Professional Documents

Culture Documents

Lubrication: Six Sigma

Lubrication: Six Sigma

Uploaded by

Brayan MejiaCopyright:

Available Formats

You might also like

- A Feminists Guide To Phone Sex by Ashley Manta PDFDocument28 pagesA Feminists Guide To Phone Sex by Ashley Manta PDFHany HoneyNo ratings yet

- ERP Implementation Failure CaseDocument8 pagesERP Implementation Failure Casepf shahidNo ratings yet

- LANXESS-Release Agents 01-2017Document20 pagesLANXESS-Release Agents 01-2017Phuong The NguyenNo ratings yet

- Canon Follows Kaizen ApproachDocument6 pagesCanon Follows Kaizen ApproachAkash Bafna100% (1)

- Technical Description: Extended MTU Lube Oil SystemDocument22 pagesTechnical Description: Extended MTU Lube Oil SystemDenNo ratings yet

- Dana Spicer Lub ApprovalsDocument16 pagesDana Spicer Lub Approvalsfdpc1987100% (1)

- T4F CSM CTR226-02 9-5-14Document278 pagesT4F CSM CTR226-02 9-5-14SitecsaNo ratings yet

- TPM Newsletter Quarter 3 October 2016Document7 pagesTPM Newsletter Quarter 3 October 2016Quality HosurNo ratings yet

- ARG LeanManufacturingandReliabilityConcepts DigitalDocument28 pagesARG LeanManufacturingandReliabilityConcepts DigitalPedro SávioNo ratings yet

- Lean EnterpriseDocument3 pagesLean EnterprisenishioyukihimeNo ratings yet

- MFG ChecklistDocument2 pagesMFG ChecklistyusranarifNo ratings yet

- 5S & Housekeeping: Training For TrainersDocument35 pages5S & Housekeeping: Training For TrainersSunilNo ratings yet

- Lubrication - Whose Job Is It Anyway?: By: Mark Barnes, Noria CorporationDocument3 pagesLubrication - Whose Job Is It Anyway?: By: Mark Barnes, Noria CorporationVictor ZhicayNo ratings yet

- How To Write A Lubrication ProcedureDocument5 pagesHow To Write A Lubrication ProceduremawooaNo ratings yet

- ERP Implementation FailureDocument7 pagesERP Implementation Failurelakshay187100% (1)

- Chapter 5 Good HousekeepingDocument3 pagesChapter 5 Good HousekeepingKaye Joy TendenciaNo ratings yet

- Oilsafe General Catalogue 2019Document78 pagesOilsafe General Catalogue 2019Hesham MahdyNo ratings yet

- PROJECTDocument1 pagePROJECTINFO QcplworldNo ratings yet

- Toyota Production System 6 Sigma ISO 9000 ObjetivesDocument5 pagesToyota Production System 6 Sigma ISO 9000 ObjetivesLuisTocaNo ratings yet

- Lean AssignmentDocument10 pagesLean AssignmentNain TikaryaNo ratings yet

- 29 - Successful Mergers & Acquisitions - Best PracticesDocument4 pages29 - Successful Mergers & Acquisitions - Best PracticesDlx AreaOne100% (1)

- 2016OilSafeCatalog PDFDocument76 pages2016OilSafeCatalog PDFwilmerNo ratings yet

- Bearing and Equipment Lubrication Strategies - Getting It RightDocument64 pagesBearing and Equipment Lubrication Strategies - Getting It Rightsrikanth siddhardhaNo ratings yet

- Modern Management TechniquesDocument58 pagesModern Management Techniquessend2hemant100% (10)

- Session 18 MGN600Document48 pagesSession 18 MGN600Manjit KaurNo ratings yet

- What Is TPM: Knowledge BaseDocument29 pagesWhat Is TPM: Knowledge BasealpanasherawatNo ratings yet

- 2018 IPPE - CallanderDocument26 pages2018 IPPE - CallanderAlpha Excellence consultingNo ratings yet

- 7 Step Guide: To ERP TransformationDocument11 pages7 Step Guide: To ERP TransformationDon RodrigueNo ratings yet

- 7 Step Guide - ERP TransformationDocument11 pages7 Step Guide - ERP TransformationPaul Vintimilla CarrascoNo ratings yet

- 5S For SuppliersDocument4 pages5S For SuppliersxyalfaxyzNo ratings yet

- 5s, Kaizen, Kanban SystemDocument11 pages5s, Kaizen, Kanban SystemFirdaus AsryNo ratings yet

- The Carve-Out Challenge: A Roadmap For SuccessDocument16 pagesThe Carve-Out Challenge: A Roadmap For SuccessPeter HertensteinNo ratings yet

- M A PDFDocument2 pagesM A PDFSrikanth Reddy DNo ratings yet

- 100 Ways To Improve Your Lubrication ProgramDocument29 pages100 Ways To Improve Your Lubrication ProgramManne RajuNo ratings yet

- BSC Report 2010-Strategy ExecutionDocument6 pagesBSC Report 2010-Strategy ExecutionDavidNo ratings yet

- The Top 3 Condition Monitoring KPIsDocument10 pagesThe Top 3 Condition Monitoring KPIssatya krishna chagantiNo ratings yet

- 5 Essential Principles For A Better Strategy Review (Palladium 2015)Document8 pages5 Essential Principles For A Better Strategy Review (Palladium 2015)Grant MillinNo ratings yet

- Setup Reduction For Flexo PrintersDocument3 pagesSetup Reduction For Flexo PrinterschandrakantgadhiaNo ratings yet

- Using Six Steps, Not Your Sixth Sense: No More Crystal-Ball ForecastingDocument2 pagesUsing Six Steps, Not Your Sixth Sense: No More Crystal-Ball ForecastingAshok MuthuswamyNo ratings yet

- Technical Topic - Lubrication Program ManagementDocument2 pagesTechnical Topic - Lubrication Program Managementdhavit wijayantoNo ratings yet

- Kaizen PDFDocument29 pagesKaizen PDFanandNo ratings yet

- Process Product PeopleDocument3 pagesProcess Product PeopleUppiliappan GopalanNo ratings yet

- Extra Readings - Lean SystemsDocument6 pagesExtra Readings - Lean Systemsabhinav.k0509No ratings yet

- The Revolution of Lean PDFDocument10 pagesThe Revolution of Lean PDFdhesselyNo ratings yet

- OilSafe Catalog 201304 PDFDocument38 pagesOilSafe Catalog 201304 PDFFernandoPelozioNo ratings yet

- Company Profile: Scrap ManegementDocument29 pagesCompany Profile: Scrap ManegementAjay KaushikNo ratings yet

- Bridging The Gap Between A Companys Strategy and Operating Model VFDocument5 pagesBridging The Gap Between A Companys Strategy and Operating Model VFRaviteja GogineniNo ratings yet

- TPMDocument10 pagesTPMMohammed AlamNo ratings yet

- Improve PhaseDocument61 pagesImprove Phaserobertofernandez091166No ratings yet

- Assignment 01Document14 pagesAssignment 01AlpeshkumarNo ratings yet

- Gargeya and Brady (2005) Article ERPS PDFDocument17 pagesGargeya and Brady (2005) Article ERPS PDFAlixon Antonio MoncadaNo ratings yet

- The Difference Between 5S and KaizenDocument8 pagesThe Difference Between 5S and KaizenNenadNo ratings yet

- Total Productive Maintenance: Aoulad Ben Taib DikraDocument4 pagesTotal Productive Maintenance: Aoulad Ben Taib DikraabirNo ratings yet

- 1.1 Lubrication Management and Organization (LUB)Document53 pages1.1 Lubrication Management and Organization (LUB)Busuioc AlexNo ratings yet

- Case5 Group4 SectionADocument3 pagesCase5 Group4 SectionAYashita PruthiNo ratings yet

- KaizenDocument21 pagesKaizendcunhabrian100% (1)

- Maintenance Practices Bloch 3Document8 pagesMaintenance Practices Bloch 3rodolfostiNo ratings yet

- 7 Steps Operational Excellence PexDocument11 pages7 Steps Operational Excellence PexManuel EstradaNo ratings yet

- Mba - 2 Pom GauravDocument7 pagesMba - 2 Pom GauravDibyendu DeyNo ratings yet

- SAP FSCM Interview Question and AnswersDocument3 pagesSAP FSCM Interview Question and AnswersjsphdvdNo ratings yet

- LEAN ENTERPRISE: Transforming Organizations Through Agile Principles and Continuous Improvement (2023 Guide for Beginners)From EverandLEAN ENTERPRISE: Transforming Organizations Through Agile Principles and Continuous Improvement (2023 Guide for Beginners)No ratings yet

- Lean QuickStart Guide: The Simplified Beginner's Guide to LeanFrom EverandLean QuickStart Guide: The Simplified Beginner's Guide to LeanNo ratings yet

- Retooling Your Lubricant Storage and Handling EquipmentDocument5 pagesRetooling Your Lubricant Storage and Handling EquipmentBrayan MejiaNo ratings yet

- Water Contamination in Hydraulic and Lube SystemsDocument11 pagesWater Contamination in Hydraulic and Lube SystemsBrayan MejiaNo ratings yet

- Oil Filtering Whitepaper 2017Document10 pagesOil Filtering Whitepaper 2017Brayan MejiaNo ratings yet

- Des-Case Product Catalog: ISSUE 3 - 2016Document25 pagesDes-Case Product Catalog: ISSUE 3 - 2016Brayan MejiaNo ratings yet

- Catalog G-1 Chem, Lubricants and AccDocument32 pagesCatalog G-1 Chem, Lubricants and AccBrayan MejiaNo ratings yet

- Emkarate Is The Only Name You Need To Know: Emkarate Refrigeration Lubricants - Approval ListDocument2 pagesEmkarate Is The Only Name You Need To Know: Emkarate Refrigeration Lubricants - Approval ListBrayan MejiaNo ratings yet

- Emkarate RL Refrigeration LubricantsDocument6 pagesEmkarate RL Refrigeration LubricantsBrayan MejiaNo ratings yet

- Bulldozer D375ADocument16 pagesBulldozer D375ABrayan MejiaNo ratings yet

- Broshure Reliance Ultrasonic WashersDocument2 pagesBroshure Reliance Ultrasonic WashersbrisaNo ratings yet

- TechCare TCCDocument6 pagesTechCare TCCironiteNo ratings yet

- MMH Dan StoringDocument13 pagesMMH Dan Storingfilza100% (1)

- ASV Posi-Track PT-100 Track Loader Mater Parts Catalogue Manual PDFDocument16 pagesASV Posi-Track PT-100 Track Loader Mater Parts Catalogue Manual PDFfisekkkd100% (2)

- Hardened Way SlidesDocument32 pagesHardened Way SlideskanagarajuNo ratings yet

- Central Lubrication System 16Document16 pagesCentral Lubrication System 16Arslan AhmedNo ratings yet

- Nassar2017 Article PreparationAndEvaluationOfTheMDocument13 pagesNassar2017 Article PreparationAndEvaluationOfTheMCristinaNo ratings yet

- SMT Crane Maintenance ManualDocument84 pagesSMT Crane Maintenance ManualArun Tiwari100% (1)

- ScopeDocument3 pagesScopeqamgr.sudairNo ratings yet

- QWS2500 SD, Or67658, Line 1 - Service ManualsDocument108 pagesQWS2500 SD, Or67658, Line 1 - Service ManualsmaciekziebaNo ratings yet

- CSP0000160-01 LubricationDocument13 pagesCSP0000160-01 LubricationA̶l̶x̶a̶n̶d̶e̶r̶ PaniNo ratings yet

- Winky 5Document2 pagesWinky 5bill_gator20059105No ratings yet

- Insertion of Suppositories 2 RemovedDocument16 pagesInsertion of Suppositories 2 Removedmikealtttt7No ratings yet

- PM Inspection SheetDocument4 pagesPM Inspection SheetYogeshNo ratings yet

- L45425en BDocument4 pagesL45425en BJerNo ratings yet

- Car Detailing GuideDocument76 pagesCar Detailing GuideZohirNo ratings yet

- TOM Training Centrifugal Compressors: IndexDocument8 pagesTOM Training Centrifugal Compressors: IndexAhmedNo ratings yet

- Service Parts List: Transmission 6422-84 4265557Document47 pagesService Parts List: Transmission 6422-84 4265557Bryan RibeiroNo ratings yet

- MAN B&W Diesel A/S: Service LetterDocument5 pagesMAN B&W Diesel A/S: Service LetterAKINMOLADUN OMOLADENo ratings yet

- Rexroth Ball ScrewDocument165 pagesRexroth Ball ScrewJacob100% (1)

- Us Terex pt-100 Forestry Mstr-Parts 1-10Document37 pagesUs Terex pt-100 Forestry Mstr-Parts 1-10Хелфор УкраинаNo ratings yet

- Effects of Bearing Cleaning Peter WardDocument16 pagesEffects of Bearing Cleaning Peter Wardanhntran4850No ratings yet

- Va1 Dec 2Document15 pagesVa1 Dec 2Xuân Định LêNo ratings yet

- Renolin Hi Temp Chain LubeDocument2 pagesRenolin Hi Temp Chain Lubempe.mohamed2010No ratings yet

- Lube Oil PresentationDocument19 pagesLube Oil Presentationasirul_meNo ratings yet

Lubrication: Six Sigma

Lubrication: Six Sigma

Uploaded by

Brayan MejiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lubrication: Six Sigma

Lubrication: Six Sigma

Uploaded by

Brayan MejiaCopyright:

Available Formats

Asset ion

it

Cond gement

Mana Lu

machinery

lubrication

Applying Lean Six Sigma Principles to

Lubrication

ter

Mark Barnes

Presen

In 2010, it was reported that as plant, is just another process. It is the process of The second phase of sort is to create organi-

selecting, purchasing, storing, dispensing and zation in how lubricants are stored, handled and

many as 43 percent of U.S. man- applying the lubricant to the machine while made available throughout the plant. 5S is a

ufacturers were deploying some maintaining (sustaining) the quality and clean- highly visual process; everything in place where

liness of the lubricant. everything has its place.

form of business improvement Lubricant storage areas

As such, 5S principles

strategy centered around lean can and should be need to be organized

manufacturing principles, Six applied to the pro- and ergonomic, with

Sigma, or the original Toyota cess of lubrication for LEAN SIX SIGMA - 5S clear visual workplace

maximum efficiency. management tools, like

production system (TPS). So let’s see how we color coding, charts,

can 5S our lubrication

1. Sort shadow boards etc.,

While the lines between these different strat- program, starting with used to denote what the

egies have been blurred over the past 10 to 15

2. Set in Order desired state should be.

sort.

years, at their core, they all focus on one funda- 3. Shine Designating an “owner”

mental tenet: Create efficiencies by improving SORT of the lube room and

business processes that eliminate waste. In this With respect to 4. Standardize other designated lu-

context, waste can mean anything from wasted lubrication, sort has bricant storage areas

time, wasted effort, or wasted raw materials. two phases. The first 5. Sustain is often an effective

Fundamental to waste elimination is the con- is to organize which means of making sure

cept of 5S. Originally developed in Japan as a lubricant needs to be standards don’t slide

way for frontline workers to provide feedback used based on appli- over time and creating

cation and operating a sense of accountability

on process improvements, the 5S concept was

originally represented by five Japanese words, context. The goal is to minimize the number of while promoting pride in doing a good job.

each starting with the letter ‘S.’ Today in North lubricants in use without compromising equip- SET IN ORDER

America, 5S is most often transliterated into ment reliability or performance. For plants that Central to the principles of 5S is efficiency.

five English words that have become the cor- have been through a 5S process, the number Requiring an operator or lube tech to walk sev-

nerstone of any lean-Six Sigma initiative. Those of lubricants used have been optimized with a eral hundred yards or more to access the oil or

words are: Sort, Set in Order, Shine, Standardize concerted effort put in place to consolidate to grease they need is, at best, creating inefficiency

and Sustain. a single lubricant supplier and, where applica- in work processes and, at worst, encouraging

ble, to eliminate unnecessary types or grades lubricants to be stored behind the machine or

APPLYING 5S TO LUBRICATION of lubricant through technical consolidation. 5S for the wrong oil to be added since it’s closer.

At its core, 5S is a methodology by which plants typically have a database (spreadsheet) Lubricants and the tools necessary to do the

technology (engineering) and psychology (peo- listing each asset and the lubricant to be used, job right need to be at hand. This may require

ple) are optimized to achieve an efficient set of with this information readily available and pub- satellite lube lockers at point of use or portable

business processes. A business process is simply lished, often as a poster or wall chart. It may lubrication carts that can be moved around as

a set of steps, rules and practices required to seem obvious, but knowing which lubricant is work is performed. Visual workplace manage-

complete any specific task. In this context, lubri- used in which machine is fundamental to future ment needs to extend to all designated remote

cation, like any other activity in a manufacturing success, but so few plants even get to first base! storage, with the same 5S principles used in

48 dec/jan14 Copyright 2013 Uptime®

the lube room. Accountability is the key for

remote storage, with weekly inspections and

check sheets used to ensure standards remain

consistent.

More often than not, errors, like adding the

wrong oil or applying the wrong grease, hap-

pen by mistake. To minimize the likelihood of

mistakes happening, a highly visual workplace

is a fundamental part of any lubrication 5S pro-

cess at all levels. The lube room, lube locker,

tools, machine etc., all need to be tagged with

a color and shape to designate which lubricant

is in use. Tags should be placed at all critical

control points where lubricants are transferred

from one point to another or to the machine.

Ideally, lube tags should not specifically state

the manufacturer or brand lubricant in use.

While this may seem counter to 5S principles,

including the brand name lubricant will cause

problems if you decide to switch suppliers in

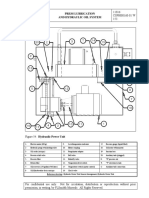

Figure 1: Lube storage areas need to promote ergonomic work flow

while promoting best practices through visual work management

(labels, color coding, shadow boards, etc.)

how a company can get 50 different mechanics,

technicians and operators all functioning at the

same level. The answer is standardization. Com-

mercial aviation is by and large an efficient, safe

business process that works because every task

from pre-flight checks to refueling, baggage

loading and flight plans is choreographed on

into the work management system for correc- checklists and standard operating procedures. If

the future. With product brand names on lube

tags, you’re just one vendor change away from tive action. Basic lubrication inspection should United Airlines can do it with hundreds of peo-

violating the last “S” in 5S – Sustain! be included as a daily ple all capable of influencing

task. Oftentimes, oper- the success of flying from

Finally, machines need to be configured to

ators can be trained to Chicago to Houston in a multi-

allow preferred practices to be deployed. De-

do these basic checks. More often than -million dollar machine flying

noting that all new oils need to be pre-filtered

before use without setting up the machine with

Make inspections sim- not, errors, like at 37,000 feet, surely adopting

quick connects or a proper breather defeats ple and easy to do and adding the wrong a similar approach can work

they get done. Allow for us on the ground. While

the purpose. Making the easy way the right

opportunity for indi- oil or applying we may not need quite the

way (transfer oil from the barrel using a porta-

ble filter cart and quick connects on the barrel viduals to interpret the wrong grease, same degree of rigor, a stan-

dard work process, checklist

and machine versus open the fill port and use what you want and happen by mistake and documentation all fea-

a hand crank oil transfer pump) is a critical step shortcuts will happen.

Lube inspections need ture heavily in successful 5S

towards making sure buy-in occurs at all levels.

to include simple, basic plants.

SHINE questions and binary But it’s not just about hav-

Cleaning and inspections are important in answers (e.g., oil level: high or low?; desiccant ing documents that serve as preventive main-

creating consistency and continuity. In addition breather: blue or pink?; filter differential pres- tenance (PM); it’s how the PM is written that

to assigning responsibility to keep lube storage sure <20 psi: yes or no?). counts. Having a PM worksheet that states “lu-

areas clean through weekly inspections, ma- bricate the motor” is not a standard operating

chines need to be kept clean, free from leak- STANDARDIZE procedure, it’s a wish! The PM should include

age and routinely inspected. Any leaks that are Having standard work procedures is a must specific details, such as which lubricant to use,

found should be noted and immediately put for any maintenance team. I often get asked basic steps to ensure compliance with best

Copyright 2013 Uptime® dec/jan14 49

Drop Tube Sampling Procedure

Courtesy of Des-Case Corporation

Figure 2: PM procedure should include enough instruction to ensure the task is completed consistently each time

practices (e.g., clean the grease fitting, allow of lubrication training will turn the plant’s

three to five seconds/shot, etc.), as well as task performance around. While it’s true having

specific details, such as the quantity of grease knowledgeable and committed people is

in shots or ounces. key, it’s only with a proper system in place

built around solid 5S principles of sort, set in

SUSTAIN

order, standardize, shine and sustain that we

I visit a lot of plants each year in many dif-

can maintain performance over the long haul.

ferent industries. But no matter the plant or

True competitive advantage comes when

industry, they all have something in common: Quality

great People

people work +

Quality

in a great system. S ystem

=

Suc

When

basic metrics for safety (“we have worked 243

that happens, great things occur! Cri$cal

Su

days without a lost time accident”) or produc-

Quality

Sy

tion (“OEE year-to-date = 94.7%”). Do we re-

Sort

ally need reminding to work safe and hit pro- • Op3mize

duction quotas? The answer is an emphatic • Organize

Success

Excel

handling

“yes!” Without standards by which we’re mea-

Excellent

sured and consistent reinforcement of those • Needs

con3nual

• With

the

right

tools

Set

in

Ord

System

Quality

oversight and and systems in place, • Lubrican

standards, it’s inevitable that things will slip reinforcement A-‐team players excel • Op3mize

over time. Shine

For lubrication, basic metrics like lubrica- • Efficient

Failure Failure • Control o

tion PM compliance (ratio of completed lube

PM on time/total number due), compliance Frustrated employees

Standardi

• Frustrated employees •

Poor

• Poka

Yok

with contamination control targets (ratio of oXen

seek

new

challenges

oXen

seek

new

• Standard

challenges

machines that meet our targets vs. the total • Standard

number of machines), or compliance with Average Excep$onal

Sustain

• Create a

lubricant health (number of machines “in the People Quality • Re-‐benc

green” from oil analysis vs. the total number

sampled) serve as the “scoreboard” by which Figure 3: While having knowledgeable and committed4

lubrication success or failure can be mea- people is important, true competitive advantage only

© 2012 Des-‐Case Corp.

sured. By tracking metrics and posting them

occurs when exceptional people work within an exceptional

conspicuously, the message is clear. We ex-

system. 5S is the key to build the system.

pect everyone to take seriously a set of per-

formance standards around lubrication, with

clear, actionable remedies if we’re in non-

compliance.

Mark Barnes, CMRP, is Vice President of

PUTTING IT ALL TOGETHER the Equipment Reliability Services team

Having taught literally hundreds of lubrica- at Des-Case Corporation. Mark has

tion classes over the past 20 years, it always been an active consultant and educator

amazes me the number of companies that in the maintenance and reliability

field for over 17 years. Mark holds a PhD in Analytical

send good people to training classes expect- Chemistry. www.descase.com

ing that simply sitting through three-days

50 dec/jan14 Copyright 2013 Uptime®

You might also like

- A Feminists Guide To Phone Sex by Ashley Manta PDFDocument28 pagesA Feminists Guide To Phone Sex by Ashley Manta PDFHany HoneyNo ratings yet

- ERP Implementation Failure CaseDocument8 pagesERP Implementation Failure Casepf shahidNo ratings yet

- LANXESS-Release Agents 01-2017Document20 pagesLANXESS-Release Agents 01-2017Phuong The NguyenNo ratings yet

- Canon Follows Kaizen ApproachDocument6 pagesCanon Follows Kaizen ApproachAkash Bafna100% (1)

- Technical Description: Extended MTU Lube Oil SystemDocument22 pagesTechnical Description: Extended MTU Lube Oil SystemDenNo ratings yet

- Dana Spicer Lub ApprovalsDocument16 pagesDana Spicer Lub Approvalsfdpc1987100% (1)

- T4F CSM CTR226-02 9-5-14Document278 pagesT4F CSM CTR226-02 9-5-14SitecsaNo ratings yet

- TPM Newsletter Quarter 3 October 2016Document7 pagesTPM Newsletter Quarter 3 October 2016Quality HosurNo ratings yet

- ARG LeanManufacturingandReliabilityConcepts DigitalDocument28 pagesARG LeanManufacturingandReliabilityConcepts DigitalPedro SávioNo ratings yet

- Lean EnterpriseDocument3 pagesLean EnterprisenishioyukihimeNo ratings yet

- MFG ChecklistDocument2 pagesMFG ChecklistyusranarifNo ratings yet

- 5S & Housekeeping: Training For TrainersDocument35 pages5S & Housekeeping: Training For TrainersSunilNo ratings yet

- Lubrication - Whose Job Is It Anyway?: By: Mark Barnes, Noria CorporationDocument3 pagesLubrication - Whose Job Is It Anyway?: By: Mark Barnes, Noria CorporationVictor ZhicayNo ratings yet

- How To Write A Lubrication ProcedureDocument5 pagesHow To Write A Lubrication ProceduremawooaNo ratings yet

- ERP Implementation FailureDocument7 pagesERP Implementation Failurelakshay187100% (1)

- Chapter 5 Good HousekeepingDocument3 pagesChapter 5 Good HousekeepingKaye Joy TendenciaNo ratings yet

- Oilsafe General Catalogue 2019Document78 pagesOilsafe General Catalogue 2019Hesham MahdyNo ratings yet

- PROJECTDocument1 pagePROJECTINFO QcplworldNo ratings yet

- Toyota Production System 6 Sigma ISO 9000 ObjetivesDocument5 pagesToyota Production System 6 Sigma ISO 9000 ObjetivesLuisTocaNo ratings yet

- Lean AssignmentDocument10 pagesLean AssignmentNain TikaryaNo ratings yet

- 29 - Successful Mergers & Acquisitions - Best PracticesDocument4 pages29 - Successful Mergers & Acquisitions - Best PracticesDlx AreaOne100% (1)

- 2016OilSafeCatalog PDFDocument76 pages2016OilSafeCatalog PDFwilmerNo ratings yet

- Bearing and Equipment Lubrication Strategies - Getting It RightDocument64 pagesBearing and Equipment Lubrication Strategies - Getting It Rightsrikanth siddhardhaNo ratings yet

- Modern Management TechniquesDocument58 pagesModern Management Techniquessend2hemant100% (10)

- Session 18 MGN600Document48 pagesSession 18 MGN600Manjit KaurNo ratings yet

- What Is TPM: Knowledge BaseDocument29 pagesWhat Is TPM: Knowledge BasealpanasherawatNo ratings yet

- 2018 IPPE - CallanderDocument26 pages2018 IPPE - CallanderAlpha Excellence consultingNo ratings yet

- 7 Step Guide: To ERP TransformationDocument11 pages7 Step Guide: To ERP TransformationDon RodrigueNo ratings yet

- 7 Step Guide - ERP TransformationDocument11 pages7 Step Guide - ERP TransformationPaul Vintimilla CarrascoNo ratings yet

- 5S For SuppliersDocument4 pages5S For SuppliersxyalfaxyzNo ratings yet

- 5s, Kaizen, Kanban SystemDocument11 pages5s, Kaizen, Kanban SystemFirdaus AsryNo ratings yet

- The Carve-Out Challenge: A Roadmap For SuccessDocument16 pagesThe Carve-Out Challenge: A Roadmap For SuccessPeter HertensteinNo ratings yet

- M A PDFDocument2 pagesM A PDFSrikanth Reddy DNo ratings yet

- 100 Ways To Improve Your Lubrication ProgramDocument29 pages100 Ways To Improve Your Lubrication ProgramManne RajuNo ratings yet

- BSC Report 2010-Strategy ExecutionDocument6 pagesBSC Report 2010-Strategy ExecutionDavidNo ratings yet

- The Top 3 Condition Monitoring KPIsDocument10 pagesThe Top 3 Condition Monitoring KPIssatya krishna chagantiNo ratings yet

- 5 Essential Principles For A Better Strategy Review (Palladium 2015)Document8 pages5 Essential Principles For A Better Strategy Review (Palladium 2015)Grant MillinNo ratings yet

- Setup Reduction For Flexo PrintersDocument3 pagesSetup Reduction For Flexo PrinterschandrakantgadhiaNo ratings yet

- Using Six Steps, Not Your Sixth Sense: No More Crystal-Ball ForecastingDocument2 pagesUsing Six Steps, Not Your Sixth Sense: No More Crystal-Ball ForecastingAshok MuthuswamyNo ratings yet

- Technical Topic - Lubrication Program ManagementDocument2 pagesTechnical Topic - Lubrication Program Managementdhavit wijayantoNo ratings yet

- Kaizen PDFDocument29 pagesKaizen PDFanandNo ratings yet

- Process Product PeopleDocument3 pagesProcess Product PeopleUppiliappan GopalanNo ratings yet

- Extra Readings - Lean SystemsDocument6 pagesExtra Readings - Lean Systemsabhinav.k0509No ratings yet

- The Revolution of Lean PDFDocument10 pagesThe Revolution of Lean PDFdhesselyNo ratings yet

- OilSafe Catalog 201304 PDFDocument38 pagesOilSafe Catalog 201304 PDFFernandoPelozioNo ratings yet

- Company Profile: Scrap ManegementDocument29 pagesCompany Profile: Scrap ManegementAjay KaushikNo ratings yet

- Bridging The Gap Between A Companys Strategy and Operating Model VFDocument5 pagesBridging The Gap Between A Companys Strategy and Operating Model VFRaviteja GogineniNo ratings yet

- TPMDocument10 pagesTPMMohammed AlamNo ratings yet

- Improve PhaseDocument61 pagesImprove Phaserobertofernandez091166No ratings yet

- Assignment 01Document14 pagesAssignment 01AlpeshkumarNo ratings yet

- Gargeya and Brady (2005) Article ERPS PDFDocument17 pagesGargeya and Brady (2005) Article ERPS PDFAlixon Antonio MoncadaNo ratings yet

- The Difference Between 5S and KaizenDocument8 pagesThe Difference Between 5S and KaizenNenadNo ratings yet

- Total Productive Maintenance: Aoulad Ben Taib DikraDocument4 pagesTotal Productive Maintenance: Aoulad Ben Taib DikraabirNo ratings yet

- 1.1 Lubrication Management and Organization (LUB)Document53 pages1.1 Lubrication Management and Organization (LUB)Busuioc AlexNo ratings yet

- Case5 Group4 SectionADocument3 pagesCase5 Group4 SectionAYashita PruthiNo ratings yet

- KaizenDocument21 pagesKaizendcunhabrian100% (1)

- Maintenance Practices Bloch 3Document8 pagesMaintenance Practices Bloch 3rodolfostiNo ratings yet

- 7 Steps Operational Excellence PexDocument11 pages7 Steps Operational Excellence PexManuel EstradaNo ratings yet

- Mba - 2 Pom GauravDocument7 pagesMba - 2 Pom GauravDibyendu DeyNo ratings yet

- SAP FSCM Interview Question and AnswersDocument3 pagesSAP FSCM Interview Question and AnswersjsphdvdNo ratings yet

- LEAN ENTERPRISE: Transforming Organizations Through Agile Principles and Continuous Improvement (2023 Guide for Beginners)From EverandLEAN ENTERPRISE: Transforming Organizations Through Agile Principles and Continuous Improvement (2023 Guide for Beginners)No ratings yet

- Lean QuickStart Guide: The Simplified Beginner's Guide to LeanFrom EverandLean QuickStart Guide: The Simplified Beginner's Guide to LeanNo ratings yet

- Retooling Your Lubricant Storage and Handling EquipmentDocument5 pagesRetooling Your Lubricant Storage and Handling EquipmentBrayan MejiaNo ratings yet

- Water Contamination in Hydraulic and Lube SystemsDocument11 pagesWater Contamination in Hydraulic and Lube SystemsBrayan MejiaNo ratings yet

- Oil Filtering Whitepaper 2017Document10 pagesOil Filtering Whitepaper 2017Brayan MejiaNo ratings yet

- Des-Case Product Catalog: ISSUE 3 - 2016Document25 pagesDes-Case Product Catalog: ISSUE 3 - 2016Brayan MejiaNo ratings yet

- Catalog G-1 Chem, Lubricants and AccDocument32 pagesCatalog G-1 Chem, Lubricants and AccBrayan MejiaNo ratings yet

- Emkarate Is The Only Name You Need To Know: Emkarate Refrigeration Lubricants - Approval ListDocument2 pagesEmkarate Is The Only Name You Need To Know: Emkarate Refrigeration Lubricants - Approval ListBrayan MejiaNo ratings yet

- Emkarate RL Refrigeration LubricantsDocument6 pagesEmkarate RL Refrigeration LubricantsBrayan MejiaNo ratings yet

- Bulldozer D375ADocument16 pagesBulldozer D375ABrayan MejiaNo ratings yet

- Broshure Reliance Ultrasonic WashersDocument2 pagesBroshure Reliance Ultrasonic WashersbrisaNo ratings yet

- TechCare TCCDocument6 pagesTechCare TCCironiteNo ratings yet

- MMH Dan StoringDocument13 pagesMMH Dan Storingfilza100% (1)

- ASV Posi-Track PT-100 Track Loader Mater Parts Catalogue Manual PDFDocument16 pagesASV Posi-Track PT-100 Track Loader Mater Parts Catalogue Manual PDFfisekkkd100% (2)

- Hardened Way SlidesDocument32 pagesHardened Way SlideskanagarajuNo ratings yet

- Central Lubrication System 16Document16 pagesCentral Lubrication System 16Arslan AhmedNo ratings yet

- Nassar2017 Article PreparationAndEvaluationOfTheMDocument13 pagesNassar2017 Article PreparationAndEvaluationOfTheMCristinaNo ratings yet

- SMT Crane Maintenance ManualDocument84 pagesSMT Crane Maintenance ManualArun Tiwari100% (1)

- ScopeDocument3 pagesScopeqamgr.sudairNo ratings yet

- QWS2500 SD, Or67658, Line 1 - Service ManualsDocument108 pagesQWS2500 SD, Or67658, Line 1 - Service ManualsmaciekziebaNo ratings yet

- CSP0000160-01 LubricationDocument13 pagesCSP0000160-01 LubricationA̶l̶x̶a̶n̶d̶e̶r̶ PaniNo ratings yet

- Winky 5Document2 pagesWinky 5bill_gator20059105No ratings yet

- Insertion of Suppositories 2 RemovedDocument16 pagesInsertion of Suppositories 2 Removedmikealtttt7No ratings yet

- PM Inspection SheetDocument4 pagesPM Inspection SheetYogeshNo ratings yet

- L45425en BDocument4 pagesL45425en BJerNo ratings yet

- Car Detailing GuideDocument76 pagesCar Detailing GuideZohirNo ratings yet

- TOM Training Centrifugal Compressors: IndexDocument8 pagesTOM Training Centrifugal Compressors: IndexAhmedNo ratings yet

- Service Parts List: Transmission 6422-84 4265557Document47 pagesService Parts List: Transmission 6422-84 4265557Bryan RibeiroNo ratings yet

- MAN B&W Diesel A/S: Service LetterDocument5 pagesMAN B&W Diesel A/S: Service LetterAKINMOLADUN OMOLADENo ratings yet

- Rexroth Ball ScrewDocument165 pagesRexroth Ball ScrewJacob100% (1)

- Us Terex pt-100 Forestry Mstr-Parts 1-10Document37 pagesUs Terex pt-100 Forestry Mstr-Parts 1-10Хелфор УкраинаNo ratings yet

- Effects of Bearing Cleaning Peter WardDocument16 pagesEffects of Bearing Cleaning Peter Wardanhntran4850No ratings yet

- Va1 Dec 2Document15 pagesVa1 Dec 2Xuân Định LêNo ratings yet

- Renolin Hi Temp Chain LubeDocument2 pagesRenolin Hi Temp Chain Lubempe.mohamed2010No ratings yet

- Lube Oil PresentationDocument19 pagesLube Oil Presentationasirul_meNo ratings yet