Professional Documents

Culture Documents

Technical Specification of As-N

Technical Specification of As-N

Uploaded by

mino pharmOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specification of As-N

Technical Specification of As-N

Uploaded by

mino pharmCopyright:

Available Formats

Airox Technologies Pvt. Ltd.

D-27, 4th Floor, Prozone Trade Centre,

API Corner, Chikalthana , Aurangabad-431 210 (M.S.)

Ph. : +91 240 6602686 .Mo. : +91 9764634964

Email : sales@airoxtechnologies.com

Web. : www.airoxtechnologies.com

DEALS IN: OXYGEN CONCENTRATOR | PNEUMATIC TUBE SYSTEM | HYPERBARIC CHAMBER | WOUNDHUB

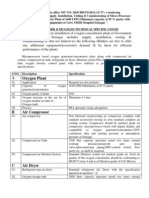

Broad Based Specifications for Microprocessor based Oxygen Concentrator Plant

1. Oxygen Concentrator Plant

Microprocessor based PSA type Oxygen concentrator plant to produce minimum 47 Nominal

cu.m/hr (min. 1795 SCFH or min. 850 LPM) at 93% Purity of medical grade oxygen at 93 % +-

3% purity. The oxygen supply be continuous and supplied through a single unit. The oxygen

should be of medical grade and shall be supplied through pipelines at 65 psig pressure.

I. Features:

• Product Flow: Minimum 850LPM /(min. 1795 SCFH/ 47 Nm3/hr)1

• Filling Capacity: 175 Cylinder (D-Type)

• Outlet pressure should not less than 4.48 kg/ CM² or 65 PSI

• Product Concentration 93% ±3%

• Product Dew Point -100°F (-73°C)

• Electrical Supply – 230 VAC , 1 Phase, 10 Amp , 3pole MCB.

• Oxygen should Produces from an independent compressed air source

• Should be Microprocessor controlled

• Should be Automatic and unattended operation

II. Should have below Certifications:

A. The oxygen generator principal manufacturer must have U.S.FDA & CE or EC

(European certificate) certification in accordance with Appendix II (excluding section 4)

of the Medical Devices Directive 93/42/EC & its amendment 2007/47/EC.(Certificate

should be given by recognized European or American third party inspection authority

like LNE )

B. EN- ISO 13485 ( 2012)( Certificate should be given by recognized European or

American third party inspection authority like GMED )

2. Compressed air System (Air compressor) -Compressed air system comprising of

screw air compressor air cooled with microprocessor based control panel coupled with

motor assembly. The compressor should be capable of delivering medical grade air. The

compressor should be capable of delivering air at minimum 7 kg/cm2 and should be

capable of working on 100% continuous duty with starting pressure as atmospheric

pressure. The compressor shall have to be with all standard accessories compatible with

oxygen generator. To save the electricity screw compressor capacity should not be more

then 55 KW.

Technical feature:

- Compressor 55 KW (Maximum capacity allowed for better electricity saving)

- Motor KW - 55 KW / 3 Phase / 415 VAC / 50 hz.

- Flow rate – 310 SCFM

- Rated power supply – 150 Amp 4 pole MCCB

- Pressure - 8 Bar.

Airox Technologies Pvt. Ltd.

D-27, 4th Floor, Prozone Trade Centre,

API Corner, Chikalthana , Aurangabad-431 210 (M.S.)

Ph. : +91 240 6602686 .Mo. : +91 9764634964

Email : sales@airoxtechnologies.com

Web. : www.airoxtechnologies.com

DEALS IN: OXYGEN CONCENTRATOR | PNEUMATIC TUBE SYSTEM | HYPERBARIC CHAMBER | WOUNDHUB

3. Air Receiver:- Air receiver of 2000 liters capacity -The air receiver tank shall be of

2000 ltrs capacity (pressure tested to two times its normal working pressure) along with

auto drain valve

4. Oxygen Receiver : Oxygen receiver of 2000 liters capacity -The oxygen receiver tank

shall be of 2000 ltrs capacity (pressure tested to two times of its normal pressure) .

5. Refrigerant Air Dryer -Refrigerant type air dryer with inlet pressure equal to outlet

pressure from air compressor, inlet air temperature less than 40deg. C, ambient

temperature +0 deg.C To +40 deg.C, Dew point temperature of maximum +3 deg.C and

inlet air capacity compatible to air delivery capacity of air compressor.

Technical feature:

Capacity – 500 CFM ( 14.16 Cu.mtr/min)

3 Phase / 415 VAC / 50 hz.

Dimensions (L X W X H) 800 mm X 1000 mm X 1350 mm.

Weight - 250 Kg

Rated power supply – 16 Amp 4 pole MCCB

6. Filtration System for Compressed air: The feed air quality to the oxygen concentrator

should be confirming to ISO8573 class 4 and should have a filtration grade of 0.01

Micron .The ambient temperature of compressed air should be 100C to 400 C and should

have maximum dew point of +3 degree centigrade (Two stage Filtration System).

Technical feature:

Pre filter – 420 CFM @7.0 Bar Pressure. Cap – 1 Micron

Post Filter – 420 CFM @7.0 Bar Pressure. Cap – 0.01 Micron

Activated Carbon Filter - 420 CFM @7.0 Bar Pressure. Cap –

<0.003mg/Cu.mtr(<0.003ppm)

7. Main Electrical Panel - The panel should have automatic starters, overload protection,

single phasing preventers, timer assemblies, or successful operation of all the

components of oxygen plant.

8. Automatic Change Over System: Providing and Fitting of 01 No. Automatic Change

Over System / Panel to control the supply of Oxygen at 4.1 bar produced by

Microprocessor based Oxygen Concentrator and supply the oxygen through Oxygen

Manifold (cylinders). If pressure drops in supply of Oxygen from Oxygen Generator

Module, the system should automatically change over supply of Oxygen from Oxygen

Manifold (cylinders) and should also automatically change over from Oxygen Manifold

(cylinders) to Oxygen Concentrator when the pressure increases in Oxygen Supply Tank

of Oxygen Generator.

9. Ultrasonic based Oxygen Analyser:

The oxygen Analyser should have following features,

Oxygen measure Standard : O2 : 0-100%

Option : 95-100% O2 (MOQ of 100 pieces is required)

Airox Technologies Pvt. Ltd.

D-27, 4th Floor, Prozone Trade Centre,

API Corner, Chikalthana , Aurangabad-431 210 (M.S.)

Ph. : +91 240 6602686 .Mo. : +91 9764634964

Email : sales@airoxtechnologies.com

Web. : www.airoxtechnologies.com

DEALS IN: OXYGEN CONCENTRATOR | PNEUMATIC TUBE SYSTEM | HYPERBARIC CHAMBER | WOUNDHUB

Oxygen accuracy ± 1.8% FS

Flow accuracy ± 0.2L/min

Flow direction No limitation

Response time 0.5 sec

Maximum inlet pressure 150 kPa

Operating temperature 10-45°C

Span Lifetime ≥ 5years

Outputs RS232 / LCD / analogue VDC

Oxygen concentration output Analogue 0-5VDC linear with 0-100% vol O2

Flow volume output Analogue 0-5VDC linear with 0-10.0L/min or 0-500 L/m

Power supply 12 VDC - 10mA

10. Medical Gas Alarm system : Providing and fitting of New Medical Gas Alarm system

in New Medical Oxygen Generation Gas Plant of Hospital.

11. The tenderer should provide 12 months warranty on the entire equipment.

12. The company should provide training for operation and maintenance system to the

hospital staff from the successful date of testing and commissioning of the system

without any extra cost.

13. The tenderer will establish service engineering branch in Andhra Pradesh state to

provide service in the case of failure of the unit within 24 hours on receipt of the

information from competent authority.

14. ELIGIBILITY CRITERIA:

1. The quoting firm's last three year average turnover should be more than 15 Crore. In

last three years their turn over should be more then 14 cr.

2. The quoting company should have local engineer in based in Andhra Pradesh.

3. The quoting firm's should have similar model installation in last 7 years,

Performance certificate with all the details should be attached.

4. The quoting firm should have at lest 05 installations in Andhra Pradesh of same

principal make whose oxygen generator quoted in the tender, Performance certificate

with all the details should be attached.

5. The quoting firm should have atlest 75-100 systems in India of same principal make

whose oxygen generator quoted in the tender, Performance certificate with all the

details should be attached. If Indian firm who has installed some other make oxygen

generator in India, that performance certificate will not be considered.

6. International Installation will not be considered.

7. Oxygen Plant must have US FDA and CE Medical Devices Certifications.

You might also like

- Longfian Scitech Jay 20 4.0 Oxygen Concentrator - User and Service ManualDocument24 pagesLongfian Scitech Jay 20 4.0 Oxygen Concentrator - User and Service ManualThomas BohlmannNo ratings yet

- Trosten Ahu CatalogueDocument88 pagesTrosten Ahu CatalogueJohn Son G80% (5)

- Basement VentilationDocument8 pagesBasement VentilationArshavin Watashi Wa100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Basic Aircraft Instrumentat Ion: Shah SultanDocument65 pagesBasic Aircraft Instrumentat Ion: Shah SultanNabil Qasem100% (3)

- Nabil Anwar Academic CV Vitae 2014Document4 pagesNabil Anwar Academic CV Vitae 2014Gary TomNo ratings yet

- Technical Specification of AS-LDocument3 pagesTechnical Specification of AS-Lmino pharmNo ratings yet

- Oxygen Plant: B Air CompressorDocument3 pagesOxygen Plant: B Air Compressorsumit11235No ratings yet

- Tender for Oxgyen Plant 200محطة توليد اوكسجينDocument8 pagesTender for Oxgyen Plant 200محطة توليد اوكسجينtinep0493No ratings yet

- Oxygen Plant Features and SpecsDocument4 pagesOxygen Plant Features and SpecsKyaw Win ZanNo ratings yet

- Specifications For The Single Cylinder Research EngineDocument12 pagesSpecifications For The Single Cylinder Research EngineBurce MherjheNo ratings yet

- EAG2020-541 E575R 8000 LPH Paras Pakistan Revision ADocument3 pagesEAG2020-541 E575R 8000 LPH Paras Pakistan Revision AArun BajajNo ratings yet

- Simplest Mechanical TasksDocument36 pagesSimplest Mechanical TaskssivaeinfoNo ratings yet

- PSA Nitrogen Generator NO1Document116 pagesPSA Nitrogen Generator NO1Ahmad SaeedNo ratings yet

- M/S. Airro Engineering Co.: Operation & Instructions Manual FOR Oxygen PlantDocument16 pagesM/S. Airro Engineering Co.: Operation & Instructions Manual FOR Oxygen PlantDr Gajanan ShirkeNo ratings yet

- MGPLSDocument4 pagesMGPLSpankaj kadkolNo ratings yet

- UndergroundDocument6 pagesUndergroundNabeel KTNo ratings yet

- Agilent GC MS SpecificationDocument5 pagesAgilent GC MS Specificationashif28No ratings yet

- Eleweout-IMT ENG PODocument2 pagesEleweout-IMT ENG POCharles RoumiNo ratings yet

- 924h Wheel Loader ManualDocument36 pages924h Wheel Loader ManualefreirecrecenteNo ratings yet

- Pegasys Manual Inst Oper MantDocument12 pagesPegasys Manual Inst Oper MantDaniel LagosNo ratings yet

- CATERPILLAR Filter Cab Air Quality System PEHJ0300 00Document2 pagesCATERPILLAR Filter Cab Air Quality System PEHJ0300 00Parinpa KetarNo ratings yet

- Parking Structures Guidelines enDocument8 pagesParking Structures Guidelines enEleni AsimakopoulouNo ratings yet

- Industrial or Medical Oxygen GasDocument10 pagesIndustrial or Medical Oxygen GasDelta DigitronicsNo ratings yet

- Medical Gas SytemDocument22 pagesMedical Gas SytemMamdouh AwadNo ratings yet

- Book 19 (Ca)Document12 pagesBook 19 (Ca)dirgan_udyanaNo ratings yet

- Tech Specs For Nitrogen GeneratorDocument5 pagesTech Specs For Nitrogen Generatorn.hartonoNo ratings yet

- Katalog - Eng - Op Concentrador de OxigenoDocument26 pagesKatalog - Eng - Op Concentrador de OxigenoJose Alvarez LopezNo ratings yet

- Technology Bulletin: SUBJECT: New API Recommended Practices For Coiled Tubing Well-Control Equipment AnnouncedDocument4 pagesTechnology Bulletin: SUBJECT: New API Recommended Practices For Coiled Tubing Well-Control Equipment AnnouncedJose Leonardo Materano PerozoNo ratings yet

- Atlas Copco: Medical Air Purifiers MED Series (7-145 L/s / 15-307 CFM)Document8 pagesAtlas Copco: Medical Air Purifiers MED Series (7-145 L/s / 15-307 CFM)sergioantoniozavalaNo ratings yet

- Hangzhou ChenruiDocument9 pagesHangzhou ChenruiJocelyn Ambar Gallardo ArismendiNo ratings yet

- Carrier chiller-30XADocument12 pagesCarrier chiller-30XAamitbslpawar100% (1)

- Comprerssors Manual NewDocument35 pagesComprerssors Manual Newmohamed essamNo ratings yet

- Specif-Dust Extraction SystemDocument12 pagesSpecif-Dust Extraction SystemChristopher LloydNo ratings yet

- Axial & Centifugal Jet Fans SpecificationDocument9 pagesAxial & Centifugal Jet Fans SpecificationRamakrishnan100% (1)

- Ingestive Cleaning ES9-62 Rev L PDFDocument10 pagesIngestive Cleaning ES9-62 Rev L PDFreclatis14No ratings yet

- Ultrox MedicalDocument2 pagesUltrox MedicalAbu HuzeifaNo ratings yet

- Techspecs5 Anesthesia MachineDocument5 pagesTechspecs5 Anesthesia MachineChristian Joie MasiglatNo ratings yet

- Operating & Instructions: ManualDocument20 pagesOperating & Instructions: ManualjujuroyaleNo ratings yet

- Oxygen GeneratorDocument16 pagesOxygen GeneratorImtiaz Ahmed100% (2)

- Chapter 5Document14 pagesChapter 5zainonayraNo ratings yet

- PGCIL - Technical Specifications SF6 Gas Handling PlantDocument2 pagesPGCIL - Technical Specifications SF6 Gas Handling Plantarindam hitechNo ratings yet

- Anaesthesia Machine With Integrated VentilatorDocument3 pagesAnaesthesia Machine With Integrated VentilatorRanjan ShahNo ratings yet

- Designing of Manifold RoomDocument4 pagesDesigning of Manifold RoomDurjoy_Sarker_143450% (2)

- Mini Steam Powahplant PDFDocument6 pagesMini Steam Powahplant PDFgwynieverfryceNo ratings yet

- RB1-5 (3) CO Sensor CatalogueDocument10 pagesRB1-5 (3) CO Sensor CataloguedimchienNo ratings yet

- Sumer Oxygen Generator Catalogue 276c8Document10 pagesSumer Oxygen Generator Catalogue 276c8batakero137No ratings yet

- PAC Process Brochure - 2014Document4 pagesPAC Process Brochure - 2014EmadNo ratings yet

- Oxygen PlantDocument4 pagesOxygen PlantEcg AccessoriaNo ratings yet

- Catalog O2 Gen A3 2 PGDocument2 pagesCatalog O2 Gen A3 2 PGDelta DigitronicsNo ratings yet

- Vacuum Pump SopDocument4 pagesVacuum Pump SopHarsh KhatriNo ratings yet

- Manual N2Document24 pagesManual N2jujuroyaleNo ratings yet

- CBO-40Y 200bar PSA Oxygen GeneratorDocument12 pagesCBO-40Y 200bar PSA Oxygen GeneratorDavid GuevaraNo ratings yet

- 44-127698PYL - Optima 8000 Preparing Your LabDocument7 pages44-127698PYL - Optima 8000 Preparing Your LabVishal AroraNo ratings yet

- Hangzhou Chenrui Air Separator Installation Manufacture CO., LTDDocument10 pagesHangzhou Chenrui Air Separator Installation Manufacture CO., LTDTonyNo ratings yet

- Optima 7300 V and 8300 Preparing Your LabDocument7 pagesOptima 7300 V and 8300 Preparing Your LabmvidalaguilarNo ratings yet

- Technical Document On Smoke Extract & Car Park FansDocument4 pagesTechnical Document On Smoke Extract & Car Park FansTanveer AzizNo ratings yet

- ASHRAE 15 Mechanical Room SpecDocument6 pagesASHRAE 15 Mechanical Room SpecwillchamNo ratings yet

- Technical Specifications English of Emission TestingDocument81 pagesTechnical Specifications English of Emission TestingIdeaInaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Government of Andhrapradesh: Change of Directors & Registered Pharmacist W.E.F 05-08-2020Document2 pagesGovernment of Andhrapradesh: Change of Directors & Registered Pharmacist W.E.F 05-08-2020mino pharmNo ratings yet

- CPS001 PDFDocument1 pageCPS001 PDFmino pharmNo ratings yet

- Technical Specification of AS-LDocument3 pagesTechnical Specification of AS-Lmino pharmNo ratings yet

- Airox Presentation - 248Document36 pagesAirox Presentation - 248mino pharm0% (1)

- Airox Installation List Upto 20.08.2020Document29 pagesAirox Installation List Upto 20.08.2020mino pharmNo ratings yet

- CFA PilesDocument293 pagesCFA Pilesfludor100% (1)

- DSM Developer GuideDocument67 pagesDSM Developer Guiderdos14No ratings yet

- Pigging FrequencyDocument7 pagesPigging Frequencykhalid ahmedNo ratings yet

- Trasmisión Linea N Chevrolet PDFDocument0 pagesTrasmisión Linea N Chevrolet PDFJorge Castillo HdzNo ratings yet

- Atl: Atlas Transformation Language: ATLAS Group Lina & Inria NantesDocument62 pagesAtl: Atlas Transformation Language: ATLAS Group Lina & Inria NantesDiana SeguroNo ratings yet

- 01 Kros Ch01Document28 pages01 Kros Ch01Nikhil Gandhi0% (1)

- Technology QuizDocument1 pageTechnology Quizlizbet08No ratings yet

- 70HFR120Document5 pages70HFR120Faulhaber AdrianNo ratings yet

- ZF-FreedomLine TransmissionDocument21 pagesZF-FreedomLine TransmissionHerbert M. Zayco100% (2)

- 10318-00-153-PD-0002 Welding Maps and Piping ReportingDocument24 pages10318-00-153-PD-0002 Welding Maps and Piping ReportingAnanthakrishnan VNo ratings yet

- Building A Yagi Antenna For UHF - J-Tech Engineering, LTDDocument15 pagesBuilding A Yagi Antenna For UHF - J-Tech Engineering, LTDRobert GalargaNo ratings yet

- NZXNLXPost Processor ManualDocument173 pagesNZXNLXPost Processor ManualOuss AmaNo ratings yet

- Chapter 31 Electromagnetic InductionDocument12 pagesChapter 31 Electromagnetic InductionJasmine YangNo ratings yet

- Electrical Engineering Question Paper-II: - Kirchoff's LossDocument25 pagesElectrical Engineering Question Paper-II: - Kirchoff's LossbasavarajNo ratings yet

- Penawaran Harga Mowa@ Astra Honda Motor Office JakartaDocument3 pagesPenawaran Harga Mowa@ Astra Honda Motor Office JakartaYulianto EkoNo ratings yet

- Arku Leveling Methods - ENDocument3 pagesArku Leveling Methods - ENjnrvilhenaNo ratings yet

- Site Modernization Report Of: G3962ASNMO - 2 - ETDocument7 pagesSite Modernization Report Of: G3962ASNMO - 2 - ETNyonyo Korshie LotsuNo ratings yet

- The Data Warehouse Environment - Building The Data WareHouseDocument52 pagesThe Data Warehouse Environment - Building The Data WareHousebondaigiaNo ratings yet

- Dishwasher Is A Machine For Cleaning Dishware and Cutlery Automatically. Unlike ManualDocument4 pagesDishwasher Is A Machine For Cleaning Dishware and Cutlery Automatically. Unlike ManualXMEN ツ MoRtAlNo ratings yet

- A320 CW and W Procedures.1.0Document6 pagesA320 CW and W Procedures.1.0kowgliNo ratings yet

- Ices Indian Universities InstitutionsDocument3 pagesIces Indian Universities InstitutionsOperationNo ratings yet

- Self-Adhesive Resin Cements - Adhesive Performance To Indirect Restorative CeramicsDocument7 pagesSelf-Adhesive Resin Cements - Adhesive Performance To Indirect Restorative CeramicsAna Massiel NarváezNo ratings yet

- 6HP19 21 ManualDocument66 pages6HP19 21 ManuallyutenkoeNo ratings yet

- 1) Eng - Khan StructuralEngineer - CVwithPicDocument2 pages1) Eng - Khan StructuralEngineer - CVwithPicmjnasar khan jamalNo ratings yet

- Public Administration Unit-9 Scientific Management-F.W. TaylorDocument9 pagesPublic Administration Unit-9 Scientific Management-F.W. TaylorDeepika Sharma100% (2)

- Cheat Sheets - Coding and DecodingDocument6 pagesCheat Sheets - Coding and DecodingDileep Kumar MotukuriNo ratings yet

- T 3Document31 pagesT 3iwanmscNo ratings yet

- Assignment Prosman 2020Document4 pagesAssignment Prosman 2020HomeSweet HomeNo ratings yet