Professional Documents

Culture Documents

Ci̇vata Sikma Torklari

Ci̇vata Sikma Torklari

Uploaded by

akın ersözOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ci̇vata Sikma Torklari

Ci̇vata Sikma Torklari

Uploaded by

akın ersözCopyright:

Available Formats

Specification Item code: 11175682

Index: 002

SITE PORTAL FLANGE JOINT ASSEMBLY BOLTING PROCEDURE

Site inspection of flange joint mating surfaces

Manufacture Requirements For Flanges

In order for satisfactory flange friction grip coefficient values outlined by the design

requirements, (0.55 friction coefficient requirements as per FEM table T.A 3.2.2.2.2.3.1)

then the flange joints must be shot blasted to Sa 2 1/2 requirements ISO 8501-1. This

gives rise to a peak to valley roughness of 60-80μm typically. Flange squareness with

bolt hole must be maintained. Prior to leaving LCC all friction grip flange joint are

painted with International paints Interzinc 22 paint, this paint system provides a dual

function:

Protects the flange joint mating surfaces from corrosion during transport,

while promoting good friction coefficient for the flange mating surface.

If site personnel find a situation where the flange protection cover Interzinc 22 has been

removed due to transport accidents, etc, then it is necessary to rough sand or wire bush

and clean the affected areas before assembling the joint. Note, the joint must be

assembled within five hours of sanding and all debris cleaned from the flange

mating surfaces. Site personnel should photograph the affected area before and after

dressing to maintain records for PA files.

Bolt Joining Procedures

Before & during the joint assembly the site supervisor must ensure:

Correct bolts, washers, nuts and lock nuts are being used for the assembly.

Bolts threads are adequately lubricated with Liebherr Special Screw Paste and the

nut face that mates with washer has the Liebherr Special Screw Paste sparingly

applied.

A LCC copy of the required torque values plus the assembly diagram/Binding BOM

for the bolted joint assembly must be available. The appropriate sequence to tighten

a joint should be used i.e.,

o All bolts tightened to 80% of final torque value before final torque sequence is

carried out.

A valid certified torque wrench is available. A copy of the certificate should be

obtained for LCC records – PA file.

LCC

Date Work Prepared Checked Approved

No copying or duplication of this document without the permission of Liebherr.

This document has been issued electronically and is valid without signature.

1

Specification Item code: 11175682

Index: 002

A valid certified power pack and pressure gauge is available. A copy of the

certificate should be obtained for LCC records – PA file.

A data sheet outlining the correct pressure settings for the power pack being used is

required in order to achieve the correct torque settings. A copy of this data sheet

should be obtained for LCC records and state what pressure settings were used –

PA File.

Ensure hydraulic pressure line fittings are correctly secured, as partially secured

fittings will give rise to incorrect torque results (lower torque valves).

Ensure when pressure setting is set that the pressure setting relief valve is locked in

position using the lock nut, if the relief valve is not locked then the valve may change

position as a result of vibration thus causing incorrect pressure settings. Check at

regular intervals to see if the pressure setting is maintained.

Observe work methods when torqueing the bolts. Ensure that the torque wrench is

perpendicular to the flange and there are no kinks present on the pressure lines.

Once joint is fully torqued, caulk joint seam with appropriate sealant and paint as per

standard LCC painting policies.

Degrease each bolt assembly and apply primer & paint as carried out by our

standard LCC painting policies.

Figure 1 Pre-stressed High-tensile Bolt Connections Greasing

LCC

Date Work Prepared Checked Approved

No copying or duplication of this document without the permission of Liebherr.

This document has been issued electronically and is valid without signature.

2

Specification Item code: 11175682

Index: 002

Figure 2 Pre-stressed High-tensile Bolt Connections

LCC

Date Work Prepared Checked Approved

No copying or duplication of this document without the permission of Liebherr.

This document has been issued electronically and is valid without signature.

3

Specification Item code: 11175682

Index: 002

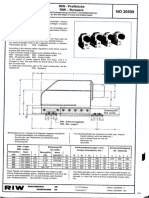

Table 1. Pre-stressed High-tensile Bolt Connections Torque Values

Torque Wrench Assembly

Property Class 8.8 Property Class 10.9 Property Class 12.9

ISO 4014 ISO 4014

ISO 4014 ISO 4017 ISO 4017

ISO 4017 ISO 7412 ISO 4762 ISO 4762

DIN 931 DIN 6914 DIN 931 DIN 931

DIN 933 DIN 933 DIN 933

DIN 912 DIN 912

kp.m N.m lb/ft kp.m N.m lb/ft kp.m N.m lb/ft kp.m N.m lb/ft

M12 5.2 51 37 9.8 96 70 7.4 73 53

M14 8.4 82 61 13 127 94

M16 14 137 101 24.7 242 178 19.1 187 138

M18 18 177 130 26 255 188

M20 25.9 254 187 48.3 474 350 37 363 267

M22 35.8 351 258 66 647 477 51.1 501 370

M24 44.8 439 323 83 814 600 64 628 462

M27 70 686 506 123 1206 890 100 981 723

M30 95.8 939 692 136.8 1342 990

M33 130.9 1284 946 187 1834 1352 230.8 2264 1669

M36 167.3 1641 1209 239 2344 1728 296.1 2904 2141

M39 217.3 2131 1570 310.4 3044 2244 383.6 3762 2773

M42 268.4 2632 1940 383.4 3760 2772 476.3 4670 3444

M45 335.4 3289 2424 479.1 4693 3463 594.8 5833 4300

M48 403.6 3958 2918 576.6 5655 4168 717.8 7039 5190

LCC

Date Work Prepared Checked Approved

No copying or duplication of this document without the permission of Liebherr.

This document has been issued electronically and is valid without signature.

4

You might also like

- Demag DKUN Hoist Operating ManualDocument80 pagesDemag DKUN Hoist Operating ManualMarco Silva67% (3)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Estimating Concrete Strength by The Maturity Method: Standard Practice ForDocument10 pagesEstimating Concrete Strength by The Maturity Method: Standard Practice ForMichael PEtrovNo ratings yet

- The Sinister Dialectic and Diabolical Aims of The Order of Nine AnglesDocument6 pagesThe Sinister Dialectic and Diabolical Aims of The Order of Nine AnglesBillion dalaNo ratings yet

- 002 - GET InstallationDocument20 pages002 - GET InstallationVictor Marcos BautistaNo ratings yet

- Collateral DocumentsDocument59 pagesCollateral DocumentsdannyNo ratings yet

- Screwdriver - SZS 1,0X5,5 VDE - 1209114: Key Commercial DataDocument3 pagesScrewdriver - SZS 1,0X5,5 VDE - 1209114: Key Commercial DataDkalestNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument13 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- 0.3 Technical - Spec. - DrawingDocument9 pages0.3 Technical - Spec. - DrawingAchmad ChusnadiNo ratings yet

- MD Eng 259 PDFDocument71 pagesMD Eng 259 PDFChirag SolankiNo ratings yet

- Bolted Flange and Gasket Joints Assembly ProcedureDocument9 pagesBolted Flange and Gasket Joints Assembly ProceduremohdNo ratings yet

- Ancon Tapered Thread Couplers International Version PDFDocument16 pagesAncon Tapered Thread Couplers International Version PDFAhmadHamdyNo ratings yet

- Service Manual: Issue Date: 30 November 2004Document29 pagesService Manual: Issue Date: 30 November 2004CapitanSalamiNo ratings yet

- Line-000-Ca-4-0012 - Specification For Piling Work - Rev. 0Document8 pagesLine-000-Ca-4-0012 - Specification For Piling Work - Rev. 0Daniel SinagaNo ratings yet

- Flygt d2740 OnderdelenlijstDocument14 pagesFlygt d2740 OnderdelenlijstJOSUE JAMES ROBLADILLO TICONANo ratings yet

- rh560 Hammers Specification Sheet English PDFDocument6 pagesrh560 Hammers Specification Sheet English PDFIng del PeleNo ratings yet

- rh560 DTH Hammers EnglishDocument8 pagesrh560 DTH Hammers EnglishFelipeDeejayValenzuelaNo ratings yet

- 019-3203 - Orifice Plate - Rev 1Document11 pages019-3203 - Orifice Plate - Rev 1Sunil KoricherlaNo ratings yet

- Powerchain CY Cable: Application StandardsDocument2 pagesPowerchain CY Cable: Application StandardsRuben Checalla RamosNo ratings yet

- Manual Bomba ManualDocument4 pagesManual Bomba ManualGerson Rojas HuamaniNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument12 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- SL 718Document7 pagesSL 718Jessey StonerNo ratings yet

- Electrostatic PrecipitatorDocument52 pagesElectrostatic PrecipitatorsergioNo ratings yet

- Branch Cable Primer TDS - Feb 2018Document11 pagesBranch Cable Primer TDS - Feb 2018Kerr AgotNo ratings yet

- FS 4003-Nav Aid-Well Platform-Rev 3Document17 pagesFS 4003-Nav Aid-Well Platform-Rev 3Dinesh RajNo ratings yet

- FS 3301 - FS-Temperature SwitchDocument8 pagesFS 3301 - FS-Temperature SwitchBinu ManiNo ratings yet

- FS 4015 NGR, Rev - 0Document8 pagesFS 4015 NGR, Rev - 0Dinesh RajNo ratings yet

- SBEC13032008ENR2Document26 pagesSBEC13032008ENR2Impress Production PlanningNo ratings yet

- Lennox-VRF Submittals IDU VE8K009N STDDocument2 pagesLennox-VRF Submittals IDU VE8K009N STDDaniel Sullón López100% (1)

- Untitled 1Document2 pagesUntitled 1Ducke LatumetenNo ratings yet

- Splicing and Termination of MV Cables Rev.02 Re-Submitted - 9 Apr-15Document8 pagesSplicing and Termination of MV Cables Rev.02 Re-Submitted - 9 Apr-15kbldamNo ratings yet

- HPT Stage 1 Blades and Duct SegmentsDocument28 pagesHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekNo ratings yet

- Technical Specification For Perforated DIN RAILDocument9 pagesTechnical Specification For Perforated DIN RAILFrancis SonkengNo ratings yet

- HDB BreakersDocument88 pagesHDB Breakersmargotsilva96No ratings yet

- LT1140Document2 pagesLT1140John McClaneNo ratings yet

- Operation, Installation, Maintenance Manual Air Intake Silencer Item: 02D001 Ton: 1021D001Document6 pagesOperation, Installation, Maintenance Manual Air Intake Silencer Item: 02D001 Ton: 1021D001Arun KarthikeyanNo ratings yet

- Ba-Et - GL 502 - enDocument44 pagesBa-Et - GL 502 - enH.H. SNo ratings yet

- 40.17models V2725 V2726Document6 pages40.17models V2725 V2726Riaz EbrahimNo ratings yet

- Supplementary Operating Manual KSB EthanormDocument10 pagesSupplementary Operating Manual KSB EthanormLucas Rizzardi SaldanhaNo ratings yet

- KEBAB MkII Installation Guide D501206 Ver.1.00Document16 pagesKEBAB MkII Installation Guide D501206 Ver.1.00Mimaki TechNo ratings yet

- VK3502 Quick Response Upright Sprinkler K8.0 (115) : 1. Product IdentificationDocument16 pagesVK3502 Quick Response Upright Sprinkler K8.0 (115) : 1. Product Identificationyjayasanka588No ratings yet

- Air Release and Hydraulic ReleaseDocument20 pagesAir Release and Hydraulic ReleaseWilber Anibal MoralesNo ratings yet

- Technical Data Sheet: MX8534 Standard/Quick Response Extended Coverage ELO Pendent Sprinkler K11.2Document5 pagesTechnical Data Sheet: MX8534 Standard/Quick Response Extended Coverage ELO Pendent Sprinkler K11.2ciccioNo ratings yet

- Technical Data Sheet: MX8534 Standard/Quick Response Extended Coverage ELO Pendent Sprinkler K11.2Document5 pagesTechnical Data Sheet: MX8534 Standard/Quick Response Extended Coverage ELO Pendent Sprinkler K11.2ciccioNo ratings yet

- Aips01-02-015 Installation of Blind Type ThreadedDocument22 pagesAips01-02-015 Installation of Blind Type ThreadedAlberto Biedma FernándezNo ratings yet

- Assymetrical WedgeDocument1 pageAssymetrical WedgeNurettin IsikNo ratings yet

- Extreme Copper PCBsDocument12 pagesExtreme Copper PCBsskgNo ratings yet

- Torque Chart B7 Metric Rev.01Document3 pagesTorque Chart B7 Metric Rev.01Vinoth BalaNo ratings yet

- Printed-Circuit Board Connector - BCH-381HF-14 BK - 5452344: Key Commercial DataDocument6 pagesPrinted-Circuit Board Connector - BCH-381HF-14 BK - 5452344: Key Commercial DataEduardo Brayan Melchor BricenoNo ratings yet

- Projects & Development India LTD: EM238-TC-5201 0 Document No REV Sheet 1 of 9Document10 pagesProjects & Development India LTD: EM238-TC-5201 0 Document No REV Sheet 1 of 960606060No ratings yet

- Coil Spring For Fiat BogieDocument99 pagesCoil Spring For Fiat BogieBhabasankar SamantaNo ratings yet

- FS 3200 - FS-Flow SwitchDocument4 pagesFS 3200 - FS-Flow SwitchBinu ManiNo ratings yet

- Ferrule - AI 1,5 - 10 BK - 3200195: Key Commercial DataDocument4 pagesFerrule - AI 1,5 - 10 BK - 3200195: Key Commercial Dataleontius mesantonoNo ratings yet

- VD-LINE-WP57-SUB-ATM-0001-017 - ERECTION AND INSTALLATION PROCEDURE ATM TANK - Rev.1Document18 pagesVD-LINE-WP57-SUB-ATM-0001-017 - ERECTION AND INSTALLATION PROCEDURE ATM TANK - Rev.1tomy.jipNo ratings yet

- Draft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFDocument27 pagesDraft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFVishal Kinikar0% (1)

- Anchr Bolt RefDocument9 pagesAnchr Bolt ReferleosNo ratings yet

- S171 172 Service ManualDocument19 pagesS171 172 Service Manualwill du camNo ratings yet

- HX500GII-on MK5G2PK01E 40Document25 pagesHX500GII-on MK5G2PK01E 40al221511243No ratings yet

- Skyworth (Group) Co., LTD.: Engineering Evaluation Report (Components)Document42 pagesSkyworth (Group) Co., LTD.: Engineering Evaluation Report (Components)Abir AhmedNo ratings yet

- QVD Water Tank 704Document4 pagesQVD Water Tank 704dendi hidayatNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- Hydraulic Buffers For CranesDocument4 pagesHydraulic Buffers For Cranesakın ersözNo ratings yet

- Commerciale DRH - Inglese - KMAN02CG00-CRYP PDFDocument36 pagesCommerciale DRH - Inglese - KMAN02CG00-CRYP PDFakın ersözNo ratings yet

- Bumper StandartDocument1 pageBumper Standartakın ersözNo ratings yet

- Effective Control: Spring BuffersDocument3 pagesEffective Control: Spring Buffersakın ersözNo ratings yet

- TM-02 Spring Rail Clamp 04-2014Document23 pagesTM-02 Spring Rail Clamp 04-2014akın ersözNo ratings yet

- Weighing System Inquiry FormDocument4 pagesWeighing System Inquiry Formakın ersözNo ratings yet

- For Industrial Applications: Ffective ControlDocument8 pagesFor Industrial Applications: Ffective Controlakın ersözNo ratings yet

- Hyfil K8Document2 pagesHyfil K8akın ersözNo ratings yet

- KC SERISI - Standart TabloDocument6 pagesKC SERISI - Standart Tabloakın ersözNo ratings yet

- Siemens Motor KodlariDocument1 pageSiemens Motor Kodlariakın ersözNo ratings yet

- Hea - Heb - HemDocument12 pagesHea - Heb - Hemakın ersözNo ratings yet

- 2017 - 01 - 12 - Static - 185t PH Crane PDFDocument128 pages2017 - 01 - 12 - Static - 185t PH Crane PDFakın ersözNo ratings yet

- Tanker Analiz RaporuDocument23 pagesTanker Analiz Raporuakın ersözNo ratings yet

- 20190305Document2 pages20190305akın ersözNo ratings yet

- Hea - Heb - HemDocument12 pagesHea - Heb - Hemakın ersözNo ratings yet

- ABM 2020 Price ListDocument3 pagesABM 2020 Price Listakın ersözNo ratings yet

- Kumsan CatalogueDocument72 pagesKumsan Catalogueakın ersöz100% (1)

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- PV Elite Örnek PDFDocument223 pagesPV Elite Örnek PDFakın ersözNo ratings yet

- Catalog Marine Engineering Interactive PDFDocument67 pagesCatalog Marine Engineering Interactive PDFakın ersözNo ratings yet

- Art Collector I105 07.09 2023Document236 pagesArt Collector I105 07.09 2023JjxpresidentNo ratings yet

- Concrete TechnologyDocument118 pagesConcrete Technologyeskinderm100% (30)

- Hydrogen System ValidationDocument4 pagesHydrogen System Validationanita shindeNo ratings yet

- LS-Fiber Optical Interface Mini Card For Loop-AM3440: FeaturesDocument4 pagesLS-Fiber Optical Interface Mini Card For Loop-AM3440: FeaturesAmrNo ratings yet

- CW9 Identifying Functions 5Document2 pagesCW9 Identifying Functions 5Xavier BurrusNo ratings yet

- ICTP VaporPressureGroup 2 PDFDocument27 pagesICTP VaporPressureGroup 2 PDFHarySetiyawanNo ratings yet

- Class 11 Cell Cycle and Cell DivisionDocument2 pagesClass 11 Cell Cycle and Cell Divisionjeeneet.alwalNo ratings yet

- AQUAVARI - Kinetic Air Valve WeightsDocument47 pagesAQUAVARI - Kinetic Air Valve WeightssandeshNo ratings yet

- API Vol 2Document220 pagesAPI Vol 2Mosam ShuklaNo ratings yet

- Agricultural Transformation Agency (ATA) Office of Human ResourceDocument2 pagesAgricultural Transformation Agency (ATA) Office of Human ResourceRedwanNo ratings yet

- (Urban and Industrial Environments) Andrew Karvonen - Politics of Urban Runoff - Nature, Technology, and The Sustainable City-The MIT Press (2011)Document307 pages(Urban and Industrial Environments) Andrew Karvonen - Politics of Urban Runoff - Nature, Technology, and The Sustainable City-The MIT Press (2011)Florina PtlNo ratings yet

- Produc Ts BMW Icom BMW Icom A2 Icom A3Document2 pagesProduc Ts BMW Icom BMW Icom A2 Icom A3ThiagoNo ratings yet

- Cell Structure and Organisation NotesDocument27 pagesCell Structure and Organisation NotesGift Blessed NgoveNo ratings yet

- Physical Fitness - Certificate 2022Document2 pagesPhysical Fitness - Certificate 2022Warrior SoulNo ratings yet

- Kelompok 10 - 1-s2.0-S002364381730004X-mainDocument4 pagesKelompok 10 - 1-s2.0-S002364381730004X-mainAngelina NitaNo ratings yet

- Piping DesignDocument122 pagesPiping Designfacebookshop100% (9)

- Disaster Management in Indian Railways: (Para 1.10.1)Document33 pagesDisaster Management in Indian Railways: (Para 1.10.1)lvsaruNo ratings yet

- Bhs Inggris A - SoalDocument9 pagesBhs Inggris A - SoalKhaerul AnamNo ratings yet

- Data Sheet: DEGALAN® LP 64/12Document2 pagesData Sheet: DEGALAN® LP 64/12Akhtar aliNo ratings yet

- E-Techno: Cbse Class-Ix - E6 - E-Techno JEE TEST DATE: 17-11-2020Document16 pagesE-Techno: Cbse Class-Ix - E6 - E-Techno JEE TEST DATE: 17-11-2020Himanshu ThakurNo ratings yet

- Scad World School Pre Mid Term Exam - July2019 Physics Class XiDocument2 pagesScad World School Pre Mid Term Exam - July2019 Physics Class XiComputer FacultyNo ratings yet

- Exp#1 Diode Characteristics V2Document12 pagesExp#1 Diode Characteristics V2Shehda ZahdaNo ratings yet

- Isye6501 Office Hour Fa22 Week10 MonDocument8 pagesIsye6501 Office Hour Fa22 Week10 MonXuan KuangNo ratings yet

- Scheme & Syllabus 2017-18Document72 pagesScheme & Syllabus 2017-18Ritik GandhiNo ratings yet

- Competition4Job: Rajasthan Police Constable Model Set Paper G.KDocument71 pagesCompetition4Job: Rajasthan Police Constable Model Set Paper G.KRADHEYSHYAM_KALAWATNo ratings yet

- English Grade 3Document269 pagesEnglish Grade 3Berhanu AlemuNo ratings yet

- Water Distribution System of Barangay Poblacion, Kapatagan, Lanao Del Norte (A Framework Study)Document4 pagesWater Distribution System of Barangay Poblacion, Kapatagan, Lanao Del Norte (A Framework Study)LeMoneNo ratings yet

- 2021 05 15 - LogDocument33 pages2021 05 15 - LogTeuku ChalisNo ratings yet