Professional Documents

Culture Documents

07.4 111 FW ML PF WPS 20mm ENG

07.4 111 FW ML PF WPS 20mm ENG

Uploaded by

ViktorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07.4 111 FW ML PF WPS 20mm ENG

07.4 111 FW ML PF WPS 20mm ENG

Uploaded by

ViktorCopyright:

Available Formats

Company name:

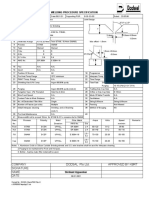

WELDING PROCEDURE SPECIFICATION

WPS

Subject STEERING ENGINE FOUNDATION’S BRACKETS ( 5 PCS) Revision No.:0

WPQR no. - Standard ISO 15609-1:2004

WPS no. WPS-07.4 Welding process 111/ MA

Joint type FW bs nb (ml) Welding position PF

Thickness in T1 (mm) 20 Joint preparation / Welding sequence

Thickness in T2 (mm) 65

Pipe diameter (mm) N/A

Edge preparation Gas cutting and

grinding

Backing material

N/A

Backing gouging

N/A

Interpass temp. (°C) max.

NA

Preheating temp (°C) min.

NA .

Weaving in mm Weld using straight run

( weld seams - 95 mm)

Baking or draying: NA

Base material, Filler and auxiliary specification / Standard

Index Base material T1 Base material T2 Consumable 1 Consumable 2 Gas Flux

Trade name

Grade A Grade A Esab OK 48.00 N/A N/A N/A

Spec/standard CEN ISO/TR 15608 CEN ISO/TR 15608 ISO 2560-A N/A N/A N/A

Type/quality Group 1.1 Group 1.1 E 42 4 B 4 2 H5 N/A N/A N/A

Welding parameters:

Run Welding Filler Filler Current Travel Wire

Amperes Volts Gas flow Heat input

no. process index dia. AC/DC speed feed

(+;-;+/-) (mm/min) (m/min)

1 111 1 2.0 75-80 21 DC(+) 58 N/A N/A -

2 111 1 4.0 120-125 24 DC(+) 64 N/A N/A -

3 111 1 4.0 120-125 24 DC(+) 64 N/A N/A -

4 111 1 4.0 120-125 24 DC(+) 64 N/A N/A -

5 111 1 4.0 120-125 24 DC(+) 64 N/A N/A -

Tacking/N/A

Tacking parameters Length Preheat before tacking (°C)

NA

Other information / - After each pass mechanical grinding till bright metal.

Torch angel / N/A Cleaning method Mechanical Tungsten type N/A

grinding

Stand of distance (mm) / - Nozzle diameter (mm)/ N/A Tungsten diameter (mm) N/A

Heat treatment

PWHT °C / Time h / Time min. Heating/cooling rates °C/min Max. temperature gradient

(°C)

N/A N/A N/A N/A N/A

Approval for production

Manufacturer / Yard Classification Society

Place & Date 2020.02.10

Signature & Stamp /

You might also like

- Company Profile - Rizhao Steel YingkouDocument41 pagesCompany Profile - Rizhao Steel Yingkourashid isaarNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Marine Engine Foundation Design GuideDocument26 pagesMarine Engine Foundation Design GuideVu Thong100% (1)

- Brain ForkDocument6 pagesBrain ForkRiki MandolNo ratings yet

- Design and Analysis of Geometrical Parameters Influencing On Curvic CouplingDocument5 pagesDesign and Analysis of Geometrical Parameters Influencing On Curvic CouplingIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad Bilal100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- 15CrMo Alloy Steel TubeDocument5 pages15CrMo Alloy Steel TubeIbnu KhusnaNo ratings yet

- RT AccepDocument1 pageRT AccepEILA545 QAQCNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- VP16 PDFDocument13 pagesVP16 PDFKara WhiteNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- ARKAN SHADES Welding Inspection & Paint InspectionDocument2 pagesARKAN SHADES Welding Inspection & Paint InspectionSpectex dubaiNo ratings yet

- WPQ Ejcom Nr476Document13 pagesWPQ Ejcom Nr476Touil HoussemNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- WPS Reg Rev.0Document3 pagesWPS Reg Rev.0Ed FangNo ratings yet

- GB-T 232-2010 Metallic Materials-Bend TestDocument14 pagesGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.No ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Electrofusion Calibration Report IPlast105 - 1462Document1 pageElectrofusion Calibration Report IPlast105 - 1462Alicia Lizbeth Cutipa LaymeNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Solid Wire On Cast Irons (MAG Welding) : Welding Consumables Sales Department Weldtech@hishiko - Co.jpDocument1 pageSolid Wire On Cast Irons (MAG Welding) : Welding Consumables Sales Department Weldtech@hishiko - Co.jpKamranEhsanNo ratings yet

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDocument1 pageEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeNo ratings yet

- Procedure Qualification Record (PQR) : JointDocument2 pagesProcedure Qualification Record (PQR) : JointBalkishan DyavanapellyNo ratings yet

- 1.4462 PropertiesDocument1 page1.4462 PropertiesutreshwarmiskinNo ratings yet

- Welder Test Param19!03!201211Document151 pagesWelder Test Param19!03!201211VapaVapaNo ratings yet

- Welding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2Document2 pagesWelding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2phong NguyenduyNo ratings yet

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 pagesSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNo ratings yet

- Spec Sheet - Handler 210Document4 pagesSpec Sheet - Handler 210Hobart Welding ProductsNo ratings yet

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- Golden Joint ChecklistDocument2 pagesGolden Joint ChecklistMohd Effiezool YaserNo ratings yet

- Carbon Steel Pipes - Comparing AmericanDocument2 pagesCarbon Steel Pipes - Comparing AmericanKazi Anwarul Azim SohelNo ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- WPS - 023Document10 pagesWPS - 023MAT-LION0% (1)

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- ABout Preheat Before WeldingDocument2 pagesABout Preheat Before WeldingHary Olya AdriansyahNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- Paharpur Cooling Towers LTD: Magnetic Particle Testing ReportDocument1 pagePaharpur Cooling Towers LTD: Magnetic Particle Testing ReportGoutam Kumar DebNo ratings yet

- Procedure Qualification RecordsDocument2 pagesProcedure Qualification RecordsRM ENTERPRISESNo ratings yet

- Welding Domex SteelsDocument16 pagesWelding Domex Steelspozolab100% (1)

- Weld Consumables SelectionDocument3 pagesWeld Consumables SelectionArputharaj Maria LouisNo ratings yet

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- 1 MTCDocument2 pages1 MTCRazvan CristeaNo ratings yet

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- CF8M VS CF8 Stainless Steel Casting - JC CastingDocument7 pagesCF8M VS CF8 Stainless Steel Casting - JC CastingSHivaprasad APITNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocument1 pageFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- Weld Visual Inspection For Store Girder 1Document1 pageWeld Visual Inspection For Store Girder 1Ashwani DograNo ratings yet

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFvijay rajputNo ratings yet

- 3-PMI Test ProcedureDocument4 pages3-PMI Test ProcedureSezgin CkllıNo ratings yet

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- 07.3 111 FW ML PF WPS 20mm EngDocument1 page07.3 111 FW ML PF WPS 20mm EngViktorNo ratings yet

- DSB LR 07Document2 pagesDSB LR 07ViktorNo ratings yet

- 07.3 111 FW ML PF WPS 20mm EngDocument1 page07.3 111 FW ML PF WPS 20mm EngViktorNo ratings yet

- Technical Parameters of Transformer-250KVADocument1 pageTechnical Parameters of Transformer-250KVAViktorNo ratings yet

- Technical Sheet TERACOL TDocument2 pagesTechnical Sheet TERACOL TViktorNo ratings yet

- Mass of Mooring Winch Completed - 4.7 TDocument1 pageMass of Mooring Winch Completed - 4.7 TViktorNo ratings yet

- Chapter 09 Controller PrinciplesDocument40 pagesChapter 09 Controller PrinciplesMuthuMuthuNo ratings yet

- Guia de Embreagens LUKDocument36 pagesGuia de Embreagens LUKXman BrazilNo ratings yet

- Guyson Ultrasonic Spare Parts ListDocument1 pageGuyson Ultrasonic Spare Parts ListYoutube For EducationNo ratings yet

- 2001 - Fluid MechanicsDocument11 pages2001 - Fluid MechanicsChilvin ChipmunkNo ratings yet

- Surface Condenser: Applications of Surface Condensers and Requirement of Surface CondenserDocument17 pagesSurface Condenser: Applications of Surface Condensers and Requirement of Surface Condenserdroffilcz27100% (2)

- Wood-Based Structural Panels in Compression: Standard Test Methods ForDocument6 pagesWood-Based Structural Panels in Compression: Standard Test Methods ForAnvit GadkarNo ratings yet

- Specialists in Aerospace Tooling For Bearing Staking, Removal and TestingDocument2 pagesSpecialists in Aerospace Tooling For Bearing Staking, Removal and TestingWimper SpeedNo ratings yet

- ME 333 Final ExamDocument8 pagesME 333 Final ExamHassan Ayub KhanNo ratings yet

- Aircraft Brake and Method With Electromechanical Actuator ModulesDocument8 pagesAircraft Brake and Method With Electromechanical Actuator ModulesHassanNo ratings yet

- BARD Control Panel AB3000-B-spDocument4 pagesBARD Control Panel AB3000-B-spAfi IfaNo ratings yet

- MT 1440 E3 Operator ManuelDocument138 pagesMT 1440 E3 Operator ManuelEmrah MertyürekNo ratings yet

- Project Standards and Specifications Emergency Isolation Measures Rev01Document5 pagesProject Standards and Specifications Emergency Isolation Measures Rev01Tatak Bay AhmedNo ratings yet

- Hvac AssignmentDocument9 pagesHvac AssignmentCharu GargNo ratings yet

- Bolt Group Coefficient For Eccentric LoadsDocument5 pagesBolt Group Coefficient For Eccentric LoadsAnonymous 1rLNlqUNo ratings yet

- Pulleys CalculationDocument21 pagesPulleys CalculationRALPH JULES SARAUS100% (1)

- API Mpms 5.6 CoriolisDocument4 pagesAPI Mpms 5.6 CoriolisadatahdNo ratings yet

- Scrubbing Tower DesignDocument10 pagesScrubbing Tower DesignPrathmesh GujaratiNo ratings yet

- Supercored Supercored Supercored Supercored 71MAG 71MAG 71MAG 71MAGDocument8 pagesSupercored Supercored Supercored Supercored 71MAG 71MAG 71MAG 71MAGGian Marco ColicchiaNo ratings yet

- Analysis and Design of Hospital Building C+G+5 Using EtabsDocument4 pagesAnalysis and Design of Hospital Building C+G+5 Using EtabsSarah FatimaNo ratings yet

- 08 - Short Columns - 8BDocument9 pages08 - Short Columns - 8BArsi RajputNo ratings yet

- 5-2 Static Friction: Figure 5.2: On A Frictionless Floor, Your ShoeDocument2 pages5-2 Static Friction: Figure 5.2: On A Frictionless Floor, Your ShoeAydan QuliyevaNo ratings yet

- Characterisation of Rheology and Stability of DMS Milled Grades of FerrosiliconDocument13 pagesCharacterisation of Rheology and Stability of DMS Milled Grades of FerrosiliconThabiso SetlhabiNo ratings yet

- Cross Knurling Profile DIN 82-RGV-Case Study-APPORODocument3 pagesCross Knurling Profile DIN 82-RGV-Case Study-APPOROsrikanth_krishnamu_3No ratings yet

- Jsu Fizik Kertas 1 Peperiksaan Akhir Tahun 2011Document2 pagesJsu Fizik Kertas 1 Peperiksaan Akhir Tahun 2011Bradley PetersNo ratings yet

- 1 Thin Shells PDFDocument16 pages1 Thin Shells PDFMarcus Vinicius FaleiroNo ratings yet

- Time: 3 Hours Answer All Questions Maximum: 100 MarksDocument3 pagesTime: 3 Hours Answer All Questions Maximum: 100 MarksAnonymous ZB6qyhD6No ratings yet