Professional Documents

Culture Documents

New Catalytic Process For Production of Olefins: 1. Theme Description

New Catalytic Process For Production of Olefins: 1. Theme Description

Uploaded by

Sandra Mayta SilloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Catalytic Process For Production of Olefins: 1. Theme Description

New Catalytic Process For Production of Olefins: 1. Theme Description

Uploaded by

Sandra Mayta SilloCopyright:

Available Formats

New Catalytic Process for

Production of Olefins

Author: Marcello De Falco, Associate Professor, University

UCBM – Rome (Italy)

1. Theme description

Olefins, mainly ethylene (C2H4) and propylene (C3H6), are key

intermediate and feedstock for the production of a wide number

of chemical products, as the polyolefins (polyethylene – PE,

polypropylene – PP), Mono-ethylene glycol (MEG), Ethylene

Oxide (EO) and derivatives, Propylene Oxide (PO) and

derivatives, Polyvinyl chloride (PVC), ethylene dichloride

(EDC), Styrene, Acrylonitrile, Cumene, Acetic Acid, etc.

At the present, the worldwide demand of ethylene/propylene is

more than 200 million tons per year but the conventional

processes suffer for a series of problems as the high cost and

low conversion efficiency.

In the following, the traditional technologies, i.e. the

Thermal Steam Cracking and the Fluid Catalytic Cracking, are

firstly presented. Then the innovation in the olefins

production are described and assessed.

2. Olefins production conventional

processes

The most used olefins industrial production processes are:

Thermal Steam Cracking (TSC);

Fluid Catalytic Cracking (FCC).

TSC is a thermal process by which a feedstock, typically

composed by naphtha, ethane or propane, is heated up in a

furnace composed by both a convection and radiant section, and

mixed with steam to reduce the coke formation. The steam

addition depends on the TSC feedstock (from 0.2 kg steam to kg

of hydrocarbon for ethane to 0.8 kg steam to kg of hydrocarbon

for naphtha).

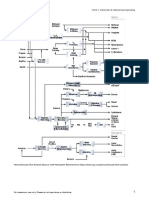

Then the products (ethylene, propylene, butadiene, hydrogen)

are quickly cooled down to avoid subsequent reactions

(quenching) and then are separated by means of a series of

operations (refer to Figure 1).

The reactions structure involved in thermal cracking is

complex and, generally, is based on a free radical mechanism.

Basically, two types of reactions are supported in a thermal

cracking process:

primary cracking, with the initial formation of paraffin

and olefins;

secondary cracking, with the formation of light products

rich in olefins are formed.

TSC is an energy intensive process: the specific energy

consumption per kg of produced olefin is 3.050 kcal/kg.

FCC is a multi-component catalytic system, where the catalyst

pellets are “fluidized” thanks to the inlet steam flow-rate

and the cracking process is supported at lower temperature

than TSC. A typical block diagram is shown in Figure 2, while

a FCC reactor drawing is reported in Figure 3.

Olefins production traditional technologies suffer from

inefficiency due to high temperature/high energy costs,

complex and expensive separation units and significant CO 2

emissions.

As a consequence, a strong interest towards the development of

more flexible, more efficient with a lower environmental

impact and less expensive catalytic olefin production

technologies is growing.

In the following, some of the most interesting technologies

developed during the last years are presented and described.

Fig. 1 – Thermal Steam Cracking plant layout [1]

Fig. 2 – Fluid Catalytic Cracking block diagram [2]

Fig. 3 – FCC reactor drawing [2]

3. Innovative Technologies

Advanced Catalytic Olefins (ACO)

The Advanced Catalytic Olefins (ACO TM ) technology has been

developed by Kellogg Brown & Root LLC (KBR) and SK Innovation

Global Technology. The process is an FCC-type with an improved

catalyst able to convert the feedstock in larger quantities of

ethylene and propylene, with a higher share of propylene than

conventional processes (the ratio of produced propylene to

produced ethylene is 1 versus 0.7 of the commercial

processes). The ACO process produces 10-25% more olefins than

the traditional FCC processes, with a reduction of consumed

energy per unit of olefins by 7-10% [3].

The plant configuration is composed of 4 sections:

riser/reactor, disengager, stripper and regenerator. Figure 4

shows a simplified process scheme, while Figure 5 illustrates

a picture of the first ACO commercial demonstration unit,

installed in South Korea and with a production capacity of 40

kta of olefins.

Fig. 4 – ACO plant process scheme [3]

Fig. 5 – ACO Commercial Demonstration unit installed in Ulsan

(South Korea)

PCC Process

The Propylene Catalytic Cracking is a fluid solids naphtha

cracking process patented by Exxon Mobil and based on an

optimization of catalyst, reactor design and operating

conditions set able to modulate the reactions selectivity,

leading to crucial economic benefits in comparison with the

conventional processes.

The PCC process is able to produce directly the propylene at

the chemical grade concentrations, thus avoiding the expensive

fractionation units. Moreover, the specific operating

conditions allows the minimization of aromatics

production [4].

Exxon is testing the innovative solutions on tailored pilot

facilities.

Indmax FCC Process

The Indmax process, developed by the Indian Oil Corporation,

is able to convert heavy feedstock to light olefins. It is a

FCC-type process where the reactions are supported by a

patented catalyst, able to reduce the contact time and thus

leading to higher selectivity to light olefins (ethylene and

propylene).

Another crucial characteristic of I-FCC process is the high

production flexibility: the process can be easily adjusted to

modulate the output, maximizing propylene, gasoline or

producing combinations (propylene and ethylene or propylene

and gasoline) [5].

Aither Chemicals’ catalytic process

Aither Chemicals, a company located in the U.S., developed an

innovative catalytic cracking process for the production of

ethylene, acetic acid, ethylene derivatives as ethylene oxide

(EO) and ethylene glycol (EG), polyethylene (PE, LLDPE, HDPE),

acetic acid derivatives as acetic anhydride, ethylene-acetic-

acid derivatives such as vinyl acetate monomer (VAM), ethyl

vinyl acetate (EVA) and other chemicals and plastics [6]. The

process uses oxygen instead of water steam and, globally,

needs much lower energy (-80%) and produces 90% less carbon

dioxide, being more environmentally sustainable.

Moreover, the CO2 and CO streams are captured at the outlet of

the catalytic process and utilized for producing chemicals and

polymer, thus nullifying the GreenHouse Gases emissions.

The production volumes foreseen for the innovative process are

224 ktons of ethylene, 112 ktons of acetic acid, 30 ktons of

CO2 and 15 ktons of CO.

Methane-to-olefins processes

Many research efforts are devoted to find new routes and

process configurations to convert directly natural gas to

olefins by low temperature reactors.

There are two possible methane-to-olefins (MTO) processes:

Indirect process, by which methane is converted into

syngas, methanol or ethane and then olefins are

produced;

Direct process, by which olefins are directly produced

from the methane in a single conversion step composed by

modified Fischer-Tropsch reaction.

Even if the direct route seems to be more interesting, at the

present not a good light olefins selectivity has been

obtained [7] and the MTO processes are more energy intensive

than the conventional cracking technologies. The only pre-

commercial scale application has been developed by UOP and

Total Petrochemicals in Feluy (Belgium): the plan is an

indirect process able to produce ethylene and propylene

through methanol and syngas.

Fig. 6 – MTO plant in Feluy, Belgium [8]

Some interesting patents have been produced on the MTO

topic [9], [10], [11], as well some accurate scientific

publications on important international journals [12], [13],

[14].

Propane Dehydrogenation

The company UOP developed an innovative Propane

Dehydrogenation (PDH) process able to produce ethylene and

propylene at lower cost thanks to a lower energy usage and a

more stable platinum-based catalyst [15]. The process, called

Oleflex, is divided in three sections: the reaction,

consisting of four radial-flow reactors, the product

purification and the catalyst regeneration. Fig. 7 shows a

process layout. Currently, 6 Oleflex units are installed and

produce more than 1.250.000 MTA of propylene worldwide.

Fig. 7 – UOP’s Oleflex process layout [8]

Shell Higher Olefins Process

The Shell Higher Olefins Process (SHOP) is an innovative

olefins production technology, developed by Royal Dutch Shell,

based on a homogeneous catalyst and used for production of

linear α – olefins (from C4 to C40) and internal olefins from

ethene.

The process architecture consists of three steps:

Oligomerization (conversion of a monomer or a mixture of

monomers into an oligomer, temperature = 90–100°C,

pressure = 100–110 bar, polar solvent);

Isomerization (molecules rearrangement reaction by a

metal catalyst, 100–125° C and 10 bar);

Methathesis (alkenes are converted into new products by

breaking – up and reformation of C-C double bonds by an

alumina-based catalyst, 100–125° C and 10 bar) [17].

At the present, SHOP is widely applied and the worldwide

production capacity is 1.190.000 t of linear alpha and

internal olefins per year.

Catalytic Partial Oxidation of ethane

ENI and the Italian research centre CNR developed an ethylene

production process through Short Contact Time – Catalytic

Partial Oxidation (CPO) of ethane.

The process is supported by a patented monolithic catalyst

able to improve the ethylene yield up to 55 wt.% [18].

At the present, the technology has been validated trough a

bench-scale unit, by which the optimal operating conditions

have been identified. However, the industrial scale

application is not ready yet, since an optimization of the CPO

reactor design and the improvement of the catalyst reliability

are needed.

_______________

[1]

http://nptel.ac.in/courses/103107082/module7/lecture2/lecture2

.pdf

[2]

http://nptel.ac.in/courses/103107082/module6/lecture5/lecture5

.pdf

[3]

http://www.kbr.com/Newsroom/Publications/Articles/Advanced-Cat

alytic-Olefins-ACO-First-Commercial-Demonstration-Unit-Begins-

Operations.pdf

[4] M.W. Bedell, P.A. Ruziska, T.R. Steffens. On-Purpose

Propylene from Olefinic Streams. Davison Catalagram, 94 (2004)

– Special Edition: Propylene –

[5] http://www.cbi.com/images/uploads/tech_sheets/I-FCC-12.pdf

[6]

http://www.aitherchemicals.com/2012/06/21/aither-announces-ope

n-season/

[7] https://www.tut.fi/ms/muo/polyko/materiaalit/aa/apdf/polyk

o_technology_for_the_production_of_olefins.pdf

[8]

http://plasticsengineeringblog.com/2013/02/20/how-shale-gas-is

-changing-propylene/

[9] http://www.google.co.in/patents/US4450310

[10] http://www.google.com/patents/WO2014031524A1?cl=en

[11] http://www.freepatentsonline.com/7091391.html

[12]

http://www.sciencedirect.com/science/article/pii/S036054420800

0042

[13] http://www.hindawi.com/journals/jchem/2013/676901/

[14] http://www.netl.doe.gov/KMD/Cds/disk28/NG7-4.PDF

[15]

http://www.uop.com/?document=uop-olefin-production-solutions-b

rochure&download=1

[16] epg.science.cmu.ac.th/…/article-download.php?id=

[17] http://www.kataliza.chemia.polsl.pl/makro-ic-wyk4a.pdf

[18] L. Basini, S. Cimino, A. Guarinoni “Short Contact Time

Catalytic Partial Oxidation (SCT-CPO) for Synthesis Gas

Processes and Olefins Production”. Ind. Eng. Chem. Res., 2013,

52 (48), 17023–17037.

You might also like

- New Olefin Production Technologies in SINOPECDocument10 pagesNew Olefin Production Technologies in SINOPECTrevor J. HutleyNo ratings yet

- UOP Oleflex ProcessDocument2 pagesUOP Oleflex ProcessssslayerNo ratings yet

- EO Technology OverviewDocument23 pagesEO Technology OverviewSoumitra DeshmukhNo ratings yet

- 01pa JB 2 6 PDFDocument9 pages01pa JB 2 6 PDFMarcelo Varejão CasarinNo ratings yet

- Ethylbenzene A4Document8 pagesEthylbenzene A4Sữa Chua VinamilkNo ratings yet

- Advanced Catalytic Olefins ACO First Commercial Demonstration Unit Begins OperationsDocument12 pagesAdvanced Catalytic Olefins ACO First Commercial Demonstration Unit Begins OperationsmakhadermfNo ratings yet

- Uop HF Alkylation Technology: Kurt A. Detrick, James F. Himes, Jill M. Meister, and Franz-Marcus NowakDocument24 pagesUop HF Alkylation Technology: Kurt A. Detrick, James F. Himes, Jill M. Meister, and Franz-Marcus NowakBharavi K SNo ratings yet

- Ethylene From EthanolDocument45 pagesEthylene From EthanolDannica Keyence MagnayeNo ratings yet

- Procesos de Obtencion de PolipropilenoDocument2 pagesProcesos de Obtencion de PolipropilenoInés Diaz GuevaraNo ratings yet

- Advances in The OCC Process For Propylene ProductionDocument6 pagesAdvances in The OCC Process For Propylene ProductionAngel Richard MamaniNo ratings yet

- The Production of Cumene Using Zeolite Catalyst Aspen Model DocumentationDocument16 pagesThe Production of Cumene Using Zeolite Catalyst Aspen Model Documentationديانا محمدNo ratings yet

- Chemi Properties (Full Permission)Document9 pagesChemi Properties (Full Permission)Vinay BabuNo ratings yet

- Industrial Catalytic Processes-Phenol Production: Robert J. SchmidtDocument15 pagesIndustrial Catalytic Processes-Phenol Production: Robert J. SchmidtUzair WahidNo ratings yet

- Propylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIIDocument12 pagesPropylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIImaheshNo ratings yet

- 0910 8 AbsDocument9 pages0910 8 Absjlcheefei9258No ratings yet

- Process Design For The Production of Ethylene From EthanolDocument144 pagesProcess Design For The Production of Ethylene From EthanolJorge RicoNo ratings yet

- Process Design For The Production of Ethylene From EthanolDocument144 pagesProcess Design For The Production of Ethylene From EthanolWilmer Rios DiazNo ratings yet

- Gas: China: Volume One-Scienceand TechnologyDocument4 pagesGas: China: Volume One-Scienceand TechnologyAnurita GhoshNo ratings yet

- Extended AbstractDocument4 pagesExtended AbstractEdrian A. MañalongNo ratings yet

- Che MaturDocument4 pagesChe MaturTralalaNo ratings yet

- Ethylene Glycol ProductionDocument3 pagesEthylene Glycol ProductionQuang NguyễnNo ratings yet

- Ethylene Midterms PetrochemDocument8 pagesEthylene Midterms PetrochemEfraim AbuelNo ratings yet

- Methanol-to-Propylene Technology: by Intratec SolutionsDocument4 pagesMethanol-to-Propylene Technology: by Intratec SolutionsYuliaDwiRahmawatiNo ratings yet

- Development of Highly Selective Process For Mono-Ethylene Glycol Production From Ethylene Oxide Via Ethylene Carbonate Using Phosphonium Salt CatalystDocument5 pagesDevelopment of Highly Selective Process For Mono-Ethylene Glycol Production From Ethylene Oxide Via Ethylene Carbonate Using Phosphonium Salt CatalystirfanNo ratings yet

- 1 .1-S2.0-S2213343721006503-MainDocument14 pages1 .1-S2.0-S2213343721006503-Mainmohamed magedNo ratings yet

- Processes Review of Propylene Production by Catalytic Cracking of C4-C8 OlefinsDocument12 pagesProcesses Review of Propylene Production by Catalytic Cracking of C4-C8 OlefinsAndres Carmona OsorioNo ratings yet

- TVK Ethylene Plant OverviewDocument32 pagesTVK Ethylene Plant Overviewstavros7100% (2)

- Converting Olefins To Propene - Ethene To Propene and Olefin CrackingDocument59 pagesConverting Olefins To Propene - Ethene To Propene and Olefin Crackingsaeed babaeiNo ratings yet

- ChemBioEng Reviews - 2017 - Mohsenzadeh - Bioethylene Production From Ethanol A Review and Techno Economical EvaluationDocument17 pagesChemBioEng Reviews - 2017 - Mohsenzadeh - Bioethylene Production From Ethanol A Review and Techno Economical EvaluationHossam M. Abd El RahmanNo ratings yet

- Process Analytics in Ethylene Production PlantsDocument11 pagesProcess Analytics in Ethylene Production PlantsIka SulistyaningtiyasNo ratings yet

- FILE 20220921 173401 Homogeneously Catalyzed Industrial ProcessesDocument31 pagesFILE 20220921 173401 Homogeneously Catalyzed Industrial ProcessesPham ThaoNo ratings yet

- Synthesis of Biomass-Derived Gasoline Fuel Oxygenates by Microwave IrradiationDocument18 pagesSynthesis of Biomass-Derived Gasoline Fuel Oxygenates by Microwave IrradiationDevesh Pratap ChandNo ratings yet

- Alkylation and Polymerization ProcessDocument61 pagesAlkylation and Polymerization ProcessWan Afiff100% (2)

- Pce-II Unit-I & II 1Document84 pagesPce-II Unit-I & II 1Pavan SatishNo ratings yet

- Industrial Catalytic Processes Phenol PRDocument15 pagesIndustrial Catalytic Processes Phenol PRJesús MorenoNo ratings yet

- Applications of The Olefin Metathesis Reaction To Industrial ProcessesDocument15 pagesApplications of The Olefin Metathesis Reaction To Industrial ProcessesPetr Vaněk100% (1)

- The Industrial Applications of Fluidized Bed Reactors Is As FollowsDocument3 pagesThe Industrial Applications of Fluidized Bed Reactors Is As FollowsAyodeji Arowolo MustaphaNo ratings yet

- Design of EthylbenzeneDocument5 pagesDesign of Ethylbenzenesahar vahdatifarNo ratings yet

- Ethylene ProductionDocument23 pagesEthylene ProductionDavid ZamoraNo ratings yet

- SINOPEC Methanol-To-Olefins (S-MTO) Technology Process PDFDocument1 pageSINOPEC Methanol-To-Olefins (S-MTO) Technology Process PDFHendriyana StNo ratings yet

- Glycol PlantDocument8 pagesGlycol PlantDian Risti PurwantiNo ratings yet

- Executive Summary: Ethylene OxideDocument7 pagesExecutive Summary: Ethylene OxideBlueblurrr100% (1)

- Assignment 1Document8 pagesAssignment 1Sulman KhalidNo ratings yet

- UOP Olefin Production Solutions BrochureDocument2 pagesUOP Olefin Production Solutions BrochureAbhik Banerjee100% (1)

- Butenediol PDFDocument6 pagesButenediol PDFJaamac Dhiil100% (1)

- Ethylene Glycol ProductionDocument1 pageEthylene Glycol ProductionAlexander50% (2)

- Report Control SystemDocument17 pagesReport Control SystemHussein Al HabebNo ratings yet

- Phenol Evaluation - FinalDocument23 pagesPhenol Evaluation - FinalCristian TorrezNo ratings yet

- Production of Ethylene and Propylene From Methanol: I. Over ViewDocument10 pagesProduction of Ethylene and Propylene From Methanol: I. Over ViewPhạm Ngọc ThạchNo ratings yet

- 7 - OligomerizationDocument16 pages7 - OligomerizationAn Lê TrườngNo ratings yet

- Industrial Applications of Olefin MetathesisDocument7 pagesIndustrial Applications of Olefin Metathesisdogmanstar100% (1)

- Advances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsFrom EverandAdvances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsLalit Kumar SinghNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerFrom EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Solid Waste Incinerator ManufacturersDocument2 pagesSolid Waste Incinerator Manufacturersbl engineeringNo ratings yet

- Structure Determination of Organic Compounds - ChemvoiceDocument37 pagesStructure Determination of Organic Compounds - ChemvoiceJubin Kumar0% (1)

- 750 Mapefibrest42 GBDocument2 pages750 Mapefibrest42 GBJulianNo ratings yet

- Determination of COD From Supplied Sample.Document3 pagesDetermination of COD From Supplied Sample.Anonymous G304U86No ratings yet

- Heat Transfer Oil SheetDocument1 pageHeat Transfer Oil SheetShamim SazzadNo ratings yet

- Biochemistry Papers MSUDocument20 pagesBiochemistry Papers MSUShiv BhattNo ratings yet

- Prime CoatDocument2 pagesPrime CoatBilal AhmadNo ratings yet

- Materials, Equipments and Fabrication TechniqueDocument17 pagesMaterials, Equipments and Fabrication TechniqueNagarjun CherukuriNo ratings yet

- Chem NotesDocument148 pagesChem Noteskiruba devi .kNo ratings yet

- 978 1 62100 769 2 - ch1Document45 pages978 1 62100 769 2 - ch1João RodriguesNo ratings yet

- TP135 Full ContentDocument65 pagesTP135 Full ContentedgardNo ratings yet

- Paste ThickenerDocument18 pagesPaste Thickenerraymondt153905No ratings yet

- Carbohydrates and Amino Acids Polymers-01-TheoryDocument36 pagesCarbohydrates and Amino Acids Polymers-01-TheoryRaju SinghNo ratings yet

- Chapter.5.ENV HYDRAULICS Students HandoutDocument53 pagesChapter.5.ENV HYDRAULICS Students HandoutTimothy KiryaNo ratings yet

- Topic: Metals and Non-Metals Worksheet KeyDocument6 pagesTopic: Metals and Non-Metals Worksheet KeyPranav SaiNo ratings yet

- MSDS - Loctite Silver Grade Anti-SiezeDocument8 pagesMSDS - Loctite Silver Grade Anti-SiezeToddy SamuelNo ratings yet

- Reactions of Synthetic ImportanceDocument28 pagesReactions of Synthetic ImportanceRx Nadeem ChhipaNo ratings yet

- Chemistry H3 Syllabus 2012Document29 pagesChemistry H3 Syllabus 2012Simon KohNo ratings yet

- Material Equivalent GradeDocument3 pagesMaterial Equivalent GradeRevanNo ratings yet

- MD1 Intro Block Sample ExamDocument13 pagesMD1 Intro Block Sample ExamFrank Mbuli EmorolaNo ratings yet

- GEA Spray Drying: Small-Scale Solutions For R&D and ProductionDocument20 pagesGEA Spray Drying: Small-Scale Solutions For R&D and ProductionPatricio ValenciaNo ratings yet

- Technical Bulletin: Pickling Methods For Duplex Stainless SteelDocument3 pagesTechnical Bulletin: Pickling Methods For Duplex Stainless SteelPhoenix KukuruyukNo ratings yet

- 22 - Analytical TechniquesDocument19 pages22 - Analytical TechniquesRaisa Binte HudaNo ratings yet

- Hafta 6Document22 pagesHafta 6n24zz5hvjwNo ratings yet

- Theoretical and Electrochemical AssessmeDocument10 pagesTheoretical and Electrochemical Assessmechérifa boulechfarNo ratings yet

- Analisa Fizik SPMDocument1 pageAnalisa Fizik SPMkamalharmozaNo ratings yet

- Chapter 5 Refrigerant Systems Chemistry.Document12 pagesChapter 5 Refrigerant Systems Chemistry.Arib RahhimNo ratings yet

- Kids Toothpaste: Phase Ingredients % W/WDocument2 pagesKids Toothpaste: Phase Ingredients % W/WrekhilaNo ratings yet

- The Solubility of Gases in Liquids: Introductory InformationDocument7 pagesThe Solubility of Gases in Liquids: Introductory InformationEwindNo ratings yet

- Ppe MCQ - 300Document36 pagesPpe MCQ - 300raveen_82mechNo ratings yet