Professional Documents

Culture Documents

Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDF

Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDF

Uploaded by

Cikalong YardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDF

Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDF

Uploaded by

Cikalong YardCopyright:

Available Formats

Chiksan® Swivel Joints

Repacking Instructions

ALL LONGSWEEP MODELS

STANDARD SERVICE

Tools Required

Trirace shown. Some

Truarc pliers, awl or similar pointed tool, vise, screwdriver

models have two races

DISASSEMBLY

1. Remove ball plug snap rings using Truarc pliers. 8. Clean all parts with petroleum solvent.

2. Remove ball plugs using awl or pointed tool. 9. Inspect parts for excessive wear, corrosion or other damage.

3. Secure female component in vise with ball plug holes positioned over a a. Inspect ball races for dents or grooves.

suitable container. b. Check male and female components for excessive erosion or

4. Rotate male component. Ball bearings should drop out. corrosion.

NOTE: It may be necessary to thin hardened lubricant with petroleum c. Carefully inspect the inside surfaces of elbows for evidence of

solvent. erosion or corrosion.

5. Separate male and female components after ball bearings have been WARNING: Longsweep Swivel Joints exhibiting a wall thickness

removed. below the minimum allowable shall be removed from service.

CAUTION: Do not damage machined surfaces when separating Replace all parts that show evidence of damage in the ball races,

components. Protect sealing surfaces at all times. sealing surfaces, or other areas.

6. Carefully remove old packing from female packing chamber using a screw- 10. Sealing surfaces must be completely smooth. Remove minor scratches or

driver. pitting by polishing with fine abrasive.

CAUTION: Use extreme care in removing old packing to prevent 11. Reclean all parts after polishing to remove metal particles and foreign

damage to sealing surfaces. matter.

7. Remove grease retainer and secondary O-ring seal from female

component except as indicated in Inset A.

ASSEMBLY

1. Apply a thin coat of lubricant to ball races, sealing surfaces and new 11. Lubricate bearings as follows:

packing. a. Install grease fitting

CAUTION: Make sure correct lubricant is used for intended service b. Use small, hand-held grease gun to force a small amount of

conditions. (See Lubricant Data). lubricant through the fitting.

2. Install new grease retainer in female component or on male. (See CAUTION: Make sure correct lubricant is used for intended service

inset A.) conditions (See Lubricant Data).

CAUTION: Retainer lip must face away from ball races. c. Rotate male component 90 degrees (quarter turn) and add more

grease through each fitting.

3. Install new secondary O-ring seal on male component.

d. Repeat step “c” (above) two more times, lubricating at each

4. Install new packing in female component packing chamber.

quarter turn.

CAUTION: Anti-extrusion ring must face outward, toward ball races. e. Check smoothness of rotation.

5. Secure female component in vise with ball plug holes on top. CAUTION: Excessive lubrication can cause swivel to bind, distort the

6. Insert male component into female component. anti-extrusion ring and displace the packing. Use only enough

7. Look through ball plug hole to align ball races. lubricant to obtain smooth rotation. If the swivel is more difficult to

8. Drop balls into races. Rotate male component and add balls until rotate after greasing than before, or if lubricant is detected on inside

all three races are filled with the proper number of balls.

FORM # 50052 (2-97)

of primary packing, or if distortion of packing is noted on inner

WARNING: Count the number of balls installed in each race to be diameter, disassemble joint and carefully inspect all seals for damage.

certain that the proper number of balls are installed. Incorrect Replace damaged seals and any packing which has been distorted or

number may cause binding or excessive wear and reduced pressure or displaced into the bore.

structural capacity. 12. Remove grease fitting and install lube fitting plug.

9. Insert ball plugs. (See Inset B for 3” XHTL.) 13. After assembly the swivel joint should be pressure tested to the

10. Insert ball plug snap rings. full rated pressure.

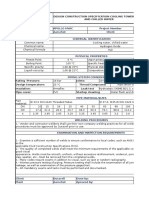

FEATURES AND REPLACEMENT PARTS

NO. GREASE LUBE BALL REPAIR PACKING BALL PLUG SINGLE PLUG

MODEL RACES RETAINER PLUG PLUG KIT SET SET SET

1” LS10, LS15 3 a d f 3143455 3143454 3143211 3142813

1-1/2” HPLS 2 b d f 3127210 3137068 3129000 3139416

1-1/2” LS10, LS15 3 a d f 3143327 3142960 3143211 CF

2” XHLS 2 c d f 3126627 3137070 3129001 3139418

2” LS10, LS15 3 a d f 3139666 3143979 3144007 3139418

2” EHLS 2 c d f 3127211 3137071 3129001 3139418

2” LS20 3 a d f 3144633 3144636 3144007 3139418

3” HPLS 2 c d g 3124431 3137074 3129004 3139421

3” XHTL 3 c e h 3122371 3137079 3129006 3139423

3” LS7.5, LS10, LS15 3 a d f 3144795 3144796 3144007 3139418

3” EHTL 3 c e h 3124644 3137081 3129007 3139424

3” LS20 3 a d f 3145398 3145262 3145264 CF

4” XHTL 3 a e j CF 3137083 3137086 CF

4” LS15 3 a d f 3145399 3145263 3145264 CF

4” LS10 3 a d f 3261027 3261023 3145264 CF

CF = Consult Factory

(a) Female groove, (b) 42 ring, (c) notched ring in male groove, (d) screw in body, (e) screw in ball plug,

(f) rubber plug, no seal, (g) rubber plug, nylon disc, (h) rubber plug, o-ring seal, (j) metal plug, o-ring seal.

PACKING IDENTIFICATION

Unless otherwise specified on purchase order, or required for application described on purchase

order, FMC will supply nitrile packing with brass anti-extrusion ring (OOB).

Compound

Code* Compound Anti-Extrusion Ring Designation

OO Nitrile Brass OOB

HH Fluorocarbon Rubber Stainless Steel HHS

*Compound code and part number appear on inside diameter of each packing.

LUBRICANT DATA

Lubricant Temperature Range Container* Part Number

Standard Swivel Joint Lubricant – 50°F to 212°F 2-lb can 3115574

*For special service conditions, consult factory for lubrication recommendations.

NOTE:

Refer to FMC product catalogs, brochures and installation, operating and maintenance manuals for additional product safety

information or contact FMC at 800/772-8582.

Direct orders to sales offices at the following locations:

Division Headquarters Odessa, Texas Anchorage, Alaska LaTalaudiere, France Los Morochas, Venezuela

6677 North Gessner Road Phone: 915/550-2084 Phone: 907/563-3990 Phone: (33) 4/7747-5015 Phone: (58) 65/26901

Houston, Texas 77040 U.S.A. Fax: 915/366-8538 Fax: 907-563-5810 Fax: (33) 4/7747-5014 Fax: (58) 65/23406

Phone: 713/510-6800

Fax: 713/510-6803 Broussard, Louisiana Aberdeen, Scotland Singapore Maturin, Venezuela

http://www/fmc/com/Eteg Phone: 318/837-9263 Phone: (44) 1224/898-555 Phone: (65) 862-3659 Phone: (58) 92/220003

FORM # 50052 (2-97)

E-mail: fluid_control@fmc.com Fax: 318/837-5844 Fax: (44) 1224/249-460 Fax: (65) 861-8251 Fax: (58) 92/220178

FMC Fluid Control Division Denver, Colorado The Netherlands Dubai, United Arab Emirates Villahermosa, Mexico

2825 West Washington Phone: 303/623-4622 Phone: (31) 172/470-024 Phone: (971) 4/310-948 Phone: (52) 93/50-0123

P.O. Box 1377 Fax: 303-623-7347 Fax: (31) 172/470-026 Fax: (971) 4/310-950 Fax: (52) 93/50-1661

Stephenville, Texas 76401

Toll Free: 1-800-772-8582

Fax: 254/968-5709

You might also like

- Bomco F-500 800 1000 ManualDocument98 pagesBomco F-500 800 1000 ManualFU LIN LINo ratings yet

- Blak-JAK 7500psi Washpipe CartridgeDocument2 pagesBlak-JAK 7500psi Washpipe CartridgeLuka Bardic100% (1)

- Swaco Disc Choke Console Manual 9090080 (E) PDFDocument166 pagesSwaco Disc Choke Console Manual 9090080 (E) PDFguoss10673100% (2)

- Sugar Plant Specifications 5000 TCD-7500 TCDDocument104 pagesSugar Plant Specifications 5000 TCD-7500 TCDtsrinivasan508375% (4)

- D30E200 Hook-Block - Operations Manual (30780000 Rev.0) American BlockDocument29 pagesD30E200 Hook-Block - Operations Manual (30780000 Rev.0) American BlockMaria Julieta Calderon Ortiz100% (2)

- Parmac 122 D631468-XDocument31 pagesParmac 122 D631468-XEdisson Santiago Deaza Gómez100% (2)

- National FB-1600 Parts List PDFDocument14 pagesNational FB-1600 Parts List PDFMauricio GarciaNo ratings yet

- Design Guide For Layout and Plot PlanDocument63 pagesDesign Guide For Layout and Plot PlanKokil JainNo ratings yet

- MKP Manual - RT175 Rev.B. R080416 PDFDocument13 pagesMKP Manual - RT175 Rev.B. R080416 PDFguillermo100% (1)

- #HB-1-81 22SR Lip Manual PDFDocument22 pages#HB-1-81 22SR Lip Manual PDFLucas Maldonado100% (1)

- Ezy Torq Operating ManualDocument28 pagesEzy Torq Operating ManualSyed Zain Ahmad100% (2)

- Cameron - DL-Annular BopDocument1 pageCameron - DL-Annular BopAnonymous 48jYxR1C100% (1)

- Swivel Tool CatalogDocument16 pagesSwivel Tool CatalogVishal RamsookNo ratings yet

- Weco Wing Union Part ListDocument18 pagesWeco Wing Union Part ListAli100% (1)

- Forum Aot Hercules Anchor PDFDocument26 pagesForum Aot Hercules Anchor PDFyesica100% (1)

- Oil Country TongsDocument79 pagesOil Country TongsKevin PaulNo ratings yet

- ANSI NEMA MW 1000-2003 Rev.1.2005Document220 pagesANSI NEMA MW 1000-2003 Rev.1.2005carlosantunez111100% (5)

- Master and Casing Bushing - ACEWELDocument8 pagesMaster and Casing Bushing - ACEWELcristinelb100% (1)

- Varco (Manual) - Weldless, Toolpusher, Perfections Links - OptDocument2 pagesVarco (Manual) - Weldless, Toolpusher, Perfections Links - Optrenjith rs100% (1)

- InternationalDocument40 pagesInternationalayman akrabNo ratings yet

- Towsend CatalogoDocument98 pagesTowsend CatalogoLuis Enrique Rico100% (3)

- Townsend 2008 Catalog (BESMINDO)Document97 pagesTownsend 2008 Catalog (BESMINDO)Boedi SyafiqNo ratings yet

- DL Annular Blowout Preventer 21-1/4" 3000 Psi WPDocument27 pagesDL Annular Blowout Preventer 21-1/4" 3000 Psi WPJeneesh Shanmughan100% (1)

- Deadline Anchors BrochureDocument3 pagesDeadline Anchors Brochurejlmunozv100% (3)

- Westco Model5500 Tubing TongDocument51 pagesWestco Model5500 Tubing Tong000No ratings yet

- Llave TW-60Document71 pagesLlave TW-60Brandy English100% (5)

- Stuckey Casing ScrapersDocument5 pagesStuckey Casing ScrapersGeorge Lamey0% (1)

- GE HY Kellyguard FS 080709-2Document2 pagesGE HY Kellyguard FS 080709-2caballero_tigreNo ratings yet

- Axon-Type50u Ram BopDocument4 pagesAxon-Type50u Ram BopMohie Khosravani0% (1)

- List Sparepart MI-SWACO Shale ShakerDocument23 pagesList Sparepart MI-SWACO Shale ShakerahnafNo ratings yet

- Hydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedDocument4 pagesHydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedJose BarreroNo ratings yet

- KoomeyDocument105 pagesKoomeyJohnny SanchezNo ratings yet

- Bop Type U & Um Replacement Parts CatalogDocument36 pagesBop Type U & Um Replacement Parts CatalogTaras100% (3)

- Crown Block Saver ComponentsDocument6 pagesCrown Block Saver Componentsmohamed salemNo ratings yet

- Swaco' Style Drilling Choke PartsDocument1 pageSwaco' Style Drilling Choke PartsBodega 3001No ratings yet

- Deadline AnchorDocument1 pageDeadline AnchorJesus Sanchez67% (3)

- Manual-0002 CDocument87 pagesManual-0002 CBoedi SyafiqNo ratings yet

- D-GASSERS Orizontal + Vertical PDFDocument2 pagesD-GASSERS Orizontal + Vertical PDFciucalata880% (1)

- Catalogo Ramde ColombiaDocument16 pagesCatalogo Ramde ColombiaSharay Villanova100% (1)

- BVM Catelogue New-2016 PDFDocument116 pagesBVM Catelogue New-2016 PDFOperation100% (1)

- ZY-ZJ-800&1000 Operation & Maintenance Manual PDFDocument69 pagesZY-ZJ-800&1000 Operation & Maintenance Manual PDFOperaciones Gep100% (1)

- Ds Shearing Blind Ram Tc1399Document2 pagesDs Shearing Blind Ram Tc1399Gregory StewartNo ratings yet

- GE Hydril CatalogoDocument26 pagesGE Hydril CatalogoAlfred Hernandez MendozaNo ratings yet

- Varco Ibop Valves PDFDocument50 pagesVarco Ibop Valves PDFAnonymous MxwCc4100% (3)

- SEC5 (1) WashpipeDocument22 pagesSEC5 (1) WashpipeCarlos Alberto PerdomoNo ratings yet

- American Block Swivels Model A-200Document20 pagesAmerican Block Swivels Model A-200aldino020203100% (2)

- Well Control EquipmentDocument8 pagesWell Control Equipmentyamid muñozNo ratings yet

- Demco Gate ValvesDocument52 pagesDemco Gate ValvesJuan Lorenzo100% (1)

- 1625-De Dwks Parts ListDocument69 pages1625-De Dwks Parts ListSasan AbbasiNo ratings yet

- Den Con 2009 2010 CatalogDocument36 pagesDen Con 2009 2010 CatalogAdrian Cantaragiu100% (1)

- Well Control Equipment Catalogue: IntegrityDocument21 pagesWell Control Equipment Catalogue: Integritycrni rokoNo ratings yet

- Packard CatalogDocument22 pagesPackard Catalogcrni roko100% (1)

- Cameron Manual Type F FCDocument7 pagesCameron Manual Type F FCEnrique HortaNo ratings yet

- IRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Document68 pagesIRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Tanyawat Sahsakmontri100% (2)

- KellyguardDSV (6845C)Document22 pagesKellyguardDSV (6845C)David0% (1)

- 2P36784, Plug ValveDocument34 pages2P36784, Plug ValveEdwin HernandezNo ratings yet

- HDBIDocument5 pagesHDBIkevlar315No ratings yet

- TimkenTT en Vol1 Iss3Document2 pagesTimkenTT en Vol1 Iss3grupa2904No ratings yet

- RTS TG M78Document9 pagesRTS TG M78woosah1234No ratings yet

- MN3085 - 0222 (W)Document12 pagesMN3085 - 0222 (W)mariamalloney1730No ratings yet

- Geared Coupling Manual PDFDocument5 pagesGeared Coupling Manual PDFSatNo ratings yet

- Spindle Guide: Note!Document5 pagesSpindle Guide: Note!Subramoniam MarineNo ratings yet

- Sisu Citius Series 44-49-66 74 and 84 Engines Workshop Manual 60 118Document59 pagesSisu Citius Series 44-49-66 74 and 84 Engines Workshop Manual 60 118Сергей ПриймакNo ratings yet

- Erapol EHP70DDocument2 pagesErapol EHP70DqwepoolNo ratings yet

- Salt TestDocument16 pagesSalt Testم.ذكى فضل ذكى100% (1)

- Astm D698Document4 pagesAstm D698Rofi Trianto S100% (1)

- JMC FORMAT FOR RCC Cable TrenchDocument1 pageJMC FORMAT FOR RCC Cable TrenchKuldeep KumarNo ratings yet

- Quickspecs: HP Compaq La1956X 19-Inch Led Backlit MonitorDocument10 pagesQuickspecs: HP Compaq La1956X 19-Inch Led Backlit Monitorleoncito6977No ratings yet

- CNHT'2022Document4 pagesCNHT'2022Talhi Mama0% (1)

- Ch3-Basic Steam CycleDocument6 pagesCh3-Basic Steam CycleRENGANATHAN PNo ratings yet

- Inverter 12v 3kv PDFDocument13 pagesInverter 12v 3kv PDFirfz44No ratings yet

- Porosity and Pore Size Distribution in Recycled ConcreteDocument9 pagesPorosity and Pore Size Distribution in Recycled ConcreteBagus Rizqi KurniawanNo ratings yet

- Intalox PackingDocument16 pagesIntalox Packingmfaizal81No ratings yet

- Fix Tube Sheet Heat Exchanger MaintenanceDocument10 pagesFix Tube Sheet Heat Exchanger MaintenanceKarthik MadhuNo ratings yet

- CUMI His & ProfileDocument6 pagesCUMI His & ProfileKARTHIKEYAN MNo ratings yet

- Diy Sls 3d PrinterDocument32 pagesDiy Sls 3d PrinterTF Escritório MGNo ratings yet

- Egr - Procesos de Manufactura - 2.1Document11 pagesEgr - Procesos de Manufactura - 2.1Eleazar GarciaNo ratings yet

- New Microsoft Office Excel WorksheetDocument11 pagesNew Microsoft Office Excel WorksheetUmar NazarNo ratings yet

- 3M Scotch 23 TDSDocument2 pages3M Scotch 23 TDSVivek JayswalNo ratings yet

- PU-SE-2003 & 2008 Course-QP-OCT-2012Document799 pagesPU-SE-2003 & 2008 Course-QP-OCT-2012rbc1230% (1)

- Trumpf TC 200 R: With Complete EquipmentDocument7 pagesTrumpf TC 200 R: With Complete EquipmentOscar Ivan Rendon GuangaNo ratings yet

- Ammonia ScrubbersDocument7 pagesAmmonia Scrubbersangelo pascuaNo ratings yet

- Cargo MT AfricaDocument72 pagesCargo MT AfricaPavel ViktorNo ratings yet

- Paint Quantity EstimationDocument2 pagesPaint Quantity EstimationChethanNo ratings yet

- JR R P Asphalt Reinforcement Rehabilitaion of Concrete Pavements HaTelit-DresdenDocument2 pagesJR R P Asphalt Reinforcement Rehabilitaion of Concrete Pavements HaTelit-DresdenjasbojanotNo ratings yet

- Domestic Production and Foreign Trade The American Capital Position Re-ExaminedDocument23 pagesDomestic Production and Foreign Trade The American Capital Position Re-ExaminedKevin Mcdonald100% (2)

- Cored Wires - ESAB - OK TubrodDocument87 pagesCored Wires - ESAB - OK TubrodElias KapaNo ratings yet

- Hot CrackingDocument3 pagesHot CrackingFsNo ratings yet

- Carbon Nanotubes: Centre For Nanoscience and Technology, Pondicherry University Puducherry-605 014, IndiaDocument62 pagesCarbon Nanotubes: Centre For Nanoscience and Technology, Pondicherry University Puducherry-605 014, IndiaMohammad RameezNo ratings yet

- CHW Piping SpecsDocument42 pagesCHW Piping SpecsEugen LupanNo ratings yet