Professional Documents

Culture Documents

CAN Interface For FMS: Important!

CAN Interface For FMS: Important!

Uploaded by

abo mhdeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAN Interface For FMS: Important!

CAN Interface For FMS: Important!

Uploaded by

abo mhdeCopyright:

Available Formats

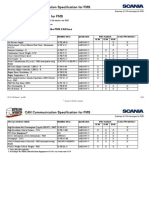

CAN interface for FMS

Introduction

Introduction

This document contains information on the FMS standard. The FMS standard is an More information on the FMS standard can be found at www.fms-standard.com.

open interface developed by several truck manufacturers. FMS-Standard description

version 03 is supported. More information on the C137 connector is found in the C137 document – Connector

for FMS.

The C137 connector is Scania’s interface for FMS standard messages.

Detailed information on CAN messages for FMS is found in the CAN Specification

IMPORTANT! for FMS document which is in English.

For FMS standard messages, it is not permitted to connect to any other connector or

other CAN bus. Incorrect connection can cause functional disorder.

22:10-079 Issue 2 en-GB 1 (10)

©

Scania CV AB 2015, Sweden

CAN interface for FMS

Introduction

Abbreviations in this document

Abbreviation Explanation

CAN Controller Area Network

ECU Electronic Control Unit

FMS Fleet Management System

BCI Bodywork Communication Interface

TCO Tachograph

DTCO Digital tachograph with remote driver card information downloading

OBD On-board diagnostics

EOBD European On-board Diagnostics

TP.CM Transport Protocol - Connection Management

TP.DT Transport Protocol - Data Transfer

22:10-079 Issue 2 en-GB 2 (10)

©

Scania CV AB 2015, Sweden

CAN interface for FMS

Requirements for CAN communication with the vehicle

Requirements for CAN communication with

the vehicle

This section describes the requirements for FMS-CAN communication. SAE J1939

forms the basis of the protocol, but large parts are not implemented. These parts are

SAE J1939-81 (Network Management), main part of SAE J1939-73 (Diagnostics)

and parts of SAE J1939-21 (Data Link Layer).

The C137 connector is green and is located under the central electric unit in the cab.

The twisted-pair cable is blue and white. CAN-low is connected to pin 9, CAN-high

351 572

is connected to pin 6.

Connector C137

SAE J1939-81 Network Management

More information on the connector is found in the C137 document – Connector for

The address space in a Scania vehicle is static. Because of this, there is no need for

FMS CAN.

the Network Management described in SAE J1939-81.

• Fixed addressing is used in accordance with Preferred addresses for Industry

group 0, Global and Industry group 1, On-highway Equipment.

• Source addresses for equipment which does not normally belong to the vehicle

follow the requirements in J1939, ISO 11992 or OBD/EOBD.

343 377

Location of C137

22:10-079 Issue 2 en-GB 3 (10)

©

Scania CV AB 2015, Sweden

CAN interface for FMS

Requirements for CAN communication with the vehicle

SAE J1939-21 Data Link Layer

SAE J1939-21 defines 5 message types:

• Commands - Not supported.

• Requests - Not supported.

• Broadcast/Response - All available information is sent periodically.

• Acknowledgement - Not supported.

• Group Functions - Proprietary messages och Multipacket messages, TP.CM,

TP.DT, are supported.

Note:

According to section 5.2.1 SAE J1939-21, revised version July 1998, priority bits in

message identifiers must be filtered out and ignored by the receivers.

General guidelines

• Control units connected to a CAN bus must be able to handle up to 100% CAN

bus load with the correct messages with no significant functional limitations or

malfunctions.

• Under normal circumstances the CAN bus load should never exceed 80%.

• Avoid closing control loops over the CAN because the guaranteed access time is

relatively long and fast control loops require a lot of bandwidth. If closed control

loops over the CAN are still required, then they must be fully capable of sending

the necessary CAN messages using only half the transmission frequency.

22:10-079 Issue 2 en-GB 4 (10)

©

Scania CV AB 2015, Sweden

CAN interface for FMS

Connectors and cables

Connectors and cables

• Scania uses connectors according to the FMS standard. More information on the FMS standard can be found at www.fms-standard.com.

• Scania uses twisted-pair cables (twisted 40 times per metre) with no shield or

jacket.

• The electrical properties (resistance, impedance, capacitance etc.) are defined in

SAE J1939-15 Physical Layer Light.

• The cable cross-sectional areas for cables fitted by the bodybuilder must be at

least 0.75 mm² inside the cab and 1.5 mm² outside the cab.

• Scania recommends the following colours and markings for the FMS-CAN net-

work cables:

– CAN-low should be marked as CAN_L and CAN-high as CAN_H.

– CAN_L should be white and CAN_H should be blue. To avoid misunder-

standing it is important that the cables retain their colour for the lifetime of the

vehicle.

22:10-079 Issue 2 en-GB 5 (10)

©

Scania CV AB 2015, Sweden

CAN interface for FMS

Connection to FMS-CAN

Connection to FMS-CAN

Topology

The topology is primarily a bus cable with the nodes connected to the bodybuilder’s < 30 m

FMS-CAN network with at least 0.1 metre between each node.

C137 ECU X

• The length of the cables should not exceed 30 metres (main cable) between the > 0.1 m

connector in the truck and the control unit with the other termination resistor.

<3m

• If more than one control unit is connected, the length of the cables between the

main cable and control unit should not exceed 3 metres.

• The cables should be as short as possible to minimise the effect of electromagnet-

ic interference.

ECU Z ECU Y

• The number of control units in the bodybuilder’s FMS-CAN network should not

348 622

exceed 9.

The figure shows the principle of the bodybuilder’s FMS-CAN network topology:

• C137 is the connector that makes the interface to Scania’s network.

• ECU X is the FMS control unit in the bodywork with a termination resistor. See

also next section.

22:10-079 Issue 2 en-GB 6 (10)

©

Scania CV AB 2015, Sweden

CAN interface for FMS

Termination resistors

Termination resistors Scania ECU X

CAN_H CAN_H

6

The FMS-CAN bus cable must be terminated using a 120 Ohm resistor at each end

in accordance with SAE J1939-15 Physical Layer.

C137

R

Depending on the other control units connected to the CAN bus, there must be a 120

Ohm termination resistor in the control unit which is connected to the FMS-CAN in-

9

terface for bodybuilders. CAN_L CAN_L

b346398

If the control unit is not equipped with an internal termination resistor, an external

termination resistor must be connected as close to the control unit as possible (see

illustration).

22:10-079 Issue 2 en-GB 7 (10)

©

Scania CV AB 2015, Sweden

CAN interface for FMS

Termination resistors

Termination of the bodybuilder’s FMS-CAN bus.

There must be a 120 Ohm termination resistor at each end of the FMS-CAN bus for

the communication to work without interference. Check that there is a termination

resistor at each end of the FMS-CAN bus using a multimeter. The resistance should

be 60 Ohm (two 120 Ohm resistors connected in parallel).

A number of different systems can be connected to the cable harness of the body-

builder’s FMS-CAN bus. Certain systems have a built-in termination resistor and

others are unterminated.

The table shows when there is to be a termination resistor in connector C137 or in the

control unit connected to C137.

Systems in the vehicle Termination resistor in

DTCO Scania Communicator FMS-CAN interface the control unit connect-

C200 ed to C137

No No Yes Yes

Yes No Yes No

Yes Yes Yes No

No Yes Yes Yes

Yes No No Yes

Yes Yes No Yes

22:10-079 Issue 2 en-GB 8 (10)

©

Scania CV AB 2015, Sweden

CAN interface for FMS

Fault validation of communication (time-out)

Fault validation of communication (time-

out)

Avoid FMS-CAN communication when the starter key is in the lock or radio posi-

tion. Also avoid communication during the starting sequence of the control units con-

nected to the bodybuilder’s FMS-CAN network.

During normal operation, when the starter key is in the drive position, a message

should not be validated as missed (time-out) until at least 5 times the message period

time. A longer fault validation time is permitted.

During the engine starting sequence, when the starter motor is turning, the supply

voltage can be extremely low. Therefore, communication from the FMS-CAN can-

not be guaranteed during this sequence. For this reason, no fault codes related to

FMS-CAN communication should be set when the system voltage is below 18 V.

When the starter key is turned to the drive position, the FMS-CAN communication

will be started within 10,000 ms. A message cannot be considered missing until after

10,000 ms + 5 x the message period time. Example: If a message has a period time

of 100 ms it cannot be considered missing until after 10,000 + 5 x 100 = 10,500 ms.

Longer fault validation times are permitted.

22:10-079 Issue 2 en-GB 9 (10)

©

Scania CV AB 2015, Sweden

CAN interface for FMS

Source addresses

Source addresses

The source addresses according to the table are used for messages that are forwarded

from Scania’s FMS-CAN bus to the bodybuilder’s FMS-CAN bus via the C137 in-

terface. The addresses in the table must not be used by any other control unit in the

bodybuilder’s FMS-CAN network. This may lead to clashes and functional distur-

bances.

Note:

The table shows the addresses currently in use, but addresses may be added in the

future.

Name Explanation Source address

(Hex)

EMS Engine Management System 00

GMS Gearbox Management System 03

BMS Brake Management System 0B

RET Retarder 10

ICL Instrument Cluster 17

LAS Locking and Alarm System 1D

VIS Visibility System 1E

COO Coordinator 27

BWE Bodywork Electrical System E6

SMS Suspension Management System 2F

APS Air Processing System 30

TCO Tachograph EE

22:10-079 Issue 2 en-GB 10 (10)

©

Scania CV AB 2015, Sweden

You might also like

- Scania Trucks Fault Codes PDF - CAN Interface For BodyworkDocument139 pagesScania Trucks Fault Codes PDF - CAN Interface For BodyworkVictor Sampa100% (7)

- Advanced Micro Controller 2: 1. PurposeDocument3 pagesAdvanced Micro Controller 2: 1. PurposeAdi VNo ratings yet

- j1939 ProtocolDocument2 pagesj1939 ProtocolFaraz ElectronicNo ratings yet

- 03-CAN Fault CodesDocument27 pages03-CAN Fault CodesEbied Yousif AlyNo ratings yet

- CAN Interface For FMS General: Important!Document12 pagesCAN Interface For FMS General: Important!Daniel Henrique PiovesaniNo ratings yet

- CAN Interface For FMS General: Important!Document12 pagesCAN Interface For FMS General: Important!noranNo ratings yet

- CAN Interface SCANIADocument80 pagesCAN Interface SCANIAManuel Solar Rigoni Dinky89% (9)

- Fms Prep ScaniaDocument80 pagesFms Prep Scaniaipdown4250% (2)

- BWM 0000823 01Document13 pagesBWM 0000823 01AliNo ratings yet

- Scania j1939 FMSDocument80 pagesScania j1939 FMSzibetto67% (3)

- Technote DWDM 00 - 2Document12 pagesTechnote DWDM 00 - 2integragroupinfoNo ratings yet

- BWM - 0000868 - 01 - C137 - Connector For FMS CANDocument3 pagesBWM - 0000868 - 01 - C137 - Connector For FMS CANwqd dqwdwdNo ratings yet

- Tech Net Bus Info Volvo CanBUSDocument11 pagesTech Net Bus Info Volvo CanBUSalfe20001120No ratings yet

- Computer Solutions LTD: CAN - A Brief TutorialDocument7 pagesComputer Solutions LTD: CAN - A Brief Tutorialhitech_emi3591No ratings yet

- Scania Trucks Fault Codes PDF - CAN Interface For BodyworkDocument139 pagesScania Trucks Fault Codes PDF - CAN Interface For Bodyworknugrahaananta45No ratings yet

- SRM6310E-QTM Manual Addendum Instructions For Modicon Quantum Form Factor Ethernet Radio ModemDocument1 pageSRM6310E-QTM Manual Addendum Instructions For Modicon Quantum Form Factor Ethernet Radio ModemFarid AhmadNo ratings yet

- Infoplc Net s7 Fc300Document10 pagesInfoplc Net s7 Fc300Patricio Antonio Cortés PeñaNo ratings yet

- A Brief Introduction To Controller Area NetworkDocument6 pagesA Brief Introduction To Controller Area NetworkSergio FinkNo ratings yet

- CAN Physical Layer and Termination Guide - National InstrumentsDocument3 pagesCAN Physical Layer and Termination Guide - National InstrumentsdubimouNo ratings yet

- CAN FD Introduction enDocument42 pagesCAN FD Introduction enCastilhoMec100% (1)

- Scania Communicator 300 Industrial Engines and Power Generation Engines DC09, DC13, DC16, OC16 Marine Engines DI09, DI13, DI16Document16 pagesScania Communicator 300 Industrial Engines and Power Generation Engines DC09, DC13, DC16, OC16 Marine Engines DI09, DI13, DI16Ben ThreadwellNo ratings yet

- Idoc - Tips Cascadia ManualDocument25 pagesIdoc - Tips Cascadia ManualOctavio ArayaNo ratings yet

- Technical Article: Networking Heavy-Duty Vehicles Based On SAE J1939Document12 pagesTechnical Article: Networking Heavy-Duty Vehicles Based On SAE J1939jfranco78No ratings yet

- Cascadia Manual PDFDocument25 pagesCascadia Manual PDFIngrid GarciaNo ratings yet

- No Zone Default-Zone Permit Zone Mode Enhanced: #ClusDocument15 pagesNo Zone Default-Zone Permit Zone Mode Enhanced: #ClusanilNo ratings yet

- CAN TutorialDocument22 pagesCAN TutorialNaveen BasavarajacharNo ratings yet

- CAN TutorialDocument22 pagesCAN TutorialApoorva BhattNo ratings yet

- 02 2430eu01al 01 Basic FunctionalityDocument42 pages02 2430eu01al 01 Basic FunctionalityMohamed shabanaNo ratings yet

- Asset1R CANBus Overview FinalDocument4 pagesAsset1R CANBus Overview FinalKhor Tze MingNo ratings yet

- Application Note On Upgradation of C-Dot Dss To Support V5.2 InterfaceDocument72 pagesApplication Note On Upgradation of C-Dot Dss To Support V5.2 InterfaceMahesh Kumar NigamNo ratings yet

- BWM 0000866 99 PDFDocument37 pagesBWM 0000866 99 PDFjose breno vieira silvaNo ratings yet

- 6325 rn017 1Document5 pages6325 rn017 1iaomsuet100% (1)

- 16-2 p30 Mapping of j1939 To Can FD Cia602 ZeltwangerDocument2 pages16-2 p30 Mapping of j1939 To Can FD Cia602 ZeltwangerAlireza RakhshNo ratings yet

- A Brief Introduction To Controller Area Network PDFDocument6 pagesA Brief Introduction To Controller Area Network PDFSiva100% (1)

- A Brief Introduction To Controller Area Network PDFDocument6 pagesA Brief Introduction To Controller Area Network PDFSivaNo ratings yet

- CAN - A Brief Tutorial: Nuts and BoltsDocument4 pagesCAN - A Brief Tutorial: Nuts and Boltsmailtomyidyaar98100% (1)

- Basic Study of Automotive Protocols / Standards: Arun Nath K SDocument15 pagesBasic Study of Automotive Protocols / Standards: Arun Nath K SnickynandanamNo ratings yet

- Wp-cdm625 Acm White PaperDocument14 pagesWp-cdm625 Acm White PaperarzeszutNo ratings yet

- Autosar Secoc For Can FDDocument2 pagesAutosar Secoc For Can FDgptgNo ratings yet

- Can FD SpecDocument34 pagesCan FD SpecPreetham BaskaranNo ratings yet

- Wp-cdm625 - Acm - White - Paper ACM in The CDM-625Document14 pagesWp-cdm625 - Acm - White - Paper ACM in The CDM-625Fath GruntNo ratings yet

- Combining Canopen and Sae J1939 NetworksDocument5 pagesCombining Canopen and Sae J1939 NetworksFouad NadjiNo ratings yet

- Saes T 914Document14 pagesSaes T 914luke luckyNo ratings yet

- Configuring Trunking On Cisco MDSDocument14 pagesConfiguring Trunking On Cisco MDSshchaitNo ratings yet

- 10G LAN - WAN Protocol ConverterDocument3 pages10G LAN - WAN Protocol ConverterTony OkinyiNo ratings yet

- SL-253 (Collision Avoidance)Document1 pageSL-253 (Collision Avoidance)Gerhard MNo ratings yet

- I Jcs It 2012030294Document5 pagesI Jcs It 2012030294Ahmed AricheNo ratings yet

- App Note BMS InterfacingDocument6 pagesApp Note BMS InterfacingdmaslachNo ratings yet

- Service Delivery Form: Form Date (Day/month/year) : 19/03/2021 Order Type: ModifyDocument22 pagesService Delivery Form: Form Date (Day/month/year) : 19/03/2021 Order Type: ModifyJohnNo ratings yet

- Ixxat Sae j1939Document3 pagesIxxat Sae j1939Dinesh KumarNo ratings yet

- Transitioning Applications From CAN 2.0 To CAN FDDocument8 pagesTransitioning Applications From CAN 2.0 To CAN FDdk contatoNo ratings yet

- CCSDS Telemetry/Telecommand Standards Restructured As Communications ProtocolsDocument27 pagesCCSDS Telemetry/Telecommand Standards Restructured As Communications ProtocolseccoctoberNo ratings yet

- J1939Training Rev2Document72 pagesJ1939Training Rev2Timon2005100% (2)

- What Is CAN-FDDocument41 pagesWhat Is CAN-FDSandeep MishraNo ratings yet

- Design and Implementation of SAE J1939 Vehicle Diagnostics SystemDocument4 pagesDesign and Implementation of SAE J1939 Vehicle Diagnostics Systemk019No ratings yet

- CAN Bus Explained - A Simple Intro (2019)Document13 pagesCAN Bus Explained - A Simple Intro (2019)Hermawan 0103100% (2)

- Implementing DVB AsiDocument7 pagesImplementing DVB AsiEddie Batista De Lima FilhoNo ratings yet

- Link Vlt5000 Profibus and Simatic s7 Mc50a202Document8 pagesLink Vlt5000 Profibus and Simatic s7 Mc50a202sybaritzNo ratings yet

- WAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksFrom EverandWAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksNo ratings yet

- Gruppe04 enDocument106 pagesGruppe04 enabo mhdeNo ratings yet

- Gruppe07 enDocument322 pagesGruppe07 enabo mhdeNo ratings yet

- Gruppe06 enDocument96 pagesGruppe06 enabo mhdeNo ratings yet

- Buch 2 Kapitel 8Document2 pagesBuch 2 Kapitel 8abo mhdeNo ratings yet

- Gruppe02 enDocument54 pagesGruppe02 enabo mhdeNo ratings yet

- Tda1029 PDFDocument16 pagesTda1029 PDFromanbunNo ratings yet

- LTC4162 LDocument52 pagesLTC4162 Lmar_barudjNo ratings yet

- Instrukcja Obsługi TC544 - WWW - EBMiA.plDocument4 pagesInstrukcja Obsługi TC544 - WWW - EBMiA.plAjay Kumar GiriNo ratings yet

- Alternator ADUDocument4 pagesAlternator ADUMark Christian GapasNo ratings yet

- IRGIB10B60KD1: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDocument12 pagesIRGIB10B60KD1: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeSmain BendeddoucheNo ratings yet

- Adafruit Motor/Stepper/Servo Shield For Arduino v2 Kit - v2.3Document3 pagesAdafruit Motor/Stepper/Servo Shield For Arduino v2 Kit - v2.327051977No ratings yet

- L010976 - EMJ-04 Servo MotorDocument3 pagesL010976 - EMJ-04 Servo MotorRintuMathunniNo ratings yet

- II Puc Physics Board MaterialDocument170 pagesII Puc Physics Board MaterialMadhav SahNo ratings yet

- Electric Plugs Per Country PDFDocument4 pagesElectric Plugs Per Country PDFandrei_bertea7771No ratings yet

- Raymarine l365Document83 pagesRaymarine l365learco babiniNo ratings yet

- Ee310 Experiment 6 PDFDocument26 pagesEe310 Experiment 6 PDFJoseph KitongaNo ratings yet

- JA505 Chapter 1Document34 pagesJA505 Chapter 1khalifawhanNo ratings yet

- Specification of 313kVA Cummins Diesel Generator With Hosem Alternator DSE7320 A-C350-1-16292699396637e5ad3552450Document8 pagesSpecification of 313kVA Cummins Diesel Generator With Hosem Alternator DSE7320 A-C350-1-16292699396637e5ad3552450Luis MejiaNo ratings yet

- Product Specification: Cosmo K1010Document6 pagesProduct Specification: Cosmo K1010James HarrisonNo ratings yet

- Afterlife2019 PDFDocument6 pagesAfterlife2019 PDFMensur Memara SalkanovicNo ratings yet

- X L W C: Motor Shaft CapacitiveDocument14 pagesX L W C: Motor Shaft CapacitiveMuhammad Fauzan Ansari Bin AzizNo ratings yet

- Allen Bradley QD Cord SelectionDocument162 pagesAllen Bradley QD Cord SelectionAnonymous AsIbqUNo ratings yet

- 7 A H-Bridge For DC-Motor Applications 30348: Preliminary DatasheetDocument4 pages7 A H-Bridge For DC-Motor Applications 30348: Preliminary DatasheetallisonNo ratings yet

- Electrician Career ExplorationDocument3 pagesElectrician Career Explorationapi-240869472No ratings yet

- FAST34Document21 pagesFAST34papaki2No ratings yet

- M07 Mitad & StoveDocument83 pagesM07 Mitad & Stovebilisummaa100% (2)

- Sd30mtsw01ci Manual SW Sd300 Eng Revc WDocument115 pagesSd30mtsw01ci Manual SW Sd300 Eng Revc Wjack_clift100% (1)

- List Material MEDocument31 pagesList Material MEMK-23B UMINo ratings yet

- Instrumentation Cables: Product CatalogueDocument44 pagesInstrumentation Cables: Product Cataloguexinying liuNo ratings yet

- Integrated Circuit True RMS-to-DC Converter: Data SheetDocument15 pagesIntegrated Circuit True RMS-to-DC Converter: Data SheetSaikumarNo ratings yet

- Unit 1. ElectrochemistryDocument50 pagesUnit 1. ElectrochemistryRohit AgrawalNo ratings yet

- UPS & InvertersDocument56 pagesUPS & InvertersMustafa SobhyNo ratings yet

- Thalia P - Instruction ManualDocument23 pagesThalia P - Instruction ManualMichael OliverNo ratings yet

- Risk Assesment For Electrical Conducting & Installation WorkDocument3 pagesRisk Assesment For Electrical Conducting & Installation Worksinziana ghinet100% (1)

- megaTRON S4 HPS GB - 2019 09 WebDocument6 pagesmegaTRON S4 HPS GB - 2019 09 WebDaniel MedinaNo ratings yet