Professional Documents

Culture Documents

PDK Valve Body and Temp Sensor

PDK Valve Body and Temp Sensor

Uploaded by

Krzysztof KjbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDK Valve Body and Temp Sensor

PDK Valve Body and Temp Sensor

Uploaded by

Krzysztof KjbCopyright:

Available Formats

3

Service

Technical Information

90/11 ENU 3823

Repairing Temperature Sensor in PDK Transmission (90/11)

Information

This Technical Information replaces the TI dated August 10, 2012.

Changes/additions compared to the previous Technical Information:

"Parts Info." section: Part number for screws for electrohydraulic control unit omitted. Screws must

not be replaced.

Steps “5” and “14”: New illustration.

Vehicle Type: Boxster (987)/Boxster S (987)

Cayman/Cayman S/Cayman R

911 Carrera (997)/911 Carrera S (997)/911 Turbo (997)/911 Turbo S (997)

Model Year: As of 2009 up to 2011

Equipment: PDK transmission (I-no. 250)

Concerns: Temperature sensor in PDK transmission

Information: Defective crimp connection on temperature sensor in PDK transmission.

Defective crimp connections on the temperature sensor in the PDK transmission can cause the warning

message “Gearbox emergency operation” to be displayed.

In addition, the fault memory entries

• P0711 with P17F0/P17F1/P17F2

• P172D by itself or with P17F1/P17F2/P17F2

are stored in the PDK control unit.

Information

For details of the exact procedure for the various fault codes, see flow charts '3730 - Flow charts for

PDK fault codes'.

Action Replace the temperature sensor in the PDK transmission.

Required:

The repairs are documented and invoiced under fault location (FES5) “38230” and damage code (SA4)

“4021” in the PQIS job.

Also attach the related Vehicle Analysis Log (VAL) to this PQIS job.

Work on the PDK transmission requires absolute cleanliness and extreme care.

2013© Porsche Cars North America, Inc. Jun 13, 2013

AfterSales Page 1 of 13

3

Service

Technical Information

3823 ENU 90/11

Information

The procedure described here may only be carried out using the crimping tool 'AD-1377 Crimp Tool'

(000.043.207.78).

Part Nos.: 997.612.930.01 New/ Transmission fluid temperature sensor repair kit

9G1.321.025.00 ATF pan, complete (with aluminum screws and drain plug)

000.043.207.78 New/ Crimping tool 'AD-1377 Crimp Tool'

Information

Only one crimping tool can be ordered for each Porsche dealership and additional crimping tools

cannot be supplied.

Tools: Nr.155-2 Pos.2 - Hand pliers

Nr.155-1 Pos.2 - Hot-air blower

9768 - Electronic torque wrench, 2 - 100 Nm/1.5 - 74 ftlb.

WE1372 - Manual metering pump

9818 - PIWIS Tester II

Work Procedure: 1 Jack and raise the vehicle at the prescribed jacking points.

Workshop Manual '4X00IN01 Lifting the vehicle'

2 Remove underbody panelling.

Workshop Manual '519419 Removing and installing cover for rear underbody - section on

"Removing"'

3 Drain ATF.

Workshop Manual '370255 Changing ATF - section on "Draining"'

4 Remove ATF pan.

Jun 13, 2013 2013© Porsche Cars North America, Inc.

Page 2 of 13 AfterSales

3

Service

Technical Information

90/11 ENU 3823

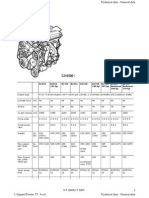

Tightening sequences for PDK transmission

Information

Although you have drained the ATF, there will still be residual oil in the ATF pan.

4.1 Loosen all screws on the ATF pan except for screws 1 and 3 in reverse tightening sequence

and then unscrew them.

WARNING

Hot fluid

• Danger of scalding

Let the fluid cool down.

Wear personal protective gear.

4.2 Carefully lever off the ATF pan on the opposite side to screws 1 and 3 and catch any oil that

overflows.

4.3 Unscrew screws 1 and 3 on the ATF pan and carefully remove the ATF pan.

5 Remove electrohydraulic control unit.

2013© Porsche Cars North America, Inc. Jun 13, 2013

AfterSales Page 3 of 13

3

Service

Technical Information

3823 ENU 90/11

Overview of tightening sequence for electrohydraulic control unit

5.1 Unscrew screws 16 and 18.

5.2 Screw two M6 x 300 screws approx. 10 turns into screw holes 16 and 18.

5.3 Unscrew the remaining screws in reverse tightening sequence and carefully set the electro-

hydraulic control unit down on the screw heads of the long screws (16 and 18).

5.4 Remove retaining clip Figure 1 -1- for the temperature sensor Figure 1 -2- (retaining

clip and screw will be re-used during fitting).

Jun 13, 2013 2013© Porsche Cars North America, Inc.

Page 4 of 13 AfterSales

3

Service

Technical Information

90/11 ENU 3823

The cable plugs on the solenoid valves must

not be removed.

Figure 1

Figure 2

6 Disconnect old sensor line (starting from the front edge of the temperature sensor) Length 130

mm ( Figure 2 -A-).

7 Remove the remaining black shrink-fit hose.

2013© Porsche Cars North America, Inc. Jun 13, 2013

AfterSales Page 5 of 13

3

Service

Technical Information

3823 ENU 90/11

Figure 3

8 Strip white and orange line Length 5 mm ( Figure 3 -A-).

When stripping the lines, make sure not to damage or disconnect any strands.

9 Crimping on new temperature sensor.

9.1 Slide shrink-fit sleeve over the line Figure

4.

Twist the individual strands.

9.2 Slide insulated cable connection sleeve over

the stripped area of the line as far as the insu-

lation.

All strands of the line must be covered

(crimped).

If more than two strands are sticking out

of the insulated cable connection sleeve Figure 4

following crimping, the PDK transmission

must be replaced.

Jun 13, 2013 2013© Porsche Cars North America, Inc.

Page 6 of 13 AfterSales

3

Service

Technical Information

90/11 ENU 3823

9.3 First hold the insulated cable connection

sleeve firmly in the red crimping jaw of the

crimping tool (do not press together).

Make sure that the edge of the insulated cable

connection sleeve is aligned with the edge of

the crimping tool Figure 5.

9.4 Guide the new cable with temperature sensor

as far as it will go into the insulated cable

connection sleeve. Check that the line

colors are assigned correctly.

Figure 5

All strands of the line must be in the

insulated cable connection sleeve.

If more than two strands are sticking out of the insulated cable connection sleeve

following crimping, the transmission must be replaced.

9.5 Crimp the insulated cable connection sleeve using the red crimping jaw of the crimping tool.

Information

Press the crimping tool together firmly as far as it will go. It only opens again after it has been

completely actuated .

10 Repeat the process (crimping) on the second line 9.1.

11 Slide the shrink-fit sleeves over the crimped contacts

and shrink the sleeves with a hot-air blower Figure

6.

Information

Adhesive in the heat shrink sleeves turns to liquid

when heated. The adhesive can emerge slightly at

the ends of the heat shrink sleeves after they shrink.

Figure 6

2013© Porsche Cars North America, Inc. Jun 13, 2013

AfterSales Page 7 of 13

3

Service

Technical Information

3823 ENU 90/11

12 Slide the additional black protective tube as far as it

will go over the two new crimps.

12.1 The existing black protective tube and the

new protective tube must overlap. There

must be no bare cable visible ( Figure 7

-arrow-).

12.2 Shrink protective tube using a hot-air blower.

Figure 7

13 Fit temperature sensor with the clip Tightening

torque 6 Nm (4.5 ftlb.) ( Figure 8 -arrow-).

14 Install electrohydraulic control unit.

Figure 8

Jun 13, 2013 2013© Porsche Cars North America, Inc.

Page 8 of 13 AfterSales

3

Service

Technical Information

90/11 ENU 3823

Overview of tightening sequence for electrohydraulic control unit

Information

• Before installation, check the sealing faces on the electrohydraulic control unit and on the trans-

mission for damage and dirt/grime.

• Damaged or soiled parts must not be used. Ensure absolute cleanliness during installation.

14.1 The wire harness for the solenoid valves and the cable for the temperature sensor must be

routed in the recess between the transmission housing and electrohydraulic control unit

because otherwise the cables can be crushed, resulting in damage and malfunctions.

14.2 Check that the wire harness is positioned correctly after installing the electrohydraulic

control unit.

14.3 Make sure that the electrohydraulic control unit is flat on the PDK transmission housing.

14.4 The electrohydraulic control unit must be positioned exactly with respect to the port plate.

2013© Porsche Cars North America, Inc. Jun 13, 2013

AfterSales Page 9 of 13

3

Service

Technical Information

3823 ENU 90/11

14.5 Fit and tighten screws 1 to 15 in the specified sequence.

14.6 Unscrew long screws (16 and 18).

14.7 Fit and tighten screws 16 to 20 in the specified sequence.

14.8 Check the position of the electrohydraulic control unit again.

14.9 Tighten screws 1 to 20.

Observe tightening specifications for screws for electrohydraulic control unit.

Screws are tightened in 2 steps:

Step 1: Tightening torque 1.5 Nm (1 ftlb.) +1.5 Nm (+1 ftlb.)

Step 2: Tightening torque 7.9 Nm (6 ftlb.) +0.2 Nm (+0.1 ftlb.)

15 Install new ATF pan.

Tightening sequences for PDK transmission

Information

Always use a new ATF pan and new aluminum screws.

The sealing faces of the transmission and ATF pan must be clean and dry for installation.

Before screwing in the new screws, blow out the threaded bore thoroughly with compressed air.

Have a clean, lint-free cloth on hand to collect any emerging particles of dirt.

15.1 Coat the sealing ring on the intake snorkel on the ATF pan with oil.

15.2 Fit ATF pan on the PDK transmission and make sure that the sealing ring on the intake

connection of the ATF pan is lying on the intake duct of the electrohydraulic control unit.

15.3 Press the ATF pan onto the PDK transmission until the sealing ring on the intake connection

clicks into the intake duct of the electrohydraulic control unit and the ATF pan is flat on the

PDK transmission.

Jun 13, 2013 2013© Porsche Cars North America, Inc.

Page 10 of 13 AfterSales

3

Service

Technical Information

90/11 ENU 3823

15.4 Screw M6 screws into the ATF pan and tighten according to the specified sequence,

Tightening sequences for PDK transmission.

Information

• The aluminum screws for the differential housing cover must be replaced.

• The aluminum screws for the Porsche Doppelkupplung (PDK) must be tightened using

the yield-point-controlled tightening method.

• Special tool 9768 - electronic torque wrench is used for this.

• To ensure that the screws are tightened uniformly, the corresponding tightening setting

“light, medium or hard” must always be used.

Tighten M6 screws at “medium” setting.

Tightening torque 2.4 Nm (1.5 ftlb.)

16 Screw in and tighten new ATF drain plug. Tightening torque 15 Nm (11ftlb.) +3 Nm (+2 ftlb.)

17 Fill in ATF.

Workshop Manual '370255 Changing ATF - section on "Filling"'.

18 Get the vehicle ready.

18.1 • Move selector lever to position “P”.

• Start the engine and leave it running at idle speed.

• Apply the parking brake.

18.2 Unscrew ATF filler screw.

18.2.1 ATF emerges: Collect emerging ATF until only drops of ATF are emerging.

18.2.2 No ATF emerges: Top up ATF until drops of ATF emerge at the filler bore.

18.2.3 Screw in ATF filler screw.

18.3 Preparatory work for checking ATF.

Information

Oil fill mode can be activated for Transmission fluid temperature 35°C +/-5°C . The trans-

mission control unit ends oil fill mode automatically after 5 minutes.

Prerequisite: Transmission fluid temperature Minimum temperature 10°C

18.3.1 Connect PIWIS Tester II.

18.3.2 Shift the selector lever through gearshift positions “R”, “N” and “D” once with the

engine running and pause for one second at each position.

18.3.3 Move selector lever to position “P”.

2013© Porsche Cars North America, Inc. Jun 13, 2013

AfterSales Page 11 of 13

3

Service

Technical Information

3823 ENU 90/11

18.3.4 Start oil fill mode on PIWIS Tester II and follow the instructions.

18.4 Check ATF in oil fill mode.

WARNING

Hot fluid

• Danger of scalding

Let the fluid cool down.

Wear personal protective gear.

18.4.1 Unscrew ATF filler screw.

18.4.2 ATF emerges: Collect emerging ATF until only drops of ATF are emerging.

18.4.3 No ATF emerges: Top up ATF until drops of ATF emerge at the filler bore.

18.5 Screw in and tighten new ATF filler screw, Tightening torque 35 Nm (26 ftlb.) +/-3 Nm

(+/-2 ftlb.) .

18.6 Disconnect PIWIS Tester II from the vehicle and switch off engine.

19 Install underbody panelling.

Workshop Manual '519419 Removing and installing cover for rear underbody - section on

"Installing"'.

Location Explanation Type Basic value Tolerance 1 Tolerance 2

Disconnect Length 130 mm

temperature

sensor line

Strip lines Length 5 mm

Screw securing Tightening torque 6 Nm (4.5 ftlb.)

retaining clip to

PDK transmission

housing

Screws securing Tightening torque 1.5 Nm (1 ftlb.) +1.5 Nm

electrohydraulic (+1 ftlb.)

control unit to

PDK transmission

Screws securing Tightening torque 7.9 Nm (6 ftlb.) +0.2 Nm

electrohydraulic (+0.1 ftlb.)

control unit to

PDK transmission

Jun 13, 2013 2013© Porsche Cars North America, Inc.

Page 12 of 13 AfterSales

3

Service

Technical Information

90/11 ENU 3823

Location Explanation Type Basic value Tolerance 1 Tolerance 2

Screw securing M6, "Medium" Tightening torque 2.4 Nm (1.5 ftlb.)

ATF pan to PDK setting

transmission

ATF drain plug in Tightening torque 15 Nm (11ftlb.) +3 Nm (+2 ftlb.)

ATF pan

Oil fill mode Transmission 35°C +/-5°C

fluid temperature

Check ATF Minimum 10°C

temperature

ATF filler Tightening torque 35 Nm (26 ftlb.) +/-3 Nm

screw on PDK (+/-2 ftlb.)

transmission

References: Workshop Manual '4X00IN01 Lifting the vehicle'

Workshop Manual '519419 Removing and installing cover for rear underbody'

Workshop Manual '370255 Changing ATF'

Important Notice: Technical Bulletins issued by Porsche Cars North America, Inc. are intended only for use by professional automotive technicians who have attended Porsche service training

courses. They are written to inform those technicians of conditions that may occur on some Porsche vehicles, or to provide information that could assist in the proper servicing of a vehicle. Porsche special

tools may be necessary in order to perform certain operations identified in these bulletins. Use of tools and procedures other than those Porsche recommends in these bulletins may be detrimental to the

safe operation of your vehicle, and may endanger the people working on it. Properly trained Porsche technicians have the equipment, tools, safety instructions, and know-how to do the job properly and

safely. If a particular condition is described, do not assume that the bulletin applies to your vehicle, or that your vehicle will have that condition. See your authorized Porsche Dealer for the latest information

about whether a particular technical bulletin applies to your vehicle. Part numbers listed in these bulletins are for reference only. Always check with your authorized Porsche dealer to verify the current and

correct part numbers. The work procedures updated electronically in the Porsche PIWIS diagnostic and testing device take precedence and, in the event of a discrepancy, the work procedures in the PIWIS

Tester are the ones that must be followed. © Porsche Cars North America, Inc.

Dealership Service Manager _______ Shop Foreman _______ Service Technician ________ _______ _______ _______

Distribution

Routing Asst. Manager _______ Warranty Admin. _______ Service Technician ________ _______ _______ _______

Dr. Ing. h.c. F. Porsche AG is the owner of numerous trademarks, both registered and unregistered, including without limitation the Porsche Crest®, Porsche®, Boxster®, Carrera®, Cayenne®,

Cayman®, Panamera®, Speedster®, Spyder®, 918 Spyder®, Tiptronic®, VarioCam®, PCM®, PDK®, 911®, 4S®, FOUR, UNCOMPROMISED.® and the model numbers and the distinctive shapes of

the Porsche automobiles such as, the federally registered 911 and Boxster automobiles. The third party trademarks contained herein are the properties of their respective owners. Porsche Cars North

America, Inc. believes the specifications to be correct at the time of printing. Specifications, performance standards, standard equipment, options, and other elements shown are subject to change without

notice. Some options may be unavailable when a car is built. Some vehicles may be shown with non-U.S. equipment. The information contained herein is for internal use only by authorized Porsche dealers

and authorized users and cannot be copied or distributed. Porsche recommends seat belt usage and observance of traffic laws at all times. Printed in the USA

2013© Porsche Cars North America, Inc. Jun 13, 2013

AfterSales Page 13 of 13

You might also like

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- A Project Report On Marketing StrategiesDocument69 pagesA Project Report On Marketing Strategiesnk2409199370% (10)

- Company Case - PorscheDocument3 pagesCompany Case - PorscheArgie Catambacan100% (1)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Vw/Audi Special Tools 0B5 (7 Speed DSG) : Part No. 0B5.TOOL04Document2 pagesVw/Audi Special Tools 0B5 (7 Speed DSG) : Part No. 0B5.TOOL04radenko100% (2)

- BMW Transmission Name Designations ExplainedDocument2 pagesBMW Transmission Name Designations Explained2bjornNo ratings yet

- 997 PDK Oil Change ProcedureDocument11 pages997 PDK Oil Change ProcedureEd MoralesNo ratings yet

- Aj6 Engineering IgnitionDocument9 pagesAj6 Engineering IgnitionBo Bobo100% (1)

- M104 IAT Temp Sensor PDFDocument7 pagesM104 IAT Temp Sensor PDFKanishka PrasadNo ratings yet

- SSP 398 Audi Lane AssistDocument28 pagesSSP 398 Audi Lane AssistRomeo BelkoNo ratings yet

- The Mercedes W108, W109 V8 With Buyer's Guide, Chassis Number And Data Card ExplanationFrom EverandThe Mercedes W108, W109 V8 With Buyer's Guide, Chassis Number And Data Card ExplanationNo ratings yet

- 6 Speed Automatic Gearbox 09g VW Golf 5 Passat b6 Eng 07 2011Document167 pages6 Speed Automatic Gearbox 09g VW Golf 5 Passat b6 Eng 07 2011Krzysztof Kjb100% (1)

- Mercedes-Benz Diagnostic Trouble CodesDocument10 pagesMercedes-Benz Diagnostic Trouble CodesKrzysztof KjbNo ratings yet

- Porsche - Case Study - FinalDocument21 pagesPorsche - Case Study - FinalSafiNo ratings yet

- Porsche - US Cayman-R - 2011 PDFDocument24 pagesPorsche - US Cayman-R - 2011 PDFSculatorNo ratings yet

- Rep S5DDocument151 pagesRep S5DDoru DariusNo ratings yet

- Hints About The 722.9 Trans...Document2 pagesHints About The 722.9 Trans...garyswindell100% (4)

- PDK Transmission Fluid ChangeDocument2 pagesPDK Transmission Fluid ChangeEd Morales100% (1)

- SMGDocument47 pagesSMGgreena3100% (2)

- Remove E60 530d Turbo PDFDocument2 pagesRemove E60 530d Turbo PDFmassimo1983100% (2)

- Engine - Repair - 1997-2000 EV Repair ManualDocument327 pagesEngine - Repair - 1997-2000 EV Repair ManualJorge Sepulveda100% (1)

- DQ200issue en PDFDocument7 pagesDQ200issue en PDFIdris TalibNo ratings yet

- 6 Spd. Automatic Transmission 09L All Wheel DriveDocument452 pages6 Spd. Automatic Transmission 09L All Wheel DriveNP100% (1)

- CSL SMG Flash GuideDocument5 pagesCSL SMG Flash GuideSandi VovkNo ratings yet

- 722.9 Stator UpdateDocument1 page722.9 Stator Updatetalleres Llanos del campoNo ratings yet

- 2015 12 Feb JPAT 4WD Single Parts Cat PDFDocument66 pages2015 12 Feb JPAT 4WD Single Parts Cat PDFLuis MigueloNo ratings yet

- Mercedes 04 WDocument6 pagesMercedes 04 WDoszlop DiannaNo ratings yet

- 722.6 ATF FlushDocument4 pages722.6 ATF FlushalintrigitalNo ratings yet

- ZF 6 HP 19Document5 pagesZF 6 HP 19RicPeNo ratings yet

- Mercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDDocument6 pagesMercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDTransmisiones Automáticas Chepe50% (2)

- Vehicle List TCU MANAGER Ver.12.08.04Document33 pagesVehicle List TCU MANAGER Ver.12.08.04Ing. Alejandro NarvaezNo ratings yet

- 18672622-2PPSRMS-2010 Porsche Panamera Service Repair Manual Software-1 PDFDocument1 page18672622-2PPSRMS-2010 Porsche Panamera Service Repair Manual Software-1 PDFTodor NakovNo ratings yet

- SB 10072385 2280Document312 pagesSB 10072385 2280David Solis50% (2)

- Manual-Audi-8Vel0BW Hybrid Four-Wheel Drive PDFDocument173 pagesManual-Audi-8Vel0BW Hybrid Four-Wheel Drive PDFCarlos Garcia GodoyNo ratings yet

- Tacho SoftDocument58 pagesTacho SoftabrahamNo ratings yet

- 09D-TG AtsgDocument75 pages09D-TG AtsgValdir Gomiero100% (3)

- 722 6 InterlockDocument2 pages722 6 InterlockJack CarlNo ratings yet

- Engine ListDocument3 pagesEngine ListLemont 3vNo ratings yet

- Bosch KE3-Jetronic Mixture AdjustmentDocument5 pagesBosch KE3-Jetronic Mixture Adjustmentasamu10No ratings yet

- Audi SSP 324 PDFDocument56 pagesAudi SSP 324 PDFMario Alberto Abarca Rodriguez100% (1)

- 722 3Document12 pages722 3Daniel AlvaradoNo ratings yet

- SM 32Document197 pagesSM 32Jean Carlo Portales ChavezNo ratings yet

- 5HP30Document43 pages5HP30David Rosado100% (1)

- Audi MentainnceDocument2 pagesAudi MentainncePetar Jankovic100% (2)

- Parts and Accessories - Installation Instructions: Park Distance Control (PDC)Document11 pagesParts and Accessories - Installation Instructions: Park Distance Control (PDC)koks_s3No ratings yet

- A0056006120-Audi A6 Suspension Service Manual - Running Gear Front-Wheel Drive and Four-Wheel DriveDocument468 pagesA0056006120-Audi A6 Suspension Service Manual - Running Gear Front-Wheel Drive and Four-Wheel DriveThomas HallwrightNo ratings yet

- 2005 9-5 EnginesDocument2 pages2005 9-5 Enginessnappydressedotter100% (1)

- 05 E85 Driveline PDFDocument24 pages05 E85 Driveline PDFZakaria KalomarNo ratings yet

- Mode Generic Title Toyota/Lexus Title: Coolant TempDocument6 pagesMode Generic Title Toyota/Lexus Title: Coolant TempMohamed Wahieb100% (1)

- StarBrochure11 05Document33 pagesStarBrochure11 05MxScribdNo ratings yet

- Air Conditioning: Service Manual: System Wiring DiagramsDocument124 pagesAir Conditioning: Service Manual: System Wiring DiagramsJonas Dos Santos Andrade100% (1)

- TCM FailDocument3 pagesTCM Failcorie132100% (1)

- 6HP26X 28X CatalogDocument42 pages6HP26X 28X CatalogSANTOSLAGUNA7100% (3)

- Clutch Release Mechanism, Servicing: 1 - Transmission 2 - Intermediate PieceDocument9 pagesClutch Release Mechanism, Servicing: 1 - Transmission 2 - Intermediate PieceNilson BarbosaNo ratings yet

- Ford Panel VansDocument18 pagesFord Panel Vansmichal123456987No ratings yet

- VW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFDocument68 pagesVW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFlucafelicianioanNo ratings yet

- Wiring DiagramsDocument10 pagesWiring DiagramsJose PichinteNo ratings yet

- ZF 6 HP 19 ADocument6 pagesZF 6 HP 19 AWagner F. Castro100% (1)

- Building a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendFrom EverandBuilding a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendNo ratings yet

- Service Bulletin: Lliiiil6. - . - .Document10 pagesService Bulletin: Lliiiil6. - . - .Krzysztof KjbNo ratings yet

- 01J - 0AN LuzyDocument4 pages01J - 0AN LuzyKrzysztof KjbNo ratings yet

- 18wrzesień 2017Document84 pages18wrzesień 2017Krzysztof KjbNo ratings yet

- ZF Transmission Adaptations Drive CycleDocument3 pagesZF Transmission Adaptations Drive CycleKrzysztof KjbNo ratings yet

- Mitsubishi F4A-51: 4 SPEED FWD With Lock Up (Electronic Con Trol)Document2 pagesMitsubishi F4A-51: 4 SPEED FWD With Lock Up (Electronic Con Trol)Krzysztof KjbNo ratings yet

- TR-60SN: (VW 09D) 6 Speed RWD (Electronic Control) (VW Touareg, Porsche Cayenne, Audi Q7)Document3 pagesTR-60SN: (VW 09D) 6 Speed RWD (Electronic Control) (VW Touareg, Porsche Cayenne, Audi Q7)Krzysztof Kjb100% (1)

- Hyd Dual STD PDFDocument3 pagesHyd Dual STD PDFKrzysztof KjbNo ratings yet

- Renault Mj1, Mj3, ML: 3 SPEED IN LINE FWD (Electronic Control)Document2 pagesRenault Mj1, Mj3, ML: 3 SPEED IN LINE FWD (Electronic Control)Krzysztof KjbNo ratings yet

- Aw80 40le PDFDocument3 pagesAw80 40le PDFKrzysztof Kjb100% (2)

- A240 Series: 4 SPEED FWD (Hydraulic & Electronic Con Trol)Document2 pagesA240 Series: 4 SPEED FWD (Hydraulic & Electronic Con Trol)Krzysztof KjbNo ratings yet

- ZF 6HP32A 1070 020 XXX (VW) : 6 SPEED IN LINE FWD (Full Electronic Control)Document5 pagesZF 6HP32A 1070 020 XXX (VW) : 6 SPEED IN LINE FWD (Full Electronic Control)Krzysztof KjbNo ratings yet

- 01J PDFDocument3 pages01J PDFKrzysztof KjbNo ratings yet

- 722 000 100 200 PDFDocument4 pages722 000 100 200 PDFKrzysztof KjbNo ratings yet

- TR-60SN: (VW 09D) 6 Speed RWD (Electronic Control) (VW Touareg, Porsche Cayenne, Audi Q7)Document3 pagesTR-60SN: (VW 09D) 6 Speed RWD (Electronic Control) (VW Touareg, Porsche Cayenne, Audi Q7)Krzysztof KjbNo ratings yet

- 01J PDFDocument3 pages01J PDFKrzysztof Kjb0% (1)

- 5R55W (Ranger / Explorer) & 5R55S: 5 SPEED 4WD WITH LOCK UP (Full Electronic Control)Document4 pages5R55W (Ranger / Explorer) & 5R55S: 5 SPEED 4WD WITH LOCK UP (Full Electronic Control)Krzysztof Kjb100% (1)

- 3.4Ltr V6 A/T (With One Touch 2-4 Selector System) : Revision 05/2008Document2 pages3.4Ltr V6 A/T (With One Touch 2-4 Selector System) : Revision 05/2008Krzysztof KjbNo ratings yet

- Porsche Michelin Fitment Guide 2015 enDocument14 pagesPorsche Michelin Fitment Guide 2015 enLaurenNo ratings yet

- Zinance PPT 02222-2Document12 pagesZinance PPT 02222-2Sanchali GoraiNo ratings yet

- Porsche Classic ORIGINALE 01Document46 pagesPorsche Classic ORIGINALE 01scorpia88100% (2)

- Auto Data 1Document13 pagesAuto Data 1YYASEER KAGDINo ratings yet

- Boron Steel 1Document7 pagesBoron Steel 1RajanikantJadhavNo ratings yet

- His Life's WorkDocument4 pagesHis Life's WorkAdds GiddyNo ratings yet

- 911 Turbo GT2 GT3 Engine RepairDocument94 pages911 Turbo GT2 GT3 Engine RepairAntonio TanoNo ratings yet

- Masters Thesis The Volkswagen Bus in AmericaDocument209 pagesMasters Thesis The Volkswagen Bus in AmericamunsterhNo ratings yet

- Assignment: Shree Chanakya Education Society's Indira Institute of Management, PuneDocument12 pagesAssignment: Shree Chanakya Education Society's Indira Institute of Management, Puneshubham shelkeNo ratings yet

- Brand ManagementDocument79 pagesBrand ManagementTrinh Thi Thu TrangNo ratings yet

- Case Analysis 6 - PorscheDocument12 pagesCase Analysis 6 - PorscheAuliaRezaMeziardiNo ratings yet

- Project 928 BookDocument144 pagesProject 928 BookOscar HamerNo ratings yet

- Model Year 2017 and EarlierDocument4 pagesModel Year 2017 and EarlierJZM GulfNo ratings yet

- MC 10183472 0001Document3 pagesMC 10183472 0001Rabih AbouZeidNo ratings yet

- Literature Review of BMWDocument8 pagesLiterature Review of BMWf1gisofykyt3100% (1)

- Automotive ClusterDocument74 pagesAutomotive Clusterch_dashNo ratings yet

- C01 Mini Case Porsche 1Document17 pagesC01 Mini Case Porsche 1c3564430No ratings yet

- Amity University: Amity School of BusinessDocument47 pagesAmity University: Amity School of BusinessPranit Singh Chawla ૧ઉ100% (1)

- Volkswagen AR2013Document324 pagesVolkswagen AR2013cherikokNo ratings yet

- Global Manufacturing of VolkswagenDocument3 pagesGlobal Manufacturing of Volkswagennarmin mammadli0% (1)

- Porsche 2016 0502Document208 pagesPorsche 2016 0502pancaro93No ratings yet

- 2006 Porsche Cayenne 2006 Porsche Cayenne: Fig. 101: Supplemental Restraints Circuit (1 of 3)Document3 pages2006 Porsche Cayenne 2006 Porsche Cayenne: Fig. 101: Supplemental Restraints Circuit (1 of 3)Edson CostaNo ratings yet

- Porsche CanadaDocument8 pagesPorsche CanadaMohammed Omer Elgindi100% (1)

- Porsche Classic CatalogDocument31 pagesPorsche Classic Catalogwindsurferke007No ratings yet

- Porsche Financial Services BrochureDocument8 pagesPorsche Financial Services BrochureAndre BarnesNo ratings yet

- 9-2007 Cayenne Service Brochure - European PDFDocument6 pages9-2007 Cayenne Service Brochure - European PDFGerrald_Ellis_3923No ratings yet