Professional Documents

Culture Documents

Gulf Synthetic Gear Oil - PAG

Gulf Synthetic Gear Oil - PAG

Uploaded by

atripathi20090 ratings0% found this document useful (0 votes)

138 views1 pageGulf Synthetic Gear Oil is a synthetic heavy-duty industrial gear oil formulated from polyalkylene glycol base stocks. It provides outstanding load carrying capacity and protection against scuffing, wear, and micro-pitting under severe operating conditions. The synthetic base stocks provide excellent thermal stability, oxidation resistance, low temperature fluidity, and protection over a wide operating temperature range. The oil is suitable for lubricating enclosed gear boxes, wind turbine gearboxes, conveyors, compressors, and other equipment operating under high loads and temperatures.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGulf Synthetic Gear Oil is a synthetic heavy-duty industrial gear oil formulated from polyalkylene glycol base stocks. It provides outstanding load carrying capacity and protection against scuffing, wear, and micro-pitting under severe operating conditions. The synthetic base stocks provide excellent thermal stability, oxidation resistance, low temperature fluidity, and protection over a wide operating temperature range. The oil is suitable for lubricating enclosed gear boxes, wind turbine gearboxes, conveyors, compressors, and other equipment operating under high loads and temperatures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

138 views1 pageGulf Synthetic Gear Oil - PAG

Gulf Synthetic Gear Oil - PAG

Uploaded by

atripathi2009Gulf Synthetic Gear Oil is a synthetic heavy-duty industrial gear oil formulated from polyalkylene glycol base stocks. It provides outstanding load carrying capacity and protection against scuffing, wear, and micro-pitting under severe operating conditions. The synthetic base stocks provide excellent thermal stability, oxidation resistance, low temperature fluidity, and protection over a wide operating temperature range. The oil is suitable for lubricating enclosed gear boxes, wind turbine gearboxes, conveyors, compressors, and other equipment operating under high loads and temperatures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Gulf Synthetic Gear Oil

Synthetic heavy-duty industrial gear oil

Product Description

Gulf Synthetic Gear Oil series are synthetic heavy duty industrial gear oils offering outstanding lubrication

performance and load carrying capacity under severe operating conditions including shock loading. These

are formulated from Polyalkylene Glycol (PAG) synthetic base stocks having exceptional micro pitting

protection, oxidation resistance and thermal properties and excellent low temperature fluidity. The

combination of naturally extremely high viscosity index base stocks coupled with carefully selected additive

technology provides excellent thermal stability, protection against scuffing and resistance against micro

pitting fatigue under wide operating temperature range.

Features & Benefits

Outstanding load carrying capability and micro-pitting performance protects gears against scuffing

and wear leading to enhanced equipment life and reduced maintenance costs

High viscosity index base stocks provide excellent low temperature fluidity and effective lubrication

over a wide temperature range

Superior thermo-oxidative stability provides enhanced system cleanliness and enables longer

service intervals

Excellent resistance to rust and corrosion protection and good demulsibility ensures trouble free

operation at high temperatures and applications encountering water contamination

Good seal and paint compatibility with a wide variety of seals and paints

Applications

ISO VG 150 – 680 meets the Siemens (Flender) BA T 7300 A+B specification for Flender Helical,

Bevel and Planetary gear units.

Heavy-duty industrial enclosed gear boxes operating under severe conditions like high load,

extreme temperatures and wide temperature ranges

ISO VG 320 is specifically developed for lubrication of wind turbine gear box manufactured by

Hansen, Flender, Rexroth, FAG, etc where such quality lubricants are recommended

Filled for life systems, chain and conveyors, kiln and ovens, compressor (reciprocating/ rotary)

Bearing and circulation systems where high temperatures are encountered

Specifications & Typical Properties

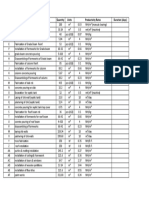

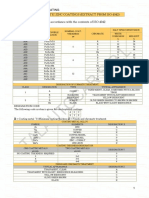

ISO Viscosity Grade 68 150 220 320 460 680 1000

Meets the following Specifications

DIN 51517 Part 3 X X X X X X X

David Brown Type G Lubricant X X X X X X X

Siemens (Flender) BA T 7300 A+B X X X X X X

Typical Properties

Test Parameters ASTM Test Values

Viscosity @ 40 ºC, cSt D 445 68 150 227 339 477 689 1000

Viscosity Index D 2270 214 232 242 252 262 272 284

Flash Point, ºC D 92 284 284 284 282 284 287 296

Pour Point, ºC D 97 -51 -47 -42 -39 -36 -33 -30

Density @ 15ºC, Kg/l D 1298 1.042 1.057 1.057 1.062 1.067 1.072 1.089

FZG, fail load stage DIN 51324 - >12 >12 >12 >12 >12 >12

Rust Test D 665A/B Pass Pass Pass Pass Pass Pass Pass

Copper Corrosion D 130 1a 1a 1a 1a 1a 1a 1a

July 2014

You might also like

- Pune List Updated PDFDocument801 pagesPune List Updated PDFatripathi200960% (5)

- Conveyor Belt TroubleshootingDocument4 pagesConveyor Belt TroubleshootingchandankrdumkaNo ratings yet

- Thermography: Gol Gumbaz, Bijapur, KarnatakaDocument14 pagesThermography: Gol Gumbaz, Bijapur, Karnatakaapi-160949726No ratings yet

- ICML 2017 Conference BookDocument69 pagesICML 2017 Conference BookCHRISTHIAN9144390% (1)

- Gulf Gear WT: High Performance Industrial Gear OilDocument1 pageGulf Gear WT: High Performance Industrial Gear Oilatripathi2009No ratings yet

- Gulf Oil Marine - Product Data SheetDocument10 pagesGulf Oil Marine - Product Data SheetObydur RahmanNo ratings yet

- Bearings: Sliding Bearings Rolling Bearings Journal ThrustDocument3 pagesBearings: Sliding Bearings Rolling Bearings Journal ThrustShirishaVijayapuramNo ratings yet

- STS 114 MCSA Report-J200628Document26 pagesSTS 114 MCSA Report-J200628Haitham YoussefNo ratings yet

- GEA14784C Pulp and Paper - R5Document8 pagesGEA14784C Pulp and Paper - R5Viet DinhTrongNo ratings yet

- CBSE Board Class 8 Maths Syllabus PDFDocument5 pagesCBSE Board Class 8 Maths Syllabus PDFrs149No ratings yet

- AV51DOT1Document25 pagesAV51DOT1AnthonyNo ratings yet

- AP POLYCET - CEEP Syllabus and Exam PatternDocument2 pagesAP POLYCET - CEEP Syllabus and Exam PatterngayathriNo ratings yet

- 9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Document3 pages9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Urke VukNo ratings yet

- Dalits and Memories of 1857 PDFDocument35 pagesDalits and Memories of 1857 PDFDev OshanNo ratings yet

- DIN 51825 German Grease Classification System PDFDocument1 pageDIN 51825 German Grease Classification System PDFFelipeSantiagoNo ratings yet

- 01 BPA Food IndustryDocument29 pages01 BPA Food IndustryMAYANK AGARWALNo ratings yet

- 2005-021 MotwaniDocument6 pages2005-021 Motwanialexander100% (1)

- GulfSea Synth Gear Oil PG 220 PDFDocument2 pagesGulfSea Synth Gear Oil PG 220 PDFObydur RahmanNo ratings yet

- Introduction To Gas Chromatography: A Comprehensive Short Course in Gas ChromatgraphyDocument4 pagesIntroduction To Gas Chromatography: A Comprehensive Short Course in Gas ChromatgraphyMohamed DahmaneNo ratings yet

- Argus-Phosphate - Phosphoric Acid Price Metholodogy PDFDocument11 pagesArgus-Phosphate - Phosphoric Acid Price Metholodogy PDFsharemwNo ratings yet

- User'S Manual: Dynamic Signal Analyzers For Vibration Analysis and MonitoringDocument41 pagesUser'S Manual: Dynamic Signal Analyzers For Vibration Analysis and MonitoringJolito RamosNo ratings yet

- CBSE Class 8 SST Worksheet - Natural Resource - WaterDocument2 pagesCBSE Class 8 SST Worksheet - Natural Resource - WaterravilullaNo ratings yet

- Aluminum Cold Mill Rolling Oil DistillationDocument3 pagesAluminum Cold Mill Rolling Oil DistillationbwelzNo ratings yet

- MCQs DOMDocument5 pagesMCQs DOMyuvraj PrajapatiNo ratings yet

- Business Culture in British India PDFDocument17 pagesBusiness Culture in British India PDFshiv161No ratings yet

- TRB1221 Ezine Nov Dec 2021 WebDocument48 pagesTRB1221 Ezine Nov Dec 2021 WebSalem IereebiNo ratings yet

- DIN 51502 SpecsDocument8 pagesDIN 51502 SpecskhaledNo ratings yet

- MoC - Vision 2047 - 12th Mar - v30.1Document71 pagesMoC - Vision 2047 - 12th Mar - v30.1V K AgrawalNo ratings yet

- Ballmillinspection PDFDocument4 pagesBallmillinspection PDFrodrigoalcainoNo ratings yet

- ROTALIGN-Ultra - Pocket-Guide - ALI 209.844 - 07-08 - 2.06 - G PDFDocument2 pagesROTALIGN-Ultra - Pocket-Guide - ALI 209.844 - 07-08 - 2.06 - G PDFDon FreemanNo ratings yet

- Choclate CADBURYDocument45 pagesChoclate CADBURYanon_131421No ratings yet

- Polytechnic Entrance Exam (CEEP-2013) Question & Answer Key PaperDocument24 pagesPolytechnic Entrance Exam (CEEP-2013) Question & Answer Key PaperMruthyunjayNo ratings yet

- Food Grade Brochure PDFDocument9 pagesFood Grade Brochure PDFMilena GonzalezNo ratings yet

- Polytechnic Entrance Exam (CEEP-2009) Question & Answer Key PaperDocument15 pagesPolytechnic Entrance Exam (CEEP-2009) Question & Answer Key PaperMruthyunjayNo ratings yet

- Hamon Cooling Towers ENG LRDocument12 pagesHamon Cooling Towers ENG LRamey8231No ratings yet

- Refinery Brochure PDFDocument5 pagesRefinery Brochure PDFmacholdingsNo ratings yet

- A O G E I R - D S: Nalysis F Yroscopic Ffects N Otor ISC YstemsDocument48 pagesA O G E I R - D S: Nalysis F Yroscopic Ffects N Otor ISC YstemsTarun BhardwajNo ratings yet

- Volume 1 API 510 Exam - 2 PDFDocument34 pagesVolume 1 API 510 Exam - 2 PDFFarhan Ali100% (1)

- Hot Isotactic Processing (Hip) : Mehmet Can HATİBOĞLUDocument18 pagesHot Isotactic Processing (Hip) : Mehmet Can HATİBOĞLUthesecretgardenscatNo ratings yet

- Iso 6743 6 1990Document8 pagesIso 6743 6 1990hossam alebrahimNo ratings yet

- NuggetsDocument202 pagesNuggetsfazzlieNo ratings yet

- Bently Hydrobrochure r3 LR Ok For Website 11.2.18Document12 pagesBently Hydrobrochure r3 LR Ok For Website 11.2.18Deepen SharmaNo ratings yet

- Calculating Grease QuantityDocument2 pagesCalculating Grease Quantitykamal arabNo ratings yet

- ISO 6743-5 - 2006 - Part. 5 - Family T - TurbinesDocument9 pagesISO 6743-5 - 2006 - Part. 5 - Family T - TurbinesMassimiliano VolaNo ratings yet

- Chatter Suppression Techniques in Metal Cutting PDFDocument24 pagesChatter Suppression Techniques in Metal Cutting PDFDenis SatriaNo ratings yet

- Rimula R3 MV 15W40Document2 pagesRimula R3 MV 15W40AdiWijayaNo ratings yet

- CLS Body of Knowledge-2016 PDFDocument4 pagesCLS Body of Knowledge-2016 PDFSantos Junnior Hipolito SandovalNo ratings yet

- Steam Turbine OutageDocument18 pagesSteam Turbine OutageNida AliNo ratings yet

- ISO 6743-12 - 1989 - Part. 12 - Family Q - Heat Transfer FluidsDocument4 pagesISO 6743-12 - 1989 - Part. 12 - Family Q - Heat Transfer FluidsMassimiliano VolaNo ratings yet

- Trends in Industrial Gear OilDocument8 pagesTrends in Industrial Gear OilM.Tayyab100% (1)

- Nippon ArocoatDocument3 pagesNippon ArocoatHANIF IZANI ISHAKNo ratings yet

- Hastelloy G 35Document16 pagesHastelloy G 35Ir Go JarNo ratings yet

- PAP Design BasisDocument17 pagesPAP Design BasisBiju JosephNo ratings yet

- Sensor Cable Catalog EN 03122014 PDFDocument200 pagesSensor Cable Catalog EN 03122014 PDFdaviqperezNo ratings yet

- Industrial Grease Lubricant Application GuideDocument2 pagesIndustrial Grease Lubricant Application GuideOscar Cruz100% (2)

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshNo ratings yet

- Wear: Materials, Mechanisms and PracticeFrom EverandWear: Materials, Mechanisms and PracticeGwidon W. StachowiakNo ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- gulf-synthetic-gear-oilDocument1 pagegulf-synthetic-gear-oilAbdo EissaNo ratings yet

- Gulf Geartek - Hd-Sept2021 - 20211102102844Document1 pageGulf Geartek - Hd-Sept2021 - 20211102102844magadali7814No ratings yet

- PDS - GulfSea Hydraulic AW Series-1Document2 pagesPDS - GulfSea Hydraulic AW Series-1Zaini YaakubNo ratings yet

- Pioneering Efficient Energy Solutions-SHV Energy-Super GasDocument36 pagesPioneering Efficient Energy Solutions-SHV Energy-Super Gasatripathi2009No ratings yet

- Purchase Order ChecklistDocument1 pagePurchase Order Checklistatripathi2009No ratings yet

- Gulf Harmony AW: High Performance Anti-Wear Hydraulic OilDocument2 pagesGulf Harmony AW: High Performance Anti-Wear Hydraulic Oilatripathi2009No ratings yet

- Pioneering Efficient Energy SolutionDocument36 pagesPioneering Efficient Energy Solutionatripathi2009No ratings yet

- HLV Presentation To Prospects and Customers - 2013Document9 pagesHLV Presentation To Prospects and Customers - 2013atripathi2009No ratings yet

- Maxima LPG Installation PresentationDocument20 pagesMaxima LPG Installation Presentationatripathi2009No ratings yet

- Cathodic Protection - PresentationDocument24 pagesCathodic Protection - Presentationatripathi2009No ratings yet

- Gulf No Rust WXD 32 PDSDocument1 pageGulf No Rust WXD 32 PDSatripathi2009No ratings yet

- Conversion PPT (FINAL)Document34 pagesConversion PPT (FINAL)atripathi2009No ratings yet

- Gulf No Rust C2: Water Displacing Rust Preventive Forming Oily Greasy Protective FilmDocument1 pageGulf No Rust C2: Water Displacing Rust Preventive Forming Oily Greasy Protective Filmatripathi2009No ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Gulf EP Lubricant HDDocument1 pageGulf EP Lubricant HDatripathi2009No ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument11 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/Undertakingatripathi2009No ratings yet

- Mhcci ListDocument1,074 pagesMhcci ListShaiwal Parashar57% (7)

- Gulf Oil Lubricants IntroductionDocument12 pagesGulf Oil Lubricants Introductionatripathi2009No ratings yet

- Industrial Product PortfolioDocument21 pagesIndustrial Product Portfolioatripathi2009No ratings yet

- Pioneering Efficient Energy Solutions: SHV India SHV IndiaDocument41 pagesPioneering Efficient Energy Solutions: SHV India SHV Indiaatripathi2009No ratings yet

- Gulf Gear EP: Heavy Duty Automotive Gearbox OilDocument1 pageGulf Gear EP: Heavy Duty Automotive Gearbox Oilatripathi2009No ratings yet

- Gulf Corporate BrochureDocument6 pagesGulf Corporate Brochureatripathi2009No ratings yet

- VL2 - 2 X9 SL Type ADocument1 pageVL2 - 2 X9 SL Type Aatripathi2009No ratings yet

- Gulf Lubricants Brief ProfileDocument10 pagesGulf Lubricants Brief Profileatripathi2009100% (1)

- Thermic FluidDocument2 pagesThermic Fluidatripathi2009No ratings yet

- Heater Less Vaporizer PDFDocument2 pagesHeater Less Vaporizer PDFatripathi2009No ratings yet

- Central Gas Supply Systems For HP Gases 2016 V000305Document112 pagesCentral Gas Supply Systems For HP Gases 2016 V000305atripathi2009No ratings yet

- Aerosol Brochure PDFDocument4 pagesAerosol Brochure PDFatripathi2009No ratings yet

- VL1 - 2 X9 SU Type ADocument1 pageVL1 - 2 X9 SU Type Aatripathi2009No ratings yet

- IRR - SGS SLOT (2x30) With 100 KG Electrical Vapouriser - United EnggDocument8 pagesIRR - SGS SLOT (2x30) With 100 KG Electrical Vapouriser - United Enggatripathi2009No ratings yet

- Safety-Super Gas - LPG MSDS PDFDocument2 pagesSafety-Super Gas - LPG MSDS PDFatripathi2009No ratings yet

- Solution To Purple DairyDocument15 pagesSolution To Purple Dairyatripathi2009No ratings yet

- CP26 PDFDocument47 pagesCP26 PDFrafik1995No ratings yet

- Ship Loose Spools Packing DetailsDocument2 pagesShip Loose Spools Packing DetailsKarthikeyan ShanmugavelNo ratings yet

- Micro MachiningDocument26 pagesMicro MachiningJishnu UnniNo ratings yet

- Method Statement of Refrigran Pipe Insulation and Cladding InstallationDocument16 pagesMethod Statement of Refrigran Pipe Insulation and Cladding InstallationOdot Al GivaryNo ratings yet

- Standard P&I Masters Guide To Enclosed Space Entry 2017 - 08 PDFDocument32 pagesStandard P&I Masters Guide To Enclosed Space Entry 2017 - 08 PDFToheid Asadi100% (3)

- Expansion of Hydraulic Cement Mortar Bars Stored in Water: Standard Test Method ForDocument3 pagesExpansion of Hydraulic Cement Mortar Bars Stored in Water: Standard Test Method Formohammed ;arasnehNo ratings yet

- TL 11 Adingkolor RB 07 2020 enDocument3 pagesTL 11 Adingkolor RB 07 2020 enFilip PopordanoskiNo ratings yet

- CE 301-GeologyDocument1 pageCE 301-GeologychndriuhNo ratings yet

- Ionic and Covalent Bonding 1 1Document46 pagesIonic and Covalent Bonding 1 1Ivan LazaroNo ratings yet

- Binary Phase DiagramsDocument60 pagesBinary Phase DiagramsmaryzeenNo ratings yet

- Sulfinol D Evaluation.Document24 pagesSulfinol D Evaluation.Clibert RodríguezNo ratings yet

- Schedule For Welder Qualification Test: SCT-PTSC ConsortiumDocument2 pagesSchedule For Welder Qualification Test: SCT-PTSC ConsortiumTuan Pham Minh0% (1)

- Polyacrylic Acid (Paa) Polymer TechnologyDocument9 pagesPolyacrylic Acid (Paa) Polymer TechnologyDedi Cristian SitumorangNo ratings yet

- Shapes of Pre Stressed StructuresDocument16 pagesShapes of Pre Stressed StructuresDennis Dale100% (2)

- Detect and Control Water in OilDocument9 pagesDetect and Control Water in OilAbdul AzisNo ratings yet

- Table 1: Elements Symbols Atomic MassDocument7 pagesTable 1: Elements Symbols Atomic MassMadhavNo ratings yet

- Product List - Pigment IntermediatesDocument2 pagesProduct List - Pigment IntermediatesVitortsNo ratings yet

- TDS CNX Black 740 PFDocument1 pageTDS CNX Black 740 PFRajiv DubeyNo ratings yet

- Asme Sa193 Grade b16Document8 pagesAsme Sa193 Grade b16q alexNo ratings yet

- The Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFDocument36 pagesThe Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFrogersampaiocostaNo ratings yet

- Pipe Material ASTM CodesDocument2 pagesPipe Material ASTM CodesShreekanthKannathNo ratings yet

- Designation Activity Quantity Units Productivity Rates Duration (Days)Document1 pageDesignation Activity Quantity Units Productivity Rates Duration (Days)Bryle James NangleganNo ratings yet

- WPS Aws D1.1Document2 pagesWPS Aws D1.1tuatk67% (6)

- Forensic 2 Week 14Document20 pagesForensic 2 Week 14mindy sansanNo ratings yet

- Astm-A519 - 06Document13 pagesAstm-A519 - 06claudiaNo ratings yet

- Laminate CompositeDocument9 pagesLaminate CompositeDhias VidathyaNo ratings yet

- Opc Drum CoatingDocument1 pageOpc Drum CoatingLouis Chen100% (2)

- Electrolytic Zinc Coating PDFDocument2 pagesElectrolytic Zinc Coating PDFzoran100% (1)

- HTTPS://FR - Scribd.com/doc/294639869/method Statement For Cable Pulling and ConnectionsDocument22 pagesHTTPS://FR - Scribd.com/doc/294639869/method Statement For Cable Pulling and ConnectionsCripoNo ratings yet

- What Is The Difference Between OPC and PPC CementDocument2 pagesWhat Is The Difference Between OPC and PPC CementDeep Debnath100% (1)