Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

10 viewsPressure Vessels Lectures 74

Pressure Vessels Lectures 74

Uploaded by

Adeel NizamiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ever So Sleightly Martin Nash I PDFDocument2 pagesEver So Sleightly Martin Nash I PDFGary0% (2)

- Sample BQ 1Document76 pagesSample BQ 1marani_rahmat100% (2)

- Fundamentals of Electrical EngineeringDocument48 pagesFundamentals of Electrical EngineeringGee DeeNo ratings yet

- Modern Digital and Analog Communication Systems 4th Edition by LathiDocument926 pagesModern Digital and Analog Communication Systems 4th Edition by Lathimhmd_4u82% (11)

- Pressure Vessels Lectures 98Document1 pagePressure Vessels Lectures 98Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 94Document1 pagePressure Vessels Lectures 94Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 96Document1 pagePressure Vessels Lectures 96Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 95Document1 pagePressure Vessels Lectures 95Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 92Document1 pagePressure Vessels Lectures 92Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 99Document1 pagePressure Vessels Lectures 99Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 88Document1 pagePressure Vessels Lectures 88Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 93Document1 pagePressure Vessels Lectures 93Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 86Document1 pagePressure Vessels Lectures 86Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 84Document1 pagePressure Vessels Lectures 84Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 77Document1 pagePressure Vessels Lectures 77Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 69Document1 pagePressure Vessels Lectures 69Adeel NizamiNo ratings yet

- Table U-3 Year of Acceptable Edition of Referenced Standards in This Division (Cont'd)Document1 pageTable U-3 Year of Acceptable Edition of Referenced Standards in This Division (Cont'd)Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 23Document1 pageLectures Pressure Vessels 23Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 70Document1 pagePressure Vessels Lectures 70Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 85Document1 pagePressure Vessels Lectures 85Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 71Document1 pagePressure Vessels Lectures 71Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 64Document1 pagePressure Vessels Lectures 64Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 30Document1 pageLectures Pressure Vessels 30Adeel NizamiNo ratings yet

- Table U-3 Year of Acceptable Edition of Referenced Standards in This DivisionDocument1 pageTable U-3 Year of Acceptable Edition of Referenced Standards in This DivisionAdeel NizamiNo ratings yet

- Pressure Vessels Lectures 63Document1 pagePressure Vessels Lectures 63Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 21Document1 pageLectures Pressure Vessels 21Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 22Document1 pageLectures Pressure Vessels 22Adeel NizamiNo ratings yet

- Aerodrome Light PDFDocument120 pagesAerodrome Light PDF조준희No ratings yet

- Cisco CMR SidekickDocument4 pagesCisco CMR SidekickCisco ITNo ratings yet

- Drupal HandbookDocument458 pagesDrupal HandbookibnyadamNo ratings yet

- Ecs g31t-m Rev 1.0 SCHDocument28 pagesEcs g31t-m Rev 1.0 SCHiskenderbeyNo ratings yet

- F607OTSFP Válvula de Compuerta NibcoDocument1 pageF607OTSFP Válvula de Compuerta NibcoAlberth Rojas CastellanosNo ratings yet

- Deep Sea MooringDocument20 pagesDeep Sea MooringsujitNo ratings yet

- Entekochi Design Competition: Section A:2 S:3 A2.S3Document1 pageEntekochi Design Competition: Section A:2 S:3 A2.S3Kripa KBabyNo ratings yet

- Open-Delta or V-V ConnectionDocument2 pagesOpen-Delta or V-V ConnectionbudituxNo ratings yet

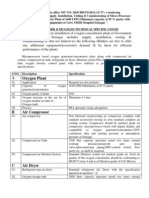

- Oxygen Plant: B Air CompressorDocument3 pagesOxygen Plant: B Air Compressorsumit11235No ratings yet

- Manual Unigas Urb4Document28 pagesManual Unigas Urb4Maurice LachaudNo ratings yet

- S K Sharma Water Chemistry in Thermal Power PlantsDocument54 pagesS K Sharma Water Chemistry in Thermal Power PlantsJayanath Nuwan SameeraNo ratings yet

- Dictionar Tehnic RomanDocument62 pagesDictionar Tehnic RomanAdi UdreaNo ratings yet

- Prepaid Customer Application Form: Mr. Mrs. MsDocument18 pagesPrepaid Customer Application Form: Mr. Mrs. MsDarjeeling Cyber Crime PSNo ratings yet

- Bunkering Checklist - Attachment XXVIDocument3 pagesBunkering Checklist - Attachment XXVIFaiqah AzmirNo ratings yet

- Pure Car CarrierDocument20 pagesPure Car CarrierzaheerbcNo ratings yet

- 9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Document3 pages9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Urke VukNo ratings yet

- FormulasDocument5 pagesFormulasPremNo ratings yet

- Victrix-24-TT-2ErP - 1039151 - 003Document48 pagesVictrix-24-TT-2ErP - 1039151 - 003Admin TestNo ratings yet

- Conducting Polymers: 22-2-96 by Colin PrattDocument7 pagesConducting Polymers: 22-2-96 by Colin PrattkshitijscribdNo ratings yet

- STR-De495 & DE595 Service ManualDocument54 pagesSTR-De495 & DE595 Service ManualwecomanniNo ratings yet

- 6A MPS, 600 Volts N-CHANNEL MOSFET: FeatureDocument2 pages6A MPS, 600 Volts N-CHANNEL MOSFET: FeatureJose VelasquezNo ratings yet

- Decon 1Document3 pagesDecon 1Lily Suherlina AhmadNo ratings yet

- An Agent of The Black Nobility Betrays HimselfDocument20 pagesAn Agent of The Black Nobility Betrays Himselfkaren hudes100% (1)

- Sinewave Inverter Using ArduinoDocument3 pagesSinewave Inverter Using Arduinomaurilioctba100% (1)

- Interview Questions: 4) What Is Difference Between Hierarchical and Constraint Picklist?Document7 pagesInterview Questions: 4) What Is Difference Between Hierarchical and Constraint Picklist?chanduNo ratings yet

- 9783319395913Document214 pages9783319395913iki292100% (1)

Pressure Vessels Lectures 74

Pressure Vessels Lectures 74

Uploaded by

Adeel Nizami0 ratings0% found this document useful (0 votes)

10 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views1 pagePressure Vessels Lectures 74

Pressure Vessels Lectures 74

Uploaded by

Adeel NizamiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

ASME BPVC.VIII.

1-2015 UG-12 – UG-16

(3) a suitable transition shall be provided between DESIGN

the root diameter and the unthreaded portion; and

UG-16 GENERAL

(4) particular consideration shall be given to any dy-

namic loadings. (a) The design of pressure vessels and vessel parts shall

conform to the general design requirements in the follow-

ing paragraphs and in addition to the specific require-

UG-13 NUTS AND WASHERS

ments for Design given in the applicable Parts of

(a) Nuts shall conform to the requirements in the ap- Subsections B and C.

plicable Part of Subsection C (see UCS-11 and UNF-13). (b) Minimum Thickness of Pressure Retaining Compo-

They shall engage the threads for the full depth of the nut. nents. Except for the special provisions listed below, the

(b) The use of washers is optional. When used, they minimum thickness permitted for shells and heads, after

shall be of wrought materials. forming and regardless of product form and material,

shall be 1/16 in. (1.5 mm) exclusive of any corrosion allow-

UG-14 RODS AND BARS ance. Exceptions are:

(1) the minimum thickness does not apply to heat

(a) Rod and bar stock may be used in pressure vessel transfer plates of plate‐type heat exchangers;

construction for pressure parts such as flange rings, stif- (2) this minimum thickness does not apply to the in-

fening rings, frames for reinforced openings, stays and ner pipe of double pipe heat exchangers nor to pipes and

stay‐bolts, and similar parts. Rod and bar materials shall tubes that are enclosed and protected from mechanical

conform to the requirements for bars or bolting in the ap- damage by a shell, casing, or ducting, where such pipes

plicable part of Subsection C. or tubes are NPS 6 (DN 150) and less. This exemption ap-

(b) Except for flanges of all types, hollow cylindrically plies whether or not the outer pipe, shell, or protective

shaped parts [up to and including NPS 4 (DN 100)] may element is constructed to Code rules. When the outer pro-

be machined from rod or bar, provided that the axial tective element is not provided by the Manufacturer as

length of the part is approximately parallel to the metal part of the vessel, the Manufacturer shall note this on

flow lines of the stock. Other parts, such as heads or caps the Manufacturer’s Data Report, and the owner or his de-

[up to and including NPS 4 (DN 100)], not including signated agent shall be responsible to assure that the re-

flanges, may be machined from rod or bar. Elbows, return quired enclosures are installed prior to operation. Where

bends, tees, and header tees shall not be machined di- pipes and tubes are fully enclosed, consideration shall be

rectly from rod or bar. given to avoiding buildup of pressure within the protec-

tive chamber due to a tube/pipe leak. All other pressure

UG-15 PRODUCT SPECIFICATION parts of these heat exchangers that are constructed to

Code rules must meet the 1/16 in. (1.5 mm) minimum

When there is no material specification listed in Sub- thickness requirements.

section C covering a particular wrought product of a (3) the minimum thickness of shells and heads of un-

grade, but there is an approved specification listed in Sub- fired steam boilers shall be 1/4 in. (6 mm) exclusive of any

section C covering some other wrought product of that corrosion allowance;

grade, the product for which there is no specification (4) the minimum thickness of shells and heads used

may be used provided: in compressed air service, steam service, and water ser-

(a) the chemical and physical properties, heat treating vice, made from materials listed in Table UCS-23, shall

requirements, and requirements for deoxidation, or grain be 3/32 in. (2.5 mm) exclusive of any corrosion allowance.

size requirements conform to the approved specification (5) this minimum thickness does not apply to the

listed in Subsection C. The stress values for that specifica- tubes in air cooled and cooling tower heat exchangers if

tion given in the tables referenced in UG-23 shall be used. all the following provisions are met:

(b) the manufacturing procedures, tolerances, tests, (-a) the tubes shall not be used for lethal UW-2(a)

and marking are in accordance with a Section II specifica- service applications;

tion covering the same product form of a similar material; (-b) the tubes shall be protected by fins or other

(c) for the case of welded tubing made of plate, sheet, mechanical means;

or strip, without the addition of filler metal, the appropri- (-c) the tube outside diameter shall be a minimum

ate stress values are multiplied by a factor of 0.85; of 3/8 in. (10 mm) and a maximum of 11/2 in. (38 mm);

(d) the product is not pipe or tubing fabricated by fu- (-d) the minimum thickness used shall not be less

sion welding with the addition of filler metal unless it is than that calculated by the formulas given in UG-27 or

fabricated in accordance with the rules of this Division 1-1 and in no case less than 0.022 in. (0.5 mm).

as a pressure part; (c) Mill Undertolerance. Plate material shall be ordered

(e) mill test reports reference the specifications used in not thinner than the design thickness. Vessels made of

producing the material and in addition make reference to plate furnished with an undertolerance of not more than

this paragraph. the smaller value of 0.01 in. (0.25 mm) or 6% of the

13

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ever So Sleightly Martin Nash I PDFDocument2 pagesEver So Sleightly Martin Nash I PDFGary0% (2)

- Sample BQ 1Document76 pagesSample BQ 1marani_rahmat100% (2)

- Fundamentals of Electrical EngineeringDocument48 pagesFundamentals of Electrical EngineeringGee DeeNo ratings yet

- Modern Digital and Analog Communication Systems 4th Edition by LathiDocument926 pagesModern Digital and Analog Communication Systems 4th Edition by Lathimhmd_4u82% (11)

- Pressure Vessels Lectures 98Document1 pagePressure Vessels Lectures 98Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 94Document1 pagePressure Vessels Lectures 94Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 96Document1 pagePressure Vessels Lectures 96Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 95Document1 pagePressure Vessels Lectures 95Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 92Document1 pagePressure Vessels Lectures 92Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 99Document1 pagePressure Vessels Lectures 99Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 88Document1 pagePressure Vessels Lectures 88Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 93Document1 pagePressure Vessels Lectures 93Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 86Document1 pagePressure Vessels Lectures 86Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 84Document1 pagePressure Vessels Lectures 84Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 77Document1 pagePressure Vessels Lectures 77Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 69Document1 pagePressure Vessels Lectures 69Adeel NizamiNo ratings yet

- Table U-3 Year of Acceptable Edition of Referenced Standards in This Division (Cont'd)Document1 pageTable U-3 Year of Acceptable Edition of Referenced Standards in This Division (Cont'd)Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 23Document1 pageLectures Pressure Vessels 23Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 70Document1 pagePressure Vessels Lectures 70Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 85Document1 pagePressure Vessels Lectures 85Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 71Document1 pagePressure Vessels Lectures 71Adeel NizamiNo ratings yet

- Pressure Vessels Lectures 64Document1 pagePressure Vessels Lectures 64Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 30Document1 pageLectures Pressure Vessels 30Adeel NizamiNo ratings yet

- Table U-3 Year of Acceptable Edition of Referenced Standards in This DivisionDocument1 pageTable U-3 Year of Acceptable Edition of Referenced Standards in This DivisionAdeel NizamiNo ratings yet

- Pressure Vessels Lectures 63Document1 pagePressure Vessels Lectures 63Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 21Document1 pageLectures Pressure Vessels 21Adeel NizamiNo ratings yet

- Lectures Pressure Vessels 22Document1 pageLectures Pressure Vessels 22Adeel NizamiNo ratings yet

- Aerodrome Light PDFDocument120 pagesAerodrome Light PDF조준희No ratings yet

- Cisco CMR SidekickDocument4 pagesCisco CMR SidekickCisco ITNo ratings yet

- Drupal HandbookDocument458 pagesDrupal HandbookibnyadamNo ratings yet

- Ecs g31t-m Rev 1.0 SCHDocument28 pagesEcs g31t-m Rev 1.0 SCHiskenderbeyNo ratings yet

- F607OTSFP Válvula de Compuerta NibcoDocument1 pageF607OTSFP Válvula de Compuerta NibcoAlberth Rojas CastellanosNo ratings yet

- Deep Sea MooringDocument20 pagesDeep Sea MooringsujitNo ratings yet

- Entekochi Design Competition: Section A:2 S:3 A2.S3Document1 pageEntekochi Design Competition: Section A:2 S:3 A2.S3Kripa KBabyNo ratings yet

- Open-Delta or V-V ConnectionDocument2 pagesOpen-Delta or V-V ConnectionbudituxNo ratings yet

- Oxygen Plant: B Air CompressorDocument3 pagesOxygen Plant: B Air Compressorsumit11235No ratings yet

- Manual Unigas Urb4Document28 pagesManual Unigas Urb4Maurice LachaudNo ratings yet

- S K Sharma Water Chemistry in Thermal Power PlantsDocument54 pagesS K Sharma Water Chemistry in Thermal Power PlantsJayanath Nuwan SameeraNo ratings yet

- Dictionar Tehnic RomanDocument62 pagesDictionar Tehnic RomanAdi UdreaNo ratings yet

- Prepaid Customer Application Form: Mr. Mrs. MsDocument18 pagesPrepaid Customer Application Form: Mr. Mrs. MsDarjeeling Cyber Crime PSNo ratings yet

- Bunkering Checklist - Attachment XXVIDocument3 pagesBunkering Checklist - Attachment XXVIFaiqah AzmirNo ratings yet

- Pure Car CarrierDocument20 pagesPure Car CarrierzaheerbcNo ratings yet

- 9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Document3 pages9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Urke VukNo ratings yet

- FormulasDocument5 pagesFormulasPremNo ratings yet

- Victrix-24-TT-2ErP - 1039151 - 003Document48 pagesVictrix-24-TT-2ErP - 1039151 - 003Admin TestNo ratings yet

- Conducting Polymers: 22-2-96 by Colin PrattDocument7 pagesConducting Polymers: 22-2-96 by Colin PrattkshitijscribdNo ratings yet

- STR-De495 & DE595 Service ManualDocument54 pagesSTR-De495 & DE595 Service ManualwecomanniNo ratings yet

- 6A MPS, 600 Volts N-CHANNEL MOSFET: FeatureDocument2 pages6A MPS, 600 Volts N-CHANNEL MOSFET: FeatureJose VelasquezNo ratings yet

- Decon 1Document3 pagesDecon 1Lily Suherlina AhmadNo ratings yet

- An Agent of The Black Nobility Betrays HimselfDocument20 pagesAn Agent of The Black Nobility Betrays Himselfkaren hudes100% (1)

- Sinewave Inverter Using ArduinoDocument3 pagesSinewave Inverter Using Arduinomaurilioctba100% (1)

- Interview Questions: 4) What Is Difference Between Hierarchical and Constraint Picklist?Document7 pagesInterview Questions: 4) What Is Difference Between Hierarchical and Constraint Picklist?chanduNo ratings yet

- 9783319395913Document214 pages9783319395913iki292100% (1)