Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

36 viewsFinal Gear Calculator

Final Gear Calculator

Uploaded by

John RossThe document provides specifications for a gear set including the number of teeth, diameters, angles, and other geometric properties. It also includes formulas from the Boston Gear Catalog used to calculate the output values from the input parameters. The output values calculated for both the gear and pinion are presented based on the given inputs.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- Problem Set 5 SolutionDocument7 pagesProblem Set 5 SolutionjewzyjewzyNo ratings yet

- Thermodynamics 2Document9 pagesThermodynamics 2Norman MpofuNo ratings yet

- Exercises Problem On Spur Gear Nomenclatures: Module 2: Activity No. 2Document4 pagesExercises Problem On Spur Gear Nomenclatures: Module 2: Activity No. 2Leyzer MalumayNo ratings yet

- Calculation of DavitDocument2 pagesCalculation of DavitpiziyuNo ratings yet

- FWEFJLNIY4QKLQXDocument13 pagesFWEFJLNIY4QKLQXSoldan MihaiNo ratings yet

- Properties of Fluids PDFDocument14 pagesProperties of Fluids PDFmaestro100% (3)

- Mastering Physics CH 02 HW College Physics I LCCCDocument33 pagesMastering Physics CH 02 HW College Physics I LCCCSamuel80% (15)

- Final Gear CalculatorDocument15 pagesFinal Gear CalculatorJennifer Nicky ShakerNo ratings yet

- Piñon y Engranaje RectosDocument39 pagesPiñon y Engranaje RectosJosue E. HernandezNo ratings yet

- Safari - May 16, 2022 at 9:00 PMDocument1 pageSafari - May 16, 2022 at 9:00 PMDagneNo ratings yet

- Gear Design Equations and Formula - Circular Pitches and Equivalent Diametral Pitches TableDocument3 pagesGear Design Equations and Formula - Circular Pitches and Equivalent Diametral Pitches Tablebman0051401No ratings yet

- Fdocuments - Ec Hoja de Calculo para Engranajes RectosDocument6 pagesFdocuments - Ec Hoja de Calculo para Engranajes Rectosag cnc & wedm machining shopNo ratings yet

- Bab 4 Pembahasan: 4.1. Data Hasil Pengamatan 4.1.1 Dimensi Roda GigiDocument7 pagesBab 4 Pembahasan: 4.1. Data Hasil Pengamatan 4.1.1 Dimensi Roda GigiKurniadi SabdaNo ratings yet

- Meshing Spur GearsDocument25 pagesMeshing Spur GearsCherrydhelNo ratings yet

- Spur GearDocument33 pagesSpur GearMau100% (1)

- Universidad Autónoma de Querétaro.: Facultad de Ingeniería. Ingeniería ElectromecánicaDocument12 pagesUniversidad Autónoma de Querétaro.: Facultad de Ingeniería. Ingeniería ElectromecánicaSalvador Vega MancillaNo ratings yet

- Lecture 2 Sample Problems WordDocument9 pagesLecture 2 Sample Problems Wordjake luis matthewNo ratings yet

- Abad AliDocument5 pagesAbad Alimhfaisal301No ratings yet

- Top Roof: Tank Tag No.: EG2-D-6306ADocument6 pagesTop Roof: Tank Tag No.: EG2-D-6306ASAMER OSMANNo ratings yet

- Tedata: Programm Benutzer Datum Kunde Proj. NRDocument3 pagesTedata: Programm Benutzer Datum Kunde Proj. NRJason CanoNo ratings yet

- Shi20396 ch13 OCTAVADocument27 pagesShi20396 ch13 OCTAVARSNo ratings yet

- Tedata: Programm Benutzer Datum Kunde Proj. NRDocument3 pagesTedata: Programm Benutzer Datum Kunde Proj. NRJason CanoNo ratings yet

- Dim. ReportDocument4 pagesDim. Reportrajit kumarNo ratings yet

- Gear Calculation Final ReportDocument2 pagesGear Calculation Final ReportNaman HumaneNo ratings yet

- Stakeout Super ElevasiDocument18 pagesStakeout Super ElevasiagusherlyNo ratings yet

- Structural Computation: Prepared byDocument7 pagesStructural Computation: Prepared byJing JingNo ratings yet

- SolutionDocument35 pagesSolutionMariel MirafloresNo ratings yet

- How To Draw Involute Bevel GearDocument2 pagesHow To Draw Involute Bevel GearMatija RepincNo ratings yet

- Perhitungan Tugas 1 Perancangan HEDocument3 pagesPerhitungan Tugas 1 Perancangan HELuthfanNo ratings yet

- MMB411 Tutorial - Gears01 Fundamentals PDFDocument29 pagesMMB411 Tutorial - Gears01 Fundamentals PDFNdivhuwo NdivhuwoNo ratings yet

- Tugas Pap Kel3Document9 pagesTugas Pap Kel316-125 Ruth Ria RistaNo ratings yet

- Project SampleDocument8 pagesProject SampleRamji RaoNo ratings yet

- Jawapan 3Document67 pagesJawapan 3SharashaNo ratings yet

- First Worm Finding Number of Teeth and Gear Diameter: DW+DG 2 1.5 in +4.7 in 2Document4 pagesFirst Worm Finding Number of Teeth and Gear Diameter: DW+DG 2 1.5 in +4.7 in 2mitha07No ratings yet

- Bevel CalcuDocument5 pagesBevel Calcupalani powerNo ratings yet

- Perancangan Alat CekDocument19 pagesPerancangan Alat CekLilyNo ratings yet

- IA-PB-15141-CP-1Document37 pagesIA-PB-15141-CP-1Aamir SuhailNo ratings yet

- 2-1 Elliptical DISH DEVLOPMENTDocument1 page2-1 Elliptical DISH DEVLOPMENTpkolNo ratings yet

- 78 - 9 - HookDocument14 pages78 - 9 - Hookrip111176No ratings yet

- Bearing Capacity Calculation: Description of StrataDocument8 pagesBearing Capacity Calculation: Description of StrataDadi YashwantNo ratings yet

- How To Draw Involute Bevel GearDocument2 pagesHow To Draw Involute Bevel GeardimtecNo ratings yet

- Isolated Footing P & MDocument8 pagesIsolated Footing P & Mمحمد حاج اسماعيلNo ratings yet

- Roda Gigi KerucutDocument4 pagesRoda Gigi KerucutOkky RachmadillaNo ratings yet

- Design of SlabDocument14 pagesDesign of Slabابراهيم المبيضينNo ratings yet

- Basic Data:: Calculation of Gust Effect FactorDocument1 pageBasic Data:: Calculation of Gust Effect FactorYaser ShabasyNo ratings yet

- Weir THK CALCDocument6 pagesWeir THK CALCSAMER OSMANNo ratings yet

- Not For Commercial Use: TedataDocument2 pagesNot For Commercial Use: Tedatawilly rojas zeballosNo ratings yet

- Interference Split (42 42) 20231105100344Document1 pageInterference Split (42 42) 20231105100344primeanshumalikashyapNo ratings yet

- Pipe Friction + Fitting (Type 2)Document3 pagesPipe Friction + Fitting (Type 2)AmroKashtNo ratings yet

- Base Plate, Pedestal and FootingDocument8 pagesBase Plate, Pedestal and FootingRai RiveraNo ratings yet

- SteelDocument78 pagesSteelzulsyamNo ratings yet

- Design Calculation of Gearbox: ST ND RD TH THDocument50 pagesDesign Calculation of Gearbox: ST ND RD TH THKaung KhantNo ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- Baja Denny (Tipe 1)Document13 pagesBaja Denny (Tipe 1)zulsyamNo ratings yet

- FootingDocument4 pagesFootingrudolfNo ratings yet

- Dimensions of Sprocket: Single-Strand Double-Strand Quadrup-StrandDocument1 pageDimensions of Sprocket: Single-Strand Double-Strand Quadrup-Strandวิทวัส นิเทียนNo ratings yet

- d d π N N: Data Collected from labDocument7 pagesd d π N N: Data Collected from labMuhammad Hammad AsgharNo ratings yet

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- Estrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignDocument12 pagesEstrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignHannahNo ratings yet

- FlangeDocument1 pageFlangeJoosung HanNo ratings yet

- Calculo de Areas VariosDocument106 pagesCalculo de Areas Variosjuan cordovaNo ratings yet

- Symbol Formula Pitch PDocument5 pagesSymbol Formula Pitch PdhaNo ratings yet

- Building Structural Analysis and Concrete Design SpreadsheetDocument124 pagesBuilding Structural Analysis and Concrete Design SpreadsheetMarc Abel Pudol EsplegueraNo ratings yet

- Stability Calculation: Specified Condition: Loadcase: Full Load DepartureDocument39 pagesStability Calculation: Specified Condition: Loadcase: Full Load DepartureFida MashfihaNo ratings yet

- Syllabus: Master of Engineering Programmes (M.Tech-Civil Engg)Document212 pagesSyllabus: Master of Engineering Programmes (M.Tech-Civil Engg)Sareesh ChandrawanshiNo ratings yet

- Chap 12 - AtomsDocument7 pagesChap 12 - AtomsSaksham KhandelwalNo ratings yet

- MT ZC243 Thermodynamics L1 2 ARH 1611376533732Document60 pagesMT ZC243 Thermodynamics L1 2 ARH 1611376533732ArivuKodi PrabhuNo ratings yet

- Coordinate Systems: ContinueDocument18 pagesCoordinate Systems: ContinueVaijantiNo ratings yet

- Tutorials On Electric FieldDocument2 pagesTutorials On Electric FieldNkeng100% (1)

- Morton E. Gurtin (Auth.), Professor Dr. C. Truesdell (Eds.) - Linear Theories of Elasticity and Thermoelasticity - Linear and Nonlinear TheDocument755 pagesMorton E. Gurtin (Auth.), Professor Dr. C. Truesdell (Eds.) - Linear Theories of Elasticity and Thermoelasticity - Linear and Nonlinear TheLiliana SanchezNo ratings yet

- Seismic Sources GeophysicsDocument25 pagesSeismic Sources GeophysicsbadrhashmiNo ratings yet

- Is Mixing A Thermodynamic Process PDFDocument10 pagesIs Mixing A Thermodynamic Process PDFCarlos JoseNo ratings yet

- Admmodule Gp12kin Ic 22Document25 pagesAdmmodule Gp12kin Ic 22Diana Silva HernandezNo ratings yet

- Finite Element AnalysisDocument14 pagesFinite Element AnalysisVinaasha BalakrishnanNo ratings yet

- On Perturbation Theory, Dyson Series, and Feynman Diagrams: Interaction PictureDocument24 pagesOn Perturbation Theory, Dyson Series, and Feynman Diagrams: Interaction PicturecdcrossroaderNo ratings yet

- FFM800 Surge Pressure PDFDocument7 pagesFFM800 Surge Pressure PDFThiruThirunavukkarasuNo ratings yet

- Chapter 1 Sceince 1Document22 pagesChapter 1 Sceince 1Subham Bhadigar100% (2)

- CH 30 Quantum PhysicsDocument1 pageCH 30 Quantum PhysicsHassan Ali BhuttaNo ratings yet

- 4 - Wellbore Performance, Pages 45-58Document14 pages4 - Wellbore Performance, Pages 45-58ehsanNo ratings yet

- Design of ReservoirDocument40 pagesDesign of Reservoirasingh400No ratings yet

- Project FoundationDocument39 pagesProject FoundationAlyfer del RosarioNo ratings yet

- Vertical Combination of SFRSDocument2 pagesVertical Combination of SFRSalejandroNo ratings yet

- DWN 93 HDB Calculation MethodDocument2 pagesDWN 93 HDB Calculation MethodSami Abdelgadir MohammedNo ratings yet

- Topic 1.1 (PPT) Units - Measurements Grade 10 PhysicsDocument93 pagesTopic 1.1 (PPT) Units - Measurements Grade 10 PhysicsLaw PeterNo ratings yet

- h31 Higher Order Derivatives Velocity and AccelerationDocument2 pagesh31 Higher Order Derivatives Velocity and AccelerationChristine StraubNo ratings yet

- Week 6 - Head LossDocument26 pagesWeek 6 - Head Losschantal mohammedNo ratings yet

- Physics Assignment ElectromagneticDocument6 pagesPhysics Assignment ElectromagneticafiqhzzhrNo ratings yet

- Get LostDocument15 pagesGet LostAnuj TapariaNo ratings yet

Final Gear Calculator

Final Gear Calculator

Uploaded by

John Ross0 ratings0% found this document useful (0 votes)

36 views12 pagesThe document provides specifications for a gear set including the number of teeth, diameters, angles, and other geometric properties. It also includes formulas from the Boston Gear Catalog used to calculate the output values from the input parameters. The output values calculated for both the gear and pinion are presented based on the given inputs.

Original Description:

Original Title

Final_Gear_Calculator.xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides specifications for a gear set including the number of teeth, diameters, angles, and other geometric properties. It also includes formulas from the Boston Gear Catalog used to calculate the output values from the input parameters. The output values calculated for both the gear and pinion are presented based on the given inputs.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

36 views12 pagesFinal Gear Calculator

Final Gear Calculator

Uploaded by

John RossThe document provides specifications for a gear set including the number of teeth, diameters, angles, and other geometric properties. It also includes formulas from the Boston Gear Catalog used to calculate the output values from the input parameters. The output values calculated for both the gear and pinion are presented based on the given inputs.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 12

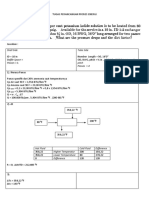

Inputs Gear Symbol Value Pinion Symbol Value

Outside Diameter in inches DoG= 3.2 DoP= 2.2

Number of Teeth NG= 30 NP= 20

Pitch Diameter in inches DG= 3 DP= 2

Fixed Constants Gear Symbol Value Pinion Symbol Value

Pressure Angle in degrees φ= 20 φ= 20

Outputs Gear Symbol Value

Diametral Pitch P= 10.0000

Base Diameter in inches DbG= 2.8191

Root Diameter in inches DRG= 2.7560

Whole Depth in inches htG= 0.2220

Addendum in inches aG= 0.1000

Dedendum in inches bG= 0.0220

Auxiliary Angle in degrees φAG= 31.3213

Interval of Contact in inches uG= 0.2298

Roll Angle at Theoretical Limit Radius in Degrees ϵlG= 11.3616

Theoretical Limit Radius in inches rlG= 1.4377

Form Diameter in inches dfG= 2.8753

Circular Tooth Thickness in inches t= 0.1571

Fillet Radius in inches rfG= 0.0300

All formulas are from the Boston Gear Ca

Values in formulas that have bars around the

pinion value if you are calculating for the gear a

Pinion Symbol Value Formula

P= 10.0000 N/D

DbP= 1.8794 Dcosφ

DRP= 1.7560 Do-2ht

htP= 0.2220 2.2/P + .002

aP= 0.1000 1/P

bP= 0.0220 ht - 2a

φAP= 28.2414 cos-1((|Db|/2)/((|D|/2)+|a|))

uP= 0.2441 ((|D|/2)+a)*sin(φA)-(|D|/2)*sin(φ)

ϵlP= 5.9508 tan-1(((D/2)sin(φ) - u)/(Db/2))

rlP= 0.9448 (Db/2)/cos(ϵl)

dfP= 1.8846 2(rl - .025*(.025/P))

t= 0.1571 Pi/2*P

rfP= 0.0300 .3/P

m the Boston Gear Catalog

have bars around them use the

ulating for the gear and vice versa

Parameter Gear Symbol Value Pinion Symbol Value

Number of Teeth NG= 78 NP= 31

Diametral Pitch Pd= 12 Pd= 12

Shaft Angle (in degrees) Σ= 90 Σ= 90

Is There a Full Set of Inputs? Yes Yes

Fixed Constants Gear Symbol Value Pinion Symbol Value

Pressure Angle (in Degrees) φ= 20 φ= 20

The gears produced by this spread sheet have no crowning

and always have a pressure angle of 20 degrees

Outputs Gear Symbol Value Pinion Symbol Value

Ratio mG= 2.516 mG= 2.516

Pitch Diameter DG= 6.500 DP= 2.583

Pitch Angle (in degrees) Γ= 68.325 ϒ= 21.675

Outer Cone Distance Ao= 3.497 Ao= 3.497

Face Width F= 0.833 F= 0.833

Equivalent 90° Ratio m90= Err:509 m90= 2.516

Working Depth hk= 0.167 hk= 0.167

Addendum (at heel of tooth) aoG= 0.051 aoP= 0.116

Whole Depth ht= 0.184 ht= 0.184

Dedendum (at heel of tooth) boG= 0.133 boP= 0.069

Dedendum Angle (In Degrees) δG= 2.182 δP= 1.126

Face Angle (in Degrees) Γo= 69.451 ϒo= 23.857

Outside Diameter DoG= 6.538 DoP= 2.798

Pitch Cone Apex to Crown XoG= 1.244 XoP= 3.207

Circular Pitch p= 0.262 p= 0.262

Root Angle (in Degrees) ΓR= 66.143 ϒR= 20.549

Back-Angle Distance No Symbol 3.497 No Symbol 3.497

All Formulas Come From table 5-22 of the Gea

Handbook

Formulas

mG=NG/NP

DG=NG/Pd and DP=NP/Pd

Γ=Σ-ϒ and If Σ=90: ϒ=tan-1(NG/NP) If Σ<90: ϒ=tan-1(sin(Σ)/(mG+cos(Σ)) If Σ>90: ϒ=tan-1(sin(180-Σ)/(mG-cos(180-Σ)))

If Σ=90: Ao=1/2(DP2+DG2)1/2, If Σ≠90: Ao=DG/(2*sin(Γ))

F=Ao/3 or F=10/Pd (use the smaller value)

If Σ=90: m90=mG, If Σ≠90: m90=(mG(cos(ϒ)/cos(Γ)))1/2

hk=2.0/Pd

aoG=(.54/Pd)+(.460/Pd*m902) and aoP=hk-aoG

ht=2.188/Pd+.002

boG=ht-aoG and boP=ht-aoP

δG=tan-1(boG/Ao) and δP=tan-1(boP/Ao)

Γo=Γ+δG and ϒo=ϒ+δP

DoG=DG+2aoG*cos(Γ) and DoP=DP+2aoP*cos(ϒ)

If Σ=90: XoG=DP/2-aoG*sin(Γ) and XoP=DG/2-aoP*sin(ϒ), If Σ≠90: XoG=Ao*cos(Γ)-aoG*sin(Γ) and XoP=Ao*cos(ϒ)-aoP*sin(ϒ)

p=π/Pd

ΓR=Γ-δG and ϒR=ϒ-δP

Back-Angle Distance = Ao

table 5-22 of the Gear Manufacturer's

Handbook

Parameter Gear Symbol Value Pinion Symbol Value

Number of Teeth NG= 78 NP= 31

Diametral Pitch Pd= 12 Pd= 12

Shaft Angle (in degrees) Σ= 90 Σ= 90

Is There a Full Set of Inputs? Yes Yes

Fixed Constants Gear Symbol Value Pinion Symbol Value

Pressure Angle (in Degrees) φ= 20 φ= 20

The gears produced by this spread sheet have no crowning

and always have a pressure angle of 20 degrees

Outputs Gear Symbol Value Pinion Symbol Value

Ratio mG= 2.516 mG= 2.516

Pitch Diameter DG= 6.500 DP= 2.583

Pitch Angle (in degrees) Γ= 68.325 ϒ= 21.675

Outer Cone Distance Ao= 3.497 Ao= 3.497

Face Width F= 0.833 F= 0.833

Equivalent 90° Ratio m90= Err:509 m90= 2.516

Working Depth hk= 0.142 hk= 0.142

Addendum (at heel of tooth) aoG= 0.043 aoP= 0.098

Whole Depth ht= 0.157 ht= 0.157

Dedendum (at heel of tooth) boG= 0.114 boP= 0.059

Dedendum Angle (In Degrees) δG= 1.865 δP= 0.969

Face Angle (in Degrees) Γo= 69.294 ϒo= 23.539

Outside Diameter DoG= 6.532 DoP= 2.766

Pitch Cone Apex to Crown XoG= 1.251 XoP= 3.214

Circular Pitch p= 0.262 p= 0.262

Root Angle (in Degrees) ΓR= 66.461 ϒR= 20.706

Back-Angle Distance No Symbol 3.497 No Symbol 3.497

All Formulas Come From table 5-22 of the Gea

Handbook

Formulas

mG=NG/NP

DG=NG/Pd and DP=NP/Pd

Γ=Σ-ϒ and If Σ=90: ϒ=tan-1(NG/NP) If Σ<90: ϒ=tan-1(sin(Σ)/(mG+cos(Σ)) If Σ>90: ϒ=tan-1(sin(180-Σ)/(mG-cos(180-Σ)))

If Σ=90: Ao=1/2(DP2+DG2)1/2, If Σ≠90: Ao=DG/(2*sin(Γ))

F=Ao/3 or F=10/Pd (use the smaller value)

If Σ=90: m90=mG, If Σ≠90: m90=(mG(cos(ϒ)/cos(Γ)))1/2

hk=1.70/Pd

aoG=(.46/Pd)+(.390/Pd*mG2) and aoP=hk-aoG

ht=1.888/Pd

boG=ht-aoG and boP=ht-aoP

δG=tan-1(boG/Ao) and δP=tan-1(boP/Ao)

Γo=Γ+δG and ϒo=ϒ+δP

DoG=DG+2aoG*cos(Γ) and DoP=DP+2aoP*cos(ϒ)

If Σ=90: XoG=DP/2-aoG*sin(Γ) and XoP=DG/2-aoP*sin(ϒ), If Σ≠90: XoG=Ao*cos(Γ)-aoG*sin(Γ) and XoP=Ao*cos(ϒ)-aoP*sin(ϒ)

p=π/Pd

ΓR=Γ-δG and ϒR=ϒ-δP

Back-Angle Distance = Ao

table 5-22 of the Gear Manufacturer's

Handbook

Horse Power Required for Desired Application Shaft Sizes (in inches)

1 1/2

RPM Required for Desired Application 5/8

20 3/4

Min. Shaft Diameter for Desired Application (in inches)

1.732

Suitable?

Not Suitable

Not Suitable

Not Suitable

You might also like

- Problem Set 5 SolutionDocument7 pagesProblem Set 5 SolutionjewzyjewzyNo ratings yet

- Thermodynamics 2Document9 pagesThermodynamics 2Norman MpofuNo ratings yet

- Exercises Problem On Spur Gear Nomenclatures: Module 2: Activity No. 2Document4 pagesExercises Problem On Spur Gear Nomenclatures: Module 2: Activity No. 2Leyzer MalumayNo ratings yet

- Calculation of DavitDocument2 pagesCalculation of DavitpiziyuNo ratings yet

- FWEFJLNIY4QKLQXDocument13 pagesFWEFJLNIY4QKLQXSoldan MihaiNo ratings yet

- Properties of Fluids PDFDocument14 pagesProperties of Fluids PDFmaestro100% (3)

- Mastering Physics CH 02 HW College Physics I LCCCDocument33 pagesMastering Physics CH 02 HW College Physics I LCCCSamuel80% (15)

- Final Gear CalculatorDocument15 pagesFinal Gear CalculatorJennifer Nicky ShakerNo ratings yet

- Piñon y Engranaje RectosDocument39 pagesPiñon y Engranaje RectosJosue E. HernandezNo ratings yet

- Safari - May 16, 2022 at 9:00 PMDocument1 pageSafari - May 16, 2022 at 9:00 PMDagneNo ratings yet

- Gear Design Equations and Formula - Circular Pitches and Equivalent Diametral Pitches TableDocument3 pagesGear Design Equations and Formula - Circular Pitches and Equivalent Diametral Pitches Tablebman0051401No ratings yet

- Fdocuments - Ec Hoja de Calculo para Engranajes RectosDocument6 pagesFdocuments - Ec Hoja de Calculo para Engranajes Rectosag cnc & wedm machining shopNo ratings yet

- Bab 4 Pembahasan: 4.1. Data Hasil Pengamatan 4.1.1 Dimensi Roda GigiDocument7 pagesBab 4 Pembahasan: 4.1. Data Hasil Pengamatan 4.1.1 Dimensi Roda GigiKurniadi SabdaNo ratings yet

- Meshing Spur GearsDocument25 pagesMeshing Spur GearsCherrydhelNo ratings yet

- Spur GearDocument33 pagesSpur GearMau100% (1)

- Universidad Autónoma de Querétaro.: Facultad de Ingeniería. Ingeniería ElectromecánicaDocument12 pagesUniversidad Autónoma de Querétaro.: Facultad de Ingeniería. Ingeniería ElectromecánicaSalvador Vega MancillaNo ratings yet

- Lecture 2 Sample Problems WordDocument9 pagesLecture 2 Sample Problems Wordjake luis matthewNo ratings yet

- Abad AliDocument5 pagesAbad Alimhfaisal301No ratings yet

- Top Roof: Tank Tag No.: EG2-D-6306ADocument6 pagesTop Roof: Tank Tag No.: EG2-D-6306ASAMER OSMANNo ratings yet

- Tedata: Programm Benutzer Datum Kunde Proj. NRDocument3 pagesTedata: Programm Benutzer Datum Kunde Proj. NRJason CanoNo ratings yet

- Shi20396 ch13 OCTAVADocument27 pagesShi20396 ch13 OCTAVARSNo ratings yet

- Tedata: Programm Benutzer Datum Kunde Proj. NRDocument3 pagesTedata: Programm Benutzer Datum Kunde Proj. NRJason CanoNo ratings yet

- Dim. ReportDocument4 pagesDim. Reportrajit kumarNo ratings yet

- Gear Calculation Final ReportDocument2 pagesGear Calculation Final ReportNaman HumaneNo ratings yet

- Stakeout Super ElevasiDocument18 pagesStakeout Super ElevasiagusherlyNo ratings yet

- Structural Computation: Prepared byDocument7 pagesStructural Computation: Prepared byJing JingNo ratings yet

- SolutionDocument35 pagesSolutionMariel MirafloresNo ratings yet

- How To Draw Involute Bevel GearDocument2 pagesHow To Draw Involute Bevel GearMatija RepincNo ratings yet

- Perhitungan Tugas 1 Perancangan HEDocument3 pagesPerhitungan Tugas 1 Perancangan HELuthfanNo ratings yet

- MMB411 Tutorial - Gears01 Fundamentals PDFDocument29 pagesMMB411 Tutorial - Gears01 Fundamentals PDFNdivhuwo NdivhuwoNo ratings yet

- Tugas Pap Kel3Document9 pagesTugas Pap Kel316-125 Ruth Ria RistaNo ratings yet

- Project SampleDocument8 pagesProject SampleRamji RaoNo ratings yet

- Jawapan 3Document67 pagesJawapan 3SharashaNo ratings yet

- First Worm Finding Number of Teeth and Gear Diameter: DW+DG 2 1.5 in +4.7 in 2Document4 pagesFirst Worm Finding Number of Teeth and Gear Diameter: DW+DG 2 1.5 in +4.7 in 2mitha07No ratings yet

- Bevel CalcuDocument5 pagesBevel Calcupalani powerNo ratings yet

- Perancangan Alat CekDocument19 pagesPerancangan Alat CekLilyNo ratings yet

- IA-PB-15141-CP-1Document37 pagesIA-PB-15141-CP-1Aamir SuhailNo ratings yet

- 2-1 Elliptical DISH DEVLOPMENTDocument1 page2-1 Elliptical DISH DEVLOPMENTpkolNo ratings yet

- 78 - 9 - HookDocument14 pages78 - 9 - Hookrip111176No ratings yet

- Bearing Capacity Calculation: Description of StrataDocument8 pagesBearing Capacity Calculation: Description of StrataDadi YashwantNo ratings yet

- How To Draw Involute Bevel GearDocument2 pagesHow To Draw Involute Bevel GeardimtecNo ratings yet

- Isolated Footing P & MDocument8 pagesIsolated Footing P & Mمحمد حاج اسماعيلNo ratings yet

- Roda Gigi KerucutDocument4 pagesRoda Gigi KerucutOkky RachmadillaNo ratings yet

- Design of SlabDocument14 pagesDesign of Slabابراهيم المبيضينNo ratings yet

- Basic Data:: Calculation of Gust Effect FactorDocument1 pageBasic Data:: Calculation of Gust Effect FactorYaser ShabasyNo ratings yet

- Weir THK CALCDocument6 pagesWeir THK CALCSAMER OSMANNo ratings yet

- Not For Commercial Use: TedataDocument2 pagesNot For Commercial Use: Tedatawilly rojas zeballosNo ratings yet

- Interference Split (42 42) 20231105100344Document1 pageInterference Split (42 42) 20231105100344primeanshumalikashyapNo ratings yet

- Pipe Friction + Fitting (Type 2)Document3 pagesPipe Friction + Fitting (Type 2)AmroKashtNo ratings yet

- Base Plate, Pedestal and FootingDocument8 pagesBase Plate, Pedestal and FootingRai RiveraNo ratings yet

- SteelDocument78 pagesSteelzulsyamNo ratings yet

- Design Calculation of Gearbox: ST ND RD TH THDocument50 pagesDesign Calculation of Gearbox: ST ND RD TH THKaung KhantNo ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- Baja Denny (Tipe 1)Document13 pagesBaja Denny (Tipe 1)zulsyamNo ratings yet

- FootingDocument4 pagesFootingrudolfNo ratings yet

- Dimensions of Sprocket: Single-Strand Double-Strand Quadrup-StrandDocument1 pageDimensions of Sprocket: Single-Strand Double-Strand Quadrup-Strandวิทวัส นิเทียนNo ratings yet

- d d π N N: Data Collected from labDocument7 pagesd d π N N: Data Collected from labMuhammad Hammad AsgharNo ratings yet

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- Estrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignDocument12 pagesEstrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignHannahNo ratings yet

- FlangeDocument1 pageFlangeJoosung HanNo ratings yet

- Calculo de Areas VariosDocument106 pagesCalculo de Areas Variosjuan cordovaNo ratings yet

- Symbol Formula Pitch PDocument5 pagesSymbol Formula Pitch PdhaNo ratings yet

- Building Structural Analysis and Concrete Design SpreadsheetDocument124 pagesBuilding Structural Analysis and Concrete Design SpreadsheetMarc Abel Pudol EsplegueraNo ratings yet

- Stability Calculation: Specified Condition: Loadcase: Full Load DepartureDocument39 pagesStability Calculation: Specified Condition: Loadcase: Full Load DepartureFida MashfihaNo ratings yet

- Syllabus: Master of Engineering Programmes (M.Tech-Civil Engg)Document212 pagesSyllabus: Master of Engineering Programmes (M.Tech-Civil Engg)Sareesh ChandrawanshiNo ratings yet

- Chap 12 - AtomsDocument7 pagesChap 12 - AtomsSaksham KhandelwalNo ratings yet

- MT ZC243 Thermodynamics L1 2 ARH 1611376533732Document60 pagesMT ZC243 Thermodynamics L1 2 ARH 1611376533732ArivuKodi PrabhuNo ratings yet

- Coordinate Systems: ContinueDocument18 pagesCoordinate Systems: ContinueVaijantiNo ratings yet

- Tutorials On Electric FieldDocument2 pagesTutorials On Electric FieldNkeng100% (1)

- Morton E. Gurtin (Auth.), Professor Dr. C. Truesdell (Eds.) - Linear Theories of Elasticity and Thermoelasticity - Linear and Nonlinear TheDocument755 pagesMorton E. Gurtin (Auth.), Professor Dr. C. Truesdell (Eds.) - Linear Theories of Elasticity and Thermoelasticity - Linear and Nonlinear TheLiliana SanchezNo ratings yet

- Seismic Sources GeophysicsDocument25 pagesSeismic Sources GeophysicsbadrhashmiNo ratings yet

- Is Mixing A Thermodynamic Process PDFDocument10 pagesIs Mixing A Thermodynamic Process PDFCarlos JoseNo ratings yet

- Admmodule Gp12kin Ic 22Document25 pagesAdmmodule Gp12kin Ic 22Diana Silva HernandezNo ratings yet

- Finite Element AnalysisDocument14 pagesFinite Element AnalysisVinaasha BalakrishnanNo ratings yet

- On Perturbation Theory, Dyson Series, and Feynman Diagrams: Interaction PictureDocument24 pagesOn Perturbation Theory, Dyson Series, and Feynman Diagrams: Interaction PicturecdcrossroaderNo ratings yet

- FFM800 Surge Pressure PDFDocument7 pagesFFM800 Surge Pressure PDFThiruThirunavukkarasuNo ratings yet

- Chapter 1 Sceince 1Document22 pagesChapter 1 Sceince 1Subham Bhadigar100% (2)

- CH 30 Quantum PhysicsDocument1 pageCH 30 Quantum PhysicsHassan Ali BhuttaNo ratings yet

- 4 - Wellbore Performance, Pages 45-58Document14 pages4 - Wellbore Performance, Pages 45-58ehsanNo ratings yet

- Design of ReservoirDocument40 pagesDesign of Reservoirasingh400No ratings yet

- Project FoundationDocument39 pagesProject FoundationAlyfer del RosarioNo ratings yet

- Vertical Combination of SFRSDocument2 pagesVertical Combination of SFRSalejandroNo ratings yet

- DWN 93 HDB Calculation MethodDocument2 pagesDWN 93 HDB Calculation MethodSami Abdelgadir MohammedNo ratings yet

- Topic 1.1 (PPT) Units - Measurements Grade 10 PhysicsDocument93 pagesTopic 1.1 (PPT) Units - Measurements Grade 10 PhysicsLaw PeterNo ratings yet

- h31 Higher Order Derivatives Velocity and AccelerationDocument2 pagesh31 Higher Order Derivatives Velocity and AccelerationChristine StraubNo ratings yet

- Week 6 - Head LossDocument26 pagesWeek 6 - Head Losschantal mohammedNo ratings yet

- Physics Assignment ElectromagneticDocument6 pagesPhysics Assignment ElectromagneticafiqhzzhrNo ratings yet

- Get LostDocument15 pagesGet LostAnuj TapariaNo ratings yet