Professional Documents

Culture Documents

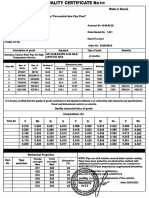

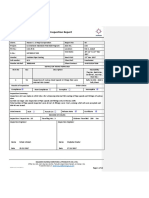

Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)

Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)

Uploaded by

rohitOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)

Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)

Uploaded by

rohitCopyright:

Available Formats

Doc. No.

METAL FORGINGS Date:

Rev:

PRIVATE LIMITED Page 1of 3

(AN I.S.O. 9001-2008 COMPANY)

METALLOGRAPHIC EXAMINATION – INCLUSION RATING EVALUATION

1) Scope:-

This specification outlines the procedures to be adopted for evaluation of the

inclusion rating of carbon, alloy and stainless steel samples representing the

heats used in the making of the forgings.

The test heads from the broken tensile test specimen shall be used for preparing

the specimen for evaluating the inclusion rating.

This procedure is based on ASTM E 45 and IS 4163 standards.

2) Equipment & Accessories:-

Polishing emery papers of grits 180, 320, 400, 500 and 600 grit.

polishing cloth, Lavigated Alumina polishing paste, Disc Polishing machine

Metallurgical microscope

3) Polishing Of Sample:-

First identify the face of the test head parallel to the direction of grain flow in

the forging it represents. This face is to be taken for polishing and examination.

If the area of the face is large, the sample may be got cut to reduce the polishing

area on a band saw machine. Cutting shall be done with good coolant

circulation to avoid heating up of the sample. Gas cutting shall not be done to

reduce the sample size. A polished area of 160 sq mm would be sufficient to

make a proper evaluation.

Polish the sample by hand on 180 grit emery paper till the scratches are

oriented in a parallel direction.

Rotate the sample at right angle and continue the hand polishing the specimen

on 320 grit emery paper such that the new finer scratches are again parallel.

Continue the polishing successively with 400, 500 and 600 grit emery papers

ensuring that at

Each stage the scratches are at right angles to the original orientation.

Prepared By Controlled by Approved by

Doc. No.:

METAL FORGINGS Date:

Rev:

PRIVATE LIMITED Page 2of 3

(ANpolish

Finally I.S.O.the9001-2008 COMPANY)

sample on sylvet cloth on the polishing machine using

lavigated alumina Suspension as the polishing medium to get a mirror finish.

Remove the excess alumina using distilled water and dry the polished sample.

Clean with a cotton moistened with alcohol.

4) Examination and Evaluation:-

Place the polished sample on the microscope stage. Ensure that the surface to

be examined is parallel to the microscope stage. If required, keep the polished

specimen on plasticize placed on a flat disc with the polished face on top and

make the surface level with the specimen leveling press.

Keep the specimen along with the disc on the microscope stage. View the

surface at 100x magnification and focus properly.

Examine the entire polished surface and for each type of inclusion make a note

of the reference number indicated in the standard diagram which corresponds to

the worst field examined in the thin, thick and over size series.

The results are recorded indicating the reference number of the worst field, the

presence of thick inclusions being indicated by the letter e, the presence of

oversize inclusions being indicated by the letter s.

The results shall be reported to the customer as specified in the purchase order.

AMMENDMENT LIST

Sr.No Doc. No. Rev. Amendmen Change In Document

. No. t date

Prepared By Controlled by Approved by

Doc. No.:

METAL FORGINGS Date:

Rev:

PRIVATE LIMITED Page 3of 3

(AN I.S.O. 9001-2008 COMPANY)

Prepared By Controlled by Approved by

You might also like

- AMS 2418 H Copper PlatingDocument8 pagesAMS 2418 H Copper PlatingJesse Krebs67% (3)

- Renault Wiring Diagram MidlumDocument302 pagesRenault Wiring Diagram MidlumGIANNIS100% (4)

- Weigh Balance Calibration CertificateDocument1 pageWeigh Balance Calibration Certificaterohit100% (4)

- RailTel PSCDL-RFP-Vol-2 Merged ModifiedDocument324 pagesRailTel PSCDL-RFP-Vol-2 Merged ModifiedJay PatelNo ratings yet

- Project Report On Aluminium ExtrusionDocument8 pagesProject Report On Aluminium ExtrusionEIRI Board of Consultants and Publishers0% (1)

- Painting - Training PPT 1Document24 pagesPainting - Training PPT 1vijay padale83% (6)

- AMS2406 Plating, Chromium Hard Deposit Rev. NDocument7 pagesAMS2406 Plating, Chromium Hard Deposit Rev. NRubén Eduardo Galindo CarmonaNo ratings yet

- Method Statement For In-Situ Metallography Test: DCSM Project 2019Document5 pagesMethod Statement For In-Situ Metallography Test: DCSM Project 2019Thinh NguyenNo ratings yet

- Anchor-Profile SSPC SPDocument9 pagesAnchor-Profile SSPC SPandy100% (1)

- Itr Steel StruktureDocument8 pagesItr Steel StruktureIjoel PutraNo ratings yet

- Documentation: Percona Technical Documentation TeamDocument242 pagesDocumentation: Percona Technical Documentation TeamMardi SeptiantoNo ratings yet

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document2 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- Qualiity Cert - Created 001Document1 pageQualiity Cert - Created 001tech.salesNo ratings yet

- Testing Coatings For Abrasion and WearDocument3 pagesTesting Coatings For Abrasion and WearEsau AguillónNo ratings yet

- Pro 803Document8 pagesPro 803sorsanbarNo ratings yet

- Mat Spec, Astm A 694 F65 Low Alloy Steel Forgings: SubseaDocument14 pagesMat Spec, Astm A 694 F65 Low Alloy Steel Forgings: SubseaJones Pereira Neto100% (1)

- قوائم فحص معدات مختلفةDocument41 pagesقوائم فحص معدات مختلفةahmedkamalelsabryNo ratings yet

- Casting High Quality C12A: Bradken Energy ProductsDocument37 pagesCasting High Quality C12A: Bradken Energy Productsdelta lab sangliNo ratings yet

- 0803126034Document167 pages0803126034siritapeNo ratings yet

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document3 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNo ratings yet

- Abrasion TaberDocument2 pagesAbrasion TaberDiego Fernado AvendañoNo ratings yet

- SWPL 316 Hy TDS 059 PDFDocument3 pagesSWPL 316 Hy TDS 059 PDFkapileswar pradhanNo ratings yet

- MSM CVY CON MST 0005 Rev.a Method Statement Cleaning Stainless SteelDocument6 pagesMSM CVY CON MST 0005 Rev.a Method Statement Cleaning Stainless SteelSreetharan SNo ratings yet

- Experimental Investigation On TIG Welded Aluminium Alloy 6082 Weldment Using Non Destructive EvaluationDocument4 pagesExperimental Investigation On TIG Welded Aluminium Alloy 6082 Weldment Using Non Destructive EvaluationEditor IJTSRDNo ratings yet

- Asa-146 NSH Apco Ir 040Document10 pagesAsa-146 NSH Apco Ir 040Fahad AhmadNo ratings yet

- Investigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorDocument6 pagesInvestigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorNsidibe Michael Etim100% (1)

- Galvanized Steel Inspection GuideDocument20 pagesGalvanized Steel Inspection GuidePham Ngoc Khan100% (2)

- SAE J1993 - FEB2019 High-Carbon Cast-Steel GritDocument3 pagesSAE J1993 - FEB2019 High-Carbon Cast-Steel Gritmarcio de rossiNo ratings yet

- Influence of Surface Finish On Cavitation ErosionDocument9 pagesInfluence of Surface Finish On Cavitation ErosionJason BarrentineNo ratings yet

- Training ReportDocument16 pagesTraining ReportJay MavaniNo ratings yet

- Section 5. Welding and BrazingDocument27 pagesSection 5. Welding and BrazingrobinyNo ratings yet

- Casting Defects Analysis in Foundry andDocument12 pagesCasting Defects Analysis in Foundry andahmedameer20189No ratings yet

- Deep Precision Industries, Rohtak Work Instruction For Thread LapsDocument2 pagesDeep Precision Industries, Rohtak Work Instruction For Thread Lapsvipulsharma655No ratings yet

- Foundry and WeldingDocument12 pagesFoundry and WeldingYuvraj MehtaNo ratings yet

- Double Column Research Paper FormatDocument7 pagesDouble Column Research Paper FormatniteshNo ratings yet

- Week 10 Macro Etching and Number RestorationDocument20 pagesWeek 10 Macro Etching and Number RestorationeoselevenNo ratings yet

- Sop TSZC TsacDocument7 pagesSop TSZC TsacCorrosion FactoryNo ratings yet

- AEI Painting Report SampleDocument2 pagesAEI Painting Report Samplemiguel carrizalesNo ratings yet

- CSWIP Welding Inspection Notes and Questions PDFDocument115 pagesCSWIP Welding Inspection Notes and Questions PDFrahim_335162856100% (3)

- Welding DocumentDocument128 pagesWelding DocumentVishal SharmaNo ratings yet

- Restoration of Obliterated Engraved Marks On Steel Surfaces by Chemical Etching ReagentDocument5 pagesRestoration of Obliterated Engraved Marks On Steel Surfaces by Chemical Etching Reagentsantino.passarinoNo ratings yet

- Https WWW - Scielo.br J MR A X5DJbhLnnjhdbzFpwV4dkzH Format PDF&Lang enDocument11 pagesHttps WWW - Scielo.br J MR A X5DJbhLnnjhdbzFpwV4dkzH Format PDF&Lang enEstefano Bruno Moritz PeruzzoNo ratings yet

- CSWIP Welding Inspection Notes and Questions (Said)Document138 pagesCSWIP Welding Inspection Notes and Questions (Said)Ericson Cabigao100% (1)

- Wi Microstructure of Cast IronDocument2 pagesWi Microstructure of Cast Ironsharif1974No ratings yet

- MME MetallographyDocument6 pagesMME MetallographyRefat Bin SultanNo ratings yet

- Gypsum Board Installation To Wall (Drywall & Partitions)Document5 pagesGypsum Board Installation To Wall (Drywall & Partitions)xomilaaNo ratings yet

- Checklist For Waterproofing - ToiletsDocument1 pageChecklist For Waterproofing - Toiletsyash shahNo ratings yet

- BARGE SPEC-signedDocument7 pagesBARGE SPEC-signedganeshcivil1984No ratings yet

- Centrale À Cycle Combiné Bi-Arbres Rades C 1 X 450MW: Specification For FinalDocument7 pagesCentrale À Cycle Combiné Bi-Arbres Rades C 1 X 450MW: Specification For FinalHaythem Ben ZidNo ratings yet

- Weld Inspection Reporting ProcedureDocument5 pagesWeld Inspection Reporting Proceduresharif1974No ratings yet

- Astm A 516 Gr.60n Plate SpecificationDocument3 pagesAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- L1 Microstructure ExaminationDocument5 pagesL1 Microstructure ExaminationDarshan ShaarmaNo ratings yet

- Iso 2819 1980Document8 pagesIso 2819 1980RobertoNo ratings yet

- PS152.04 E-Coat For Ferrous and Aluminum ComponentsDocument4 pagesPS152.04 E-Coat For Ferrous and Aluminum ComponentsJovanny RNo ratings yet

- BS 476: Part 7: 1997Document44 pagesBS 476: Part 7: 1997TheAnh TranNo ratings yet

- Desgaste Del DisilicatoDocument7 pagesDesgaste Del DisilicatoVictor LappostNo ratings yet

- Welding Inspection CSWIP (ANSWER)Document131 pagesWelding Inspection CSWIP (ANSWER)Manoj PaudelNo ratings yet

- Component Details:: Fairfield Atlas LimitedDocument3 pagesComponent Details:: Fairfield Atlas LimitedAndras StegerNo ratings yet

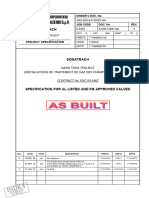

- Indra: SonatrachDocument9 pagesIndra: Sonatrachmessari mohamedakliNo ratings yet

- Centria SRS 3 NOA For Miami DadeDocument6 pagesCentria SRS 3 NOA For Miami DadeDNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Daison PaulNo ratings yet

- Indentation Techniques in Ceramic Materials Characterization: Theory and PracticeFrom EverandIndentation Techniques in Ceramic Materials Characterization: Theory and PracticeAhmad G. SolomahNo ratings yet

- Production: Punjab General Industries Private Limited Plot 149-150, - Sector-24, Faridabad, Haryana-121005Document2 pagesProduction: Punjab General Industries Private Limited Plot 149-150, - Sector-24, Faridabad, Haryana-121005rohitNo ratings yet

- 16.0 Grade Wise Chemical CompositionDocument29 pages16.0 Grade Wise Chemical CompositionrohitNo ratings yet

- Iso 9001-2015Document1 pageIso 9001-2015rohitNo ratings yet

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DateDocument1 pageAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DaterohitNo ratings yet

- Creep Testing: Test Name PrincipleDocument2 pagesCreep Testing: Test Name PrinciplerohitNo ratings yet

- As Per ISO 9001:2015 & IATF 16949:2016: Formula For Calculation of Liquidus TempratureDocument1 pageAs Per ISO 9001:2015 & IATF 16949:2016: Formula For Calculation of Liquidus TempraturerohitNo ratings yet

- 14.0grade Wise Scrap Charge Mix.Document8 pages14.0grade Wise Scrap Charge Mix.rohitNo ratings yet

- 11.0 Raw Material SpecificationDocument6 pages11.0 Raw Material SpecificationrohitNo ratings yet

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DateDocument1 pageAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DaterohitNo ratings yet

- Bond Strength Testing: Test Name PrincipleDocument2 pagesBond Strength Testing: Test Name PrinciplerohitNo ratings yet

- Pgil Master Ferro Alloy and Refrac ListDocument12 pagesPgil Master Ferro Alloy and Refrac ListrohitNo ratings yet

- The Lee Company Industrial Microhydraulics Group - Quality ManualDocument65 pagesThe Lee Company Industrial Microhydraulics Group - Quality Manualrohit100% (1)

- Co-Efficient of Friction TestingDocument1 pageCo-Efficient of Friction TestingrohitNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Quality Manual Pgi-Ml-Qm: As Per IS / ISO / IEC 17025: 2017Document25 pagesQuality Manual Pgi-Ml-Qm: As Per IS / ISO / IEC 17025: 2017rohit100% (6)

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Work Instructions Marking Machine (E9-P123)Document1 pageWork Instructions Marking Machine (E9-P123)rohitNo ratings yet

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document3 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Detecting Susceptibility To Intergranular Attack in Austenitic Stainless SteelsDocument20 pagesDetecting Susceptibility To Intergranular Attack in Austenitic Stainless SteelsrohitNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Optimization of Continuous Casting Process in Steel Manufacturing IndustryDocument5 pagesOptimization of Continuous Casting Process in Steel Manufacturing IndustryrohitNo ratings yet

- High-Temperature Quality of Accelerated SpheroidizDocument10 pagesHigh-Temperature Quality of Accelerated SpheroidizrohitNo ratings yet

- Job ResponsibilityDocument34 pagesJob Responsibilityrohit100% (1)

- Ux Experience Design ClassDocument3 pagesUx Experience Design ClassbihimNo ratings yet

- SML 6 Week TRAINING PDFDocument28 pagesSML 6 Week TRAINING PDFRajesh ThakurNo ratings yet

- Kendriya Vidyalaya Sangathan: Kolkata Region First Preboard E Informatics Practices New (065) - Class XiiDocument15 pagesKendriya Vidyalaya Sangathan: Kolkata Region First Preboard E Informatics Practices New (065) - Class XiiHaresh NathaniNo ratings yet

- JLN205MK2 InstructionDocument92 pagesJLN205MK2 InstructionSang Aji Jaya SusenoNo ratings yet

- Rule and NetiquetteDocument3 pagesRule and NetiquetteRae Nicole BawalanNo ratings yet

- Traxmaker User ManualDocument220 pagesTraxmaker User Manualrojozurdo100% (1)

- PRINCE2 فكرة عنDocument24 pagesPRINCE2 فكرة عنWalid GradaNo ratings yet

- 160 54-PW2 1 PDFDocument18 pages160 54-PW2 1 PDFMersal AliraqiNo ratings yet

- ICAML 2021: 3 International Conference On Applications of AI & Machine LearningDocument2 pagesICAML 2021: 3 International Conference On Applications of AI & Machine Learningcool_spNo ratings yet

- Huawei WLAN Wireless Backhaul Scenario Baseline V2.0Document13 pagesHuawei WLAN Wireless Backhaul Scenario Baseline V2.0Marina PavlićNo ratings yet

- Transform Datas Impact Pick The Right Success KPIDocument8 pagesTransform Datas Impact Pick The Right Success KPIMing MingNo ratings yet

- Latar BelakangDocument4 pagesLatar BelakangAlvin RusliNo ratings yet

- Xoomstv User GuideDocument3 pagesXoomstv User GuideGabriel Morales de PoolNo ratings yet

- Wave110 (AFX110CS) SuggestionRetailPriceList AUG2017Document12 pagesWave110 (AFX110CS) SuggestionRetailPriceList AUG2017Jubei AnaikeNo ratings yet

- CVG003 Jan 1982Document116 pagesCVG003 Jan 1982kmyl75No ratings yet

- Grl0050-D0a1s0n0a1k-H100000 & Grl0100-D0a1s0n0a1k-H100000 For CQ20210576Document11 pagesGrl0050-D0a1s0n0a1k-H100000 & Grl0100-D0a1s0n0a1k-H100000 For CQ20210576Muizti RimadhonaNo ratings yet

- Mapúa University: Experiment No. 3Document24 pagesMapúa University: Experiment No. 3ChesterJerichoRamosNo ratings yet

- Parts CatalogDocument40 pagesParts CatalogMarko PanajotovNo ratings yet

- Module 1Document20 pagesModule 1Enya Francene GarzotaNo ratings yet

- Online Data Entry Projects (Copy Paste - Data Mining: Work)Document4 pagesOnline Data Entry Projects (Copy Paste - Data Mining: Work)Mani KantaNo ratings yet

- EPFL TH4820 Scala ThesisDocument133 pagesEPFL TH4820 Scala ThesiskbkkrNo ratings yet

- Commissioning ProcedureDocument13 pagesCommissioning ProcedureShibu ArjunanNo ratings yet

- The Vintage Power Wagons 2016 Parts Catalog - Group 01 EngineDocument6 pagesThe Vintage Power Wagons 2016 Parts Catalog - Group 01 EnginekaiNo ratings yet

- KKE (Solar Energy - Solar - Basics)Document38 pagesKKE (Solar Energy - Solar - Basics)Iqbal Al FuadyNo ratings yet

- Spectrerf Workshop: Power Amplifier Design Using Spectrerf Mmsim 7.2.0Document91 pagesSpectrerf Workshop: Power Amplifier Design Using Spectrerf Mmsim 7.2.0Corol LanNo ratings yet

- Feed Optimization PlaybookDocument52 pagesFeed Optimization Playbookjalvathi mNo ratings yet

- Types in PythonDocument14 pagesTypes in PythonArya BhattNo ratings yet