Professional Documents

Culture Documents

DIB - Generators & Motors

DIB - Generators & Motors

Uploaded by

Deepen SharmaCopyright:

Available Formats

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Beml Report PDFDocument32 pagesBeml Report PDFCrazy TamizhaNo ratings yet

- Continental Engineering Corporation: Method Statement of Curing Compound For Precast BeamsDocument3 pagesContinental Engineering Corporation: Method Statement of Curing Compound For Precast BeamsnaseebNo ratings yet

- Uae Oil & Gas DirectoryDocument1,586 pagesUae Oil & Gas DirectoryChristopher Robin Richardson87% (23)

- Rotational Lining SystemDocument11 pagesRotational Lining SystemMubeenNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Badve Electrical Limited, Pantnagar (Udham Singh Nagar) : A Project Report OnDocument18 pagesBadve Electrical Limited, Pantnagar (Udham Singh Nagar) : A Project Report OnMedical SherniNo ratings yet

- Case Study Anti Spatter AMPCOLOY® MylarDocument3 pagesCase Study Anti Spatter AMPCOLOY® MylarashwanidusadhNo ratings yet

- Carbone Lorraine PresentationDocument128 pagesCarbone Lorraine PresentationDebarati Bhattacharjee100% (1)

- Century Paper and Pulp Lalkuan (Udham Singh Nagar) : A Project Report OnDocument18 pagesCentury Paper and Pulp Lalkuan (Udham Singh Nagar) : A Project Report OnMedical SherniNo ratings yet

- CO2 Blast CleaningDocument30 pagesCO2 Blast CleaningkangsungjinNo ratings yet

- Gas ManifoldDocument3 pagesGas ManifoldTanmayNo ratings yet

- Busbar Trunking SystemDocument21 pagesBusbar Trunking SystemJordan Ansh50% (2)

- Insulect Specification PDFDocument10 pagesInsulect Specification PDFThuan NguyenNo ratings yet

- Bhel (Transformer) Major TrainingDocument33 pagesBhel (Transformer) Major TrainingArpitSinghNo ratings yet

- Industrial Air CleanersDocument4 pagesIndustrial Air CleanerssalgoraNo ratings yet

- Cable Reeling DrumDocument4 pagesCable Reeling DrumBanamali NaskarNo ratings yet

- Ako - Cnc65 Tube Bending MachineDocument30 pagesAko - Cnc65 Tube Bending MachineNguyen Quyet Thang100% (1)

- TPM Wabco-Tvs (India) LTDDocument46 pagesTPM Wabco-Tvs (India) LTDpnithiy_elecNo ratings yet

- Millennium STEEL - Strip Cleaning TechnologyDocument5 pagesMillennium STEEL - Strip Cleaning Technologyaliali2662No ratings yet

- CrawlerMobileCrusher SDocument7 pagesCrawlerMobileCrusher Sjoyalcrusher100% (1)

- REI 2019 Show Directory - Third Cut-MinDocument419 pagesREI 2019 Show Directory - Third Cut-Minmahajan.gouravNo ratings yet

- REI 2019 Show Directory - Third Cut-Min PDFDocument419 pagesREI 2019 Show Directory - Third Cut-Min PDFManish Gade पिंपरी चिचंवडNo ratings yet

- Internship Report: Training Centre - Mysore ComplexDocument28 pagesInternship Report: Training Centre - Mysore Complexshubhashini K NNo ratings yet

- SCR Carterpillar (Catalistico de Reducion Selectiva)Document4 pagesSCR Carterpillar (Catalistico de Reducion Selectiva)Jesus Almanzar Santos100% (1)

- CTM Catalogue 2015-2016Document100 pagesCTM Catalogue 2015-2016Anonymous dXcoknUNo ratings yet

- Coating AluminiumDocument9 pagesCoating AluminiumNadangol DangolNo ratings yet

- Submitted: BY: Name-Kartik Tyagi Branch/year-M.E (4 Year Roll No:-1503340102Document29 pagesSubmitted: BY: Name-Kartik Tyagi Branch/year-M.E (4 Year Roll No:-1503340102kartik tyagiNo ratings yet

- Electromat CatalogueDocument24 pagesElectromat Cataloguekvramanan_1No ratings yet

- Scomi Oiltools DWMS OverviewDocument16 pagesScomi Oiltools DWMS Overviewmojtaba_m007No ratings yet

- Cone CrusherDocument3 pagesCone Crusherchand_yelNo ratings yet

- Amaron PowerstackDocument6 pagesAmaron PowerstackmuralieshNo ratings yet

- Seminar PPT AutomationDocument27 pagesSeminar PPT Automationamitesh_iitkgp83No ratings yet

- SPP@KSCST - Iisc.ernet - in WWW - Kscst.iisc - Ernet.in/spp - HTML: Karnataka State Council For Science and TechnologyDocument12 pagesSPP@KSCST - Iisc.ernet - in WWW - Kscst.iisc - Ernet.in/spp - HTML: Karnataka State Council For Science and TechnologyterminalcbrNo ratings yet

- Caterpillar 320cDocument28 pagesCaterpillar 320ccamelia_pirjan5776100% (3)

- Variac MFG Business Plan Annexure - 1Document6 pagesVariac MFG Business Plan Annexure - 1Manav MatetiNo ratings yet

- Portable Dust Extraction SystemDocument1 pagePortable Dust Extraction Systemswakinjesu100% (1)

- MFD - Profile P IV Sept 19Document58 pagesMFD - Profile P IV Sept 19Marketing - Magna Industries - Metal Product DivisionNo ratings yet

- 320cl (8f6)Document28 pages320cl (8f6)Andres VargasNo ratings yet

- Ice BlastingDocument20 pagesIce BlastingshervinyNo ratings yet

- Alsons PresentationDocument19 pagesAlsons PresentationAditya VuthaNo ratings yet

- MaintenanceConcerns Carbon BrushesDocument10 pagesMaintenanceConcerns Carbon Brusheskamal_khan85No ratings yet

- TC Spinners MOM - Merged - OrganizedDocument9 pagesTC Spinners MOM - Merged - OrganizedShubham BishnoiNo ratings yet

- EDX5-3.Miller 500 Eco PDFDocument8 pagesEDX5-3.Miller 500 Eco PDFDen BagusNo ratings yet

- Design and Fabrication of A Pedal-Operat PDFDocument7 pagesDesign and Fabrication of A Pedal-Operat PDFAlrhon John Dequilla EstigoyNo ratings yet

- Baumüller DCmotor - GbtrainingDocument7 pagesBaumüller DCmotor - GbtrainingMamunur RashidNo ratings yet

- Auto Tube Cleaning SystemDocument2 pagesAuto Tube Cleaning SystemTeo Pei SanNo ratings yet

- Genus Electrotech LTD.: WWW - Genuselectrotech.co - inDocument41 pagesGenus Electrotech LTD.: WWW - Genuselectrotech.co - inRam RamNo ratings yet

- Mak Hydrol: Industrial Hydraulic Fluid For Superior Performance and ProtectionDocument3 pagesMak Hydrol: Industrial Hydraulic Fluid For Superior Performance and Protectionchandan sahooNo ratings yet

- GL XX Mobilgear MS SeriesDocument3 pagesGL XX Mobilgear MS Seriesanibal_rios_rivasNo ratings yet

- Bhel ReportDocument13 pagesBhel ReportAtul TripathiNo ratings yet

- Vecom - Japanese BlackDocument2 pagesVecom - Japanese Blackdiaccessltd_17172961No ratings yet

- ASHOKADocument40 pagesASHOKAManish PatilNo ratings yet

- AKMH Selection Guide Rev B - En-UsDocument48 pagesAKMH Selection Guide Rev B - En-Usahmadf007No ratings yet

- BITUMEN REMOVAL and CLEANING MAINTENANCE SPECIFICSDocument2 pagesBITUMEN REMOVAL and CLEANING MAINTENANCE SPECIFICSoscar jackNo ratings yet

- ICS - Company Profile 2015Document13 pagesICS - Company Profile 2015nhariwijayaNo ratings yet

- Introduction About Internship Industry ProfileDocument35 pagesIntroduction About Internship Industry ProfileThushar DNo ratings yet

- Rotational Lining System and Use of High-Performance ThermoplasticsDocument11 pagesRotational Lining System and Use of High-Performance ThermoplasticsMubeenNo ratings yet

- CPC 100 Ordering Information ENUDocument33 pagesCPC 100 Ordering Information ENUDeepen SharmaNo ratings yet

- A Security Analysis and Secure Management Model For Scada SystemsDocument11 pagesA Security Analysis and Secure Management Model For Scada SystemsDeepen SharmaNo ratings yet

- ArticleDocument12 pagesArticleDeepen SharmaNo ratings yet

- DGPC/THP/HRAD/H&AD/2022/001479 Dated: 03/06/2022: TH THDocument3 pagesDGPC/THP/HRAD/H&AD/2022/001479 Dated: 03/06/2022: TH THDeepen SharmaNo ratings yet

- Work OrderDocument3 pagesWork OrderDeepen SharmaNo ratings yet

- 86 92 Kruger EngelenDocument7 pages86 92 Kruger EngelenDeepen SharmaNo ratings yet

- Data - Book - 132 KV Cable - NHPPDocument150 pagesData - Book - 132 KV Cable - NHPPDeepen SharmaNo ratings yet

- Cable Related ThesisDocument51 pagesCable Related ThesisDeepen SharmaNo ratings yet

- Alphabet Practice SheetDocument31 pagesAlphabet Practice SheetDeepen SharmaNo ratings yet

- Standard CapacitorsDocument2 pagesStandard CapacitorsDeepen SharmaNo ratings yet

- GT210-10 NGR W TransformerDocument2 pagesGT210-10 NGR W TransformerDeepen SharmaNo ratings yet

- UntitledDocument1 pageUntitledDeepen SharmaNo ratings yet

- 66kV Vltage Profile at CHP EndDocument1 page66kV Vltage Profile at CHP EndDeepen SharmaNo ratings yet

- Data Sheet 3RH2122-1BB40Document7 pagesData Sheet 3RH2122-1BB40Deepen SharmaNo ratings yet

- What's New in Mipower V 10.1 FinalDocument22 pagesWhat's New in Mipower V 10.1 FinalDeepen SharmaNo ratings yet

- UntitledDocument1 pageUntitledDeepen SharmaNo ratings yet

- Field Recalibration ReportDocument1 pageField Recalibration ReportDeepen SharmaNo ratings yet

- Technical Diagnostics For Power ApparatusDocument6 pagesTechnical Diagnostics For Power ApparatusDeepen SharmaNo ratings yet

- Cable System Transient Study Elforskrapport 2009 05Document141 pagesCable System Transient Study Elforskrapport 2009 05Deepen SharmaNo ratings yet

- Doble M4120 Ext Ref Application GuideDocument5 pagesDoble M4120 Ext Ref Application GuideDeepen SharmaNo ratings yet

- Application of HFCT and UHF Sensors in On-Line Partial Discharge Measurements For Insulation Diagnosis of High Voltage EquipmentDocument29 pagesApplication of HFCT and UHF Sensors in On-Line Partial Discharge Measurements For Insulation Diagnosis of High Voltage EquipmentDeepen SharmaNo ratings yet

- Panel Discussion & Expo: Free ParticipationDocument1 pagePanel Discussion & Expo: Free ParticipationDeepen SharmaNo ratings yet

- Checking Ground Electrode Impedance For Commercial, Industrial and Residential BuildingsDocument8 pagesChecking Ground Electrode Impedance For Commercial, Industrial and Residential BuildingsDeepen SharmaNo ratings yet

- Exide Classic OPzS - enDocument17 pagesExide Classic OPzS - enDeepen SharmaNo ratings yet

- How Complacency and Lax Protocols Led To The Nation's Second COVID-19 OutbreakDocument14 pagesHow Complacency and Lax Protocols Led To The Nation's Second COVID-19 OutbreakDeepen SharmaNo ratings yet

- VRF HVAC CatalogueDocument84 pagesVRF HVAC CatalogueDeepen Sharma100% (1)

- PTS 400.3, Class 0.02 Modular Three-Phase Portable Test SystemDocument15 pagesPTS 400.3, Class 0.02 Modular Three-Phase Portable Test SystemDeepen SharmaNo ratings yet

- Universal Blaster: Works With All Dry Ice FormsDocument2 pagesUniversal Blaster: Works With All Dry Ice FormsDeepen SharmaNo ratings yet

- Baras Kaam Accounts Cash Collection Details PDFDocument16,132 pagesBaras Kaam Accounts Cash Collection Details PDFDeepen SharmaNo ratings yet

- HRDC Out PassDocument1 pageHRDC Out PassDeepen SharmaNo ratings yet

- Advanced Driver-Assistance SystemsDocument15 pagesAdvanced Driver-Assistance Systemsfroggoand decrewNo ratings yet

- Data Management and Basics: Submitted To: Angammal Shanthi Ma'am Submitted By: Simran Gupta Prabir Das Himanshu NainDocument4 pagesData Management and Basics: Submitted To: Angammal Shanthi Ma'am Submitted By: Simran Gupta Prabir Das Himanshu NainSiddharth JhaNo ratings yet

- Mathematics 9Document5 pagesMathematics 9Van Mark TejadaNo ratings yet

- Sadsjryjtc74tv8Document3 pagesSadsjryjtc74tv8Fahad Qamar ParachaNo ratings yet

- 9 10 Curve Fitting and Interpolation Part 2Document32 pages9 10 Curve Fitting and Interpolation Part 2Marshall james G. RamirezNo ratings yet

- Modi MCM and VamDocument14 pagesModi MCM and VamJoneric RamosNo ratings yet

- ABB I-Bus KNX: Details and Solutions For Intelligent Building ControlDocument40 pagesABB I-Bus KNX: Details and Solutions For Intelligent Building ControlIorgoni LiviuNo ratings yet

- Kato-Prime 30 Welcome Bonus TC Feb2023-Mar2023Document2 pagesKato-Prime 30 Welcome Bonus TC Feb2023-Mar2023Tanjong Minyak Car Wash Sdn BhdNo ratings yet

- Challenge of Artificial IntelligenceDocument230 pagesChallenge of Artificial IntelligenceDragosNo ratings yet

- Elective Local Official'S Personal Data Sheet: PictureDocument3 pagesElective Local Official'S Personal Data Sheet: PictureYdnic OirelagNo ratings yet

- Guhan Mahalingam: Assembly EngineerDocument2 pagesGuhan Mahalingam: Assembly EngineerGuhan MNo ratings yet

- Classes & Objects-Examples C++Document12 pagesClasses & Objects-Examples C++Aer ZNo ratings yet

- 818 IC Pump: ManualDocument56 pages818 IC Pump: ManualKhalid Zghear100% (1)

- 27-Com-Su-5191-A Coating SystemsDocument81 pages27-Com-Su-5191-A Coating Systemsaslam.amb100% (1)

- Introduktion ToDocument15 pagesIntroduktion TomotadollyNo ratings yet

- Dsoc201 22231 1Document6 pagesDsoc201 22231 1MANU KaliaNo ratings yet

- Reyax RYWDB00 - ENDocument10 pagesReyax RYWDB00 - ENAMNo ratings yet

- Maha Manual 16 de Juli 2021Document21 pagesMaha Manual 16 de Juli 2021GERARDO SAYAGONo ratings yet

- DONE - Princess AmaradeviDocument6 pagesDONE - Princess AmaradeviBolo Bolo BoloNo ratings yet

- TDS Meyco Sa 167 PDFDocument3 pagesTDS Meyco Sa 167 PDFYasin AykanatNo ratings yet

- Chapter 2: Analyzing The Business Case: Kp24103 System Analysis & DesignDocument17 pagesChapter 2: Analyzing The Business Case: Kp24103 System Analysis & DesignMae XNo ratings yet

- Time Relay With External Potentiometer: CRM-91HE, CRM-2HEDocument1 pageTime Relay With External Potentiometer: CRM-91HE, CRM-2HEMartin CinčićNo ratings yet

- SMP-030 - Copia2Document23 pagesSMP-030 - Copia2Nelson RNo ratings yet

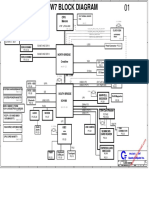

- HASEE HP500 - QUANTA SW7 - REV 1ASecDocument41 pagesHASEE HP500 - QUANTA SW7 - REV 1ASecAdam TsiolakakisNo ratings yet

- Facility Layout DesigningDocument45 pagesFacility Layout DesigningAkash SinghNo ratings yet

- imageCLASS MF230 Series SpecSheetDocument4 pagesimageCLASS MF230 Series SpecSheetPablo MartinezNo ratings yet

- Cloud Computing - WikipediaDocument24 pagesCloud Computing - Wikipediajustin time compilerNo ratings yet

- MathsDocument20 pagesMathstlabNo ratings yet

- Diat Certified Information Assurance Professional: An Online Training & Certification Programme byDocument4 pagesDiat Certified Information Assurance Professional: An Online Training & Certification Programme byV K BNo ratings yet

- Squad3.fire NSD GPMDocument7 pagesSquad3.fire NSD GPMMac CorpuzNo ratings yet

DIB - Generators & Motors

DIB - Generators & Motors

Uploaded by

Deepen SharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIB - Generators & Motors

DIB - Generators & Motors

Uploaded by

Deepen SharmaCopyright:

Available Formats

CRYOGENIC CLEANING OF GENERATORS & MOTORS

Conventional cleaning methods are Solvents and Steam / Water Jet blasting with lots of time

consuming manual labor.

Contaminants like carbon, oil, cement , paper, rubber, etc. (depending on the industry the generator

/ motor is used in) need to be removed over a period of time as these contaminants lower the

insulation resistance of the windings and can even cause mechanical failures in extreme situations.

Solvent Cleaning

Solvents are sprayed over the areas to be cleaned, while the surface is rubbed with a nylon brush or

blunt insulated stub to remove contaminants that have adhered to the surface of the windings. Solvent

soaked swabs are then used to access areas between adjacent coils and areas in which a brush /

stub cannot be used.

Solvent cleaning requires the cleaned component to be heated post cleaning to remove all traces of

solvents. Solvents often affect the outer layer of varnish and as such, application of a finishing varnish

after the dry out is mandatory.

The short falls in this cleaning method are:

Solvents are toxic. Collection and disposal of secondary waste is a major deterrent. Solvents affect

the outer layers of insulation. The abrasive action of brushes, stubs and swabs worsens the situation.

It is difficult to clean the inter spaces of adjacent coil sides and between top and bottom half coils

on the overhangs of windings. Contaminants lodged in crevices are not easily removed. Drying

out of the machine requires the use of a temperature controlled oven. This calls for dismantling of the

machine and transportation to a service facility. Such operations carry with them the associated risks

and costs.

CMW CO2 TECHNOLOGIES

608-B Kohinoor City Mall, Kirol Road Off L B S Marg, Kurla (West) Mumbai 400050 – INDIA

Telefax +91.22.25044605/06/08/09 E.mail customercare@cmw-dryice.com.com

In-situ cleaning, if carried out , will require that the machine is heated using hot air blowers or

passage of electric current through the windings. These methods are potentially hazardous. Typically

the man power required for a large machine is ten people over a 4 - 6 day period.

Steam / Hot Water Jet Cleaning

With this method of cleaning the windings are cleaned with steam or hot water mixed with a mild

detergent.

The cleaning results are good, however the major draw backs of this method are:

A perfect post cleaning dry out of the windings is mandatory. This involves dismantling

and transportation of the equipment to a service facility. In-situ cleaning is therefore ruled out.

Further, this method of cleaning has to be carried out judiciously to ensure that there is no

excessive abrasive action that may cause damage. Application of a fresh coat of finishing varnish

after the dry out is recommended. All in all, lots of down time and very costly.

ABB, GE, SIEMENS and ALSTOM generators and large motors, to name but a few in Europe,

Asia/India and the Americas, are cleaned in-situ with our Crystal Particle cleaning method. It

presents the owners / operators of such equipment with several advantages.

Dry Ice Crystal Particle Cleaning provides a "cleaner clean"

The inter space between adjacent coils and between top / bottom half coils on the overhangs are

very thoroughly cleaned. It has particularly been noted that contaminants trapped in crevices and

on overhang tie-ups are very well removed.

There is no abrasive action because of Dry Ice Blasting, if correctly carried out. Application of a

post clean up finishing varnish is not necessary in most cases. Heating of the windings after clean

up is not required (using good quality / dry blast cleaning air). It is however recommended, that

hot air is lightly blown over the cleaned area using a hand held hot air blower to

remove traces of light surface condensation, if present. Low insulation resistance values, if

attributed solely to contamination, improve considerably after the Dry Ice Crystal Particle cleaning

operation has been completed.

Typical example, demonstrating before and after readings, are:

GENERAL ELECTRIC, DC Motor, 4000KW, 700 Volt, 5800 Amperes, Excitation Voltage: 125

Volts. Speed: 150/375 RPM

Insulation Resistance Values Before After

( measured after 1min ) clean up clean up

On main field 0.6 Mega Ohms 4.5 Mega Ohms

On inter-poles and 0.85 Mega 70 Mega Ohms

compensating windings Ohms

On armature 0.85 Mega 2.0 Mega Ohms

Ohms

Another important issue is accessibility and maneuverability of Heavy Electrical Rotating

Machinery on site.

An Indian petro-chemical company is employing CO2 blast cleaning, since dismantling and shifting of

the machine is not possible within the given shut down period of 72 hours. CO2 cleaning is

CMW CO2 TECHNOLOGIES

608-B Kohinoor City Mall, Kirol Road Off L B S Marg, Kurla (West) Mumbai 400050 – INDIA

Telefax +91.22.25044605/06/08/09 E.mail customercare@cmw-dryice.com.com

extremely useful as well, when machines to be cleaned are located in areas where

overhead cranes are not available. In India for example, power plants with diesel generators, have

only a 5 ton overhead crane to facilitate the engine overhaul. Dismantling of such machines for

overhauling is an onerous task and Dry Ice Crystal Particle cleaning in-situ provides a perfect solution.

BEFORE / AFTER PHOTOS

CMW CO2 TECHNOLOGIES

608-B Kohinoor City Mall, Kirol Road Off L B S Marg, Kurla (West) Mumbai 400050 – INDIA

Telefax +91.22.25044605/06/08/09 E.mail customercare@cmw-dryice.com.com

2500 KVA Before

2500 KVA After

CMW CO2 TECHNOLOGIES

608-B Kohinoor City Mall, Kirol Road Off L B S Marg, Kurla (West) Mumbai 400050 – INDIA

Telefax +91.22.25044605/06/08/09 E.mail customercare@cmw-dryice.com.com

625 KVA Before

625 KVA After

CMW CO2 TECHNOLOGIES

608-B Kohinoor City Mall, Kirol Road Off L B S Marg, Kurla (West) Mumbai 400050 – INDIA

Telefax +91.22.25044605/06/08/09 E.mail customercare@cmw-dryice.com.com

Stator End Before

Stator End After

CMW CO2 TECHNOLOGIES

608-B Kohinoor City Mall, Kirol Road Off L B S Marg, Kurla (West) Mumbai 400050 – INDIA

Telefax +91.22.25044605/06/08/09 E.mail customercare@cmw-dryice.com.com

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Beml Report PDFDocument32 pagesBeml Report PDFCrazy TamizhaNo ratings yet

- Continental Engineering Corporation: Method Statement of Curing Compound For Precast BeamsDocument3 pagesContinental Engineering Corporation: Method Statement of Curing Compound For Precast BeamsnaseebNo ratings yet

- Uae Oil & Gas DirectoryDocument1,586 pagesUae Oil & Gas DirectoryChristopher Robin Richardson87% (23)

- Rotational Lining SystemDocument11 pagesRotational Lining SystemMubeenNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Badve Electrical Limited, Pantnagar (Udham Singh Nagar) : A Project Report OnDocument18 pagesBadve Electrical Limited, Pantnagar (Udham Singh Nagar) : A Project Report OnMedical SherniNo ratings yet

- Case Study Anti Spatter AMPCOLOY® MylarDocument3 pagesCase Study Anti Spatter AMPCOLOY® MylarashwanidusadhNo ratings yet

- Carbone Lorraine PresentationDocument128 pagesCarbone Lorraine PresentationDebarati Bhattacharjee100% (1)

- Century Paper and Pulp Lalkuan (Udham Singh Nagar) : A Project Report OnDocument18 pagesCentury Paper and Pulp Lalkuan (Udham Singh Nagar) : A Project Report OnMedical SherniNo ratings yet

- CO2 Blast CleaningDocument30 pagesCO2 Blast CleaningkangsungjinNo ratings yet

- Gas ManifoldDocument3 pagesGas ManifoldTanmayNo ratings yet

- Busbar Trunking SystemDocument21 pagesBusbar Trunking SystemJordan Ansh50% (2)

- Insulect Specification PDFDocument10 pagesInsulect Specification PDFThuan NguyenNo ratings yet

- Bhel (Transformer) Major TrainingDocument33 pagesBhel (Transformer) Major TrainingArpitSinghNo ratings yet

- Industrial Air CleanersDocument4 pagesIndustrial Air CleanerssalgoraNo ratings yet

- Cable Reeling DrumDocument4 pagesCable Reeling DrumBanamali NaskarNo ratings yet

- Ako - Cnc65 Tube Bending MachineDocument30 pagesAko - Cnc65 Tube Bending MachineNguyen Quyet Thang100% (1)

- TPM Wabco-Tvs (India) LTDDocument46 pagesTPM Wabco-Tvs (India) LTDpnithiy_elecNo ratings yet

- Millennium STEEL - Strip Cleaning TechnologyDocument5 pagesMillennium STEEL - Strip Cleaning Technologyaliali2662No ratings yet

- CrawlerMobileCrusher SDocument7 pagesCrawlerMobileCrusher Sjoyalcrusher100% (1)

- REI 2019 Show Directory - Third Cut-MinDocument419 pagesREI 2019 Show Directory - Third Cut-Minmahajan.gouravNo ratings yet

- REI 2019 Show Directory - Third Cut-Min PDFDocument419 pagesREI 2019 Show Directory - Third Cut-Min PDFManish Gade पिंपरी चिचंवडNo ratings yet

- Internship Report: Training Centre - Mysore ComplexDocument28 pagesInternship Report: Training Centre - Mysore Complexshubhashini K NNo ratings yet

- SCR Carterpillar (Catalistico de Reducion Selectiva)Document4 pagesSCR Carterpillar (Catalistico de Reducion Selectiva)Jesus Almanzar Santos100% (1)

- CTM Catalogue 2015-2016Document100 pagesCTM Catalogue 2015-2016Anonymous dXcoknUNo ratings yet

- Coating AluminiumDocument9 pagesCoating AluminiumNadangol DangolNo ratings yet

- Submitted: BY: Name-Kartik Tyagi Branch/year-M.E (4 Year Roll No:-1503340102Document29 pagesSubmitted: BY: Name-Kartik Tyagi Branch/year-M.E (4 Year Roll No:-1503340102kartik tyagiNo ratings yet

- Electromat CatalogueDocument24 pagesElectromat Cataloguekvramanan_1No ratings yet

- Scomi Oiltools DWMS OverviewDocument16 pagesScomi Oiltools DWMS Overviewmojtaba_m007No ratings yet

- Cone CrusherDocument3 pagesCone Crusherchand_yelNo ratings yet

- Amaron PowerstackDocument6 pagesAmaron PowerstackmuralieshNo ratings yet

- Seminar PPT AutomationDocument27 pagesSeminar PPT Automationamitesh_iitkgp83No ratings yet

- SPP@KSCST - Iisc.ernet - in WWW - Kscst.iisc - Ernet.in/spp - HTML: Karnataka State Council For Science and TechnologyDocument12 pagesSPP@KSCST - Iisc.ernet - in WWW - Kscst.iisc - Ernet.in/spp - HTML: Karnataka State Council For Science and TechnologyterminalcbrNo ratings yet

- Caterpillar 320cDocument28 pagesCaterpillar 320ccamelia_pirjan5776100% (3)

- Variac MFG Business Plan Annexure - 1Document6 pagesVariac MFG Business Plan Annexure - 1Manav MatetiNo ratings yet

- Portable Dust Extraction SystemDocument1 pagePortable Dust Extraction Systemswakinjesu100% (1)

- MFD - Profile P IV Sept 19Document58 pagesMFD - Profile P IV Sept 19Marketing - Magna Industries - Metal Product DivisionNo ratings yet

- 320cl (8f6)Document28 pages320cl (8f6)Andres VargasNo ratings yet

- Ice BlastingDocument20 pagesIce BlastingshervinyNo ratings yet

- Alsons PresentationDocument19 pagesAlsons PresentationAditya VuthaNo ratings yet

- MaintenanceConcerns Carbon BrushesDocument10 pagesMaintenanceConcerns Carbon Brusheskamal_khan85No ratings yet

- TC Spinners MOM - Merged - OrganizedDocument9 pagesTC Spinners MOM - Merged - OrganizedShubham BishnoiNo ratings yet

- EDX5-3.Miller 500 Eco PDFDocument8 pagesEDX5-3.Miller 500 Eco PDFDen BagusNo ratings yet

- Design and Fabrication of A Pedal-Operat PDFDocument7 pagesDesign and Fabrication of A Pedal-Operat PDFAlrhon John Dequilla EstigoyNo ratings yet

- Baumüller DCmotor - GbtrainingDocument7 pagesBaumüller DCmotor - GbtrainingMamunur RashidNo ratings yet

- Auto Tube Cleaning SystemDocument2 pagesAuto Tube Cleaning SystemTeo Pei SanNo ratings yet

- Genus Electrotech LTD.: WWW - Genuselectrotech.co - inDocument41 pagesGenus Electrotech LTD.: WWW - Genuselectrotech.co - inRam RamNo ratings yet

- Mak Hydrol: Industrial Hydraulic Fluid For Superior Performance and ProtectionDocument3 pagesMak Hydrol: Industrial Hydraulic Fluid For Superior Performance and Protectionchandan sahooNo ratings yet

- GL XX Mobilgear MS SeriesDocument3 pagesGL XX Mobilgear MS Seriesanibal_rios_rivasNo ratings yet

- Bhel ReportDocument13 pagesBhel ReportAtul TripathiNo ratings yet

- Vecom - Japanese BlackDocument2 pagesVecom - Japanese Blackdiaccessltd_17172961No ratings yet

- ASHOKADocument40 pagesASHOKAManish PatilNo ratings yet

- AKMH Selection Guide Rev B - En-UsDocument48 pagesAKMH Selection Guide Rev B - En-Usahmadf007No ratings yet

- BITUMEN REMOVAL and CLEANING MAINTENANCE SPECIFICSDocument2 pagesBITUMEN REMOVAL and CLEANING MAINTENANCE SPECIFICSoscar jackNo ratings yet

- ICS - Company Profile 2015Document13 pagesICS - Company Profile 2015nhariwijayaNo ratings yet

- Introduction About Internship Industry ProfileDocument35 pagesIntroduction About Internship Industry ProfileThushar DNo ratings yet

- Rotational Lining System and Use of High-Performance ThermoplasticsDocument11 pagesRotational Lining System and Use of High-Performance ThermoplasticsMubeenNo ratings yet

- CPC 100 Ordering Information ENUDocument33 pagesCPC 100 Ordering Information ENUDeepen SharmaNo ratings yet

- A Security Analysis and Secure Management Model For Scada SystemsDocument11 pagesA Security Analysis and Secure Management Model For Scada SystemsDeepen SharmaNo ratings yet

- ArticleDocument12 pagesArticleDeepen SharmaNo ratings yet

- DGPC/THP/HRAD/H&AD/2022/001479 Dated: 03/06/2022: TH THDocument3 pagesDGPC/THP/HRAD/H&AD/2022/001479 Dated: 03/06/2022: TH THDeepen SharmaNo ratings yet

- Work OrderDocument3 pagesWork OrderDeepen SharmaNo ratings yet

- 86 92 Kruger EngelenDocument7 pages86 92 Kruger EngelenDeepen SharmaNo ratings yet

- Data - Book - 132 KV Cable - NHPPDocument150 pagesData - Book - 132 KV Cable - NHPPDeepen SharmaNo ratings yet

- Cable Related ThesisDocument51 pagesCable Related ThesisDeepen SharmaNo ratings yet

- Alphabet Practice SheetDocument31 pagesAlphabet Practice SheetDeepen SharmaNo ratings yet

- Standard CapacitorsDocument2 pagesStandard CapacitorsDeepen SharmaNo ratings yet

- GT210-10 NGR W TransformerDocument2 pagesGT210-10 NGR W TransformerDeepen SharmaNo ratings yet

- UntitledDocument1 pageUntitledDeepen SharmaNo ratings yet

- 66kV Vltage Profile at CHP EndDocument1 page66kV Vltage Profile at CHP EndDeepen SharmaNo ratings yet

- Data Sheet 3RH2122-1BB40Document7 pagesData Sheet 3RH2122-1BB40Deepen SharmaNo ratings yet

- What's New in Mipower V 10.1 FinalDocument22 pagesWhat's New in Mipower V 10.1 FinalDeepen SharmaNo ratings yet

- UntitledDocument1 pageUntitledDeepen SharmaNo ratings yet

- Field Recalibration ReportDocument1 pageField Recalibration ReportDeepen SharmaNo ratings yet

- Technical Diagnostics For Power ApparatusDocument6 pagesTechnical Diagnostics For Power ApparatusDeepen SharmaNo ratings yet

- Cable System Transient Study Elforskrapport 2009 05Document141 pagesCable System Transient Study Elforskrapport 2009 05Deepen SharmaNo ratings yet

- Doble M4120 Ext Ref Application GuideDocument5 pagesDoble M4120 Ext Ref Application GuideDeepen SharmaNo ratings yet

- Application of HFCT and UHF Sensors in On-Line Partial Discharge Measurements For Insulation Diagnosis of High Voltage EquipmentDocument29 pagesApplication of HFCT and UHF Sensors in On-Line Partial Discharge Measurements For Insulation Diagnosis of High Voltage EquipmentDeepen SharmaNo ratings yet

- Panel Discussion & Expo: Free ParticipationDocument1 pagePanel Discussion & Expo: Free ParticipationDeepen SharmaNo ratings yet

- Checking Ground Electrode Impedance For Commercial, Industrial and Residential BuildingsDocument8 pagesChecking Ground Electrode Impedance For Commercial, Industrial and Residential BuildingsDeepen SharmaNo ratings yet

- Exide Classic OPzS - enDocument17 pagesExide Classic OPzS - enDeepen SharmaNo ratings yet

- How Complacency and Lax Protocols Led To The Nation's Second COVID-19 OutbreakDocument14 pagesHow Complacency and Lax Protocols Led To The Nation's Second COVID-19 OutbreakDeepen SharmaNo ratings yet

- VRF HVAC CatalogueDocument84 pagesVRF HVAC CatalogueDeepen Sharma100% (1)

- PTS 400.3, Class 0.02 Modular Three-Phase Portable Test SystemDocument15 pagesPTS 400.3, Class 0.02 Modular Three-Phase Portable Test SystemDeepen SharmaNo ratings yet

- Universal Blaster: Works With All Dry Ice FormsDocument2 pagesUniversal Blaster: Works With All Dry Ice FormsDeepen SharmaNo ratings yet

- Baras Kaam Accounts Cash Collection Details PDFDocument16,132 pagesBaras Kaam Accounts Cash Collection Details PDFDeepen SharmaNo ratings yet

- HRDC Out PassDocument1 pageHRDC Out PassDeepen SharmaNo ratings yet

- Advanced Driver-Assistance SystemsDocument15 pagesAdvanced Driver-Assistance Systemsfroggoand decrewNo ratings yet

- Data Management and Basics: Submitted To: Angammal Shanthi Ma'am Submitted By: Simran Gupta Prabir Das Himanshu NainDocument4 pagesData Management and Basics: Submitted To: Angammal Shanthi Ma'am Submitted By: Simran Gupta Prabir Das Himanshu NainSiddharth JhaNo ratings yet

- Mathematics 9Document5 pagesMathematics 9Van Mark TejadaNo ratings yet

- Sadsjryjtc74tv8Document3 pagesSadsjryjtc74tv8Fahad Qamar ParachaNo ratings yet

- 9 10 Curve Fitting and Interpolation Part 2Document32 pages9 10 Curve Fitting and Interpolation Part 2Marshall james G. RamirezNo ratings yet

- Modi MCM and VamDocument14 pagesModi MCM and VamJoneric RamosNo ratings yet

- ABB I-Bus KNX: Details and Solutions For Intelligent Building ControlDocument40 pagesABB I-Bus KNX: Details and Solutions For Intelligent Building ControlIorgoni LiviuNo ratings yet

- Kato-Prime 30 Welcome Bonus TC Feb2023-Mar2023Document2 pagesKato-Prime 30 Welcome Bonus TC Feb2023-Mar2023Tanjong Minyak Car Wash Sdn BhdNo ratings yet

- Challenge of Artificial IntelligenceDocument230 pagesChallenge of Artificial IntelligenceDragosNo ratings yet

- Elective Local Official'S Personal Data Sheet: PictureDocument3 pagesElective Local Official'S Personal Data Sheet: PictureYdnic OirelagNo ratings yet

- Guhan Mahalingam: Assembly EngineerDocument2 pagesGuhan Mahalingam: Assembly EngineerGuhan MNo ratings yet

- Classes & Objects-Examples C++Document12 pagesClasses & Objects-Examples C++Aer ZNo ratings yet

- 818 IC Pump: ManualDocument56 pages818 IC Pump: ManualKhalid Zghear100% (1)

- 27-Com-Su-5191-A Coating SystemsDocument81 pages27-Com-Su-5191-A Coating Systemsaslam.amb100% (1)

- Introduktion ToDocument15 pagesIntroduktion TomotadollyNo ratings yet

- Dsoc201 22231 1Document6 pagesDsoc201 22231 1MANU KaliaNo ratings yet

- Reyax RYWDB00 - ENDocument10 pagesReyax RYWDB00 - ENAMNo ratings yet

- Maha Manual 16 de Juli 2021Document21 pagesMaha Manual 16 de Juli 2021GERARDO SAYAGONo ratings yet

- DONE - Princess AmaradeviDocument6 pagesDONE - Princess AmaradeviBolo Bolo BoloNo ratings yet

- TDS Meyco Sa 167 PDFDocument3 pagesTDS Meyco Sa 167 PDFYasin AykanatNo ratings yet

- Chapter 2: Analyzing The Business Case: Kp24103 System Analysis & DesignDocument17 pagesChapter 2: Analyzing The Business Case: Kp24103 System Analysis & DesignMae XNo ratings yet

- Time Relay With External Potentiometer: CRM-91HE, CRM-2HEDocument1 pageTime Relay With External Potentiometer: CRM-91HE, CRM-2HEMartin CinčićNo ratings yet

- SMP-030 - Copia2Document23 pagesSMP-030 - Copia2Nelson RNo ratings yet

- HASEE HP500 - QUANTA SW7 - REV 1ASecDocument41 pagesHASEE HP500 - QUANTA SW7 - REV 1ASecAdam TsiolakakisNo ratings yet

- Facility Layout DesigningDocument45 pagesFacility Layout DesigningAkash SinghNo ratings yet

- imageCLASS MF230 Series SpecSheetDocument4 pagesimageCLASS MF230 Series SpecSheetPablo MartinezNo ratings yet

- Cloud Computing - WikipediaDocument24 pagesCloud Computing - Wikipediajustin time compilerNo ratings yet

- MathsDocument20 pagesMathstlabNo ratings yet

- Diat Certified Information Assurance Professional: An Online Training & Certification Programme byDocument4 pagesDiat Certified Information Assurance Professional: An Online Training & Certification Programme byV K BNo ratings yet

- Squad3.fire NSD GPMDocument7 pagesSquad3.fire NSD GPMMac CorpuzNo ratings yet