Professional Documents

Culture Documents

Model Free Flow Nose To Side Check Valve With Bypass Orifice

Model Free Flow Nose To Side Check Valve With Bypass Orifice

Uploaded by

RenjithSivaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model Free Flow Nose To Side Check Valve With Bypass Orifice

Model Free Flow Nose To Side Check Valve With Bypass Orifice

Uploaded by

RenjithSivaCopyright:

Available Formats

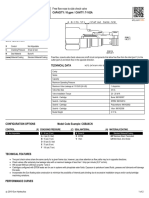

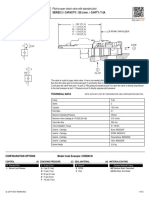

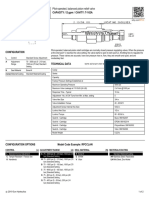

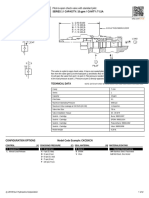

MODEL Free flow nose to side check valve with bypass orifice

CNBC CAPACITY: 7.5 gpm / CAVITY: T-162A

sunhydraulics.com/model/CNBC

Free-flow, nose-to-side check valves with a bypass orifice allow free flow from port 1 to port 2. A customer specified

orifice is included to restrict flow from port 2 to port 1. See technical data below for orifice range.

TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

Cavity T-162A

Series 0

Capacity 7.5 gpm

Maximum Operating Pressure 5000 psi

Orifice Range .016 - .062 in.

Valve Hex Size 3/4 in.

Valve Installation Torque 20 - 25 lbf ft

Seal kit - Cartridge Buna: 990162007

Seal kit - Cartridge EPDM: 990162014

Seal kit - Cartridge Polyurethane: 990162002

Seal kit - Cartridge Viton: 990162006

Model Weight 0.17 lb.

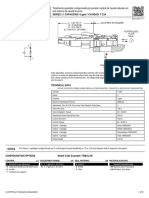

CONFIGURATION OPTIONS Model Code Example: CNBCXCN

CONTROL (X) SETTING RANGE (C) SEAL MATERIAL (N) MATERIAL/COATING

X Not Adjustable C 30 psi (2 bar) Cracking Pressure, .016 - N Buna-N Standard Material/Coating

.062 in. (0,4 - 1,6 mm) E EPDM /AP Stainless Steel, Passivated

A 4 psi (0,3 bar) Cracking Pressure, .016 V Viton

- .062 in. (0,4 - 1,6 mm)

B 15 psi (1 bar) Cracking Pressure, .016 -

.062 in. (0,4 - 1,6 mm)

D 50 psi (3,5 bar) Cracking Pressure,

.016 - .062 in. (0,4 - 1,6 mm)

E 75 psi (5 bar) Cracking Pressure, .016 -

.062 in. (0,4 - 1,6 mm)

F 100 psi (7 bar) Cracking Pressure, .016

- .062 in. (0,4 - 1,6 mm)

c 2019 Sun Hydraulics

1 of 2

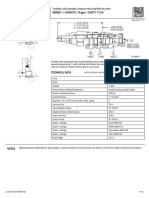

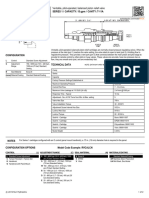

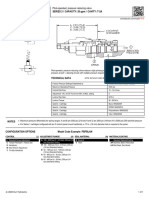

TECHNICAL FEATURES

Two-port check valves share the same cavity for a given frame size, however, pay close attention as flow paths may be in opposite directions.

Will accept 5000 psi (350 bar) at ports 1 and 2.

Valves with the opposite flow path (free flow from 2 to 1) are considered flow controls and may be found listed as fixed orifice, non-pressure compensated flow

control valve with reverse flow check.

Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage

the seals.

The customer specified orifice diameter is stamped on one of the cartridge's hex faces.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

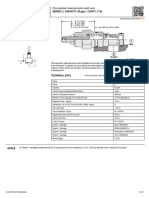

PERFORMANCE CURVES

c 2019 Sun Hydraulics

2 of 2

You might also like

- B25D & B30D Operation and Test ManualDocument316 pagesB25D & B30D Operation and Test ManualSMM ENTREPRISE67% (3)

- Week 30 Lesson PlanDocument13 pagesWeek 30 Lesson Plannurulhuda287No ratings yet

- Foundation (Thumb Rules) : Concentric FootingsDocument4 pagesFoundation (Thumb Rules) : Concentric FootingsAtul Joshi90% (10)

- Model Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162ADocument2 pagesModel Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162AsnsnagarajanNo ratings yet

- RDFALWN-CAM S Full en Us LetterDocument5 pagesRDFALWN-CAM S Full en Us LetterJustinNo ratings yet

- CODA Full en Us LetterDocument2 pagesCODA Full en Us Lettercesar5984No ratings yet

- CKBDXCV ApDocument2 pagesCKBDXCV ApŁukasz OlszewskiNo ratings yet

- FREA Full en Us A4Document2 pagesFREA Full en Us A4Rodrigo LisboaNo ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 pagesModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNo ratings yet

- Sun Hydraulics FDBA-LANDocument2 pagesSun Hydraulics FDBA-LANJustinNo ratings yet

- Model Fully Adjustable Needle Valve: SERIES 4 / CAPACITY: 60 GPM (.56 Inch) / CAVITY: T-18ADocument2 pagesModel Fully Adjustable Needle Valve: SERIES 4 / CAPACITY: 60 GPM (.56 Inch) / CAVITY: T-18AErasmo LimaNo ratings yet

- PVDB Full en Us LetterDocument2 pagesPVDB Full en Us LetterIsrael RuizNo ratings yet

- CXHAXAN - Full - en - Metric - Letter BorbetDocument2 pagesCXHAXAN - Full - en - Metric - Letter BorbetRonaldNo ratings yet

- Model Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- Model Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AVignesh PandiyanNo ratings yet

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- Sun Hydraulics NFCC-KCNDocument2 pagesSun Hydraulics NFCC-KCNJustinNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AAnurag JainNo ratings yet

- CVCV Full en Metric A4Document2 pagesCVCV Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- LRHC Full en Us A4Document1 pageLRHC Full en Us A4zapchasty29No ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 2 / Capacity: 30 GPM / Cavity: T-2ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 2 / Capacity: 30 GPM / Cavity: T-2AVEERAMANINo ratings yet

- CKEB Full en Metric LetterDocument2 pagesCKEB Full en Metric LetterRafalNo ratings yet

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Document2 pagesModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNo ratings yet

- RDJA Full en Us A4Document3 pagesRDJA Full en Us A4GERALD SIMONNo ratings yet

- DRBCLBN Full Es Us A4Document2 pagesDRBCLBN Full Es Us A4Erasmo LimaNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Document2 pagesModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNo ratings yet

- RVCALCN Full en Us A4Document2 pagesRVCALCN Full en Us A4Felipe DiazNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Sun Cartridge CXDA-XCNDocument2 pagesSun Cartridge CXDA-XCNJustinNo ratings yet

- CSAD Full en Us LetterDocument2 pagesCSAD Full en Us LetterService - Anda Hydraulics Asia Pte LtdNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Piston Relief ValveGamal El Deen KamalNo ratings yet

- RPCCLAN Full en Us LetterDocument2 pagesRPCCLAN Full en Us Lettera safaieNo ratings yet

- PBFB en Us A4Document1 pagePBFB en Us A4operacion hydratekNo ratings yet

- PDF Created On 9 Aug 2014 Page 1 of 6Document6 pagesPDF Created On 9 Aug 2014 Page 1 of 6Roget Alvis BatallanosNo ratings yet

- CXDAXCN Full Es Metric A4Document2 pagesCXDAXCN Full Es Metric A4Sara SaritaNo ratings yet

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument2 pagesModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNo ratings yet

- PRDBOEN Full en Us LetterDocument3 pagesPRDBOEN Full en Us LetterPartagon PowNo ratings yet

- Sun Hydraulics-Cbca Lan EccDocument5 pagesSun Hydraulics-Cbca Lan EcchendntdNo ratings yet

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- Sun Hydraulics RDDA-LCNDocument3 pagesSun Hydraulics RDDA-LCNJustinNo ratings yet

- Model Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AAnurag JainNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- CBCALHN-EAC Full en Us LetterDocument5 pagesCBCALHN-EAC Full en Us LetterVentas Control HidráulicoNo ratings yet

- Model Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Model All Ports Blocked Cavity Plug: Series 2 / Cavity: T-3ADocument1 pageModel All Ports Blocked Cavity Plug: Series 2 / Cavity: T-3AMarcelo Partes de OliveiraNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- Fire DRY HydrantsDocument4 pagesFire DRY HydrantsAbdullah RamadanNo ratings yet

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckDocument2 pagesModel Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckRajan BediNo ratings yet

- CVGV Full en Metric LetterDocument2 pagesCVGV Full en Metric LetterRonaldNo ratings yet

- Valvula Reguladora Continental PBFB-LAVDocument1 pageValvula Reguladora Continental PBFB-LAVsalesparts.norvateNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- FDBA en Metric LetterDocument1 pageFDBA en Metric LetterY.EbadiNo ratings yet

- + CG (NC) VSL-1Document2 pages+ CG (NC) VSL-1RenjithSivaNo ratings yet

- A Polyhydron Group Company: DescriptionDocument2 pagesA Polyhydron Group Company: DescriptionRenjithSivaNo ratings yet

- Tenderdoc NCR051Document2 pagesTenderdoc NCR051RenjithSivaNo ratings yet

- Riduttori Per Rotazione Slewing Gearboxes: RR1800 ÷ RR10000Document4 pagesRiduttori Per Rotazione Slewing Gearboxes: RR1800 ÷ RR10000RenjithSivaNo ratings yet

- Crane Manual PDFDocument453 pagesCrane Manual PDFRenjithSiva100% (1)

- Explosion Proof Directional Control Valve Type Ed6 Serie 6X Directive Atex Et IecexDocument12 pagesExplosion Proof Directional Control Valve Type Ed6 Serie 6X Directive Atex Et IecexRenjithSivaNo ratings yet

- Solenoid Controlled Relief ValvesDocument10 pagesSolenoid Controlled Relief ValvesRenjithSivaNo ratings yet

- Wa0001Document1 pageWa0001RenjithSivaNo ratings yet

- Renjith CDocument3 pagesRenjith CRenjithSivaNo ratings yet

- AbstractDocument38 pagesAbstractYugant Thakur50% (2)

- Tip Sheet 19 Environmental MonitoringDocument4 pagesTip Sheet 19 Environmental MonitoringmaritaNo ratings yet

- Improving Reading Performance of Readers At-Risk Through Phonics ApproachDocument10 pagesImproving Reading Performance of Readers At-Risk Through Phonics ApproachAILEEN JOY SabuelvaNo ratings yet

- Herramientas CSDocument2 pagesHerramientas CSCAPCOMALLSTARS POWERNo ratings yet

- Welding and Cutting Do's and Don'Ts Global EHS DD 004Document6 pagesWelding and Cutting Do's and Don'Ts Global EHS DD 004SYED AHMEDNo ratings yet

- Textbook Building Evidence For Active Ageing Policies Active Ageing Index and Its Potential 1St Edition Asghar Zaidi Ebook All Chapter PDFDocument53 pagesTextbook Building Evidence For Active Ageing Policies Active Ageing Index and Its Potential 1St Edition Asghar Zaidi Ebook All Chapter PDFmatthew.renfro133100% (17)

- CJ Relays (Acj) : Features Typical ApplicationsDocument7 pagesCJ Relays (Acj) : Features Typical ApplicationsFranciscoMedinaNo ratings yet

- Statistik Assignment 2 Aku Yg BetulDocument28 pagesStatistik Assignment 2 Aku Yg BetulMohd Razali Abd SamadNo ratings yet

- DOC-FE - IE.IN.014156.EN Fermator Programming ToolDocument13 pagesDOC-FE - IE.IN.014156.EN Fermator Programming Toolguturi satyanarayana murthyNo ratings yet

- RCC & PSC Class Notes (Vivek Gupta) PDFDocument329 pagesRCC & PSC Class Notes (Vivek Gupta) PDFHrushikesh PingaleNo ratings yet

- (Download) : Proposal Tugas Akhir TKJDocument6 pages(Download) : Proposal Tugas Akhir TKJEving JulNo ratings yet

- Impact of Chronic Illness On ChildrenDocument6 pagesImpact of Chronic Illness On ChildrenDeepa ThomasNo ratings yet

- 01 ACM - ICPC - Elementary Math - IntroductionDocument21 pages01 ACM - ICPC - Elementary Math - IntroductionMuhammadMahmoudNo ratings yet

- Conductas Agresivas en La Demencia PDFDocument3 pagesConductas Agresivas en La Demencia PDFRosa SecoNo ratings yet

- Torsten Husén A Co-Founder and Chairman of IEA From 1962 To 1978Document15 pagesTorsten Husén A Co-Founder and Chairman of IEA From 1962 To 1978Teodora GenovaNo ratings yet

- Case Study MMDocument3 pagesCase Study MMayam0% (1)

- AC2 Specification SheetDocument4 pagesAC2 Specification SheetWiwa Hernandez DonosoNo ratings yet

- Succession Planning HRDocument12 pagesSuccession Planning HRbetallion44No ratings yet

- ASME - VIII Div. 2 2004 Edition - AM-211 PDFDocument2 pagesASME - VIII Div. 2 2004 Edition - AM-211 PDFEsapermana RiyanNo ratings yet

- Q3 WK 2.1 Identifying Questions ProblemDocument44 pagesQ3 WK 2.1 Identifying Questions ProblemAkiraNo ratings yet

- Answer The Following Questions: Q1: Choose The Correct Answer (20 Points)Document13 pagesAnswer The Following Questions: Q1: Choose The Correct Answer (20 Points)Viraj JeewanthaNo ratings yet

- Architectural Design For EarthquakeDocument79 pagesArchitectural Design For EarthquakeEmmanuel DaguroNo ratings yet

- Astm 388Document8 pagesAstm 388Joseph RefuerzoNo ratings yet

- LithiumBattery EnglishDocument7 pagesLithiumBattery EnglishgojarooNo ratings yet

- Lite-On Technology Corporation: FeaturesDocument13 pagesLite-On Technology Corporation: Featuresname familyNo ratings yet

- Lesson Plan in English Using SRF: I. ObjectiveDocument10 pagesLesson Plan in English Using SRF: I. ObjectiveShee AntonioNo ratings yet

- TAC QuickReferenceGuideDocument4 pagesTAC QuickReferenceGuideAlaa Al-saggafNo ratings yet