Professional Documents

Culture Documents

Reveco-Go! Car Door Mechanical Locking (EN 81-1/-2: Articles 8.9.3 and 11.2.1, EN 81-21 Article 5.8.2)

Reveco-Go! Car Door Mechanical Locking (EN 81-1/-2: Articles 8.9.3 and 11.2.1, EN 81-21 Article 5.8.2)

Uploaded by

Yiannis ToufexisCopyright:

Available Formats

You might also like

- Servoscale: Vertical Platform Lift Model E06Document17 pagesServoscale: Vertical Platform Lift Model E06aheneke1No ratings yet

- Skoda Octavia III 2013 Octavia III 2014 Heating Air Conditioning Workshop Manual Edition 01.2015 PDFDocument134 pagesSkoda Octavia III 2013 Octavia III 2014 Heating Air Conditioning Workshop Manual Edition 01.2015 PDFВиктор Ганжа100% (3)

- TEM Vol 2 Part 2 AS17422 Traffic Control Devices For General UseDocument225 pagesTEM Vol 2 Part 2 AS17422 Traffic Control Devices For General Usedarren dmuscat1hotmail.comNo ratings yet

- Orinoco Installation ManualDocument238 pagesOrinoco Installation ManualZoroastro Mo100% (1)

- Tecniche Level GB13SPE00Document20 pagesTecniche Level GB13SPE00scritra100% (1)

- ® Elevator: Kunshan KOYO Elevator LTDDocument18 pages® Elevator: Kunshan KOYO Elevator LTDApexBD01No ratings yet

- Gen2™ Comfort Lift. Taking Ride Quality To A Higher LevelDocument10 pagesGen2™ Comfort Lift. Taking Ride Quality To A Higher LevelJitendra DwivediNo ratings yet

- IMC - SCR - Rev - E8 (42-02-7200E)Document449 pagesIMC - SCR - Rev - E8 (42-02-7200E)ElputoAmo XDNo ratings yet

- 2.0L Gasoline Engine With Start/Stop, CADA, CAEB, CDNB, CDNC: Wiring DiagramDocument24 pages2.0L Gasoline Engine With Start/Stop, CADA, CAEB, CDNB, CDNC: Wiring DiagramJose FlorezNo ratings yet

- OSC Parts Catalog Ch. 2 Controller Related ComponentsDocument97 pagesOSC Parts Catalog Ch. 2 Controller Related ComponentsAshish BothraNo ratings yet

- TDI 300 TGL Manual Rev 10 March 2019 PDFDocument110 pagesTDI 300 TGL Manual Rev 10 March 2019 PDFMAYESTON0% (1)

- Autinor: Site ManualDocument26 pagesAutinor: Site ManualMattias ThorsonNo ratings yet

- DCSS5 Service Tool ManualDocument42 pagesDCSS5 Service Tool Manualmahfoud ascenseursNo ratings yet

- Windcrest Autodialler Full Remote Programming InstructionDocument5 pagesWindcrest Autodialler Full Remote Programming InstructionChris MillsNo ratings yet

- Dielro 101: Manual TécnicoDocument50 pagesDielro 101: Manual Técnicomisubisi100% (1)

- REM EV Guide (Basic Programming) CAD+Document3 pagesREM EV Guide (Basic Programming) CAD+kieranNo ratings yet

- Lift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0Document6 pagesLift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0raymon janszenNo ratings yet

- VFD-ED-S Eng Manual 20150204 PDFDocument228 pagesVFD-ED-S Eng Manual 20150204 PDFZomaarNo ratings yet

- A EA 001 en Rev.2 200coryDocument24 pagesA EA 001 en Rev.2 200coryCarlo ApilaNo ratings yet

- Emailing Err 65-66 MonarchDocument6 pagesEmailing Err 65-66 MonarchfchumpitazNo ratings yet

- Fältcom ECII Flex: ManualDocument41 pagesFältcom ECII Flex: ManualMohamed HajjiNo ratings yet

- Er Otis Ipv Jdi TopDocument17 pagesEr Otis Ipv Jdi TopDouglas045No ratings yet

- Fermator Landing Door LD30 Maintenance Manual Premium - 09.18Document60 pagesFermator Landing Door LD30 Maintenance Manual Premium - 09.18alfreliaNo ratings yet

- REM EV Receiving Calls 201404Document2 pagesREM EV Receiving Calls 201404kieranNo ratings yet

- Ovf20 Startup RoutineDocument14 pagesOvf20 Startup RoutineRaja DuraiNo ratings yet

- Flex 2: Electric Screw Driven Platform LiftDocument24 pagesFlex 2: Electric Screw Driven Platform LiftCatur Putra Suadnyana100% (1)

- Mody Leo Toro en r4Document28 pagesMody Leo Toro en r4SinaNo ratings yet

- ZIEHL ABEGG Catalogue Drive Technology For Elevators 2020 English 1Document126 pagesZIEHL ABEGG Catalogue Drive Technology For Elevators 2020 English 1Reeta SelvaNo ratings yet

- Power Unit Type "T-3010 En"Document1 pagePower Unit Type "T-3010 En"Anton LyakhovNo ratings yet

- ProgM SEC3 SW Rev 0203B enDocument39 pagesProgM SEC3 SW Rev 0203B enyounesNo ratings yet

- XAA25302M17Document1 pageXAA25302M17Tolgahan Karadag100% (1)

- Loher Dynavert L03-04Document137 pagesLoher Dynavert L03-04Chaima Ben AliNo ratings yet

- Features Lift Controller MLC-8000 01Document4 pagesFeatures Lift Controller MLC-8000 01Hani KatanaNo ratings yet

- Technical Dossier Replacement of The Reveco I Electronics Box With The Reveco PrimaDocument8 pagesTechnical Dossier Replacement of The Reveco I Electronics Box With The Reveco Primatuner12100% (1)

- Microzed-A V Microzed-A V3.1 3.1: User'S ManualDocument38 pagesMicrozed-A V Microzed-A V3.1 3.1: User'S ManualWassim Baccari100% (2)

- DOUBLE-SECTION-CAR-GATE-INSTALLATION-GUIDE - Peele DoorDocument44 pagesDOUBLE-SECTION-CAR-GATE-INSTALLATION-GUIDE - Peele DoorRodrigo AntonioNo ratings yet

- Copia de VF7 Doc 2017Document25 pagesCopia de VF7 Doc 2017Edgar ZamoraNo ratings yet

- Manual 40.10 PM-01.2016Document28 pagesManual 40.10 PM-01.2016Anonymous Mike100% (1)

- User Manual VF7 07 2019 (V7 01 08 01)Document36 pagesUser Manual VF7 07 2019 (V7 01 08 01)paul masakuNo ratings yet

- 1 Sky301 v1 User ManualDocument14 pages1 Sky301 v1 User ManualjhfbtyNo ratings yet

- Securlift - PM - SEC - TM - en - 7 - 04Document29 pagesSecurlift - PM - SEC - TM - en - 7 - 04bdgnsNo ratings yet

- A-FLY Quotation For Schindler Parts-20170815-142636703Document2 pagesA-FLY Quotation For Schindler Parts-20170815-142636703habibullaNo ratings yet

- Aritco 7000 Maintenance ManualDocument36 pagesAritco 7000 Maintenance ManualZen-o SamaNo ratings yet

- PG Interface Card "OPC-PG3": Instruction ManualDocument1 pagePG Interface Card "OPC-PG3": Instruction ManualHani KatanaNo ratings yet

- MAN INS Bp408-Installationshandbuch SEN AIN V7Document124 pagesMAN INS Bp408-Installationshandbuch SEN AIN V7FahadNo ratings yet

- Eco+ Augusta: Instruction HandbookDocument48 pagesEco+ Augusta: Instruction HandbookTaimoor AhmedNo ratings yet

- Augusta Evo: Car DoorsDocument32 pagesAugusta Evo: Car DoorsCoil98No ratings yet

- Delta - User ManualDocument35 pagesDelta - User ManualMiroslav Ožeg100% (1)

- Manual Omronkft 3g3fv PDFDocument397 pagesManual Omronkft 3g3fv PDFJose Medina BuitragoNo ratings yet

- QCM-320 Rev-B1 - NBDZDocument19 pagesQCM-320 Rev-B1 - NBDZبن يامة حسام الدينNo ratings yet

- Micelect Technical Manual LM3D STD Din Ver 01.2004Document1 pageMicelect Technical Manual LM3D STD Din Ver 01.2004Armando100% (1)

- Model 840 Series Controller: Product Information SheetDocument4 pagesModel 840 Series Controller: Product Information SheetMatti HynniNo ratings yet

- Bull 1144 - 620 626 Rope Gripper ManualDocument40 pagesBull 1144 - 620 626 Rope Gripper ManualCarlos EduardoNo ratings yet

- 3 Coil Valve AdjustmentDocument6 pages3 Coil Valve Adjustmentvasansulo100% (1)

- ELOSDocument14 pagesELOSMostafa MohmmedNo ratings yet

- BA100.User ManualDocument40 pagesBA100.User ManualBaltija MechanikasNo ratings yet

- GLE IMEM TREND Fault 67-71Document7 pagesGLE IMEM TREND Fault 67-71Ash100% (1)

- TysenDocument96 pagesTysenMahmoud SanadNo ratings yet

- KLEEMANN Lifts UK Limited Unit 8, Arena, 14 Charbridge Lane, Bicester, OxfordshireDocument5 pagesKLEEMANN Lifts UK Limited Unit 8, Arena, 14 Charbridge Lane, Bicester, OxfordshireEsfan GaripNo ratings yet

- Shorts Metron Lift Car DoorsDocument2 pagesShorts Metron Lift Car DoorsAnton LyakhovNo ratings yet

- g400 en PDFDocument13 pagesg400 en PDFReynold SuarezNo ratings yet

- MP ecoGO.+Software+package+A1903.00+Document68 pagesMP ecoGO.+Software+package+A1903.00+bornNo ratings yet

- Prospekt34E S56 57 - 02 16Document1 pageProspekt34E S56 57 - 02 16Yiannis ToufexisNo ratings yet

- WF-QS Full-Plastic Flex Fire-Retardant Balance Compensation ChainDocument2 pagesWF-QS Full-Plastic Flex Fire-Retardant Balance Compensation ChainYiannis ToufexisNo ratings yet

- Ficha Tecnica CEM-UF-300-GI Ingles Ed 01Document4 pagesFicha Tecnica CEM-UF-300-GI Ingles Ed 01Yiannis ToufexisNo ratings yet

- Ficha Tecnica CEM-UF-300-GI Ingles Ed 01Document4 pagesFicha Tecnica CEM-UF-300-GI Ingles Ed 01Yiannis ToufexisNo ratings yet

- WCF-SERIES-Top Suspension Manual PDFDocument36 pagesWCF-SERIES-Top Suspension Manual PDFYiannis ToufexisNo ratings yet

- GWB Media Proposal PricesDocument2 pagesGWB Media Proposal PricesAnnie RodriguezNo ratings yet

- IJEM Vol 4 Iss 3 OnlineDocument82 pagesIJEM Vol 4 Iss 3 OnlinedilinNo ratings yet

- Hydraulic and Pneumantic Machine 1 Basic 8Document14 pagesHydraulic and Pneumantic Machine 1 Basic 8Valentine NwankwoNo ratings yet

- Week 3 Highway Development and PlanningDocument43 pagesWeek 3 Highway Development and PlanningLIMPAHAN, JAY MARK M.No ratings yet

- Circulation of Draft Specification Central Road Lab PDFDocument688 pagesCirculation of Draft Specification Central Road Lab PDFsuman subediNo ratings yet

- Honeycomb Bravo Configuration Sportys Preferred Settings JetDocument1 pageHoneycomb Bravo Configuration Sportys Preferred Settings JetJohn BallekomNo ratings yet

- CAM2 Magnum Turbo D 15W-40 Product BulletinDocument2 pagesCAM2 Magnum Turbo D 15W-40 Product BulletinengerbethNo ratings yet

- Freno Motor Cummi N14 & N14 PlusDocument2 pagesFreno Motor Cummi N14 & N14 PlusIsaac Jhonatan Hernández VázquezNo ratings yet

- LIBERTY PUMPS Floor With Back OutletDocument2 pagesLIBERTY PUMPS Floor With Back OutletJulio HernandezNo ratings yet

- Emergency Lowering ProceduresDocument9 pagesEmergency Lowering ProceduresJuan CarlosNo ratings yet

- Nalanda Non Residential Specifications Part I Civil WorksDocument181 pagesNalanda Non Residential Specifications Part I Civil WorksPrashamNo ratings yet

- 35 Cacho v. ManahanDocument3 pages35 Cacho v. ManahanGabrielle Adine SantosNo ratings yet

- WWW - MINEPORTAL.in: Online Test Series ForDocument141 pagesWWW - MINEPORTAL.in: Online Test Series ForChad DhirajNo ratings yet

- Case/Duct System (Automobile)Document7 pagesCase/Duct System (Automobile)Tran xuan ThuyNo ratings yet

- Inspection Report 4029888 1666782482Document16 pagesInspection Report 4029888 1666782482Nigel PasannaNo ratings yet

- 2019 - China Ride Hailing (Deloitte) 2019Document28 pages2019 - China Ride Hailing (Deloitte) 2019hjuzqxbwNo ratings yet

- Frank Hecker Insurance CardDocument1 pageFrank Hecker Insurance Cardandrewdallas948No ratings yet

- Toyota, Santa Rosa Laguna Has Sent You A Message Regarding Your Inquiry For A Toyota Raize 1.2 E MT Yahoo Mail - From Anthony GarciaDocument2 pagesToyota, Santa Rosa Laguna Has Sent You A Message Regarding Your Inquiry For A Toyota Raize 1.2 E MT Yahoo Mail - From Anthony GarciaMusic NonStopNo ratings yet

- Gold Preliminary Exit Test Answer Key: Section 1: VocabularyDocument5 pagesGold Preliminary Exit Test Answer Key: Section 1: VocabularyClau alNo ratings yet

- Supplemental Restraint System (SRS) Kia Picanto 1Document1 pageSupplemental Restraint System (SRS) Kia Picanto 1Huy Trần QuốcNo ratings yet

- Lli Ip: Downloaded From Manuals Search EngineDocument144 pagesLli Ip: Downloaded From Manuals Search EngineEduardo ArrietaNo ratings yet

- What Year Is My Club CarDocument7 pagesWhat Year Is My Club CarArgelia CgNo ratings yet

- Urban Design Module IDocument54 pagesUrban Design Module IThirumeni Madavan100% (1)

- All Check ListDocument14 pagesAll Check ListTwin BullsNo ratings yet

- CaCamsaUndergrad Thesis-ManuscripDocument47 pagesCaCamsaUndergrad Thesis-ManuscripDatuzuharto SultanNo ratings yet

- 10 OnScreen B1plus TsResPack AudiosDocument5 pages10 OnScreen B1plus TsResPack AudiosIeva AleksonyteNo ratings yet

- Policy 3850947 10182023Document2 pagesPolicy 3850947 10182023Zyra MediosNo ratings yet

Reveco-Go! Car Door Mechanical Locking (EN 81-1/-2: Articles 8.9.3 and 11.2.1, EN 81-21 Article 5.8.2)

Reveco-Go! Car Door Mechanical Locking (EN 81-1/-2: Articles 8.9.3 and 11.2.1, EN 81-21 Article 5.8.2)

Uploaded by

Yiannis ToufexisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reveco-Go! Car Door Mechanical Locking (EN 81-1/-2: Articles 8.9.3 and 11.2.1, EN 81-21 Article 5.8.2)

Reveco-Go! Car Door Mechanical Locking (EN 81-1/-2: Articles 8.9.3 and 11.2.1, EN 81-21 Article 5.8.2)

Uploaded by

Yiannis ToufexisCopyright:

Available Formats

PRODUCT TECHNICAL SHEET

MECHANICS MECHANICAL LOCKING OF REVECO-Go! CAR DOOR

REVECO-Go! CAR DOOR MECHANICAL LOCKING

(EN 81-1/-2: Articles 8.9.3 and 11.2.1, EN 81-21 Article 5.8.2)

SCOPE OF APPLICATION:

These instructions apply to Reveco-Go! 3VF car door Operators in combination with Massen landing doors only. Not valid

for the Reveco-II 3VF Operator.

Application for installations in compliance with EN 81-1 / -2: 2009, sections 11.2.1 and 8.9.3, and installations in

compliance with EN 81-21: 2009, section 5.8.2.

Item: 0000004427 FTMECESPAREVGO000_EN, 01 /2012

1/5

PRODUCT TECHNICAL SHEET

MECHANICS MECHANICAL LOCKING OF REVECO-Go! CAR DOOR

REGULATIONS:

In accordance with European Standard EN 81-1/2, section 11.2.1, when the horizontal distance between the inner

surface of the lift well and car sill exceed 0.15 m, a locking device must be used on the car doors so that they cannot be

opened by passengers from inside the car when it is located between floor levels.

In the event of an unscheduled stop near ground level (unlocking zone), with the car stopped and the operator

disconnected electrically, the car door and landing door should be able to be manually opened or partially opened at the

floor at which it has stopped, both from the landing and from inside the car.

As stated in Article 8.9.3, this device must be designed and operate similarly to the landing doors.

In installations of new lifts in already existing buildings, in compliance with EN 81-21: 2009, section 5.8.2, extensible

car sill skirts can be installed as indicated in 5.8.2 a) and 5.8.2 b), if, among other requirements, compliant with

mechanical interlock installation in car door in accordance with EN 81-1 / -2 art. 8.9.3.

OPERATING MODES:

These instructions apply to Reveco-Go! 3VF car door Operators in combination with Massen landing doors only. Not valid

for the Reveco-II 3VF Operator.

The locking system is based on the movements of the Reveco-Go! Operator Drive lever, adding a specific mechanical

coupling device that works in conjunction with the interlocking housing variant that must be fitted with the Operator. Both

the Operator and the operation have a new version of software that implements this new functionality.

Based on the expansion of the Locking device slats, an extra-travel system has been added to the slat on the opening

side. During the opening movement of the slide, this system detects if it is in an unlocking zone (through contact with the

landing door lock wheels).

After beginning the car door opening movement sequence, if it detects it is in an unlocking zone, it operates the device to

open the door lock. If, however, during this movement it detects that the car is not in the unlocking zone, the lock will

stay engaged and the door will not be able to be opened.

ELECTRICAL OPERATION CONTROL REQUIREMENTS:

The car door Operator closing signal must be active while the car is travelling and not active when the car is at rest and

with the doors closed.

Before the car moves, the operation must send a closing signal for the doors to ensure that the locking device is under

pressure and the lock engages.

After a power failure, a shutdown signal must be sent to the Operator to ensure that the slide is in the closed position

when the car begins to travel.

If there is an automatic electrical emergency operation integrated or added as an accessory to the power supply fail-

safe, before the car moves, a door closing signal must also be sent which remains active while the car is travelling to

ensure that the locking device is under pressure and the lock engages.

Failure to meet these requirements means there is a malfunction that may lead to the lift stopping and possible

deterioration in the equipment.

If the door is associated to a static installation of curtain photocell, make sure the beam height is not higher than 1750

mm to prevent it interfering with the drive lever. This is the reason why the photocell to be installed must have a working

beam ≤ 1750 mm or it must allow to cancel the LEDs located above this height.

Item: 0000004427 FTMECESPAREVGO000_EN, 01 /2012

2/5

PRODUCT TECHNICAL SHEET

MECHANICS MECHANICAL LOCKING OF REVECO-Go! CAR DOOR

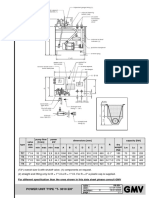

T2 DOORS MECHANICAL INTERLOCK GENERAL DIMENSIONS

DRIVE LEVER CLOSED OPENED IN UNLOCKING OPENED IN AREA BETWEEN

ZONE FLOORS

˜≈ 63

63 ˜≈ 88

88 ˜ ≈101

101

400

400

36

36

80

80

MECHANICAL AND ELECTRICAL OVERLAP WITH THE DOOR CLOSED

EMERGENCY

CLOSE

≈ 87

0

5 2

≈ 13,5

≈ 1,5

MECHANICAL OVERLAP AFTER ELECTRICAL CONTACT IS MADE

>7

Pressure on the

slats as indicated

in the figure

Item: 0000004427 FTMECESPAREVGO000_EN, 01 /2012

3/5

PRODUCT TECHNICAL SHEET

MECHANICS MECHANICAL LOCKING OF REVECO-Go! CAR DOOR

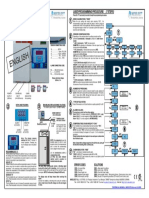

C2 DOORS MECHANICAL INTERLOCK GENERAL DIMENSIONS

DRIVE LEVER CLOSED OPENED IN UNLOCKING OPENED IN AREA BETWEEN

ZONE FLOORS

≈ 63 ≈ 88 ≈ 101

400

80 36

MECHANICAL AND ELECTRICAL OVERLAP WITH THE DOOR CLOSED

EMERGENCY

CLOSE

≈ 87

≈ 14,5 ≈ 1,5 ≈ 14,5

0

5 2

≈5

MECHANICAL OVERLAP AFTER ELECTRICAL CONTACT IS MADE

>7

Pressure on the

slats as indicated

in the figure

Item: 0000004427 FTMECESPAREVGO000_EN, 01 /2012

4/5

PRODUCT TECHNICAL SHEET

MECHANICS MECHANICAL LOCKING OF REVECO-Go! CAR DOOR

EMERGENCY UNLOCK KIT (OPTIONAL)

Item: 0000004427 FTMECESPAREVGO000_EN, 01 /2012

5/5

You might also like

- Servoscale: Vertical Platform Lift Model E06Document17 pagesServoscale: Vertical Platform Lift Model E06aheneke1No ratings yet

- Skoda Octavia III 2013 Octavia III 2014 Heating Air Conditioning Workshop Manual Edition 01.2015 PDFDocument134 pagesSkoda Octavia III 2013 Octavia III 2014 Heating Air Conditioning Workshop Manual Edition 01.2015 PDFВиктор Ганжа100% (3)

- TEM Vol 2 Part 2 AS17422 Traffic Control Devices For General UseDocument225 pagesTEM Vol 2 Part 2 AS17422 Traffic Control Devices For General Usedarren dmuscat1hotmail.comNo ratings yet

- Orinoco Installation ManualDocument238 pagesOrinoco Installation ManualZoroastro Mo100% (1)

- Tecniche Level GB13SPE00Document20 pagesTecniche Level GB13SPE00scritra100% (1)

- ® Elevator: Kunshan KOYO Elevator LTDDocument18 pages® Elevator: Kunshan KOYO Elevator LTDApexBD01No ratings yet

- Gen2™ Comfort Lift. Taking Ride Quality To A Higher LevelDocument10 pagesGen2™ Comfort Lift. Taking Ride Quality To A Higher LevelJitendra DwivediNo ratings yet

- IMC - SCR - Rev - E8 (42-02-7200E)Document449 pagesIMC - SCR - Rev - E8 (42-02-7200E)ElputoAmo XDNo ratings yet

- 2.0L Gasoline Engine With Start/Stop, CADA, CAEB, CDNB, CDNC: Wiring DiagramDocument24 pages2.0L Gasoline Engine With Start/Stop, CADA, CAEB, CDNB, CDNC: Wiring DiagramJose FlorezNo ratings yet

- OSC Parts Catalog Ch. 2 Controller Related ComponentsDocument97 pagesOSC Parts Catalog Ch. 2 Controller Related ComponentsAshish BothraNo ratings yet

- TDI 300 TGL Manual Rev 10 March 2019 PDFDocument110 pagesTDI 300 TGL Manual Rev 10 March 2019 PDFMAYESTON0% (1)

- Autinor: Site ManualDocument26 pagesAutinor: Site ManualMattias ThorsonNo ratings yet

- DCSS5 Service Tool ManualDocument42 pagesDCSS5 Service Tool Manualmahfoud ascenseursNo ratings yet

- Windcrest Autodialler Full Remote Programming InstructionDocument5 pagesWindcrest Autodialler Full Remote Programming InstructionChris MillsNo ratings yet

- Dielro 101: Manual TécnicoDocument50 pagesDielro 101: Manual Técnicomisubisi100% (1)

- REM EV Guide (Basic Programming) CAD+Document3 pagesREM EV Guide (Basic Programming) CAD+kieranNo ratings yet

- Lift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0Document6 pagesLift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0raymon janszenNo ratings yet

- VFD-ED-S Eng Manual 20150204 PDFDocument228 pagesVFD-ED-S Eng Manual 20150204 PDFZomaarNo ratings yet

- A EA 001 en Rev.2 200coryDocument24 pagesA EA 001 en Rev.2 200coryCarlo ApilaNo ratings yet

- Emailing Err 65-66 MonarchDocument6 pagesEmailing Err 65-66 MonarchfchumpitazNo ratings yet

- Fältcom ECII Flex: ManualDocument41 pagesFältcom ECII Flex: ManualMohamed HajjiNo ratings yet

- Er Otis Ipv Jdi TopDocument17 pagesEr Otis Ipv Jdi TopDouglas045No ratings yet

- Fermator Landing Door LD30 Maintenance Manual Premium - 09.18Document60 pagesFermator Landing Door LD30 Maintenance Manual Premium - 09.18alfreliaNo ratings yet

- REM EV Receiving Calls 201404Document2 pagesREM EV Receiving Calls 201404kieranNo ratings yet

- Ovf20 Startup RoutineDocument14 pagesOvf20 Startup RoutineRaja DuraiNo ratings yet

- Flex 2: Electric Screw Driven Platform LiftDocument24 pagesFlex 2: Electric Screw Driven Platform LiftCatur Putra Suadnyana100% (1)

- Mody Leo Toro en r4Document28 pagesMody Leo Toro en r4SinaNo ratings yet

- ZIEHL ABEGG Catalogue Drive Technology For Elevators 2020 English 1Document126 pagesZIEHL ABEGG Catalogue Drive Technology For Elevators 2020 English 1Reeta SelvaNo ratings yet

- Power Unit Type "T-3010 En"Document1 pagePower Unit Type "T-3010 En"Anton LyakhovNo ratings yet

- ProgM SEC3 SW Rev 0203B enDocument39 pagesProgM SEC3 SW Rev 0203B enyounesNo ratings yet

- XAA25302M17Document1 pageXAA25302M17Tolgahan Karadag100% (1)

- Loher Dynavert L03-04Document137 pagesLoher Dynavert L03-04Chaima Ben AliNo ratings yet

- Features Lift Controller MLC-8000 01Document4 pagesFeatures Lift Controller MLC-8000 01Hani KatanaNo ratings yet

- Technical Dossier Replacement of The Reveco I Electronics Box With The Reveco PrimaDocument8 pagesTechnical Dossier Replacement of The Reveco I Electronics Box With The Reveco Primatuner12100% (1)

- Microzed-A V Microzed-A V3.1 3.1: User'S ManualDocument38 pagesMicrozed-A V Microzed-A V3.1 3.1: User'S ManualWassim Baccari100% (2)

- DOUBLE-SECTION-CAR-GATE-INSTALLATION-GUIDE - Peele DoorDocument44 pagesDOUBLE-SECTION-CAR-GATE-INSTALLATION-GUIDE - Peele DoorRodrigo AntonioNo ratings yet

- Copia de VF7 Doc 2017Document25 pagesCopia de VF7 Doc 2017Edgar ZamoraNo ratings yet

- Manual 40.10 PM-01.2016Document28 pagesManual 40.10 PM-01.2016Anonymous Mike100% (1)

- User Manual VF7 07 2019 (V7 01 08 01)Document36 pagesUser Manual VF7 07 2019 (V7 01 08 01)paul masakuNo ratings yet

- 1 Sky301 v1 User ManualDocument14 pages1 Sky301 v1 User ManualjhfbtyNo ratings yet

- Securlift - PM - SEC - TM - en - 7 - 04Document29 pagesSecurlift - PM - SEC - TM - en - 7 - 04bdgnsNo ratings yet

- A-FLY Quotation For Schindler Parts-20170815-142636703Document2 pagesA-FLY Quotation For Schindler Parts-20170815-142636703habibullaNo ratings yet

- Aritco 7000 Maintenance ManualDocument36 pagesAritco 7000 Maintenance ManualZen-o SamaNo ratings yet

- PG Interface Card "OPC-PG3": Instruction ManualDocument1 pagePG Interface Card "OPC-PG3": Instruction ManualHani KatanaNo ratings yet

- MAN INS Bp408-Installationshandbuch SEN AIN V7Document124 pagesMAN INS Bp408-Installationshandbuch SEN AIN V7FahadNo ratings yet

- Eco+ Augusta: Instruction HandbookDocument48 pagesEco+ Augusta: Instruction HandbookTaimoor AhmedNo ratings yet

- Augusta Evo: Car DoorsDocument32 pagesAugusta Evo: Car DoorsCoil98No ratings yet

- Delta - User ManualDocument35 pagesDelta - User ManualMiroslav Ožeg100% (1)

- Manual Omronkft 3g3fv PDFDocument397 pagesManual Omronkft 3g3fv PDFJose Medina BuitragoNo ratings yet

- QCM-320 Rev-B1 - NBDZDocument19 pagesQCM-320 Rev-B1 - NBDZبن يامة حسام الدينNo ratings yet

- Micelect Technical Manual LM3D STD Din Ver 01.2004Document1 pageMicelect Technical Manual LM3D STD Din Ver 01.2004Armando100% (1)

- Model 840 Series Controller: Product Information SheetDocument4 pagesModel 840 Series Controller: Product Information SheetMatti HynniNo ratings yet

- Bull 1144 - 620 626 Rope Gripper ManualDocument40 pagesBull 1144 - 620 626 Rope Gripper ManualCarlos EduardoNo ratings yet

- 3 Coil Valve AdjustmentDocument6 pages3 Coil Valve Adjustmentvasansulo100% (1)

- ELOSDocument14 pagesELOSMostafa MohmmedNo ratings yet

- BA100.User ManualDocument40 pagesBA100.User ManualBaltija MechanikasNo ratings yet

- GLE IMEM TREND Fault 67-71Document7 pagesGLE IMEM TREND Fault 67-71Ash100% (1)

- TysenDocument96 pagesTysenMahmoud SanadNo ratings yet

- KLEEMANN Lifts UK Limited Unit 8, Arena, 14 Charbridge Lane, Bicester, OxfordshireDocument5 pagesKLEEMANN Lifts UK Limited Unit 8, Arena, 14 Charbridge Lane, Bicester, OxfordshireEsfan GaripNo ratings yet

- Shorts Metron Lift Car DoorsDocument2 pagesShorts Metron Lift Car DoorsAnton LyakhovNo ratings yet

- g400 en PDFDocument13 pagesg400 en PDFReynold SuarezNo ratings yet

- MP ecoGO.+Software+package+A1903.00+Document68 pagesMP ecoGO.+Software+package+A1903.00+bornNo ratings yet

- Prospekt34E S56 57 - 02 16Document1 pageProspekt34E S56 57 - 02 16Yiannis ToufexisNo ratings yet

- WF-QS Full-Plastic Flex Fire-Retardant Balance Compensation ChainDocument2 pagesWF-QS Full-Plastic Flex Fire-Retardant Balance Compensation ChainYiannis ToufexisNo ratings yet

- Ficha Tecnica CEM-UF-300-GI Ingles Ed 01Document4 pagesFicha Tecnica CEM-UF-300-GI Ingles Ed 01Yiannis ToufexisNo ratings yet

- Ficha Tecnica CEM-UF-300-GI Ingles Ed 01Document4 pagesFicha Tecnica CEM-UF-300-GI Ingles Ed 01Yiannis ToufexisNo ratings yet

- WCF-SERIES-Top Suspension Manual PDFDocument36 pagesWCF-SERIES-Top Suspension Manual PDFYiannis ToufexisNo ratings yet

- GWB Media Proposal PricesDocument2 pagesGWB Media Proposal PricesAnnie RodriguezNo ratings yet

- IJEM Vol 4 Iss 3 OnlineDocument82 pagesIJEM Vol 4 Iss 3 OnlinedilinNo ratings yet

- Hydraulic and Pneumantic Machine 1 Basic 8Document14 pagesHydraulic and Pneumantic Machine 1 Basic 8Valentine NwankwoNo ratings yet

- Week 3 Highway Development and PlanningDocument43 pagesWeek 3 Highway Development and PlanningLIMPAHAN, JAY MARK M.No ratings yet

- Circulation of Draft Specification Central Road Lab PDFDocument688 pagesCirculation of Draft Specification Central Road Lab PDFsuman subediNo ratings yet

- Honeycomb Bravo Configuration Sportys Preferred Settings JetDocument1 pageHoneycomb Bravo Configuration Sportys Preferred Settings JetJohn BallekomNo ratings yet

- CAM2 Magnum Turbo D 15W-40 Product BulletinDocument2 pagesCAM2 Magnum Turbo D 15W-40 Product BulletinengerbethNo ratings yet

- Freno Motor Cummi N14 & N14 PlusDocument2 pagesFreno Motor Cummi N14 & N14 PlusIsaac Jhonatan Hernández VázquezNo ratings yet

- LIBERTY PUMPS Floor With Back OutletDocument2 pagesLIBERTY PUMPS Floor With Back OutletJulio HernandezNo ratings yet

- Emergency Lowering ProceduresDocument9 pagesEmergency Lowering ProceduresJuan CarlosNo ratings yet

- Nalanda Non Residential Specifications Part I Civil WorksDocument181 pagesNalanda Non Residential Specifications Part I Civil WorksPrashamNo ratings yet

- 35 Cacho v. ManahanDocument3 pages35 Cacho v. ManahanGabrielle Adine SantosNo ratings yet

- WWW - MINEPORTAL.in: Online Test Series ForDocument141 pagesWWW - MINEPORTAL.in: Online Test Series ForChad DhirajNo ratings yet

- Case/Duct System (Automobile)Document7 pagesCase/Duct System (Automobile)Tran xuan ThuyNo ratings yet

- Inspection Report 4029888 1666782482Document16 pagesInspection Report 4029888 1666782482Nigel PasannaNo ratings yet

- 2019 - China Ride Hailing (Deloitte) 2019Document28 pages2019 - China Ride Hailing (Deloitte) 2019hjuzqxbwNo ratings yet

- Frank Hecker Insurance CardDocument1 pageFrank Hecker Insurance Cardandrewdallas948No ratings yet

- Toyota, Santa Rosa Laguna Has Sent You A Message Regarding Your Inquiry For A Toyota Raize 1.2 E MT Yahoo Mail - From Anthony GarciaDocument2 pagesToyota, Santa Rosa Laguna Has Sent You A Message Regarding Your Inquiry For A Toyota Raize 1.2 E MT Yahoo Mail - From Anthony GarciaMusic NonStopNo ratings yet

- Gold Preliminary Exit Test Answer Key: Section 1: VocabularyDocument5 pagesGold Preliminary Exit Test Answer Key: Section 1: VocabularyClau alNo ratings yet

- Supplemental Restraint System (SRS) Kia Picanto 1Document1 pageSupplemental Restraint System (SRS) Kia Picanto 1Huy Trần QuốcNo ratings yet

- Lli Ip: Downloaded From Manuals Search EngineDocument144 pagesLli Ip: Downloaded From Manuals Search EngineEduardo ArrietaNo ratings yet

- What Year Is My Club CarDocument7 pagesWhat Year Is My Club CarArgelia CgNo ratings yet

- Urban Design Module IDocument54 pagesUrban Design Module IThirumeni Madavan100% (1)

- All Check ListDocument14 pagesAll Check ListTwin BullsNo ratings yet

- CaCamsaUndergrad Thesis-ManuscripDocument47 pagesCaCamsaUndergrad Thesis-ManuscripDatuzuharto SultanNo ratings yet

- 10 OnScreen B1plus TsResPack AudiosDocument5 pages10 OnScreen B1plus TsResPack AudiosIeva AleksonyteNo ratings yet

- Policy 3850947 10182023Document2 pagesPolicy 3850947 10182023Zyra MediosNo ratings yet