Professional Documents

Culture Documents

Heat Exchanger Fabrication Tolerances Section 2

Heat Exchanger Fabrication Tolerances Section 2

Uploaded by

Rizqy AzharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Exchanger Fabrication Tolerances Section 2

Heat Exchanger Fabrication Tolerances Section 2

Uploaded by

Rizqy AzharCopyright:

Available Formats

HEAT EXCHANGER FABRICATION TOLERANCES SECTION 2

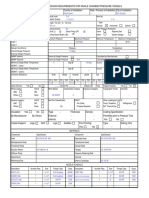

F-1 EXTERNAL DIMENSIONS, NOZZLE AND SUPPORT LOCATIONS

Standard tolerances for process flow nozzles and support locations and projections are shown in

Figure F-1. Dimensions in ( ) are millimeters.

FIGURE F-1

±1/2" (12.7)

±1/4" (6.4)

±1/4" (6.4) _ ±1/4" (6.4) ±1/4" (6.4) 4

±1/4" (6.4) ±1/4"(6.4)

±1/8" (3.2

NOMINAL NOZZLE SIZE G MAX

;Dc-q. 2" - 4" INCLUSIVE 1/16" (1.6)

6" - 12" INCLUSIVE 3/32" (2.4)

14" - 36" INCLUSIVE 3/16" (4.8)

OVER 36" 1/4" (6.4)

NOTE: THIS TABLE APPLIES TO NOZZLES

CONNECTING TO EXTERNAL PIPING ONLY.

±1/8" -4--

(3.2)

±1/8"

-(3.2)

±1/8"

41/8" (3.2111,1/8" (3.2 .,

CONNECTION NOZZLE ALIGNMENT

AND SUPPORT TOLERANCES

±1° (0.017 RAD) STACKED EXCHANGERS

3/16"(4.8) MAX

TRUE

ALLOWABLE CENTERLINE

CENTERLINE

ROTATION

ROTATIONAL TOLERANCE ON NOZZLE FACES

AT BOLT CIRCLE

www.tema.org ©Tubular Exchanger Manufacturers Association, Inc. 2-1

SECTION 2 HEAT EXCHANGER FABRICATION TOLERANCES

F-2 RECOMMENDED FABRICATION TOLERANCES

Fabrication tolerances normally required to maintain process flow nozzle and support locations are shown

in Figure F-2. These tolerances may be adjusted as necessary to meet the tolerances shown in Figure F-1.

Dimensions in ( ) are millimeters.

FIGURE F-2

2-2 ©Tubular Exchanger Manufacturers Association, Inc. www.tema.org

HEAT EXCHANGER FABRICATION TOLERANCES SECTION 2

F-3 TUBESHEETS, PARTITIONS, COVERS, AND FLANGES

The standard clearances and tolerances applying to tubesheets, partitions, covers and flanges are shown in

Figure F-3. Dimensions in ( ) are millimeters.

FIGURE F-3

STANDARD CONFINED JOINT CONSTRUCTION

D= ID DESIGN

STANDARD UNCONFINED PLAIN FACE JOINT CONSTRUCTION

I DIMENSIONS TOLERANCES 1. THIS FIGURE IS NOT INTENDED TO

R1 R2 A 7174".71787-1;6:475:21-..- PROHIBIT UNMACHINED TUBESHEET FACES

D3 D4 D5 ±1/32" (±0.8) AND FLAT COVER FACES. THEREFORE, NO

PLUS TOLERANCE IS SHOWN FOR R4.

±1116" (*1.6)

Ri = 3/16' (4.8) +0' -1/32' (+0 -0.8) 2. NEGATIVE TOLERANCE SHALL NOT BE

CONSTRUED TO MEAN THAT FINAL

R2 = 1/4' (6.4) +1/32' -0' (+0.8 -0)

DIMENSIONS CAN BE LESS THAN THAT

R3 = 1/16' (1.6) +1/32" -0' (+0.8 -0) REQUIRED BY DESIGN CALCULATIONS.

R4 = 3"

/16 (4.8) -1/32' (-0.8) (SEE NOTE 1)

3. FOR PERIPHERAL GASKETS, 'CONFINED'

II W1 W2 W3 ±1/32" (±0.8)

MEANS "CONFINED ON THE OD."

fl

4. DETAILS ARE TYPICAL AND DO NOT

ALTERNATE PRECLUDE THE USE OF OTHER DETAILS

TONGUE AND GROOVE WHICH ARE FUNCTIONALLY EQUIVALENT.

JOINT

5. FOR UNITS OVER 60" (1524) TO 100° (2540)

DIAMETER, TOLERANCES "D"AND "W" MAY

BE INCREASED TO ± 1/16" (1.6).

F-4 FLANGE FACE PERMISSIBLE IMPERFECTIONS

Imperfections in the flange facing finish, for ASME B16.5 flanges with ASME B16.20 gasket sizes used

either for nozzle or body flanges, shall not exceed the dimensions shown in Figure F-4. For custom flanges,

it is recommended that permissible imperfections should be per ASME PCC-1 Appendix D.

F-5 PERIPHERAL GASKET SURFACE FLATNESS

Peripheral gasket contact surfaces shall have a flatness tolerance of 1/32" (0.8 mm) maximum deviation

from any reference plane. This maximum deviation shall not occur in less than a 20° (0.3 Rad) arc.

www.tema.org ©Tubular Exchanger Manufacturers Association, Inc. 2-3

You might also like

- Hmel GGSRP Bathinda 16/43: Piping Material Specification 6922-6-44-0005 Rev. 0Document81 pagesHmel GGSRP Bathinda 16/43: Piping Material Specification 6922-6-44-0005 Rev. 0Krunal Shaj100% (1)

- Tubular Heat ExchangerDocument4 pagesTubular Heat Exchangerprashant_dc_inNo ratings yet

- Bolt Tightening ProcedureDocument6 pagesBolt Tightening Procedureal arabiNo ratings yet

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNo ratings yet

- Barudan BENSDocument103 pagesBarudan BENSSergio Arbey Monsalve Betancur67% (3)

- E-Jet 1800 User Manaul v1Document53 pagesE-Jet 1800 User Manaul v1Wilman Leal50% (2)

- Codes StandardsDocument61 pagesCodes Standardshrk100No ratings yet

- Specification For NDE For Piping B016-6-44-0016 - Rev. 3Document21 pagesSpecification For NDE For Piping B016-6-44-0016 - Rev. 3Ayush Choudhary50% (2)

- Api 602 Forged Steel Valve PDFDocument4 pagesApi 602 Forged Steel Valve PDFThomasFrenchNo ratings yet

- Spe 77-105 Gate Globe and Check Valves To Bs 5154Document9 pagesSpe 77-105 Gate Globe and Check Valves To Bs 5154awisakipNo ratings yet

- ASME Steam Blowing Acceptance CriteriaDocument3 pagesASME Steam Blowing Acceptance CriteriaMuhammad AlfattahNo ratings yet

- Heat Treatment Requirement As Per ASME B31.3Document2 pagesHeat Treatment Requirement As Per ASME B31.3Siddiqui Abdul Khaliq67% (3)

- API Standard 660: Shell-and-Tube Heat Exchangers For General Refinery ServicesDocument3 pagesAPI Standard 660: Shell-and-Tube Heat Exchangers For General Refinery Servicesrtrajan_mech54080% (1)

- Asme U1 FormsDocument4 pagesAsme U1 FormsoberaiNo ratings yet

- Straddle Principle For FlangesDocument1 pageStraddle Principle For Flangesameybarve67% (3)

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- 7-12-0017 Rev 5Document2 pages7-12-0017 Rev 5cynideNo ratings yet

- A494Document7 pagesA494Prakash MakadiaNo ratings yet

- Long Seam and Circumference Seam SetupDocument4 pagesLong Seam and Circumference Seam Setuppriti kumariNo ratings yet

- Mesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Document17 pagesMesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Dwayne YiiNo ratings yet

- P3TF49 - S3 BorescopeDocument12 pagesP3TF49 - S3 BorescopeRajesh KannanNo ratings yet

- Inspection and Test Paln For LSAWDocument4 pagesInspection and Test Paln For LSAWkbpatel123No ratings yet

- Flange Bolt Tightening ProcedureDocument5 pagesFlange Bolt Tightening ProcedureArya100% (1)

- Stud Bolt LengthDocument1 pageStud Bolt LengthSanthosh100% (1)

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- PSV 430066 PDFDocument41 pagesPSV 430066 PDFErikikoNo ratings yet

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Document31 pagesStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaNo ratings yet

- GMAW Welding Gas SelectionDocument4 pagesGMAW Welding Gas SelectionkapsarcNo ratings yet

- PMS-V32-Ball Valves - FlangedDocument2 pagesPMS-V32-Ball Valves - FlangedMB Azharudeen100% (1)

- ASME CODE Section VIII Div 1 Vs Div 2 Design FactorDocument7 pagesASME CODE Section VIII Div 1 Vs Div 2 Design FactorsarvannnNo ratings yet

- Pipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationDocument4 pagesPipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationsaerinNo ratings yet

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (2)

- KochDocument181 pagesKochRichard FelipNo ratings yet

- Ug-116 - RT4Document3 pagesUg-116 - RT4miteshpatel191No ratings yet

- Process Industry Practices Fabrication/Installation Details Vessel Toleran (Elevation)Document1 pageProcess Industry Practices Fabrication/Installation Details Vessel Toleran (Elevation)Federico GonzálezNo ratings yet

- Astm A 450Document10 pagesAstm A 450Telmo VianaNo ratings yet

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument3 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssNo ratings yet

- Tube-To-Tube Sheet Joint RequirementsDocument2 pagesTube-To-Tube Sheet Joint RequirementsWaqas WaqasNo ratings yet

- STD-InSP-0004 (Material Identification Proceudre)Document3 pagesSTD-InSP-0004 (Material Identification Proceudre)airbroomNo ratings yet

- Table QW-253 Welding Variables Procedure Specifications (WPS) - Shielded Metal-Arc Welding (SMAW)Document2 pagesTable QW-253 Welding Variables Procedure Specifications (WPS) - Shielded Metal-Arc Welding (SMAW)BabarNo ratings yet

- 6-79-0013 Rev 2Document6 pages6-79-0013 Rev 2MONER MANUSNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- ES 22 Color Coding of Piping MaterialsDocument3 pagesES 22 Color Coding of Piping MaterialsjojeecaresNo ratings yet

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWDocument5 pagesBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiNo ratings yet

- Piping Welding General Specification Consortium) Rev-3Document48 pagesPiping Welding General Specification Consortium) Rev-3rvsreddy1972No ratings yet

- DCP Nde DV 297 HLT 01Document7 pagesDCP Nde DV 297 HLT 01Chandrasekhar mishraNo ratings yet

- Comaprison B31.1 B31.3 PipingDocument1 pageComaprison B31.1 B31.3 PipingKhurramNo ratings yet

- SBC (Safety Break-Away Couplings) v140630Document16 pagesSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- PWHT Asme B31 3 2010 PDFDocument3 pagesPWHT Asme B31 3 2010 PDFErick HoganNo ratings yet

- Gasket Installation: DurlonDocument3 pagesGasket Installation: Durlonlorenzo100% (1)

- Steel Castings, Creep-Strength Enhanced Ferritic Alloy, For Pressure-Containing Parts, Suitable For High Temperature ServiceDocument5 pagesSteel Castings, Creep-Strength Enhanced Ferritic Alloy, For Pressure-Containing Parts, Suitable For High Temperature Servicemohammed karasnehNo ratings yet

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 3Document1 pageSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 3Suraj ShettyNo ratings yet

- TDC 1150Document3 pagesTDC 1150shazanNo ratings yet

- Interplant Standard - Steel Industry: Code of Practice For Oxygen Gas Pipeline IPSS:1-06-034-17 (First Revision)Document17 pagesInterplant Standard - Steel Industry: Code of Practice For Oxygen Gas Pipeline IPSS:1-06-034-17 (First Revision)siddhesh_guessNo ratings yet

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- Printed in GermanyDocument20 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Grinnell Mechanical Products Flexible Coupling Technical Data General DescriptionDocument4 pagesGrinnell Mechanical Products Flexible Coupling Technical Data General DescriptionСергей КолесниковNo ratings yet

- SAE-J1926 Port Reference DimensionsDocument1 pageSAE-J1926 Port Reference DimensionsSamuel RochetteNo ratings yet

- Grinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataDocument4 pagesGrinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataСергей КолесниковNo ratings yet

- Game TheoryDocument85 pagesGame TheoryMuthuKumar RajendranNo ratings yet

- Section 159Xx: Greystone Energy Systems, Inc. Sample Technical SpecificationDocument18 pagesSection 159Xx: Greystone Energy Systems, Inc. Sample Technical SpecificationPrashantNo ratings yet

- Probability TheoryDocument75 pagesProbability TheoryASHABA FREDRICK JUNIORNo ratings yet

- Business Statistics Australia New Zealand 7th Edition Selvanathan Test BankDocument20 pagesBusiness Statistics Australia New Zealand 7th Edition Selvanathan Test Bankjocastaodettezjs8100% (36)

- SSH Client LogDocument9 pagesSSH Client LogbrightmsfstarNo ratings yet

- Corrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips BurnersDocument13 pagesCorrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips Burnersravikanth_rNo ratings yet

- Electric TractionDocument52 pagesElectric Tractionranjit mallickNo ratings yet

- Guidance 112 Overview of Trending of Environmental Monitoring SampleDocument2 pagesGuidance 112 Overview of Trending of Environmental Monitoring SampleMina Maher MikhailNo ratings yet

- Isometries of The Plane - BoswellDocument7 pagesIsometries of The Plane - BoswellGuido 125 LavespaNo ratings yet

- Solution Manual For Geometry 1St Edition by Martin Gay Isbn 0134173651 9780134173658 Full Chapter PDFDocument27 pagesSolution Manual For Geometry 1St Edition by Martin Gay Isbn 0134173651 9780134173658 Full Chapter PDFsteven.davis655100% (10)

- Aerial Catalog 2 - 15Document1 pageAerial Catalog 2 - 15Juan Carlos ZapataNo ratings yet

- Dance StepsDocument4 pagesDance StepsMargie Ballesteros ManzanoNo ratings yet

- Assessment 1 With Solution PDFDocument10 pagesAssessment 1 With Solution PDFMahmoud NaserNo ratings yet

- Practice Problem 2 PDFDocument2 pagesPractice Problem 2 PDFDeeksha MishraNo ratings yet

- BIAINDocument198 pagesBIAINNicholas JohnNo ratings yet

- Theoretical Analysis of DC Link Capacitor Current Ripple Reduction in The HEV DC-DC Converter and Inverter System Using A Carrier Modulation MethodDocument8 pagesTheoretical Analysis of DC Link Capacitor Current Ripple Reduction in The HEV DC-DC Converter and Inverter System Using A Carrier Modulation MethodVanHieu LuyenNo ratings yet

- Thermal Expansion CalculatorDocument3 pagesThermal Expansion CalculatorgaurangNo ratings yet

- STD 4 Science QB 1 1Document24 pagesSTD 4 Science QB 1 1Khushboo JainNo ratings yet

- Questionare and PoemDocument3 pagesQuestionare and PoemYheng Etrazalam RalaNo ratings yet

- Exploratory Factor Analysis On Road Accidents in Cagayan de Oro CityDocument23 pagesExploratory Factor Analysis On Road Accidents in Cagayan de Oro CityEino DuldulaoNo ratings yet

- IGCSE Oct-Nov 2021 Biology Paper 21Document16 pagesIGCSE Oct-Nov 2021 Biology Paper 21Aditya SenthilNo ratings yet

- Advanced Computational Models FLUENT - NOTESDocument179 pagesAdvanced Computational Models FLUENT - NOTESapi-3803751100% (3)

- Association in Java - 2022Document26 pagesAssociation in Java - 2022rocky singhNo ratings yet

- Wi-Fi Security: Canadian Institute of Technology (Cit)Document11 pagesWi-Fi Security: Canadian Institute of Technology (Cit)Bum MusicNo ratings yet

- 2.1.1.1 Video - Getting Started With Packet TracerDocument2 pages2.1.1.1 Video - Getting Started With Packet TracerFernando Totoli FerreiraNo ratings yet

- HybridcapacitorDocument23 pagesHybridcapacitorMathir LiansyahNo ratings yet

- Component Identification ElectronicsDocument23 pagesComponent Identification ElectronicsManjunatha Swamy VNo ratings yet

- Tooo': oOO OO.Document28 pagesTooo': oOO OO.ediasianagriNo ratings yet