Professional Documents

Culture Documents

Passat b4 PDF

Passat b4 PDF

Uploaded by

golf1991Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Passat b4 PDF

Passat b4 PDF

Uploaded by

golf1991Copyright:

Available Formats

Volkswagen Passat B4 - Rear axle - Front Wheel Drive Vehicles, servicing Page 1 / 22

42 - 1

Rear axle - Front Wheel Drive Vehicles, servicing

Note :

Rear axle and wheel bearing are identical for both

Basic and Plus suspension.

Axle beam must not be welded or straightened.

Wheel bolt, 110 Nm

Self-locking hex nut, 70 Nm

Axle beam must be in

horizontal position (curb

weight condition) when

tightening nut.

Rear axle - Front Wheel Drive Vehicles, servicing Page 2 / 22

Hex bolt, 25 Nm

Suspension strut

Removing and installing

42-1, Removing and

installing suspension strut to

body to 42-1, Removing

and installing suspension

strut

Disassembling and

assembling 42-1,

Suspension strut - vehicles

with Front Wheel Drive,

disassembling and

assembling

Wheel bearing

Servicing, vehicles with drum

brakes 42-3, Wheel

bearing - Front-Wheel Drive

Vehicles - drum brakes,

servicing

Servicing, vehicles with disc

brakes 42-3, Wheel

bearing - Front Wheel Drive

Vehicles - disc brakes,

servicing

Self-locking hex nut, 80 Nm

Only use self-locking nut

with permanent washer

Axle beam must be in

horizontal position (curb

weight condition) when

tightening nut

Hex bolt

Install, starting from vehicle

center

Bolt with collar, 70 Nm

If thread is damaged, re-

work cap nut in longmember

Rear axle - Front Wheel Drive Vehicles, servicing Page 3 / 22

42-1, Cap nut in

longitudinal member -

vehicles with Front Wheel

Drive, reworking

Mounting bracket with bracket

for brake pressure regulator

Installation position 42-1,

Bolt mounting bracket to axle

beam

After installing, check overall

toe of rear axle, adjust if

necessary

Do not loosen when

removing rear axle, if

possible

Hex collar nut, 35 Nm

Bracket for regulator spring

Bonded rubber bushing

Interior: Note installation

position Topic 42-1

Exterior: Note installation

position Topic 42-1

Removing 42-1,

Removing

Installing 42-1, Installing

Only replace as a pair

Axle beam

Contact surface and

threaded holes for stub axle

free of paint and dirt

Bracket for parking brake cable

Rear axle - Front Wheel Drive Vehicles, servicing Page 4 / 22

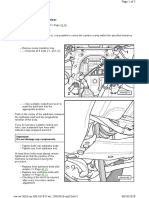

Removing and installing suspension strut to body

- Remove and install automatic belt retractor cover

Repair Manual, Body Exterior, Interior, Repair Group 70,

- Remove and install automatic belt retractor

Repair Manual, Body Exterior, Interior, Repair Group 68,

Tightening torque for bolt of automatic belt retractor -

arrow - : 40 Nm.

Removing and installing suspension strut to body

Remove and install both mounting bolts - arrows - from

Rear axle - Front Wheel Drive Vehicles, servicing Page 5 / 22

vehicle interior (direction of view through left rear side

window).

Tightening torque: 25 Nm

Removing and installing suspension strut

For bolting, suspension strut is also engaged with 4

retaining tabs to body. To remove, turn suspension strut

until retaining tabs are above recesses.

Bolt mounting bracket to axle beam

Tilt angle to axle beam 13 30’ 1 .

Bonded rubber bushing, removing and installing

Repair procedure was modified due to the introduction

of new special tools.

Rear axle - Front Wheel Drive Vehicles, servicing Page 6 / 22

Special tools, testers and auxiliary items required

Bushing Press 3111

Torque Wrench 40-200Nm VAG1332

Engine-/Gearbox Jack VAG1383A with universal

transmission support V.A.G 1359/2

Brake Pedal Actuator VAG1869/2

Tensioning Strap T10038

Wheel Hub Support T10149

Hydraulic Press VAS6178 VAS6178

Hollow Piston Cylinder VAS6179

Basic Set For Hydraulic Bearing VAS6180

Assembly tool VAS6295

Removing

- Measure dimension - a - from wheel center to lower

edge of wheelhousing using, for example, a tape

measure.

- Note the measured value. It will be needed for tightening

rear axle bolts to mounting bracket.

- Insert Brake Pedal Actuator VAG1869/2 .

Rear axle - Front Wheel Drive Vehicles, servicing Page 7 / 22

- Raise vehicle to installation height.

Note:

Use rust solvent (commercially available) for bushing

seat and, if possible, and leave it for a while.

Vehicles with ABS

- Fold up rear seatbench and disconnect harness

connectors - 1 - .

- Loosen rubber grommets - arrows - from underbody

and push wheel speed sensor wire out of interior.

Continuation for all vehicles

- Remove parking brake cables from brackets.

- Disconnect brake lines - arrow A - and pull brake hose -

1 - out of retainer.

Vehicles with brake pressure regulator

- Remove bolts - arrows B - .

Continuation for all vehicles

- Place Engine-/Gearbox Jack VAG1383A underneath.

Rear axle - Front Wheel Drive Vehicles, servicing Page 8 / 22

- Unbolt mounting bracket bolt - 2 - at rear axle on both

sides.

- Lower rear axle using Engine-/Gearbox Jack

VAG1383A .

- Re-install mounting bolts for rear axle - 1 - in mounting

bracket and secure.

- Secure rear axle on both sides using Tensioning Strap

T10038 - 2 - .

Note:

Place Engine-/Gearbox Jack VAG1383A with

universal transmission support V.A.G 1359/2 under

control arm (danger of accident from components

falling out when pulling out bushing).

- Attach pressure plate VAS6295/2 - 1 - at inner bushing

and insert pressure pin VAS6295/4 - 3 - into bushings

from outside.

Rear axle - Front Wheel Drive Vehicles, servicing Page 9 / 22

The cut edges of the pressure plate VAS6295/2 - 1 -

must point toward the axle and must be securely

inserted between bushing and axle - arrows - .

- Attach Hydraulic Press VAS6178 VAS6178 with

Pressure Plate 3111/5 behind outer bonded rubber

bushing

The cut edges of the Pressure Plate 3111/5 - 2 - must

point toward the axle and must be securely inserted

between bushing and axle - arrows - .

- Secure Pressure Plate 3111/5 using bolts of pressure

plate VAS6295/2

- Press out bonded rubber bushing.

1 - Pressure Plate VAS6295/2

2 - Pressure Plate 3111/5

3 - Pressure pin VAS6295/4

4 - Pressure pin VAS 6180/4 long

5 - Pull rods VAS6295/3

6 - Cylinder mount VAS6295/1

7 - Hydraulic Press VAS6178 VAS6178

- Attach Hydraulic Press VAS6178 VAS6178 with

Pressure Plate 3111/5 and press out bonded rubber

bushing

The cut edges of the Pressure Plate 3111/5 - 1 - must

point toward the axle and must be securely inserted

between bushing and axle - arrows - .

Rear axle - Front Wheel Drive Vehicles, servicing Page 10 / 22

1 - Pressure Plate 3111/5

2 - Pressure pin VAS6295/4

3 - Pressure disc VAS6295/6

4 - Pressure pin VAS6180/4 long

5 - Pull rods VAS6295/3

6 - Cylinder mount VAS6295/1

7 - Hydraulic Press VAS6178 VAS6178

Installing

Installation position of inner bonded rubber bushing

Protruding lip - arrow - points in direction of travel.

- Preassemble bonded rubber bushing with the special

tools to facilitate centering in rear axle.

1 - Pressure disc VAS6295/6

2 - Bonded rubber bushing

3 - Adaptor 3111/9

4 - Pressure pin VAS6295/4

Rear axle - Front Wheel Drive Vehicles, servicing Page 11 / 22

- Now, attach bonded rubber bushing - 1 - with Adaptor

3111/9 - 2 - and Pressure pin VAS6295/4 - 3 - to rear

axle.

- Attach Hydraulic Press VAS6178 VAS6178 with

Pressure Plate 3111/5 and press in bonded rubber

bushing.

The cut edges of the Pressure Plate 3111/5 - 1 - must

point toward the axle and the eye for the bonded

rubber bushing must be free - arrows - .

1 - Pressure Plate 3111/5

2 - Bonded rubber bushing

3 - Adaptor 3111/9

4 - Pressure pin VAS6295/4

5 - Pressure pin VAS6180/6

6 - Pull rods VAS6295/3

7 - Cylinder mount VAS6295/1

Rear axle - Front Wheel Drive Vehicles, servicing Page 12 / 22

8 - Hydraulic Press VAS6178 VAS6178

Installation position of outer bonded rubber bushing

Protruding lip - arrow - points in opposite to direction of

travel.

- Now, attach bonded rubber bushing - 1 - with Adaptor

3111/9 - 2 - and Pressure pin VAS6295/4 - 3 - to rear

axle.

Note:

Make sure that Pressure pin VAS6295/4 engages in

the already pressed in bonded rubber bushing, thus

centering the bonded rubber bushing to be pressed

in.

- Attach Hydraulic Press VAS6178 VAS6178 with

Pressure Plate 3111/5 and press in bonded rubber

bushing.

Rear axle - Front Wheel Drive Vehicles, servicing Page 13 / 22

The cut edges of the Pressure Plate 3111/5 - 1 - must

point toward the axle and must be securely inserted

between inner bushing and axle - arrows - .

1 - Pressure Plate 3111/5

2 - Bonded rubber bushing

3 - Adaptor 3111/9

4 - Pressure pin VAS6295/4

5 - Pull rods VAS6295/3

6 - Pressure pin VAS6180/6

7 - Cylinder mount VAS6295/1

8 - Hydraulic Press VAS6178 VAS6178

- Raise rear axle using Engine-/Gearbox Jack

VAG1383A , remove Tensioning Strap T10038 and

mounting bolts.

- Insert rear axle into mounting brackets and secure using

mounting bolts and new nuts.

- Re-install mounting bolts for rear axle in mounting

bracket and secure.

Secure vehicle to lifting platform

Caution!

If the vehicle is not secured, there is danger that the

vehicle could slip off the lift!

Rear axle - Front Wheel Drive Vehicles, servicing Page 14 / 22

Bolting mounting bracket at rear axle must only occur

after dimension - a - measured before installation

between the wheel hub center and the lower edge of

wheelhousing has been attained!

Otherwise, the rubber bushing will be stressed resulting in

a shortened service life.

- Turn wheel hub far enough until one of the holes for

wheel bolts is on top.

- Install Wheel Hub Support T10149 with wheel bolt.

- Using engine/transmission jack, lift wheel bearing

housing until dimension - a - has been reached.

Warning!

Do not lift or lower vehicle with

engine/transmission jack below vehicle.

Do not leave engine/transmission jack below

vehicle any longer than necessary.

- Tighten threaded connection of mounting bracket to rear

axle to tightening torque.

Rest of installation is the reverse of removal.

- Bleed brake system 47-6, Brake system - vehicles with

and without ABS, ABS/EDL, bleeding .

Tightening torque

Mounting bracket to rear axle 80 Nm

Use new bolts and nuts!

Brake pressure regulator to rear axle 35 Nm

Cap nut in longitudinal member - vehicles with Front

Wheel Drive, reworking

Rear axle - Front Wheel Drive Vehicles, servicing Page 15 / 22

If cap nut thread is damaged in longitudinal member, either

thread must be cut or cap nut must be drilled through.

When drilling, proceed as follows:

- Remove rear axle.

- Drill upward through damaged cap nut in longitudinal

member using drill 10.2 mm .

Note:

Do not cant drill when drilling.

Warning!

Use safety goggles.

- Cut new thread M12 x 1.5 in cap nut.

- For mounting of rear axle, use new bolt N10 127 4 (M12

x 1.5 x 30) and washer N 11 531 7.

Tightening torque: 70 Nm

Note:

The procedure described here, must only be

performed on one cap nut per vehicle side.

Modified welded studs for mounting brake lines and

parking brake cables

The welded T-pins at the rear axle were replaced by

threaded welded studs. The clips of the brake lines and

parking brake cables were also modified.

After current supplies of rear axles are exhausted, only

rear axles with threaded welded studs are available as a

replacement part.

Rear axle for vehicles up to July 1994

Rear axle - Front Wheel Drive Vehicles, servicing Page 16 / 22

Characteristics:

1 - T-pins for bracket of brake line and ABS cable channel

2 - Grooved pin for clip of parking brake cable

3 - Clip for parking brake cables with protective sleeve

4 - Parking brake cable with protective sleeve

Dimension - A - : 15 mm

Rear axle for vehicles as of August 1994

Characteristics:

1 - Bracket for brake line

Rear axle - Front Wheel Drive Vehicles, servicing Page 17 / 22

2 - Threaded welded stud for bracket of brake line and clip

for parking brake cable

3 - Bracket for brake line and ABS cable channel

Dimension - A - : 12 mm

4 - Brake line (as a replacement part by the meter)

- Make sure that brake lines make no contact with

longitudinal member of body and rear muffler when rear

axle is at maximum spring loading.

5 - Parking brake cable without protective sleeve

If this rear axle is installed in a vehicle manufactured up to

July 1994, the replacement parts listed in the table must

also be used.

Replacement parts required:

Nomenclature Part no. Quantity

ABS cable channel 535 971 851 B 1

(For vehicles with ABS only) 535 971 852 B 1

Bracket - 1 - 1H0 611 797 C 2

(brake line)

Bracket - 3 - 191 611 797 A 2

(brake line)

Brake line - 4 - (self-prepared) See Electronic parts catalog "ETKA" -

Clip - 6 - 1H0 609 734 D 2

(parking brake cable)

Suspension strut - vehicles with Front Wheel Drive,

disassembling and assembling

Rear axle - Front Wheel Drive Vehicles, servicing Page 18 / 22

Concealment cap

Pry out using screwdriver

press in 42-1, Pressing

cap into suspension strut

bearing

O-ring

Self-locking hex nut, 25 Nm

Belleville washer

Upper rubber bushing

Seal (foam)

Replace

Suspension strut bearing

Rear axle - Front Wheel Drive Vehicles, servicing Page 19 / 22

Always replace foam seat

Welded nuts must lie in

grooves of spring seat

Align welded nuts and cap

toward center of shock

absorber 42-1, Align

suspension strut bearing

toward shock absorber

center

Spacer tube

Lower rubber bushing

Cap (metal)

For Wagon higher than for

Sedan

Washer

Spring seat

For Wagon thinner than for

Sedan

Installation position 42-1,

Installation position of spring

seat

Buffer stop

For Wagon shorter than for

Sedan

Protective tube

For Wagon longer than for

Sedan

Cap (plastic)

Coil spring

Removing and installing

42-1, Spring, removing and

installing

Allocation Electronic parts

Rear axle - Front Wheel Drive Vehicles, servicing Page 20 / 22

catalog "ETKA"

For Wagon with upper

protective hose

Base plate

Securing ring

Lower spring plate

Shock absorbers

individually replaceable

Removing and installing

42-1, Removing and

installing suspension strut to

body

Disposal Special

information, suspension No

2

Check shock absorber for

leaks and noises Special

information, suspension No.

17

Allocation Electronic parts

catalog "ETKA"

Spring, removing and installing

Rear axle - Front Wheel Drive Vehicles, servicing Page 21 / 22

Note:

Instead of V.A.G 1403 , Spring Compressor

VAG1752/1 can also be used.

Installation position of spring seat

Align suspension strut bearing toward shock absorber center

A - Axis of shock absorber eye

B - Axis of suspension strut bearing

a - 50

Axis - C - of cap 90 offset toward axis - A - of shock

absorber eye.

Rear axle - Front Wheel Drive Vehicles, servicing Page 22 / 22

Pressing cap into suspension strut bearing

You might also like

- 1995 Dodge Ram Service Manual PDFDocument1,754 pages1995 Dodge Ram Service Manual PDFFelipe Ferreira94% (36)

- Ford Mustang Manual SummaryDocument4 pagesFord Mustang Manual SummarythibNo ratings yet

- 1999 Odyssey Wiring DiagramsDocument98 pages1999 Odyssey Wiring Diagramsmike100% (1)

- L314 Freelander 2004 LHDDocument165 pagesL314 Freelander 2004 LHDDubois Box100% (1)

- Volkswagen VIN NumberDocument5 pagesVolkswagen VIN NumberBorcan CristiNo ratings yet

- Wiring Part 1Document41 pagesWiring Part 1Familia Rojas Martinez100% (1)

- VW Golf 5 Steering, Torque SpecificationsDocument2 pagesVW Golf 5 Steering, Torque SpecificationsNPNo ratings yet

- VW Passat B5 42-1 Rear Axle, FFDocument19 pagesVW Passat B5 42-1 Rear Axle, FFJosé Luis Ormeño100% (1)

- Metagal CatalogoDocument21 pagesMetagal CatalogoPaulo Sergio UtinettiNo ratings yet

- Daewoo D70SDocument4 pagesDaewoo D70SLe Thanh100% (1)

- 1950 Mercury Parts CatalogDocument4 pages1950 Mercury Parts CatalogRoberto Valdes0% (1)

- Boston Matrix - PorscheDocument27 pagesBoston Matrix - PorscheArun KumarNo ratings yet

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part8Document200 pages1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part8CandieApple100% (6)

- VW Passat B4 - Steering Column, Steering Column Tube and Steering WheelDocument12 pagesVW Passat B4 - Steering Column, Steering Column Tube and Steering WheelNPNo ratings yet

- 2012 Audi S4 Fuel System ManualDocument136 pages2012 Audi S4 Fuel System ManualmattNo ratings yet

- Launch ControlDocument11 pagesLaunch ControlJohn ByroNo ratings yet

- 2013 Volkswagen Golf 88284Document321 pages2013 Volkswagen Golf 88284George PonparauNo ratings yet

- 6-Cylinder Injection Engine 3.2LDocument201 pages6-Cylinder Injection Engine 3.2Lberenice togaNo ratings yet

- 1.8T 5V (Awm)Document413 pages1.8T 5V (Awm)Vladimir Socin ShakhbazyanNo ratings yet

- Golf 2010 2.0LDocument162 pagesGolf 2010 2.0LJorge MorochoNo ratings yet

- 2013 MalibuDocument434 pages2013 MalibuBrad FrancNo ratings yet

- Catalog Powerflex VWDocument17 pagesCatalog Powerflex VWMihai Ginel MateiNo ratings yet

- VIN DecoderDocument22 pagesVIN DecoderZO OtzoyNo ratings yet

- Diagramas Electricos Audi A4 B9 8W - EWD (Desde Julio de 2015)Document1,605 pagesDiagramas Electricos Audi A4 B9 8W - EWD (Desde Julio de 2015)javier borrego0% (1)

- The Sharan: 2006 Model YearDocument25 pagesThe Sharan: 2006 Model YearwytalikNo ratings yet

- MacPherson StrutDocument5 pagesMacPherson StrutChandra HarshaNo ratings yet

- VW Passat B4 - Pressurized Line and Cooling Line - Vehicles With VR6 EngineDocument6 pagesVW Passat B4 - Pressurized Line and Cooling Line - Vehicles With VR6 EngineNPNo ratings yet

- BKR 4-Cyl Injection EngineDocument141 pagesBKR 4-Cyl Injection EngineАлла Харютина100% (1)

- APR 2.0T (EA113) Intake Manifold Runner Flap Delete (RFD) ™ SystemDocument2 pagesAPR 2.0T (EA113) Intake Manifold Runner Flap Delete (RFD) ™ Systemkrmass25100% (2)

- 2008 Chrysler Town and Country AccessoriesDocument8 pages2008 Chrysler Town and Country AccessoriesswiftNo ratings yet

- Escape 2008Document628 pagesEscape 2008kuya batokNo ratings yet

- 4-Cyl. Direct Inj. Engine (1.8l and 2.0l 4V, Chain Drive)Document363 pages4-Cyl. Direct Inj. Engine (1.8l and 2.0l 4V, Chain Drive)Amarech NimaniNo ratings yet

- Cadenas ChevroletDocument83 pagesCadenas ChevroletAlfredo SalasNo ratings yet

- SSP 211 New BeetleDocument14 pagesSSP 211 New Beetleภูเก็ต เป็นเกาะNo ratings yet

- VCDS 19.6 EST Installing GuideDocument1 pageVCDS 19.6 EST Installing GuideAngel Julian HernandezNo ratings yet

- Install Cruise Control T4Document9 pagesInstall Cruise Control T4daveyp2001100% (1)

- D3E801E5545-Wheel and Tire GuideDocument298 pagesD3E801E5545-Wheel and Tire GuideZoltan Marosan100% (1)

- Jeep Cherokee KL 2015-2019 Brakes 3Document26 pagesJeep Cherokee KL 2015-2019 Brakes 3Henry SilvaNo ratings yet

- Antilock Braking System (ABS) in Automobiles PDFDocument5 pagesAntilock Braking System (ABS) in Automobiles PDFInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- VW Tiguan 2008 Maintenance EngDocument196 pagesVW Tiguan 2008 Maintenance EngTugay DağtekinNo ratings yet

- Gti VR6 1.8L 2004.Document243 pagesGti VR6 1.8L 2004.Eduardo OlivaNo ratings yet

- Wiring Electric CombiDocument4 pagesWiring Electric Combijorge almarazNo ratings yet

- SSP824803-SSP 824803 Volkswagen 2 0 Liter Chain-Driven TSI EngineDocument59 pagesSSP824803-SSP 824803 Volkswagen 2 0 Liter Chain-Driven TSI EngineGerardo Frias GarciaNo ratings yet

- 39-64 Final Driveshaft ServiceDocument19 pages39-64 Final Driveshaft ServiceNilson BarbosaNo ratings yet

- (TM) Volkswagen Manual de Taller Volkswagen Passat 2006 en Ingles PDFDocument300 pages(TM) Volkswagen Manual de Taller Volkswagen Passat 2006 en Ingles PDFVartic Lilia100% (1)

- MBenz ML320 W163 M112 ElectricalSpecificationsDocument14 pagesMBenz ML320 W163 M112 ElectricalSpecificationsrodolfodiazNo ratings yet

- Adding Turbo To VR6 3.2 QA #1Document9 pagesAdding Turbo To VR6 3.2 QA #1LucasPalombaNo ratings yet

- Service Action 0S318 2010 Transit 2.2 Diesel - Intercooler To TurboDocument6 pagesService Action 0S318 2010 Transit 2.2 Diesel - Intercooler To TurboSanan Mammadov100% (1)

- NP 247Document1 pageNP 247Carlos Arturo de DiosNo ratings yet

- Corrado vr6Document19 pagesCorrado vr6danieluki100% (4)

- Review of Dual Clutch Transmission SystemsDocument7 pagesReview of Dual Clutch Transmission Systemselrobo0905No ratings yet

- Tracción ControlDocument212 pagesTracción Controltallermae100% (1)

- Engine MechanicallDocument119 pagesEngine MechanicallGabriel BalcazarNo ratings yet

- Electrical Eurovan 1993Document13 pagesElectrical Eurovan 1993Jose Antonio Mellado Diaz100% (1)

- 1.4l 90kW TSI Engine With Turbocharger: Self-Study Programme 405Document32 pages1.4l 90kW TSI Engine With Turbocharger: Self-Study Programme 405Andrei BaluseNo ratings yet

- mk5 Front Seat Covers and Padding Cover and Upholstery For Rear Seats.Document20 pagesmk5 Front Seat Covers and Padding Cover and Upholstery For Rear Seats.mihai mihalcescu100% (1)

- WIRINGDocument207 pagesWIRINGChe VarianNo ratings yet

- VNX - Su Clio 2Document1,289 pagesVNX - Su Clio 2cvn2100% (2)

- MK3 V3-SC Stage 1 and 2 Installation ManualDocument31 pagesMK3 V3-SC Stage 1 and 2 Installation ManualmorulasNo ratings yet

- Passat CCB6 Footwell Lights DIYDocument6 pagesPassat CCB6 Footwell Lights DIYOlivierPeñaNo ratings yet

- Passat B5 - Rear Brake DiscDocument28 pagesPassat B5 - Rear Brake DiscBusu CypNo ratings yet

- Front Suspension - Basic Suspension, ServicingDocument20 pagesFront Suspension - Basic Suspension, ServicingEttore ScolaNo ratings yet

- g5!46!02 - Rear Wheel Brakes, ServicingDocument13 pagesg5!46!02 - Rear Wheel Brakes, ServicingcezarsandufreeNo ratings yet

- Phaeton Front SuspensionDocument84 pagesPhaeton Front SuspensionnathanstittNo ratings yet

- Tou 40Document126 pagesTou 40Calin GeorgeNo ratings yet

- Tou - 48-02 Wire DiagramDocument10 pagesTou - 48-02 Wire Diagramamando manuelNo ratings yet

- S3 Centring Front Axle Camber PDFDocument3 pagesS3 Centring Front Axle Camber PDFAlexNo ratings yet

- Valve Guides: Valve Guides D12, D12A, D12B, D12CDocument7 pagesValve Guides: Valve Guides D12, D12A, D12B, D12Cgolf1991No ratings yet

- Service Manual Trucks: Specifications, D12B D12B-345 D12B-385 D12B-425Document34 pagesService Manual Trucks: Specifications, D12B D12B-345 D12B-385 D12B-425golf1991No ratings yet

- Chery Spare Parts System Manual: Input Your NameDocument6 pagesChery Spare Parts System Manual: Input Your Namegolf1991No ratings yet

- HINO h07 - DDocument89 pagesHINO h07 - Dgolf1991100% (1)

- Power For Growth: The Heart of EveryDocument5 pagesPower For Growth: The Heart of Everygolf1991No ratings yet

- Спецификации PERKINS 1104 электронный ТНВДDocument40 pagesСпецификации PERKINS 1104 электронный ТНВДgolf1991100% (1)

- TEXPACK TemplateDocument43 pagesTEXPACK TemplatekallatisNo ratings yet

- Ford - Fiesta B299 - Workshop Manual - 2011 - 2011 - 2Document10 pagesFord - Fiesta B299 - Workshop Manual - 2011 - 2011 - 2Go NaoNo ratings yet

- Hyundai Santro Xing Gls - User ManualDocument5 pagesHyundai Santro Xing Gls - User Manualdheerajdorlikar33% (3)

- Rotor Intercambió CARTERDocument22 pagesRotor Intercambió CARTERalfredo.almeidaNo ratings yet

- ACDelco BatteriesDocument64 pagesACDelco Batteriesbookslover1100% (1)

- Assets Uploads Next Generation Triton 24MY Pre Launch BrochureDocument13 pagesAssets Uploads Next Generation Triton 24MY Pre Launch Brochuremerciamaeaguirre55No ratings yet

- Creta2022 Price List VIG AUTODocument4 pagesCreta2022 Price List VIG AUTOmathew jNo ratings yet

- Fuji RabbitDocument3 pagesFuji RabbityypokpNo ratings yet

- McLaren 765LT Order 7V8MJ1M Summary 2023-10-19Document7 pagesMcLaren 765LT Order 7V8MJ1M Summary 2023-10-19marcospiazuelo08No ratings yet

- Car Sales Kaggle DV0130EN Lab3 StartDocument22 pagesCar Sales Kaggle DV0130EN Lab3 StartMohamed AhmedNo ratings yet

- Tacoma 2023Document26 pagesTacoma 2023SujalsathwaraNo ratings yet

- Kia Seltos BrochureDocument2 pagesKia Seltos BrochuresopedalleyNo ratings yet

- Manual de Usuario Dacia Sandero (2011) (238 Páginas)Document2 pagesManual de Usuario Dacia Sandero (2011) (238 Páginas)Ignacio VillarNo ratings yet

- Canon Dc100 + Dc100e Service Manual & Repair Guide: Download HereDocument7 pagesCanon Dc100 + Dc100e Service Manual & Repair Guide: Download HerekperenNo ratings yet

- Reeba PPT OperationsDocument15 pagesReeba PPT Operationssridevi gopalakrishnanNo ratings yet

- TransportifyDocument5 pagesTransportifyJohn Christian EsguerraNo ratings yet

- Manual de Taller Corsa Diesel 1.7Document4 pagesManual de Taller Corsa Diesel 1.7Uzuma Naru0% (2)

- A Paragraph To Describe Sports CarDocument3 pagesA Paragraph To Describe Sports CarMuammar Riski RamadanNo ratings yet

- 230720M Aygo X Tech SpecsDocument2 pages230720M Aygo X Tech SpecsColin SimpsonNo ratings yet

- BMW 1er 116d M SportDocument11 pagesBMW 1er 116d M SportCristescu IsaNo ratings yet

- Holden Acadia 872744Document11 pagesHolden Acadia 872744Luke AustinNo ratings yet

- Lancia Thesis 2.0 Turbo IskustvaDocument7 pagesLancia Thesis 2.0 Turbo IskustvaCollegeApplicationEssayHelpManchester100% (2)