Professional Documents

Culture Documents

Masterflow 928T: Cementitious High Strength Non-Shrink Precision Grout

Masterflow 928T: Cementitious High Strength Non-Shrink Precision Grout

Uploaded by

Anonymous XVEucVMsEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masterflow 928T: Cementitious High Strength Non-Shrink Precision Grout

Masterflow 928T: Cementitious High Strength Non-Shrink Precision Grout

Uploaded by

Anonymous XVEucVMsECopyright:

Available Formats

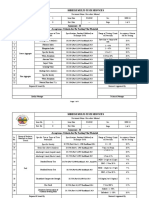

MasterFlow®928T (Formerly Known as Masterflow928T)

Cementitious high strength non-shrink precision grout

DESCRIPTION PROPERTIES

MasterFlow 928T is a non-shrink, natural

Supply form Free flowing

aggregate precision grout with excellent high early

cement grey

and ultimate strengths. It is specially formulated to powder

provide extended working time even at high

ambient temperatures when mixed and placed at Density (wet) 2200Kg/m3

any recommended consistency. MasterFlow 928T Water to powder ratio 0.15

is normally placed at a flowable consistency to

Volume expansion < 1.5 % (Plastic

completely fill voids between 25mm and 100mm. stage)

Thicknesses greater than 100mm are possible with

the addition of aggregate. >0.05%

(hardened stage)

RECOMMENDED USES

Compressive 1 Day 35 MPa

MasterFlow 928T is used for all precision, non- strength at 25°C

shrink grouting applications with clearances of 3 Days 55 MPa

(ASTM C 109,

10mm or more, including: 70mm Cube) 7 Days 65 MPa

• critical equipment baseplates, soleplates & 28 Days 75 MPa

columns;

• precast wall panels, beams, columns, structural Flexural strength 28 Days 9 MPa

(ASTM C 78)

building members and curtain walls;

• patching poured in place concrete structures, Modulus of 28 Days >32 GPa

e.g. honeycombing, using preplaced aggregate Elasticity

techniques; Pull out Bond 7 Days >17 MPa

• underpinning; strength

• concrete repair applications where a form and

Bond Strength 28 Days >3 MPa

pour material is required; to concrete

• applications requiring high early compressive

strengths and high ultimate compressive Dynamic load Condition of undamaged

strengths. resistance sample

FEATURES AND BENEFITS Compressive Slightly higher

strength

• High early strength– Ensures rapid

commissioning of new equipment and Specimen subjected to alternating loads of 5 and 25

MPa at 300 cycles per minute and for 2000000 cycles

structures.

and then tested for compressive strength

• High ultimate strength– Ensures permanence

of the installation under static and moderate VOC content:(SCAQMD 304-91) 6 g/L

repetitive loads.

• Flowable long life grout– Easy to grout ESTIMATING DATA

intricate spaces normally inaccessible by One 25 kg bag of MasterFlow 928T mixed with

conventional grouting technique. 3.75 L water will yield 13 L of flowable grout at

• Extended working time– Facilitates grouting of 20°C:

large or difficult placements in a single pour,

often without the use of a pump. APPLICATION

• Dense, non-shrink grout– Hardens free of For information about application, please obtain a

bleeding, settlement and drying shrinkage, copy of the BASF “Application Guide for

ensuring tight contact with all grouted surfaces. MasterFlow Cementitious Precision Grouts” from

• Easy to use– Requires no special mixing your local representative. For ‘dry pack’ (damp

equipment, it can be mixed in a standard pack) application, refer to MasterFlow 700.

concrete mixer or in a pail using a grout stirrer.

• No added chloride –Does not add to chloride PACKAGING

load of structure MasterFlow 928T is packaged in 25kg bags.

MasterFlow®928T

PRECAUTIONS

SHELF LIFE For detailed Health, Safety and Environmental

MasterFlow 928T has a shelf life of approximately Recommendations, please consult and follow all

6 months when stored in a cool dry environment. instructions on the product Material Safety Data

Sheet (MSDS) from our office or our website.

MasterFlow 928T/02/0415

The technical information and application advice given in this BASF Construction Chemicals publication are based on the present

state of our best scientific and practical knowledge. As the information herein is of a general nature, no assumption can be made as

STATEMENT OF

to a product's suitability for a particular use or application and no warranty as to its accuracy, reliability or completeness either

RESPONSIBILITY

expressed or implied is given other than those required by law. The user is responsible for checking the suitability of products for

(Disclaimer)

their intended use.

® = registered trademark of BASF group in many countries

NOTE Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF Construction Chemicals

either orally or in writing may be followed, modified or rejected by the owner, engineer or contractor since they, and not BASF

Construction Chemicals, are responsible for carrying out procedures appropriate to a specific application.

BASF India Limited

Construction Chemicals Division

Plot.No.12,TTC Area

Thane Belapur Road,Turbhe

Navi Mumbai - 400705,India

Tel: +91 22 67127600, Fax: +91 22 67917358

E-mail: construction-india@basf.com , www.master-builders-solutions.basf.in

You might also like

- A Complete MDMA Synthesis For The First Time Chemist: Compilation and Editorial by Bright StarDocument14 pagesA Complete MDMA Synthesis For The First Time Chemist: Compilation and Editorial by Bright StarAdrien G. S. Wald100% (3)

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- Tundish Cover Ladle NodularizingDocument2 pagesTundish Cover Ladle Nodularizingarnaldorcr8646No ratings yet

- USTER HVI Spectrum Measuring PrinciplesDocument45 pagesUSTER HVI Spectrum Measuring PrinciplesRAMARAMRAM100% (2)

- Masterflow 810: Non-Shrink, Precision Cementitious Grout For Use in General Civil Engineering WorksDocument2 pagesMasterflow 810: Non-Shrink, Precision Cementitious Grout For Use in General Civil Engineering WorksPradeep KumaraNo ratings yet

- Cementitious-Grout MasterFlow 718Document2 pagesCementitious-Grout MasterFlow 718Abhi MitraNo ratings yet

- Basf Masterflow 880 TdsDocument2 pagesBasf Masterflow 880 TdsEndi Sutopo TopsvaraNo ratings yet

- MasterFlow810 TDSDocument2 pagesMasterFlow810 TDSPT PP BIH SanurNo ratings yet

- Masterflow 622: Heavy Duty Epoxy Resin Chocking GroutDocument2 pagesMasterflow 622: Heavy Duty Epoxy Resin Chocking GroutAndri AjaNo ratings yet

- Masterflow 880: Cementitious High Strength, Non-Shrink, Iron Reinforced Precision GroutDocument2 pagesMasterflow 880: Cementitious High Strength, Non-Shrink, Iron Reinforced Precision GroutMu FaddaNo ratings yet

- MasterRheobuild 858M TDSDocument3 pagesMasterRheobuild 858M TDSabukayes.abdinNo ratings yet

- Mastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayDocument3 pagesMastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayAbi SomutNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- Basf Masteremaco S 488 v1 TdsDocument2 pagesBasf Masteremaco S 488 v1 Tdsraahul_nNo ratings yet

- Duro-Crete: King Packaged Materials CompanyDocument2 pagesDuro-Crete: King Packaged Materials Company4919404No ratings yet

- Masterseal 345 TdsDocument2 pagesMasterseal 345 TdsMarko BlagojevicNo ratings yet

- Masterflow 400: DegussaDocument2 pagesMasterflow 400: Degussafaisal nadeemNo ratings yet

- BASF - MasterEmaco N 5200CI - TDSDocument3 pagesBASF - MasterEmaco N 5200CI - TDSKelvinNo ratings yet

- Sikagrout 215 New - Pds en PDFDocument3 pagesSikagrout 215 New - Pds en PDFDeny Anarista SitorusNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enfikryh_2No ratings yet

- Sikagrout 214 11 Pds enDocument3 pagesSikagrout 214 11 Pds ensalma karimahNo ratings yet

- Basf Masterglenium Sky 920 Tds PDFDocument4 pagesBasf Masterglenium Sky 920 Tds PDFvikasNo ratings yet

- Masteremaco S 488: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortarDocument2 pagesMasteremaco S 488: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortarAvinash PrajapatiNo ratings yet

- MasterEase 3824 v1Document2 pagesMasterEase 3824 v1dachepalli963No ratings yet

- Mastertop - 100 v2Document2 pagesMastertop - 100 v2sasikumar durairajanNo ratings yet

- Sikagrout® 215 (New) : Product Data SheetDocument3 pagesSikagrout® 215 (New) : Product Data SheetWan Fikri DarmawanNo ratings yet

- POLYPOXY-NF Technical Data SheetDocument2 pagesPOLYPOXY-NF Technical Data SheetCommando crawlerNo ratings yet

- MasterGlenium SKY 8758 - MM v1 - 0119Document2 pagesMasterGlenium SKY 8758 - MM v1 - 0119Aung Naing Latt AungNo ratings yet

- Sikagrout Deep PourDocument3 pagesSikagrout Deep PourLuis Andrade InsúaNo ratings yet

- Masterflow 870 TdsDocument2 pagesMasterflow 870 TdsPretty MarpaungNo ratings yet

- Masterroc tsl865 TdsDocument3 pagesMasterroc tsl865 Tdsroshansm1978No ratings yet

- MasterGlenium SKY 617 (Ingles)Document4 pagesMasterGlenium SKY 617 (Ingles)maxlehenerNo ratings yet

- PDS Tammsgrout Supreme 4 July 2023 Replaces July 2022Document2 pagesPDS Tammsgrout Supreme 4 July 2023 Replaces July 2022Randy PolancoNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enAdiprabowo WicaksonoNo ratings yet

- Sikagrout 215 M - Pds en PDFDocument3 pagesSikagrout 215 M - Pds en PDFPrabowo SandiNo ratings yet

- Sikarep® Microcrete-4: Product Data SheetDocument2 pagesSikarep® Microcrete-4: Product Data Sheetsidharthsud28No ratings yet

- Masterflow 870 TDSDocument2 pagesMasterflow 870 TDSmokthyeluen3832No ratings yet

- Masterinject - 1315 v4Document2 pagesMasterinject - 1315 v4subhashisNo ratings yet

- TDS Consol Grout 600 MFDocument2 pagesTDS Consol Grout 600 MFPEP GUDANGNo ratings yet

- BASF MasterEmaco S488Document2 pagesBASF MasterEmaco S488HJNo ratings yet

- Masterflow 928 TdsDocument5 pagesMasterflow 928 Tdsrobin rezkNo ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 Tdschopdekar1969_890124No ratings yet

- Masteremaco S 322: Non Shrink, Natural Aggregate, Fibre Reinforced For Marine Environment Structure and Concrete RepairDocument2 pagesMasteremaco S 322: Non Shrink, Natural Aggregate, Fibre Reinforced For Marine Environment Structure and Concrete RepairHasbi Ashidiqi PNo ratings yet

- Mastertop 1240 Plus PDFDocument4 pagesMastertop 1240 Plus PDFFrancois-No ratings yet

- Masterflow 648 TdsDocument2 pagesMasterflow 648 Tdsruhy690No ratings yet

- Sikagrout®-215 (New) : Product Data SheetDocument3 pagesSikagrout®-215 (New) : Product Data SheetWahyu MahaendraNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 Newmanuel rgNo ratings yet

- Sikagrout FM - Pds en PDFDocument3 pagesSikagrout FM - Pds en PDFANDI SETIAWANNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewAlex Tri WijayantoNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewPeralatan Divisi3No ratings yet

- MasterEase 3818 v3Document2 pagesMasterEase 3818 v3dachepalli963No ratings yet

- Sikarep Microcrete-4Document4 pagesSikarep Microcrete-4indrajeet4911No ratings yet

- Masterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutDocument3 pagesMasterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutGavriel NgNo ratings yet

- Masteremaco S 5410 Ci Tds PDFDocument3 pagesMasteremaco S 5410 Ci Tds PDFSolomon AhimbisibweNo ratings yet

- MasterRheobuild 859 Technical Data SheetDocument3 pagesMasterRheobuild 859 Technical Data Sheetabukayes.abdinNo ratings yet

- Conbextra GP PremixDocument3 pagesConbextra GP Premixtabah sentosaNo ratings yet

- PDS SikaGrout-215P PDFDocument3 pagesPDS SikaGrout-215P PDFDeny PutraNo ratings yet

- Cement Properties and CharacteristicsDocument2 pagesCement Properties and CharacteristicsAnonymous XVEucVMsENo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- Is 2502-1963 - Code of Practice For Bending and Fixing of Bars For Concrete ReinforcementDocument29 pagesIs 2502-1963 - Code of Practice For Bending and Fixing of Bars For Concrete ReinforcementAnonymous XVEucVMsENo ratings yet

- IS 516-Part-5 Sec 1-2018 (UPV)Document18 pagesIS 516-Part-5 Sec 1-2018 (UPV)Anonymous XVEucVMsENo ratings yet

- IS 1199-Part 2-2018Document24 pagesIS 1199-Part 2-2018Anonymous XVEucVMsENo ratings yet

- Renderoc CSDocument2 pagesRenderoc CSAnonymous XVEucVMsENo ratings yet

- Conbextra EBG (M) : Epoxy Resin Bearing GroutDocument3 pagesConbextra EBG (M) : Epoxy Resin Bearing GroutAnonymous XVEucVMsENo ratings yet

- IS 2720-PART 3 - 1980 - Determination of Specific Gravity - Sec 1Document10 pagesIS 2720-PART 3 - 1980 - Determination of Specific Gravity - Sec 1Anonymous XVEucVMsENo ratings yet

- Is 2720-PART 4-1985 - Grain Size AnalysisDocument40 pagesIs 2720-PART 4-1985 - Grain Size AnalysisAnonymous XVEucVMsENo ratings yet

- IS 2720-PART 2-1973 - Determination of Water ContentDocument21 pagesIS 2720-PART 2-1973 - Determination of Water ContentAnonymous XVEucVMsENo ratings yet

- Shiva - SR Network Engineer 1Document4 pagesShiva - SR Network Engineer 1api-347320755100% (1)

- 5 Types of Flow MetersDocument2 pages5 Types of Flow Metersabdulkidwai20090% (1)

- The Dark Side of Winsock - Lecture NotesDocument23 pagesThe Dark Side of Winsock - Lecture NotesragorillaNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- Krasnov Aerodynamics PDFDocument513 pagesKrasnov Aerodynamics PDFmisterno94No ratings yet

- Bhy 65Document4 pagesBhy 65Manoj SahuNo ratings yet

- Dharmendra bIOdata PDFDocument4 pagesDharmendra bIOdata PDFDharmendra RajanNo ratings yet

- 1 Basic1Document42 pages1 Basic1Raja Saad0% (1)

- Giao Trinh ExcelDocument100 pagesGiao Trinh ExcelHuỳnh Hồng HanhNo ratings yet

- 1 Assignment Solution MEENG322 3BDocument5 pages1 Assignment Solution MEENG322 3BKing Cyruz PabloNo ratings yet

- Api MetaDocument970 pagesApi Metasonuindia88No ratings yet

- Dremel 2012-2013 PDFDocument70 pagesDremel 2012-2013 PDFMarcelo AlegreNo ratings yet

- Cobra Skid Unit (Motor Propriu, 280bar, 28lpm) - 230611 - 160153Document3 pagesCobra Skid Unit (Motor Propriu, 280bar, 28lpm) - 230611 - 160153Pert CristianNo ratings yet

- ETEEAP - MemorazonDocument18 pagesETEEAP - MemorazonRAP & GAB TVNo ratings yet

- Gauge R&RDocument7 pagesGauge R&Rsumeetsaini88No ratings yet

- TM213TRE.425-EnG Automation Runtime V4330Document60 pagesTM213TRE.425-EnG Automation Runtime V4330meirelgNo ratings yet

- 1932 Oct 23 Ogden Standard-Examiner - Ogden City UTDocument1 page1932 Oct 23 Ogden Standard-Examiner - Ogden City UTMatt NovakNo ratings yet

- Coal Conveyor Protection-Ih153es Ir Ember DetectorDocument72 pagesCoal Conveyor Protection-Ih153es Ir Ember DetectorShanmuganathan ShanNo ratings yet

- Shreeji Multi-Tech ServicesDocument4 pagesShreeji Multi-Tech ServicesSHREEJI MULTIT-ECHNo ratings yet

- Method of SectionsDocument12 pagesMethod of SectionsAbdul Aziz Abdul RahimNo ratings yet

- Trunking Between Two Elastix PBX Systems PDFDocument15 pagesTrunking Between Two Elastix PBX Systems PDFAkhil PaulNo ratings yet

- Activated Sludge Rheology A Critical Review On Data Collection and ModellingDocument20 pagesActivated Sludge Rheology A Critical Review On Data Collection and ModellingZohaib Ur RehmanNo ratings yet

- PHD ProposalDocument9 pagesPHD ProposalStephen S. MwanjeNo ratings yet

- Ultrasonic Clamp On Insertion Flow MeterDocument4 pagesUltrasonic Clamp On Insertion Flow Meterjitender.singh29No ratings yet

- SATS SAR Rectangular Portals: (Rail Application Stormwater Culvert) - Class 1 LoadingDocument1 pageSATS SAR Rectangular Portals: (Rail Application Stormwater Culvert) - Class 1 LoadingEphraim BarezNo ratings yet

- OWAS MethodDocument4 pagesOWAS MethodAditya YudhatamaNo ratings yet

- Telemecanique Altivar61 Manual 037 90kwDocument47 pagesTelemecanique Altivar61 Manual 037 90kwcuongNo ratings yet