Professional Documents

Culture Documents

Ode Solenoid Valve 21wa3z0b130 - 21wa4z0b130

Ode Solenoid Valve 21wa3z0b130 - 21wa4z0b130

Uploaded by

Uno MariconOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ode Solenoid Valve 21wa3z0b130 - 21wa4z0b130

Ode Solenoid Valve 21wa3z0b130 - 21wa4z0b130

Uploaded by

Uno MariconCopyright:

Available Formats

Solenoid valve 2/2 way N.O.

21WA3Z0B130

÷

With pilot control 21WA4Z0B130

PRESENTATION:

S.V. with pilot control for interception of fluids compatible with

the construction materials. .

A minimum operational pressure of 0,2 bar is required.

The materials used and the tests carried out ensure maximum

reliability and duration.

USE: Automation

Heating

PIPE: G 3/8 - G 1/2

COILS: 8W - Ø 13

BDA - BDS - BSA 155°C (class F)

BDP 160°C (high temperature)

BDF - BDV 180°C (class H)

MOULDING AND BOBBIN ARE MADE BY 100% VIRGIN

MATERIAL.

Max. allowable pressure (PS) 20 bar

Environment temperature:

with coil class F or high temperature - 10°C + 60°C

with coil class H - 10°C + 80°C

Gaskets Temperature Medium

B=NBR (nitrile rubber) - 10°C + 90°C Air, inert gas, water

E=EPDM

- 10°C +140°C Water, low pressure steam

(ethylene-propylene)

Mineral oils (2°E), gasoline

V=FKM (fluoroelastomer) - 10°C +140°C

gas oil

For seals other than NBR replace the letter “B” with the ones

corresponding to theother seals. E.I. 21WA3Z0V130.

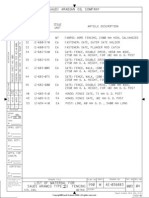

Ø Pressure

Pipe Max viscosity Kv Power

Code min M.O.P.D.

ISO 228/1

cSt °E mm l/mn (watt) bar AC bar DC bar

G 3/8 21WA3Z0B130 60

12 ~2 13 8 0,2 16 16

G 1/2 21WA4Z0B130 70

The “ODE ” reserves the right to carry out technical and aesthetic modifications without prior notification.

05-03-2009 ODE 21WA3Z0B130 ÷ 21WA4Z0B130

MATERIALS:

Body Brass - UNI EN 12165 CW617N

Armature tube Stainless steel AISI series 300

Fixed core Stainless steel AISI series 400

Plunger Stainless steel AISI series 400

Phase displacement ring Copper - Cu 99,9%

Spring Stainless steel AISI series 300

Seal Standard: B=NBR

On request: E=EPDM V=FKM

Orifice Brass - UNI EN 12165 CW617N

On request:

Connector Pg 9 or Pg 11

Connector conformity ISO 4400

FEATURES:

Electrical conformity IEC 335

Protection degree IP 65 EN 60529 (DIN 40050)

with coil fitted by connector.

SPARE PARTS:

1. Coil: KIT:

See coils list KT130KB30-A=2+3

2. Complete plunger:

Code R450886/B MAINTENANCE KIT:

3. Complete armature tube: G 3/4-G 1

Code R450606 KTG0W3KB19=2+4+5

4. Gasket O-Ring: G 1 1/4-G 1 1/2

G 3/4-G 1 Code R990002/B KTG0W5KB35=2+4+5

G 1 1/4-G 1 1/2 Code R990005/B G2

G2 Code R990081/B KTG0W7KB50=2+4+5

5. Complete diaphragm:

G 3/4-G 1 Code R450431/B

G 1 1/4-G 1 1/2 Code R450466/B

G2 Code R450432/B

DIMENSIONS:

Pipe A B C

Type

ISO 228/1 mm mm mm

COIL POWER ABSORPTION DIMENSIONS

21W3KB190 G 3/4 105

65 104 W Inrush Hold TYPE D E F

21W4KB250 G1 112

VA ~ VA ~ mm mm mm

21W5KB350 G 1 1/4

98 125 144 8W 25 14,5 B 30 42 54

21W6KB400 G 1 1/4

21W7KB500 G2 118 141 172

21W3KB190 ÷ 21W7KB500 ODE 05-03-2009

You might also like

- 01 - ENG - Archlesia - Interiorbook 1 - Free - 2Document14 pages01 - ENG - Archlesia - Interiorbook 1 - Free - 2joshe C.A89% (9)

- Clamps, Utility, Laboratory, and Holders, Buret and Clamp: Standard Specification ForDocument6 pagesClamps, Utility, Laboratory, and Holders, Buret and Clamp: Standard Specification ForAhmed AlzubaidiNo ratings yet

- Company OIL Saudi Arabian: MNL JUL 86Document1 pageCompany OIL Saudi Arabian: MNL JUL 86RanielNo ratings yet

- Kira + Andrew Cartagena GuideDocument20 pagesKira + Andrew Cartagena GuideKira & Andrew100% (1)

- Combination of Microneedling and Glycolic Acid Peels For TheDocument7 pagesCombination of Microneedling and Glycolic Acid Peels For Thealejandrogonzalez89No ratings yet

- Problems That Aarong Solves Potential Customers UpdatedDocument3 pagesProblems That Aarong Solves Potential Customers UpdatedMd.TahmidNo ratings yet

- Katalog Came PDFDocument242 pagesKatalog Came PDFTsuronoNo ratings yet

- Park Map ENDocument2 pagesPark Map ENashkan2000sgNo ratings yet

- Corten Steel: Adriano Claudio Scarfo 547503Document17 pagesCorten Steel: Adriano Claudio Scarfo 547503Adriano Claudio ScarfoNo ratings yet

- Fevicol PurDocument3 pagesFevicol PurVenkata ChadaNo ratings yet

- Steel Fire-Rated Doors and Multi-Purpose DoorsDocument20 pagesSteel Fire-Rated Doors and Multi-Purpose DoorsJhon BantingNo ratings yet

- WWW Amardeepsteel Com Corten Steel Products HTMLDocument1 pageWWW Amardeepsteel Com Corten Steel Products HTMLAmardeep steelNo ratings yet

- Ae 036883 003Document1 pageAe 036883 003narutothunderjet216100% (1)

- Olv SV 630 - 750 BF enDocument54 pagesOlv SV 630 - 750 BF enzniwiarz3410100% (1)

- Thecnical Catalog 2011 (English)Document168 pagesThecnical Catalog 2011 (English)felipeobradorNo ratings yet

- Ae 036881 002Document1 pageAe 036881 002narutothunderjet216No ratings yet

- Tosaca Catalogue PDFDocument16 pagesTosaca Catalogue PDFgabNo ratings yet

- Ul AppletonDocument2 pagesUl AppletonDIEGO SANCHEZ100% (1)

- Steel Properties Material Grade Comparison ChartDocument1 pageSteel Properties Material Grade Comparison Chartgk80823No ratings yet

- Safety Data Sheet NALCON® 7634: Section: 1. Product and Company IdentificationDocument12 pagesSafety Data Sheet NALCON® 7634: Section: 1. Product and Company IdentificationFSAAVEDRAFNo ratings yet

- Farrisone: Home Notices Sales and Marketing Technical Documents Training Order InformationDocument1 pageFarrisone: Home Notices Sales and Marketing Technical Documents Training Order InformationAlexander Charry GiraldoNo ratings yet

- SS Surface FinishesDocument1 pageSS Surface FinishesWendyNo ratings yet

- Ficha Tecnica Careta Warrior Tech 9-13 Helmet EsabDocument2 pagesFicha Tecnica Careta Warrior Tech 9-13 Helmet EsabJACQUELINE CASTILLONo ratings yet

- Airtech - Pc51-Z - OrderingDocument4 pagesAirtech - Pc51-Z - OrderingSnaider SilveraNo ratings yet

- KSR 1003 H e Side Mounted Magnetic Float SwitchesDocument20 pagesKSR 1003 H e Side Mounted Magnetic Float SwitchesRoshan ShanmughanNo ratings yet

- Automatizacija ESAB PDFDocument100 pagesAutomatizacija ESAB PDFsocomenin2013No ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Mip - Chain Va.754Document16 pagesMip - Chain Va.754Jiggy JickNo ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Catalogo GIACOMINIDocument45 pagesCatalogo GIACOMINIIsrael Silva Hgo.No ratings yet

- Ss Grade 50 - Galvanized Steel Coils & SheetsDocument1 pageSs Grade 50 - Galvanized Steel Coils & SheetshealgoseNo ratings yet

- 1.9.1.2-ALCRO - Arc Sprayed Iron-Chrome-Aluminum WireDocument4 pages1.9.1.2-ALCRO - Arc Sprayed Iron-Chrome-Aluminum WirechonubobbyNo ratings yet

- Canalta Parts CatalogueDocument27 pagesCanalta Parts CatalogueFer VF100% (1)

- Galvosil 15680 Data SheetDocument2 pagesGalvosil 15680 Data Sheetn00b1810No ratings yet

- VV450 Parts Manual For CustomerDocument55 pagesVV450 Parts Manual For CustomerRoy F Bastari100% (1)

- 5806en PDFDocument94 pages5806en PDFSofian AmaraNo ratings yet

- Wellmark PSVDocument6 pagesWellmark PSVHomer SilvaNo ratings yet

- Product Catalogue - BussmannDocument2 pagesProduct Catalogue - Bussmannavishai04No ratings yet

- Forney TA-1252 CO-PILOT USER MANUAL V3.3 - S3Document14 pagesForney TA-1252 CO-PILOT USER MANUAL V3.3 - S3wdcarson27No ratings yet

- Aplikasi Flexible Connector Food GradeDocument23 pagesAplikasi Flexible Connector Food GraderafiradityaNo ratings yet

- Alloy Cross Reference Table PDFDocument4 pagesAlloy Cross Reference Table PDFChad MitchellNo ratings yet

- ATC BrochureDocument24 pagesATC BrochureCésar HermosoNo ratings yet

- Tyco Catalogue NetDocument34 pagesTyco Catalogue NetAhmad Nasser0% (1)

- Ace Group Rev 7Document1 pageAce Group Rev 7Tezso JacobNo ratings yet

- Technical Specification For Perforated DIN RAILDocument9 pagesTechnical Specification For Perforated DIN RAILFrancis SonkengNo ratings yet

- Ydfc-Mde English IomDocument13 pagesYdfc-Mde English IomMichael FutolNo ratings yet

- Cosmotec Panel CoolingDocument11 pagesCosmotec Panel CoolingsaedmarwaNo ratings yet

- EN 12277 enDocument1 pageEN 12277 enDean WilyNo ratings yet

- Central Station Double Skin Air Handling Units: TW/TWH SeriesDocument53 pagesCentral Station Double Skin Air Handling Units: TW/TWH Seriesjana perumalNo ratings yet

- Lista de Componentes ExC3000Document1 pageLista de Componentes ExC3000pressisoNo ratings yet

- PX185 - PX300 Installation ManualDocument25 pagesPX185 - PX300 Installation Manualasifaliabid100% (1)

- Catalog AccadoDocument87 pagesCatalog AccadobizzplussNo ratings yet

- Kalpraxis Cement Plants PDFDocument14 pagesKalpraxis Cement Plants PDFalbertbunguriNo ratings yet

- Cooper Cameron ValveDocument2 pagesCooper Cameron ValveKishor VananNo ratings yet

- Siemens Euroset 802 ManualDocument2 pagesSiemens Euroset 802 ManualAr MaNo ratings yet

- STING - Technical Catalogue 8210GB 200902Document52 pagesSTING - Technical Catalogue 8210GB 200902hungdinhthanhNo ratings yet

- Shell Gadus S2 V100 2Document2 pagesShell Gadus S2 V100 2Muhammad SaputraNo ratings yet

- Solenoide Ode - GenebreDocument10 pagesSolenoide Ode - GenebreRenzo Huarcaya HuaraccNo ratings yet

- Solenoid ValveDocument2 pagesSolenoid ValveHeru PurwantoNo ratings yet

- Solenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Document2 pagesSolenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Ramius HamdaniNo ratings yet

- 6 21a2k0e45 or 1 4Document2 pages6 21a2k0e45 or 1 4Juan PiñerosNo ratings yet

- 6 Solenoid Valve ODEDocument2 pages6 Solenoid Valve ODEHA TRADINGSNo ratings yet

- 21XN4K1V120Document2 pages21XN4K1V120Ramius HamdaniNo ratings yet

- Organization TheoryDocument21 pagesOrganization Theoryvenkataramanan89% (9)

- Spouses Tapayan v. Ponceda MartinezDocument3 pagesSpouses Tapayan v. Ponceda MartinezDGDelfinNo ratings yet

- Dr. Lamia El Wakeel, PhD. Lecturer of Clinical Pharmacy Ain Shams UniversityDocument19 pagesDr. Lamia El Wakeel, PhD. Lecturer of Clinical Pharmacy Ain Shams UniversitysamvetNo ratings yet

- Regular: Akkurat LL AraDocument23 pagesRegular: Akkurat LL ArablackinNo ratings yet

- Senior High School Students' Academic Stress, Academic Motivation, and Its Relationship With Their Academic PerformanceDocument45 pagesSenior High School Students' Academic Stress, Academic Motivation, and Its Relationship With Their Academic PerformanceInternational Publication100% (1)

- Table SettingDocument4 pagesTable SettingBianca FormantesNo ratings yet

- Life Insurance Closed Books and Related Management ChallengesDocument2 pagesLife Insurance Closed Books and Related Management ChallengesVenkatakrishnan RamachandranNo ratings yet

- Introduction To Mobile Robotics 6-Week Immersion Unit: Goal: Introduce Students ToDocument3 pagesIntroduction To Mobile Robotics 6-Week Immersion Unit: Goal: Introduce Students ToRio ArdianNo ratings yet

- FGD GypsumDocument15 pagesFGD GypsumAnonymous 0vtkoS155No ratings yet

- Trimestral LogicDocument4 pagesTrimestral LogicGabriel FigueroaNo ratings yet

- Assignment/ Tugasan - Basic Interpersonal CommunicationDocument4 pagesAssignment/ Tugasan - Basic Interpersonal CommunicationMuhamad SaifulNo ratings yet

- Gumis - Cruising - English - v.2.0Document20 pagesGumis - Cruising - English - v.2.0KESSLER OFFSHORENo ratings yet

- Lesson 1 Practice 3Document1 pageLesson 1 Practice 3Omar LópezNo ratings yet

- Back Shu PointsDocument2 pagesBack Shu Pointspenfo100% (2)

- Sun City Biker - November 2011Document24 pagesSun City Biker - November 2011Spotlight EP NewsNo ratings yet

- Editing EssayDocument7 pagesEditing Essayapi-581857550No ratings yet

- Regmi 07Document257 pagesRegmi 07Abhimanyu KumarNo ratings yet

- Reivew Quizz 4 MKTDocument103 pagesReivew Quizz 4 MKTNguyen Duong Tu Quynh (K17 HCM)No ratings yet

- What Is An Injunction? When Can You Get One?Document2 pagesWhat Is An Injunction? When Can You Get One?FindLawNo ratings yet

- Haryana Naib Tehsildar Exam 2015 Most Expected Questions (Free Sample)Document6 pagesHaryana Naib Tehsildar Exam 2015 Most Expected Questions (Free Sample)Ruby SinghNo ratings yet

- Week 1&2-CPHM PDFDocument4 pagesWeek 1&2-CPHM PDFAziz AyobNo ratings yet

- Business Level StrategyDocument35 pagesBusiness Level StrategyShiva Kumar Dunaboina100% (1)

- Claremont COURIER 11-13-15Document28 pagesClaremont COURIER 11-13-15Peter WeinbergerNo ratings yet

- Answers To Russell and Norvig Question 7.3Document6 pagesAnswers To Russell and Norvig Question 7.3Hassan AbuduNo ratings yet

- Unit 1: The Unending Conversation: Guiding QuestionsDocument3 pagesUnit 1: The Unending Conversation: Guiding QuestionsJUAN GALLON MONCAYONo ratings yet

- Carotenoids: Actual Knowledge On Food Sources, Intakes, Stability and Bioavailability and Their Protective Role in HumansDocument25 pagesCarotenoids: Actual Knowledge On Food Sources, Intakes, Stability and Bioavailability and Their Protective Role in HumansGalinaNo ratings yet