Professional Documents

Culture Documents

Gas-Actuated Temperature Switch Stainless Steel Switch Enclosure Model TWG

Gas-Actuated Temperature Switch Stainless Steel Switch Enclosure Model TWG

Uploaded by

chauOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas-Actuated Temperature Switch Stainless Steel Switch Enclosure Model TWG

Gas-Actuated Temperature Switch Stainless Steel Switch Enclosure Model TWG

Uploaded by

chauCopyright:

Available Formats

Mechatronic

Electrical

temperature

temperature measurement

measurement

Gas-actuated temperature switch

Stainless steel switch enclosure

Model TWG

WIKA data sheet TV 31.60

Process Performance Series

Applications

■■ Temperature monitoring and direct switching of electrical

loads

■■ General process instrumentation in the chemical and

petrochemical industries, oil and gas industries, power

generation, water/wastewater industries, mining

Special features

■■ No power supply needed for switching of electrical loads

■■ Setting ranges from -30 ... +70 to 0 ... 600 °C

■■ Ex ia version available

■■ 1 or 2 independent set points, SPDT or DPDT, high

switching power up to AC 250 V, 20 A

■■ Direct mounting or remote mounting with capillary ≤ 10 m

Model TWG, remote mounting with capillary

Description

These high-quality and robust temperature switches have The measuring element is a gas-actuated system with a

been developed especially for safety-critical applications. The Bourdon tube element. This system allows wide setting range

high quality of the products and manufacturing in accord- up to 0 ... 600 °C.

ance with ISO 9001 ensure reliable monitoring of your plant.

In production, the switches are traced by quality assurance The measuring system parts and the flexible spiral armour

software at every step and subsequently are 100 % tested. are made of stainless steel.

In order to ensure as flexible operation as possible, the The model TWG temperature switch is extremely robust and

temperature switches are fitted with micro switches, which guarantees optimal operating characteristics and the highest

enable the switching of an electrical load of up to AC 250 V, measuring performances with repeatability lower than 0.5 %

20 A directly. of span.

For lower switching power ratings, such as for PLC

applications, argon gas-filled micro switches with gold-plated

contacts can be selected as an option.

WIKA data sheet TV 31.60 ∙ 02/2016 Page 1 of 5

Data sheets showing similar products:

Temperature switch; flameproof enclosure Ex d; model TAG; see data sheet TV 31.61

Standard version Ignition protection type (option)

■■ Ex ia I Ma (mines)

Measuring system ■■ Ex ia IIC T6/T4 1) Ga (gas)

Gas-actuated temperature system (SAMA class III B) ■■ Ex ia IIIC T85/T135 1) Da (dust)

1) The temperature class is related to the ambient temperature range. See the type

Switch enclosure examination certificate for further details.

Stainless steel 316L, case cover with bayonet lock, protec-

tion against unauthorised access, lead sealing by customer Safety-related maximum values

possible. Laser-engraved product label from stainless steel (only for Ex ia version)

Maximum values

Ingress protection

Voltage Ui DC 30 V

IP66 per EN 60529 / lEC 60529, NEMA 4X

Current li 100 mA

Permissible ambient temperature Power Pi 0.75 W

-40 ... +85 °C Internal capacitance Ci 0 μF

Internal inductance Li 0 mH

Switch contact

Micro switches with fixed dead band

■■ 1 x or 2 x SPDT (single pole double throw)

■■ 1 x DPDT (double pole double throw)

Micro switches with adjustable dead band

■■ 1 x SPDT (single pole double throw)

The DPDT function is realised with 2 simultaneously

triggering SPDT micro switches within 0.2 % of the span.

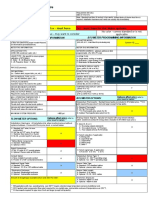

Contact version Electrical rating (resistive load) Suitable for

AC DC Ex ia option

UN 1 x SPDT, silver 250 V, 15 A 24 V, 2 A, 125 V, 0.5 A, 220 V, 0.25 A No

US 1 x SPDT, silver, hermetically sealed, argon gas filling 2) 250 V, 15 A 24 V, 2 A, 220 V, 0.5 A Yes

UO 1 x SPDT, gold-plated, hermetically sealed, argon gas filling 2) 125 V, 1 A 24 V, 0.5 A Yes

UG 1 x SPDT, gold-plated 125 V, 1 A 24 V, 0.5 A No

UR 1 x SPDT, silver, adjustable dead band 250 V, 20 A 24 V, 2 A, 220 V, 0.5 A Yes 3)

DN 2 x SPDT or 1 x DPDT, silver 250 V, 15 A 24 V, 2 A, 125 V, 0.5 A, 220 V, 0.25 A No

DS 2 x SPDT or 1 x DPDT, silver, hermetically sealed, argon gas 250 V, 15 A 24 V, 2 A, 220 V, 0.5 A Yes

filling 2)

DO 2 x SPDT, or 1 x DPDT gold-plated, hermetically sealed, 125 V, 1 A 24 V, 0.5 A Yes

argon gas filling 2)

DG 2 x SPDT or 1 x DPDT, gold-plated 125 V, 1 A 24 V, 0.5 A No

2) Permissible ambient temperature range: -30 ... +70 °C

3) WIKA recommends argon gas-filled contact versions, use of adjustable dead band allowed

Set point adjustment Please specify:

The set point can be specified by the customer or factory set Set point, switching direction for each contact, e.g.:

within the setting range. Subsequent adjustment of the set Set point 1: 30 °C, falling, set point 2: 60 °C, rising.

point on site is made using the adjustment screw, which is With two micro switches, the set points can be set

fastened to the switch and thus secured against loss. independently of each other.

For optimal performance we suggest to adjust the set point

Repeatability of the set point between 25 ... 75 % of the span.

≤ 0.5 % of span

Example:

Distance between set points Setting range: 0 ... 100 °C with one switch contact

For versions with 2 x SPDT the distance between the set Repeatability: 0.5 % of 100 °C = 0.5 °C

points must be > 5 % of the respective span. Dead band: 4.5 °C (see table setting ranges)

2 x repeatability + dead band = 2 x 0.5 °C + 4.5 °C = 5.5 °C

Rising temperature: Adjust set point between 5.5 ... 100 °C.

Falling temperature: Adjust set point between 0 ... 94.5 °C.

Page 2 of 5 WIKA data sheet TV 31.60 ∙ 02/2016

Version

■■ Direct mounting

■■ Remote mounting with capillary

Sensor dimensions

Direct mounting

Process conncection Stem diameter Active length Insertion length

D

∅ D in mm X in mm Y in mm

12 (standard) 85 145 1)

9.5 (option) 135 195 1)

1) Other insertion length for direct mounting, ≤ 1 m

Remote mounting with capillary

Bulb Insertion Capillary

Process conncection

length length

D

Stem Active

↕

Ymin in mm K in m

diameter length

∅ D in mm X in mm

12 (standard) 85 2) ≥ 145 2) 2, 4, 6, 8, 10

9.5 (option) 135 ≥ 195

2) X = 103 mm; Y = 163 mm for setting range 0 ... 600 °C

Adjustable insertion length Y for remote mounting with Electrical connection

capillary ■■ ½ NPT female (standard)

Due to the flexibility of the spiral armour, the insertion length ■■ ¾ NPT, M 20 x 1.5, G ½, G ¾ female

(Y) can be adjusted during installation with the sliding ■■ Cable gland non-armoured, nickel-plated brass

compression fitting. The values are calculated as per the ■■ Cable gland non-armoured, stainless steel (AISI 304)

following equation: ■■ Cable gland armoured, nickel-plated brass

Minimum insertion length Ymin = see table above ■■ Cable gland armoured, stainless steel (AISI 304)

Maximum insertion length Ymax = capillary length (K) x 150 ■■ MIL connector, 7-pin, DTL 5015

Example: For cable connections to the internal terminal block use wire

Capillary length K: 2 m cross-sections between 0.5 ... 2.5 mm2.

Setting range: 0 ... 100 °C For the internal and external grounding cable connection

Stem diameter ∅ D: 12 mm to the protective conductor screws use wire cross-sections

≤ 4 mm2.

Minimum insertion length Ymin = 145 mm

Maximum insertion length Ymax = 2 x 150 mm = 300 mm Dielectric strength

Safety class I (IEC 61298-2: 2008)

Adjustable insertion length Y = 145 ... 300 mm

The capillary length is reduced accordingly. Mounting

Maximum capillary reduction ■■ Direct (only for direct mounting)

K¯= Ymax - Ymin = 300 - 145 = 155 mm ■■ Wall mounting (only for remote mounting with capillary)

- Standard: Mounting fixture from stainless steel (AISI 304)

Minimum capillary length - Option: Mounting bracket for 2" pipe mounting

Kmin = K - K¯ = 2,000 – 155 = 1,845 mm

Weight

Due to the adjustable insertion length (Y) of approx. 2.2 kg (with 2 m capillary)

145 ... 300 mm, the resulting capillary length (K) varies

between 2.0 ... 1,845 m.

Process conncection

Stainless steel compression fitting, sliding on capillary or

stem

■■ ½ NPT male (standard)

■■ ¾ NPT, male

■■ G ½ A, male

■■ G ¾ A, male

WIKA data sheet TV 31.60 ∙ 02/2016 Page 3 of 5

Setting range

Setting range Working range Proof Fixed dead band Adjustable dead band

temperature

in °C in °C in °C 1 contact, 2 contacts, 1 contact,

UN, US, UO, UG DN, DS, DO, DG UR

in °C in °C in °C

-30 ... +70 -40 ... +70 120 ≤ 4.5 ≤ 4.5 15 ... 35

0 ... 100 -40 ... +100 120 ≤ 4.5 ≤ 4.5 15 ... 35

0 ... 160 -40 ... +160 190 ≤5 ≤5 18 ... 35

0 ... 250 -40 ... +250 300 ≤6 ≤6 21 ... 45

0 ... 400 1) -40 ... +400 500 ≤ 10 ≤ 10 33 ... 77

0 ... 600 2) -40 ... +600 600 ≤ 17 ≤ 17 50 ... 115

1) For direct mounting version maximum working range ≤ 250 °C

2) Not available for direct mounting

Thermowell Options

In principle, the operation of a temperature switch without ■■ Other process conncection, also with adapter

a thermowell is possible with low process-side loading (low ■■ Capillary length to customer specification

pressure, low viscosity and low flow velocities). ■■ Permissible ambient temperature -60 ... +85 °C 1)

However, in order to enable exchanging the temperature ■■ Helical bulb (ambient temperature: -30 ... +70 °C)

switch during operation (e.g. instrument replacement or ■■ Contact bulb, to measure surface temperatures on flat

calibration) and to ensure a better protection of the instru- surfaces or pipes

ment and also the plant and the environment, it is advisable ■■ Other insertion length for direct mounting, ≤ 1 m

to use a thermowell from the extensive WIKA thermowell ■■ Offshore version 2)

portfolio. ■■ NACE version 2)

For further information on the calculation of the thermowell,

see Technical information IN 00.15. 1) Only available for contacts without hermetic sealing

2) WIKA recommends argon gas-filled contact versions, allowed use of adjustable

dead band.

Approvals

Logo Description Country

EC declaration of conformity European Community

■■ Low voltage directive 2006/95/EC, EN 60730-1

■■ ATEX 1) directive 94/9/EC; annex III, IV (option)

IM1

II 1 GD

IECEx 1) per IEC 60079-0, IEC 60079-11, IEC 60079-26 (option) IECEx member states

Ex ia I Ma

Ex ia IIC T6/T4 2) Ga

Ex ia IIIC T85/T135 2) Da

EAC (option) Eurasian Economic Community

Hazardous areas (option)

KOSHA (option) South Korea

Hazardous areas

1) Double marking ATEX and IECEx on the same product label.

2) The temperature class is related to the ambient temperature range.

Manufacturer‘s information and certifications

Logo Description

SIL 2 rating (option), per IEC 61508

Functional safety

The electrical rating for DC applications is limited to

30 V ... 100 mA

Page 4 of 5 WIKA data sheet TV 31.60 ∙ 02/2016

Certificates (option)

■■ 2.2 test report per EN 10204

■■ 3.1 inspection certificate per EN 10204

Approvals and certificates, see website

Dimensions in mm

Direct mounting Remote mounting with capillary

Process conncection

Electrical connection

Electrical connection ↕ Process conncection

For sensor dimensions D, X and Y see page 3

Ordering information

Model / Mounting / Number of switches / Contact type / Capillary length / Setting range / Process conncection/ Electrical

connection / Options

© 2011 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

WIKA data sheet TV 31.60 ∙ 02/2016 Page 5 of 5

02/2016 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Magnetic Switch For Bypass Level Indicators Model BGU: ApplicationsDocument10 pagesMagnetic Switch For Bypass Level Indicators Model BGU: ApplicationschauNo ratings yet

- Wika PSM-690 - D12 - 110818Document8 pagesWika PSM-690 - D12 - 110818chauNo ratings yet

- Appendix: Cross Reference BFTDocument7 pagesAppendix: Cross Reference BFTchauNo ratings yet

- In-Line Diaphragm Seal With Sterile Connection For Sanitary Applications Models 981.22, 981.52 and 981.53, Clamp ConnectionDocument5 pagesIn-Line Diaphragm Seal With Sterile Connection For Sanitary Applications Models 981.22, 981.52 and 981.53, Clamp ConnectionchauNo ratings yet

- Valve Manifold For Differential Pressure Gauges Model 910.25Document4 pagesValve Manifold For Differential Pressure Gauges Model 910.25chauNo ratings yet

- Thermowell With Flange (Fabricated) Version Per DIN 43772 Form 2F, 3F Models TW40-8, TW40-9Document3 pagesThermowell With Flange (Fabricated) Version Per DIN 43772 Form 2F, 3F Models TW40-8, TW40-9chauNo ratings yet

- Diaphragm Pressure Gauge For The Process Industry Models 432.50, 433.50, Up To 10-Fold Overload Safety, Max. 40 BarDocument4 pagesDiaphragm Pressure Gauge For The Process Industry Models 432.50, 433.50, Up To 10-Fold Overload Safety, Max. 40 BarchauNo ratings yet

- Bimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55Document11 pagesBimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55chauNo ratings yet

- Process Transmitter Model UPT-20, With Pressure Port Model UPT-21, With Flush DiaphragmDocument14 pagesProcess Transmitter Model UPT-20, With Pressure Port Model UPT-21, With Flush DiaphragmchauNo ratings yet

- Threaded Process Connection, Diaphragm Seals Model 990.31, Plastic DesignDocument2 pagesThreaded Process Connection, Diaphragm Seals Model 990.31, Plastic DesignchauNo ratings yet

- Threaded Process Connection, Diaphragm Seals Model 990.34, Welded DesignDocument4 pagesThreaded Process Connection, Diaphragm Seals Model 990.34, Welded DesignchauNo ratings yet

- Diaphragm Seal With Flange Connection With Internal Diaphragm, Threaded Design Model 990.41, Large Working VolumeDocument7 pagesDiaphragm Seal With Flange Connection With Internal Diaphragm, Threaded Design Model 990.41, Large Working VolumechauNo ratings yet

- Bimetal Thermometer Model 54, Industrial Series: ApplicationsDocument7 pagesBimetal Thermometer Model 54, Industrial Series: ApplicationschauNo ratings yet

- Machine Glass Thermometers Model 32, V-Form: ApplicationsDocument5 pagesMachine Glass Thermometers Model 32, V-Form: ApplicationschauNo ratings yet

- Bimetal Thermometer Model 52, Industrial Series: ApplicationsDocument6 pagesBimetal Thermometer Model 52, Industrial Series: ApplicationschauNo ratings yet

- Wika Model TI 30Document2 pagesWika Model TI 30Michael SheehanNo ratings yet

- Foxboro RTDDocument12 pagesFoxboro RTDJonathanGonzalezDiazNo ratings yet

- Pentronic - Temperature SensorsDocument16 pagesPentronic - Temperature SensorsVladislavNo ratings yet

- Data Sheet For Temperature Gauges and ThermowellsDocument29 pagesData Sheet For Temperature Gauges and ThermowellsSardar PerdawoodNo ratings yet

- Temp Gauge Ds Tm8101 en CoDocument8 pagesTemp Gauge Ds Tm8101 en CorahmadhaniNo ratings yet

- 14 Common Questions About Thermocouple Temperature MeasurementDocument6 pages14 Common Questions About Thermocouple Temperature MeasurementYiDan LiNo ratings yet

- Thermowell and Immersion Probe Installation OverviewDocument7 pagesThermowell and Immersion Probe Installation OverviewBEN ADEGBULUNo ratings yet

- 3300 Rev 1 - Functional Specification For Temperature GaugeDocument9 pages3300 Rev 1 - Functional Specification For Temperature GaugeYashwanth KumarNo ratings yet

- Asme PTC 19.3 TW-2010Document56 pagesAsme PTC 19.3 TW-2010Rem FgtNo ratings yet

- Installation, Operation & Maintenance Manual: FLT 93 Series FlexswitchDocument106 pagesInstallation, Operation & Maintenance Manual: FLT 93 Series FlexswitchmaurimouNo ratings yet

- SERIES 17000, 18000: ThermoswitchDocument7 pagesSERIES 17000, 18000: ThermoswitchItaloOliveiraNo ratings yet

- Solve 6 Leading Pressure & Temp Measurement ProblemsDocument23 pagesSolve 6 Leading Pressure & Temp Measurement ProblemsKamitkumar PatelNo ratings yet

- Krohne TD Optitemp Tra TcaDocument60 pagesKrohne TD Optitemp Tra TcaCardoso MalacaoNo ratings yet

- Numbers 1Document1,033 pagesNumbers 1Feras Mohammed SiddigNo ratings yet

- TSWDocument1 pageTSWPankaj RamoleNo ratings yet

- Thermoelectric CatalogueDocument229 pagesThermoelectric CataloguevyasathNo ratings yet

- Ba01028ten 1717Document114 pagesBa01028ten 1717nguyenkien2502No ratings yet

- A500, A512 Series PDFDocument2 pagesA500, A512 Series PDFthanh nguyenNo ratings yet

- GMS Instruments Catalogus 2021 RDocument92 pagesGMS Instruments Catalogus 2021 RAdrian RojasNo ratings yet

- 3-2 Control SystemDocument11 pages3-2 Control Systemاسماعیل ادریس عبدالعزیز100% (1)

- Instrument Indent Material ListDocument24 pagesInstrument Indent Material Listsujit100% (2)

- Btu Meter FormDocument2 pagesBtu Meter Formtkm2004No ratings yet

- Termometro Bimetalico Angulo AjustableDocument4 pagesTermometro Bimetalico Angulo AjustableFernando CarreñoNo ratings yet

- Asme PTC 19.3 TW (2010)Document2 pagesAsme PTC 19.3 TW (2010)a.r.sarate0% (1)

- Thermowell PDFDocument2 pagesThermowell PDFalisuseNo ratings yet

- NORSOK I-104 - Rev. 2 - June 1998Document51 pagesNORSOK I-104 - Rev. 2 - June 1998Walid LabidiNo ratings yet

- S 55 WikaDocument2 pagesS 55 WikaAliArababadiNo ratings yet

- WFC Gap AnalysisDocument2 pagesWFC Gap AnalysisDilodilaver DilaverNo ratings yet

- Pamphlet 165 Edition 2 FINALDocument26 pagesPamphlet 165 Edition 2 FINALmbtcpNo ratings yet

- Duct Immersion Strap On Temperature Andover TT XDocument6 pagesDuct Immersion Strap On Temperature Andover TT XDavid CantoralNo ratings yet