Professional Documents

Culture Documents

Plastic Waste, Replacement of Fossil Energy?

Plastic Waste, Replacement of Fossil Energy?

Uploaded by

Olli234Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plastic Waste, Replacement of Fossil Energy?

Plastic Waste, Replacement of Fossil Energy?

Uploaded by

Olli234Copyright:

Available Formats

WASTE PLASTIC AS SOLUTION FOR REPLACING FOSSIL FUEL

ENERGY

Humaira Anjani (11160980000005)

Major of mining engineering, faculty of scienc of technology, UIN Syarif Hidayatullah Jakarta

E-mail : Ladyminer98@gmail.com

Abstract- The objective of this paper is to analyze the pyrolysis method which is the method of

converting waste plastic which is available in our day life into fuel oil which can be used for the

different purpose. The methodology used for writing this paper is a literature study. Plastic is those

substances which can take many years to decompose if dispose of simply to the environment. Different

Temperature are have a role for thermally crack the plastics. Usage of waste plastic as a substitute

give many benefits such as does not need to buy any new vehicle or equipment to use this substance.

Also, this method fulfilled Indonesia’s concept of energy independence 4A+1S concept. However

further processing and experiments are needed to get cleaner exhaust.

Keywords : Plastic waste, fuel, pyrolysis

INTRODUCTION un-conventional also support the SDG’S

Since half of the world’s oil used in act. This is the method that extracting oil

many vehicle (cars, trucks, trains, planes, fuel from a plastic waste called plastic

etc) sector for fueling the energy, there pyrolysis. For many years plastic has

is enormous interest in reforming that become a serious problem in our

sector of the economy. There is now a environment, they remain in the

race to see who will dominate the environment for a long period of time

automotive future, as nations make the which affects environmental quality.

historic transition from fossil fuels to the

non-conventional energy resources.

Without a doubt the most popular

automotive fuel currently gasoline.

There should be an effort to find ways to

replace fossil fuels with more

environmentally friendly alternatives,

particularly renewable energy resources,

as potential solutions to the current

environmental problems associated with

the harmful pollutant emission from Fig1 : plastic waste

Due to population increase, the demand

fossil fuels, or perhaps the solution even

for plastic products has steadily

closer than we thought and this

increased, previous waste management

methods such as landfill disposal, molecule called polymer. When this

incineration, and recycling have failed to long chain of monomers breaks at

provide opportunities for the complete certain points or when lower molecular

reuse of plastic waste. The polymer weight fractions are formed this is

energy system uses a process called termed as degradation of the polymer.

catalytic pyrolysis to efficiently convert Plastics are branched or linear polymers

plastics to crude oil. The system consisting of various types, two of

provides an integrated plastic waste which are LDPE and Polypropylene.

processing system which offers an (PP) Polypropylene is one type of plastic

alternative while also being viable, that is thermoplastic in nature, which

economical and environmentally can return to its original form through

responsible waste management solution. heating, easily processed and formed

into a film, fiber, or packaging. As for

Plastics examples from

Plastics are long chain polymers from Polypropylene is sacks, ropes, drink

atoms that bind to one another. This bottles, fibers, tubs, insulators, plastic

chain forms many repetitive molecular chairs, and rugs. This type is the best

units, or "monomers". choice for plastic materials, especially

Requirements for synthetic or for those related to food and beverage

semi-synthetic polymerization products, storage. Characteristics of transparent

but there are several natural polymers and cloudy bottles, not clear but

including plastics. Plastics are formed translucent, stronger and lighter with

from organic condensation or polymers low vapor permeability, stable with high

which can also consist of other temperatures, and shiny. Hard but

substances to improve performance or flexible and softened at 140 ° C.

economics (Wikipedia, 2009; Azizah, LDPE is one type of plastic that is often

2009). All plastics are polymers found in the surrounding environment,

manufactured from the petroleum lighter namely in the form of a plastic bag so

ends like propylene, mostly containing that it is very potential to be utilized in

carbon and hydrogen and few other the pyrolysis process to minimize the

elements like chlorine, nitrogen, etc. existence of millions of plastic bags

Polymers are made up of small every day. The mechanical properties of

molecules called monomers which the type of LDPE plastic are strong,

combine and form a single large

rather translucent, flexible and slightly principal application

fatty surface. Law of thermodynamics.

Partial Combustion and Thermodynamic

pyrolysis Aspects

Pyrolysis is a process of controlled The pyrolysis process requires high

heating of a material in the absence of temperatures, namely in the temperature

oxygen. range of 400-500 ° C. This temperature

In the process of plastic pyrolysis can be achieved by utilizing the sensible

macromolecular structure of polymer are heat from partial combustion of PP and

broken into smaller molecules and LDPE plastics. Partial combustion used

sometimes monomer units. Further is indirect combustion which utilizes

degradation is of these subsequent heat from an ignition source.

molecules depends on a number of the The amount of heat obtained is analyzed

different condition including(and not using the concept of heat balance or

limited to) temperature, residence time, energy equilibrium based on the

presence of a catalyst and other process application of thermodynamic law I.

conditions. The pyrolysis reaction can Changes in potential energy and kinetic

be done with or without a catalyst. energy can be ignored so that the energy

Products from pyrolysis consist of gas, balance of the combustion reaction can

liquid, and solid residual fractions be expressed by the following

(Buekens and Huang, 1998). At a

temperature of 300-500 ° C based on equation:

research by Andarini and Purwo (2013) The pyrolysis process requires a high

that the plastic will melt and then turn temperature so that the optimum heat is

into gas. During the process, long chains needed by assuming the system is

of hydrocarbons will be cut into short adiabatic then:

chains. Furthermore, the cooling process Hout = Hin

is carried out on the gas so that it will Value h for each mass unit are:

experience condensation and form a

liquid. This liquid will later become fuel,

The value of h is a function of

both in the form of gasoline and diesel

temperature or h = f (T) so that using the

fuel.

analysis of the calculation of the energy

equilibrium equation can be obtained the

amount of temperature in the final result

of the partial combustion process According to Saiful Muslimin’s

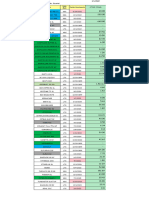

(Priambodo, 2008). The amount of experiment (2014) ,

partial combustion final temperature that Machine result

can meet the continuity of the pyrolysis Capacity

reaction is at intervals of 400 ° C-500 °

C so that the regulation of the number of

LDPE and Polyprophylene molecules Solar Petrol, Minyak

can be optimized by adjusting the size of premium tanah

the pyrolysis reactor integrated in the rate

motor vehicle engine. 10 Kg 6 liters 2.5 liters 1.5 liters

30 kg 18 liters 7.5 liters 4.5 liters

Source of Heat : 3Kg LPG

Time needed : 3-4 hours for 2

production cycles

Profits : IDR 226.000 for 1 production

cycle

Quality : laboratorium checked for

bensin (premium rate) contains 0,02Mg/l

Lead, for solar or diesel : 0mg/l

Fig 2: pyrolysis flow chart , sumber : American Odor : plastic smell

chemistry council(2016)

Test on vehicle : Cars and motorcycle

Advantages and disadvantages

test (solar usage) : has no problem

Advantages :

1.Affordable price

2.Substance availability

Disadvantages :

1. Further processing is needed to get a

more high-quality product (cleaner

emission/exhaust)

2. Further processing makes the price

higher

Hanifah and Rendita’s Experiment Profits (income-outcome) = IDR6000 -

(2016) IDR4000 = IDR2000.

Plastic Sampl solar Petrol( Minya

Type e in premi k A rate of return (ROR) analysis was

KG um tanah carried out which showed that the

rate)

process can be profitable for a large

PET 1 0.3l 0.5l 0.2l

scale plant with an annual feed rate of

LPDE 1 500 (non

120,000 tonnes. Additionally, it was

Liter effecti

found that the payback period for the

only vely

large scale plant was 1.42 years which

in efficie

total nt)

corresponds to a ROR of 35.97%. This

According from Hanifah and Rendita’s work included a sensitivity analysis

research : study on the annual profits, although this

Price for PET/Kg from “pengepul” or was done only for the product sale price

collectors are IDR 2000/Kg ignoring other important technical and

Price for LPDE/Kg from “pengepul” or economic parameters (e.g. capital

collectors are IDR500/Kg investment, raw material costs)

Selling price

Petrol/premium like : IDR6000/l Congeniality with Indonesia’s concept

Diesel/solar like : IDR5000/l of energy independence

Availability: plastics are easy to find

DISCUSSION Accessibility: everyone can use this

If viewed from the economic aspect, energy in every aspect (farming, etc.)

According to from both experiments Affordability: Price is affordable for all

plastic can be a solution for a substitute segments of society, doesn’t need any

for fossil energy. According to Hanifah new vehicle or types of equipment for

and Rendita research, if the usage

petrol/premium like the price is Acceptability: according to research, the

IDR6000/l, then it needed 2Kg of raw numbers of people who used this energy

materials since 1Kg of PET material resource are increasing

only produce 0.5l petrol/premium like Sustainability: as long as human still use

fuel. 2Kg of PET price is IDR4000. plastics, it becomes sustainable

Because all the aspect above is fulfilled,

it is suitable to be applied in Indonesia.

Simulation

This mine is an open pit mine This simulation shows that if in the

producing 5,000 tonnes ore and 5,000 future solar from waste plastic will be

tonnes waste per day. Rock mass produced, Cost will be saved

characteristics for both ore and waste are IDR21.844,800 /day

typical of those of granite or porphyritic

material. Operating conditions, wage

scales, and unit prices are typical for

western U.S. mining operations.

All costs listed are in 2012 US$.

requirements and costs are listed below:

Table 1 and 2 : mining equipment cost (costmine

2014-2015)

Diesel fuel needs in a day : 4,75Liter

If using an ordinary diesel fuel price

Cost :

Bio solar price = IDR9.800/L

4751 X IDR98000 = IDR45.559,800

Waste plastic solar like = IDR5000/L

4751 X IDR5000 = IDR23.755.000

Conclusion 16j.energy.2018.02.094.pdf(Accesed on

it could be concluded, we need to 7th may 2019)

collectively work for development for

alternative fuels because it will be Armalid, Hanifah Nisa and co. 2016.

important in the future for sustainable Dari sampah plastik menjadi BBM

development. Also, the cost of ramah lingkungan. Makalah.

conventional fuels like gasoline or diesel

is increasing at an alarming rate and the Pd. Rajak and co. 2012. Analysis of

cost of the manufactured from plastic or diesel fuel from plastic wastes by

other wastes is considerably low which cataclytic pyrolysis. India. Mechanical

would further help in controlling Engineering BIT SINDRI.

inflation.

that thermal pyrolysis of plastic waste Mohammed M.garib Alla and co. 2014.

leads to the production of fuel oil, Conversion of plastic waste to liquid

valuable resource recovery, and fuel. International journal of technical

reduction of the waste problem. Thermal research and applications PP.29-31 Vol2,

pyrolysis of waste plastic waste has also issue 3 (may-june 2014)

several advantages over other alternative

recycling methods. It has been shown Brydson, J.A and scienceDirect. Plastic

that the conversion at a lower Burheim,ODne Stokke. 2017.

temperature in the presence of catalyst Engineering energy storage. USA.

into liquid is a feasible process. Elvsneir inc

Consequently. However, further studies

are necessary to utilize pyrolytic oil as G. N Tiwari and R.K Mishra. 2012.

liquid fuel or feedback. Advanced Renewable Energy Sources.

New delhi. RSC Publishing

References

Fivga, Antzela.2018. Pyrolysis of plastic Michael Pauken,PHD. 2011.

waste for production of heavy fuel Thermodynamics for dummies.

substitute: a techno-economic assesment. Canada.Wiley

file:///C:/Users/anjani/Downloads/10.10

Publishing Inc. Pauken,PHD. 2011. Thermodynamics

for dummies. Canada.Wiley

Mining Cost website

http://costs.infomine.comMichael

You might also like

- Estimation of Protein by The Biuret MethodDocument2 pagesEstimation of Protein by The Biuret MethodUsman Ghani100% (1)

- PD Aspen 1Document6 pagesPD Aspen 1Trebob GardayaNo ratings yet

- Organic and InorganicDocument2 pagesOrganic and InorganicJudy Panguito Aralar50% (2)

- 2015 NYJC H2 Chem PrelimDocument55 pages2015 NYJC H2 Chem PrelimTan Jia YiNo ratings yet

- Pengertian PirolisisDocument7 pagesPengertian PirolisisalmamrgtaaNo ratings yet

- Turning Plastic Waste Into OilDocument10 pagesTurning Plastic Waste Into OilSanjana SharmaNo ratings yet

- Conversion of Polypropylene Plastic Waste Into Liquid Fuel With Catalytic Cracking Process Using Al2O3 As CatalystDocument7 pagesConversion of Polypropylene Plastic Waste Into Liquid Fuel With Catalytic Cracking Process Using Al2O3 As CatalystDika CodNo ratings yet

- Conversion of Polypropylene Plastic Waste Into Liquid Fuel With Catalytic Cracking Process Using Al2O3 As CatalystDocument7 pagesConversion of Polypropylene Plastic Waste Into Liquid Fuel With Catalytic Cracking Process Using Al2O3 As CatalystDika CodNo ratings yet

- Pyrolysis of Plastic Waste For Liquid Fuel Production As Prospective Energy ResourcesDocument8 pagesPyrolysis of Plastic Waste For Liquid Fuel Production As Prospective Energy ResourcesVallari DangiNo ratings yet

- Jurnal Ing 2Document6 pagesJurnal Ing 2Haryati Putri HasibuanNo ratings yet

- Extraction of Hydrocarbons Using Plastic WasteDocument7 pagesExtraction of Hydrocarbons Using Plastic WasteMohan KumarNo ratings yet

- Alternate Fuel From Synthetic Plastics Waste - ReviewDocument5 pagesAlternate Fuel From Synthetic Plastics Waste - ReviewSachin SahaniNo ratings yet

- Production of High Grade Liquid Fuel For CI Engine by Thermo-Catalytic Cracking of Waste PlasticDocument7 pagesProduction of High Grade Liquid Fuel For CI Engine by Thermo-Catalytic Cracking of Waste PlasticYulia Rodriguez LamarNo ratings yet

- Conversion of Ldpe Plastic Waste Into Liquid Fuel by Thermal Degradation PDFDocument4 pagesConversion of Ldpe Plastic Waste Into Liquid Fuel by Thermal Degradation PDFandreyan zuniardiNo ratings yet

- 2.catalytic Pyrolysis of Waste Plastic MixtureDocument2 pages2.catalytic Pyrolysis of Waste Plastic MixtureNaveen PatilNo ratings yet

- 3786-Article Text-40614-1-10-20220630Document6 pages3786-Article Text-40614-1-10-20220630indah rumah4No ratings yet

- Fuels From Plastic WastesDocument2 pagesFuels From Plastic WastesInternational Jpurnal Of Technical Research And ApplicationsNo ratings yet

- PyrolysisDocument24 pagesPyrolysisBoaz SunaNo ratings yet

- Pyrolysis of Waste Polystyrene and High-Density PolyethyleneDocument19 pagesPyrolysis of Waste Polystyrene and High-Density PolyethyleneAnge Rodrigue SehiNo ratings yet

- Waste Plastic Pyrolysis Oil As Alternative For SI and CI EnginesDocument8 pagesWaste Plastic Pyrolysis Oil As Alternative For SI and CI EnginesShahidulHoqueSohelNo ratings yet

- Seminar TopicDocument4 pagesSeminar TopicChandana BJNo ratings yet

- Bio-Oil Production Via Co-Pyrolysis of Almond Shell As Biomass and HighDocument7 pagesBio-Oil Production Via Co-Pyrolysis of Almond Shell As Biomass and HighhammadahmedNo ratings yet

- Ijct 25 (4) 336-344Document9 pagesIjct 25 (4) 336-344hari reddyNo ratings yet

- Processing PP, PET and PE Plastic Waste Into Oil Fuel and Its CharacteristicsDocument4 pagesProcessing PP, PET and PE Plastic Waste Into Oil Fuel and Its Characteristicssry rahmadaniNo ratings yet

- Utilization of Polymer Wastes As Transport Fuel Resources-A Recent DevelopmentDocument5 pagesUtilization of Polymer Wastes As Transport Fuel Resources-A Recent DevelopmentGlan DevadhasNo ratings yet

- 1 s2.0 S0927024819305379 MainDocument10 pages1 s2.0 S0927024819305379 MainKatherinaNo ratings yet

- TejuDocument17 pagesTejuTejas JawanjalNo ratings yet

- Alternate Fuel Preparation in Low Cost From Waste Plastic A ReviewDocument2 pagesAlternate Fuel Preparation in Low Cost From Waste Plastic A ReviewDana MateiNo ratings yet

- Gasoline Grade Fuel From Metalized PETDocument10 pagesGasoline Grade Fuel From Metalized PETjimbo09No ratings yet

- Conversion of Mixed Waste Plastic Into Fuel For Diesel Engines Through Pyrolysis Process A ReviewDocument24 pagesConversion of Mixed Waste Plastic Into Fuel For Diesel Engines Through Pyrolysis Process A ReviewMay PassarapornNo ratings yet

- Fuel From Plastic WasteDocument17 pagesFuel From Plastic WasteDinesh YadavNo ratings yet

- Full Length Article: SciencedirectDocument7 pagesFull Length Article: Sciencedirectlucerito mirandaNo ratings yet

- Design and Fabrication of Extraction of Fuel From Waste Plastics Using PyrolysisDocument5 pagesDesign and Fabrication of Extraction of Fuel From Waste Plastics Using PyrolysisVishal BhagwatNo ratings yet

- Preliminary Report Part 1Document21 pagesPreliminary Report Part 1ameyakemNo ratings yet

- Low Density Polyethylene (Ldpe) Pada Suhu 250 °C Dan 300 °C Soelarso Pani, Heribertus Sukarja, Yustinus Sigit PDocument7 pagesLow Density Polyethylene (Ldpe) Pada Suhu 250 °C Dan 300 °C Soelarso Pani, Heribertus Sukarja, Yustinus Sigit PAndi DulungNo ratings yet

- SRP Batch 8 Review For FinalDocument18 pagesSRP Batch 8 Review For Finalsrijavarma0811No ratings yet

- Thermal Pyrolysis of Polypropylene Plastic Waste IDocument7 pagesThermal Pyrolysis of Polypropylene Plastic Waste IDiego CamachoNo ratings yet

- Optimization of Catalytic Pyrolysis Process For Change of Plastic WasteDocument4 pagesOptimization of Catalytic Pyrolysis Process For Change of Plastic WasteDana MateiNo ratings yet

- Informacion Energitica y Exergetica de Los Productos Sometidos A Pirólisis TermicaDocument12 pagesInformacion Energitica y Exergetica de Los Productos Sometidos A Pirólisis TermicaLivio EscuderoNo ratings yet

- Distilasi PDFDocument8 pagesDistilasi PDFLusiana Eka KurniawatiNo ratings yet

- Pyrolysis of Waste Plastics Into Fuels Model: RV College of EngineeringDocument3 pagesPyrolysis of Waste Plastics Into Fuels Model: RV College of EngineeringBhoomika HollaNo ratings yet

- InTech-Recent Advances in The Chemical Recycling of Polymers PP Ps Ldpe Hdpe PVC PC Nylon PmmaDocument64 pagesInTech-Recent Advances in The Chemical Recycling of Polymers PP Ps Ldpe Hdpe PVC PC Nylon PmmaJorge HINCAPIE CARDENASNo ratings yet

- Draft1 Muhammad Lutfi Amin 4001415049Document9 pagesDraft1 Muhammad Lutfi Amin 4001415049kipilNo ratings yet

- Biodiesel Using Plastic Waste Material or Waste OilDocument5 pagesBiodiesel Using Plastic Waste Material or Waste OilLeo BoyNo ratings yet

- Aspen Hysys Plastic PyrolysisDocument6 pagesAspen Hysys Plastic PyrolysishanaNo ratings yet

- Recycle DieselDocument33 pagesRecycle DieselDauda BabaNo ratings yet

- Conversion of Waste Plastics Into Low-Emissive HydDocument8 pagesConversion of Waste Plastics Into Low-Emissive HydNebojsa RadulovicNo ratings yet

- Design and Fabrication of Pyrolysis UnitDocument3 pagesDesign and Fabrication of Pyrolysis UnitInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Production of Fuels From Nigeria's Untapped Waste Wealth' Using PyrolysisDocument14 pagesProduction of Fuels From Nigeria's Untapped Waste Wealth' Using PyrolysisADEOLANo ratings yet

- Research PaperDocument6 pagesResearch PaperDhawalSoniNo ratings yet

- Pyrolysis PlasticDocument16 pagesPyrolysis Plasticdiego NNo ratings yet

- Journal of Analytical and Applied PyrolysisDocument7 pagesJournal of Analytical and Applied PyrolysisJuan Carlos FigueroaNo ratings yet

- Chemical Recycling of Plastic Wastes Made From Polyethylene (LDPE and HDPE) and Polypropylene (PP)Document7 pagesChemical Recycling of Plastic Wastes Made From Polyethylene (LDPE and HDPE) and Polypropylene (PP)clairedelafuente38No ratings yet

- DiscussionDocument1 pageDiscussionRonnick De La TongaNo ratings yet

- Fuel From Waste PlasticDocument17 pagesFuel From Waste PlasticNagabhushanaNo ratings yet

- Conversion of Plastic Waste To: FuelDocument7 pagesConversion of Plastic Waste To: FuelJob TipsNo ratings yet

- Clean Energy From Plastic Production ofDocument8 pagesClean Energy From Plastic Production ofsumeet ranaNo ratings yet

- polymers-15-00859Document10 pagespolymers-15-00859Olatz PalmaNo ratings yet

- Feasibility Study of Conversion of Selected Plastic in To Synthetic Fuel (Synthetic Diesel) - A ReviewDocument5 pagesFeasibility Study of Conversion of Selected Plastic in To Synthetic Fuel (Synthetic Diesel) - A Reviewsamsurendran_mech4020No ratings yet

- Fuels From Plastic WastesDocument10 pagesFuels From Plastic WastesRock onNo ratings yet

- Green Carbon Dioxide: Advances in CO2 UtilizationFrom EverandGreen Carbon Dioxide: Advances in CO2 UtilizationGabriele CentiNo ratings yet

- Handbook of Composites from Renewable Materials, Design and ManufacturingFrom EverandHandbook of Composites from Renewable Materials, Design and ManufacturingNo ratings yet

- 11th Worksheet 2022-23 Unit 7,8,12,13Document8 pages11th Worksheet 2022-23 Unit 7,8,12,13ADITYA SONINo ratings yet

- 33-Liquid Detergent FabconDocument9 pages33-Liquid Detergent FabconSeyha L. AgriFoodNo ratings yet

- Stoichiometry: Stoichen ElementDocument55 pagesStoichiometry: Stoichen ElementKoonj LashariNo ratings yet

- Final 01 A Some Basic Concept of Chemistry PDFDocument22 pagesFinal 01 A Some Basic Concept of Chemistry PDFSwastik TripathiNo ratings yet

- Overview of Water-Based PaintDocument27 pagesOverview of Water-Based PaintHà Phương Nguyễn100% (4)

- Dyeing of Cotton Fabric With Reactive Dyes - Textile LearnerDocument9 pagesDyeing of Cotton Fabric With Reactive Dyes - Textile LearnerAnas ZidaneNo ratings yet

- Module 4 Aldehydes and KetonesDocument11 pagesModule 4 Aldehydes and Ketonesaliya margo gonzales100% (1)

- The Empirical Formula of Manganese ChlorideDocument2 pagesThe Empirical Formula of Manganese ChloridekrystalNo ratings yet

- Vikrant Ganvir - Material Today Proceeding Paper-Complete ManuscriptDocument12 pagesVikrant Ganvir - Material Today Proceeding Paper-Complete ManuscriptSarvesh AghavNo ratings yet

- 12 Che Vol-1 Important QuestionsDocument12 pages12 Che Vol-1 Important QuestionsJagan EashwarNo ratings yet

- Assignment Mole Concept JH Sir-2686Document22 pagesAssignment Mole Concept JH Sir-2686Nitin DasNo ratings yet

- Powde R: Pharmaceutical TechnologyDocument9 pagesPowde R: Pharmaceutical TechnologyAngela DelarmenteNo ratings yet

- Test of Carbohydrates, Fats, ProteinsDocument3 pagesTest of Carbohydrates, Fats, Proteinsaeriel judsonNo ratings yet

- P Block II PDFDocument68 pagesP Block II PDFAdarshNo ratings yet

- Comparison of Surface Properties Between Kaolin and Metakaolin in Concentrated Lime SolutionsDocument3 pagesComparison of Surface Properties Between Kaolin and Metakaolin in Concentrated Lime SolutionsShweta MahajanNo ratings yet

- g11 Module 1 in General Chemistry 1pdfDocument39 pagesg11 Module 1 in General Chemistry 1pdfAlthea EdulanNo ratings yet

- fITOSANITARIOS 22-03-22Document4 pagesfITOSANITARIOS 22-03-22María JesúsNo ratings yet

- Nitric Acid (SUMMARY CHEMISTRY CHAPTER)Document2 pagesNitric Acid (SUMMARY CHEMISTRY CHAPTER)the lillyNo ratings yet

- 67952Document89 pages67952lee diquiatco0% (1)

- Carbon Nano Particles. ReviewDocument16 pagesCarbon Nano Particles. Reviewankita awasthiNo ratings yet

- Mining GlossaryDocument68 pagesMining GlossaryMa2nk AsepNo ratings yet

- C - Forano - Recent Trends in Electrochmical Detection of Phosphate in Actual Waters - 2018Document9 pagesC - Forano - Recent Trends in Electrochmical Detection of Phosphate in Actual Waters - 2018박지훈No ratings yet

- Oleochemical - WikipediaDocument3 pagesOleochemical - WikipediaNur Atiqah Ahmad100% (1)

- Numbering Metals and Alloys in The Unified Numbering System (UNS)Document7 pagesNumbering Metals and Alloys in The Unified Numbering System (UNS)Erick VargasNo ratings yet

- Sáng Chế Đề Cập Đến Công Thức Tạo SƠN PHỒNG NỞ Bao Gồm Một Loại Đất Sét Sống - WO2008129242A2Document45 pagesSáng Chế Đề Cập Đến Công Thức Tạo SƠN PHỒNG NỞ Bao Gồm Một Loại Đất Sét Sống - WO2008129242A2Tran Anh VanNo ratings yet

- Acids and BasesDocument20 pagesAcids and Basestahartpro786No ratings yet

- Chem022 - To Dye ForDocument4 pagesChem022 - To Dye ForPaige DarbonneNo ratings yet