Professional Documents

Culture Documents

Gulf Gear WT: High Performance Industrial Gear Oil

Gulf Gear WT: High Performance Industrial Gear Oil

Uploaded by

atripathi2009Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gulf Gear WT: High Performance Industrial Gear Oil

Gulf Gear WT: High Performance Industrial Gear Oil

Uploaded by

atripathi2009Copyright:

Available Formats

Gulf Gear WT

High performance Industrial Gear Oil

Product Description

Gulf Gear WT series are high performance extreme pressure oils designed for lubrication of heavy duty

industrial gears. These are formulated with high quality mineral base oils along with specially selected

additive technology to provide excellent load carrying capacity even under extreme conditions including

shock loading. These heavy duty Industrial gear oils provide excellent protection against scuffing and

resistance against micro-pitting in the gear boxes under wide operating temperature range and meets latest

Flender specifications.

Features & Benefits

Excellent load carrying and anti-friction characteristics reduce gear tooth and bearing wear.

Good oxidation and thermal stability help withstand high thermal loading and keeping system clean

by resisting sludge built up.

Excellent micro-pitting performance to reduce the risk of premature failure due to surface distress.

Special additive technology helps in clean gear performance under condition of high temperature

and oxidation.

Protects system from rust and corrosion even in presence of water contamination.

Compatible with generally used inside gear box paints and standard sealing materials.

Applications

Heavy duty Industrial gear transmissions requiring EP performance.

Circulating and splash lubricated systems.

Steel gear transmissions.

Recommended for use in gear boxes that requires lubricants meeting Flender specification.

Note:

1) While changing the gear oil, drain off the previous oil completely and inspect internally.

Flush the gear box with fresh Gulf Gear WT. Drain the flushed oil and then fill with fresh Gulf

Gear WT. For complete benefit, Gulf Gear WT should not be mixed with other lubricants.

2) Not recommended for use in automotive hypoid gears.

Specifications, Approvals & Typical Properties

Meets the following Specification VG 68 VG 100 VG 150 VG 220 VG 320 VG 460 VG 680

DIN 51517 Part III, AGMA 9005-E02 (EP) X X X X X X X

Flender FVA 54/7, AIST 224 X X X X

Has the following Approval

Siemens Revision 13 for Flender gear units X X X

Typical Properties

Test Parameters ASTM Typical Values

Viscosity @ 40 ºC, cSt D 445 66.16 101.2 145.2 221 322 462 682.4

Viscosity Index D 2270 100 97 96 97 98 98 91

Flash Point, ºC D 92 228 240 246 256 258 278 255

Density @ 15ºC, Kg/l D 1298 0.885 0.889 0.893 0.894 0.899 0.900 0.932

Pour Point D 97 -15 -15 -12 -15 -15 -9 -6

Copper Corrosion (3 hour @100 ºC) D130 1a 1a 1a 1a 1a 1a 1a

FZG scuffing load stage (A/16.6/90) DIN ISO 12 >12 >12 >12 >12 >12 >12

14635-1

March 2014

You might also like

- 82497524-2-ADM2-FRO (1) Mercedez PDFDocument155 pages82497524-2-ADM2-FRO (1) Mercedez PDFAndre VP100% (3)

- Chapter 02 PDFDocument12 pagesChapter 02 PDFshahin gholamiNo ratings yet

- Pune List Updated PDFDocument801 pagesPune List Updated PDFatripathi200960% (5)

- Lubricants For The Manufacturing IndustryDocument20 pagesLubricants For The Manufacturing IndustrynarenjiNo ratings yet

- TE90 Service ManualDocument0 pagesTE90 Service ManualJeferson SilvaNo ratings yet

- Gulf Synthetic Gear Oil - PAGDocument1 pageGulf Synthetic Gear Oil - PAGatripathi2009No ratings yet

- Gulf Oil Marine - Product Data SheetDocument10 pagesGulf Oil Marine - Product Data SheetObydur RahmanNo ratings yet

- 9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Document3 pages9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Urke VukNo ratings yet

- Approved Lubrication DDocument2 pagesApproved Lubrication DMostafa MohamedNo ratings yet

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshNo ratings yet

- Flender Gear UnitsDocument74 pagesFlender Gear Unitssdk00No ratings yet

- 01 BPA Food IndustryDocument29 pages01 BPA Food IndustryMAYANK AGARWALNo ratings yet

- Shell Melina S30: Performance, Features & BenefitsDocument2 pagesShell Melina S30: Performance, Features & BenefitsStefas DimitriosNo ratings yet

- Food Grade Brochure PDFDocument9 pagesFood Grade Brochure PDFMilena GonzalezNo ratings yet

- Report On Oil Types and Applications: 3 YearDocument5 pagesReport On Oil Types and Applications: 3 YearMahmoud KassabNo ratings yet

- Rimula R3 MV 15W40Document2 pagesRimula R3 MV 15W40AdiWijayaNo ratings yet

- Gulf Lubricants Brief ProfileDocument10 pagesGulf Lubricants Brief Profileatripathi2009100% (1)

- Gear Lubrication 3Document9 pagesGear Lubrication 3rashm006ranjan100% (1)

- GulfSea Synth Gear Oil PG 220 PDFDocument2 pagesGulfSea Synth Gear Oil PG 220 PDFObydur RahmanNo ratings yet

- Large Engine Lubricants: OutlineDocument17 pagesLarge Engine Lubricants: OutlineJahmia CoralieNo ratings yet

- AV51DOT1Document25 pagesAV51DOT1AnthonyNo ratings yet

- Gulf Marine Corporate Presentation Ppt2009 07Document22 pagesGulf Marine Corporate Presentation Ppt2009 07Philippe-Andre BoileauNo ratings yet

- 01.03.01 Coolant TR0199991209109 - enDocument18 pages01.03.01 Coolant TR0199991209109 - enEbied Yousif AlyNo ratings yet

- Bearings: Sliding Bearings Rolling Bearings Journal ThrustDocument3 pagesBearings: Sliding Bearings Rolling Bearings Journal ThrustShirishaVijayapuramNo ratings yet

- FH51 HydraulicFluid PDFDocument1 pageFH51 HydraulicFluid PDFSam GiovanniniNo ratings yet

- Shell Albida EMS2Document1 pageShell Albida EMS2Muhammad Haris BaigNo ratings yet

- Lube Oil AnalysisDocument8 pagesLube Oil AnalysisVuthpalachaitanya KrishnaNo ratings yet

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezNo ratings yet

- Aluminum Cold Mill Rolling Oil DistillationDocument3 pagesAluminum Cold Mill Rolling Oil DistillationbwelzNo ratings yet

- SS-150 Servo System Oil Details PDFDocument1 pageSS-150 Servo System Oil Details PDFJagadeesh SharanNo ratings yet

- GulfSea Power MDO Series PDFDocument2 pagesGulfSea Power MDO Series PDFObydur RahmanNo ratings yet

- Hydraulic Oils PDFDocument3 pagesHydraulic Oils PDFdonyaNo ratings yet

- MAK Oil SpecDocument8 pagesMAK Oil SpecAnonymous alQXB11EgQNo ratings yet

- Flender Gear Units: Vertical-Mill Gear UnitDocument102 pagesFlender Gear Units: Vertical-Mill Gear Unitsdk00No ratings yet

- Mobil GuideDocument19 pagesMobil GuidemademanNo ratings yet

- OEM Approval GuideDocument8 pagesOEM Approval GuideEsteban Fernando Meza IbacetaNo ratings yet

- How To Select and Service Turbine OilsDocument5 pagesHow To Select and Service Turbine Oilsmvanzijp100% (1)

- Military Joint Oil Analysis Manual Vol IIDocument408 pagesMilitary Joint Oil Analysis Manual Vol IIVijay HanagandiNo ratings yet

- Aerzen Lubricants BrochureDocument1 pageAerzen Lubricants BrochureRanier Garcia0% (1)

- Industrial Product PortfolioDocument21 pagesIndustrial Product Portfolioatripathi2009No ratings yet

- Lubricants For Buses and TrucksDocument16 pagesLubricants For Buses and Trucksvijay9994No ratings yet

- Api Engine Oil Classifications Brochure2Document13 pagesApi Engine Oil Classifications Brochure2Sinh LeNo ratings yet

- Chevron Y Texaco TablaDocument40 pagesChevron Y Texaco TablasofelsbabaNo ratings yet

- Ester SynthesisDocument7 pagesEster SynthesisNgô Ngọc Mai PhươngNo ratings yet

- C1 - 중국- 철강 홍보자료 - EDM - 4급 - v0.1Document62 pagesC1 - 중국- 철강 홍보자료 - EDM - 4급 - v0.1Vinh Chu VănNo ratings yet

- LUBRICANTING OilDocument18 pagesLUBRICANTING OilChetan AgroyaNo ratings yet

- Is 13656 2002 PDFDocument24 pagesIs 13656 2002 PDFSiddharth GuptaNo ratings yet

- Machinery Lubrication November December 2017 PDFDocument89 pagesMachinery Lubrication November December 2017 PDFJorge Cuadros BlasNo ratings yet

- Diala S4 ZX-IDocument3 pagesDiala S4 ZX-IHenry UntirtaNo ratings yet

- HiTEC-419 PDSDocument2 pagesHiTEC-419 PDSSong Hum KangNo ratings yet

- Lubrimist Model Ivt PDFDocument2 pagesLubrimist Model Ivt PDFLluhiNo ratings yet

- Fuchs - Titan Race PRO S Full Syn PAO EsterDocument2 pagesFuchs - Titan Race PRO S Full Syn PAO EsterB3NNo ratings yet

- Skill Builder: Service Guide For Quintolubric 888 SeriesDocument4 pagesSkill Builder: Service Guide For Quintolubric 888 SeriesAymanSayedElantableeNo ratings yet

- LUB OILS NOHAB W25 W25SG W25DF 9193911800eDocument2 pagesLUB OILS NOHAB W25 W25SG W25DF 9193911800eLIVIA100% (2)

- Klueberlub BE 41-1501 097115 PI GB enDocument3 pagesKlueberlub BE 41-1501 097115 PI GB enwajahat ali KhanNo ratings yet

- TRB1221 Ezine Nov Dec 2021 WebDocument48 pagesTRB1221 Ezine Nov Dec 2021 WebSalem IereebiNo ratings yet

- HP Industrial Lubricants Product GuideDocument82 pagesHP Industrial Lubricants Product GuidemrbairwaNo ratings yet

- Turbocharged Direct Injection Is Engine Oils Next Big Hurdle PDFDocument5 pagesTurbocharged Direct Injection Is Engine Oils Next Big Hurdle PDFMishu MarcelNo ratings yet

- Requirements and Oil Quality: Installation ManualDocument10 pagesRequirements and Oil Quality: Installation ManualABDUL REHMAN PIPRANINo ratings yet

- Wear: Materials, Mechanisms and PracticeFrom EverandWear: Materials, Mechanisms and PracticeGwidon W. StachowiakNo ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Valvoline Heavy Duty TDL PRO 75W-90-PI SheetDocument2 pagesValvoline Heavy Duty TDL PRO 75W-90-PI SheetJUAN BAUTISTANo ratings yet

- Gulf Geartek - Hd-Sept2021 - 20211102102844Document1 pageGulf Geartek - Hd-Sept2021 - 20211102102844magadali7814No ratings yet

- Pioneering Efficient Energy Solutions-SHV Energy-Super GasDocument36 pagesPioneering Efficient Energy Solutions-SHV Energy-Super Gasatripathi2009No ratings yet

- Purchase Order ChecklistDocument1 pagePurchase Order Checklistatripathi2009No ratings yet

- Gulf Harmony AW: High Performance Anti-Wear Hydraulic OilDocument2 pagesGulf Harmony AW: High Performance Anti-Wear Hydraulic Oilatripathi2009No ratings yet

- Pioneering Efficient Energy SolutionDocument36 pagesPioneering Efficient Energy Solutionatripathi2009No ratings yet

- HLV Presentation To Prospects and Customers - 2013Document9 pagesHLV Presentation To Prospects and Customers - 2013atripathi2009No ratings yet

- Maxima LPG Installation PresentationDocument20 pagesMaxima LPG Installation Presentationatripathi2009No ratings yet

- Cathodic Protection - PresentationDocument24 pagesCathodic Protection - Presentationatripathi2009No ratings yet

- Gulf No Rust WXD 32 PDSDocument1 pageGulf No Rust WXD 32 PDSatripathi2009No ratings yet

- Conversion PPT (FINAL)Document34 pagesConversion PPT (FINAL)atripathi2009No ratings yet

- Gulf No Rust C2: Water Displacing Rust Preventive Forming Oily Greasy Protective FilmDocument1 pageGulf No Rust C2: Water Displacing Rust Preventive Forming Oily Greasy Protective Filmatripathi2009No ratings yet

- Gulf Synthetic Gear Oil - PAGDocument1 pageGulf Synthetic Gear Oil - PAGatripathi2009No ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument11 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/Undertakingatripathi2009No ratings yet

- Gulf Gear EP: Heavy Duty Automotive Gearbox OilDocument1 pageGulf Gear EP: Heavy Duty Automotive Gearbox Oilatripathi2009No ratings yet

- Gulf Lubricants Brief ProfileDocument10 pagesGulf Lubricants Brief Profileatripathi2009100% (1)

- Safety-Super Gas - LPG MSDS PDFDocument2 pagesSafety-Super Gas - LPG MSDS PDFatripathi2009No ratings yet

- Gulf EP Lubricant HDDocument1 pageGulf EP Lubricant HDatripathi2009No ratings yet

- Industrial Product PortfolioDocument21 pagesIndustrial Product Portfolioatripathi2009No ratings yet

- Gulf Corporate BrochureDocument6 pagesGulf Corporate Brochureatripathi2009No ratings yet

- Thermic FluidDocument2 pagesThermic Fluidatripathi2009No ratings yet

- Gulf Oil Lubricants IntroductionDocument12 pagesGulf Oil Lubricants Introductionatripathi2009No ratings yet

- Aerosol Brochure PDFDocument4 pagesAerosol Brochure PDFatripathi2009No ratings yet

- Heater Less Vaporizer PDFDocument2 pagesHeater Less Vaporizer PDFatripathi2009No ratings yet

- Pioneering Efficient Energy Solutions: SHV India SHV IndiaDocument41 pagesPioneering Efficient Energy Solutions: SHV India SHV Indiaatripathi2009No ratings yet

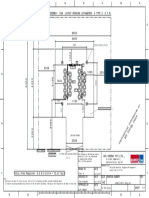

- VL2 - 2 X9 SL Type ADocument1 pageVL2 - 2 X9 SL Type Aatripathi2009No ratings yet

- Solution To Purple DairyDocument15 pagesSolution To Purple Dairyatripathi2009No ratings yet

- VL1 - 2 X9 SU Type ADocument1 pageVL1 - 2 X9 SU Type Aatripathi2009No ratings yet

- IRR - SGS SLOT (2x30) With 100 KG Electrical Vapouriser - United EnggDocument8 pagesIRR - SGS SLOT (2x30) With 100 KG Electrical Vapouriser - United Enggatripathi2009No ratings yet

- Central Gas Supply Systems For HP Gases 2016 V000305Document112 pagesCentral Gas Supply Systems For HP Gases 2016 V000305atripathi2009No ratings yet

- Series Gu Control Valves Globe-Single Seated, Top Guided: ConstructionDocument16 pagesSeries Gu Control Valves Globe-Single Seated, Top Guided: ConstructionMichael H. PrevooNo ratings yet

- Chapter Three Concrete DamDocument57 pagesChapter Three Concrete Dammimahmoud100% (1)

- Conveyor Company Profile - CONVEYORDocument8 pagesConveyor Company Profile - CONVEYORpeprevillaNo ratings yet

- Btech 3 Week 3Document4 pagesBtech 3 Week 3stevennguimsNo ratings yet

- Effect of J-Groove On The Suppression of Swirl Flow in A Conical DiffuserDocument8 pagesEffect of J-Groove On The Suppression of Swirl Flow in A Conical DiffuserYoung Do ChoiNo ratings yet

- Composite Structures: Piotr Lacki, Anna Derlatka, Przemys Ław Kasza TDocument7 pagesComposite Structures: Piotr Lacki, Anna Derlatka, Przemys Ław Kasza TLuis BermudezNo ratings yet

- CLS - JEEAD Set JeeDocument20 pagesCLS - JEEAD Set JeeSachin KumarNo ratings yet

- Car Parts BasicsDocument24 pagesCar Parts Basicstoyota952No ratings yet

- Physical Science Worksheet Conservation of Energy #2: KE MV GPE MGH Me Ke + GpeDocument4 pagesPhysical Science Worksheet Conservation of Energy #2: KE MV GPE MGH Me Ke + GpeJudy MelegritoNo ratings yet

- HCL Clamping Product CatalogueDocument60 pagesHCL Clamping Product CatalogueGrimmo1979No ratings yet

- Ci NLDocument12 pagesCi NLanuraeNo ratings yet

- Ford Kuga 2.5L 2008 Timing BeltDocument5 pagesFord Kuga 2.5L 2008 Timing BeltSenaMecánicaElectrónicaNo ratings yet

- Wascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFDocument2 pagesWascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFmairimsp2003No ratings yet

- El Khana Aburyzal Sihombing - 201971054 - Modul 2Document10 pagesEl Khana Aburyzal Sihombing - 201971054 - Modul 2Elkhana AburyzalNo ratings yet

- Pneumatic Systems Part 2 ModuleDocument6 pagesPneumatic Systems Part 2 Modulekulet.yangNo ratings yet

- UntitledDocument12 pagesUntitledFHGDTY? HNo ratings yet

- Jis New Vs Old KeywayDocument1 pageJis New Vs Old KeywayASHOKNo ratings yet

- Chapter 1:types of Flow in Open ChannelDocument61 pagesChapter 1:types of Flow in Open ChannelHani BarjokNo ratings yet

- Inference of Geotechnical Property ValuesDocument44 pagesInference of Geotechnical Property Valuesriz2010No ratings yet

- NP 51863Document9 pagesNP 51863Teresa CarterNo ratings yet

- TCS 3050 50 1019 2Document17 pagesTCS 3050 50 1019 2Samari LarryNo ratings yet

- LG-6001 Lead Gage: Operation ManualDocument24 pagesLG-6001 Lead Gage: Operation ManualSukumarNo ratings yet

- Energy Audit - QuestionnaireDocument4 pagesEnergy Audit - QuestionnaireRukma Goud ShakkariNo ratings yet

- States of Matter - Solutions and MixturesDocument25 pagesStates of Matter - Solutions and MixturesYasinth ThivagarNo ratings yet

- 900FH&1000FH Turbines 2Document12 pages900FH&1000FH Turbines 2RyanNo ratings yet

- Compendiu Aer Comprimat PDFDocument230 pagesCompendiu Aer Comprimat PDFVisan GheorgheNo ratings yet

- D61ex 15e0Document642 pagesD61ex 15e0JEFFERSONDIAS83No ratings yet

- 52605-02 Ingilizce 1 Property Classes of Special Service FastenersDocument7 pages52605-02 Ingilizce 1 Property Classes of Special Service FastenersEmir AkçayNo ratings yet