursorSachin KumarNo ratings yet

- GSB Samaj Foundation - List of Goud Saraswat Brahmin SurnamesDocument2 pagesGSB Samaj Foundation - List of Goud Saraswat Brahmin SurnamesShree Vishnu ShastriNo ratings yet

- Regional Trial Court: Motion To Quash Search WarrantDocument3 pagesRegional Trial Court: Motion To Quash Search WarrantPaulo VillarinNo ratings yet

- David M. Kroenke's: Database ProcessingDocument25 pagesDavid M. Kroenke's: Database ProcessingasalajalagiNo ratings yet

- Parallelizing Partial Digest Problem On Multicore System PDFDocument10 pagesParallelizing Partial Digest Problem On Multicore System PDFnazibNo ratings yet

- OSINTDocument49 pagesOSINTMARCUS VINICIUSNo ratings yet

- Cartoon and Texture Decomposition Based Color Transfer For Fabric ImagesDocument12 pagesCartoon and Texture Decomposition Based Color Transfer For Fabric ImagesPooja GNo ratings yet

- Basement and Retaining WallsDocument42 pagesBasement and Retaining WallsSamata Mahajan0% (1)

- SLIM Sparse Linear Methods For Top-N Recommender SystemsDocument10 pagesSLIM Sparse Linear Methods For Top-N Recommender SystemsfcrkudxujdemptrdapNo ratings yet

- Umakanth's PMP Mock PDFDocument15 pagesUmakanth's PMP Mock PDFSDASDASDFADFSASDFNo ratings yet

- Essentials of Marketing Research 4th Edition Hair Test Bank DownloadDocument22 pagesEssentials of Marketing Research 4th Edition Hair Test Bank Downloademmanuelmabelnjt7nn100% (35)

- Dynamic Simulation of A Crude Oil DistillationDocument14 pagesDynamic Simulation of A Crude Oil DistillationAL-JABERI SADEQ AMEEN ABDO / UPMNo ratings yet

- Final Broucher 11-4 NewDocument3 pagesFinal Broucher 11-4 Newmilan07No ratings yet

- Braille Actuator Report MAJORDocument32 pagesBraille Actuator Report MAJORSwapnil BeheraNo ratings yet