Professional Documents

Culture Documents

Chapter 05 Spacers PDF

Chapter 05 Spacers PDF

Uploaded by

Leonardo Barrios CarreraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 05 Spacers PDF

Chapter 05 Spacers PDF

Uploaded by

Leonardo Barrios CarreraCopyright:

Available Formats

SPACERS

Well Area Operations Drilling Cements RPW2021A 1

Agip KCO Drilling Supervisor Training Course

TABLE OF CONTENTS

GENERAL INFORMATION

SPACERS

FLUSHES

CHEMICAL WASHES

OTHER REMARKS ABOUT SPACERS, FLUSHES AND CHEMICAL

WASHES

Well Area Operations Drilling Cements RPW2021A 2

Agip KCO Drilling Supervisor Training Course

GENERAL INFORMATION

To achieve good primary cementing, the cement has to completely fill the space

that was previously occupied by the mud, or other fluid previously in the well.

Cement slurries and mud are often incompatible and when they come into contact

with each other; they can form a viscous interface which causes increases in the

pumping pressure with the danger of breaking into weak formations and losing the

slurry in the uncased hole.

Therefore, the mud must be removed using suitable and efficient systems; this is

done using SPACERS, FLUSHES AND CHEMICAL WASHES.

Well Area Operations Drilling Cements RPW2021A 3

Agip KCO Drilling Supervisor Training Course

GENERAL INFORMATION

A SPACER, FLUSH or CHEMICAL WASH is therefore a fluid which flows between

mud in the well and the slurry and is used at all times.

Having as its main purpose that of removing the mud, it must be pumped in ahead of

the slurry but it is also useful behind the slurry to prevent contact with the mud even if

there is a mechanical displacement plug between the two fluids.

Three types of spacers exist

¾ Spacer

¾ Flush

¾ Chemical wash

Well Area Operations Drilling Cements RPW2021A 4

Agip KCO Drilling Supervisor Training Course

GENERAL INFORMATION

Cement slurry

rising through the annulus

Well Area Operations Drilling Cements RPW2021A 5

Agip KCO Drilling Supervisor Training Course

GENERAL INFORMATION

LOW

MOBILE

MOBILITY

MUD

MUD

FILTRATE CEMENT

FILTRATE

FILTER

CAKE

FORMATION CASING

Cement slurry cannot remove a viscous mud

Well Area Operations Drilling Cements RPW2021A 6

Agip KCO Drilling Supervisor Training Course

SPACERS

A Spacer is weighted with a material, generally barite, but sometimes hematite

or fine grain sand.

A spacer is used for the following reasons:

¾ it is a fairly viscous fluid so it does not leak into, and channel the mud

however irremovable it has become.

¾ its density is mid-way between that of the mud and that of the cement and

so it does not excessively reduce the hydrostatic pressure in certain

formations.

¾ it can contain abrasive particles.

Spacers are available for both WBM (water base muds) and OBM (oil base

muds).

When used with OBM, one or more surfactants are added to the spacer which

leave the surfaces of the casing and uncased hole water wet.

Well Area Operations Drilling Cements RPW2021A 7

Agip KCO Drilling Supervisor Training Course

SPACERS

Displacement efficiency

Formation

Standoff = C / (A-B)

Mud

B

C A

Casing

Cement

Cemented Area

Displacement

Efficiency =

Annular Area

Well Area Operations Drilling Cements RPW2021A 8

Agip KCO Drilling Supervisor Training Course

FLUSH

A Flush is a fluid which has not been weighted with material.

Typical examples of flushes are:

¾ plain water

¾ diesel

¾ brine; if the slurry is prepared with.

A flush is used for the following reasons:

¾ it is a Newtonian fluid which will readily go into turbulent flow and so in theory it is

highly effective in removing, and above all washing, the annulus.

¾ it is a light fluid which helps contain the total hydrostatic pressure in cases where

the density of the slurry risks triggering absorptions in some sections.

¾ it is a readily available fluid and is often inexpensive or even cheap.

When OBM is used, surfactants should be added also to flushes.

Well Area Operations Drilling Cements RPW2021A 9

Agip KCO Drilling Supervisor Training Course

CHEMICAL WASH

Chemical wash means a fluid with or without weighting material but which is

above all able to react with the filter cake, dissolve oily films on the walls and

leave them water wet, dissolve and remove emulsions created on close contact

of water fluids and oil (water block), or even react with fluids already present in

the formation or which will be pumped in subsequently.

For example, you could imagine a sodium silicate which reacts forming a filter

cake, with the formation chlorides, CaCl2 pumped previously for the same

purpose or with the slurry itself, greatly accelerating the setting time.

Common examples of chemical washes are:

¾ Silicates

¾ highly basic solutions

¾ organic and weak inorganic acids

¾ Phosphates

Well Area Operations Drilling Cements RPW2021A 10

Agip KCO Drilling Supervisor Training Course

OTHER REMARKS ABOUT SPACERS, FLUSHES AND

CHEMICAL WASHES

¾ their volume should be such as to provide a contact time with the walls of at least ten

minutes; in practical terms, this means a column with a height of between 150 and

300 metres is needed.

¾ must contain NaCl or KCl in the case of formations containing expanding clays.

¾ if they have to come into contact with the slurry, as is generally the case, they must

be absolutely compatible with it, as well as with the mud.

¾ they must not be damaging for pay formations or hamper the passage of the

hydrocarbons

¾ they must be easy to prepare, easy to find, stable and cheap.

¾ they are valid on their own but better results are obtained if several, each with a

specific characteristic, are used one after the other.

Well Area Operations Drilling Cements RPW2021A 11

Agip KCO Drilling Supervisor Training Course

OTHER REMARKS ABOUT SPACERS, FLUSHES AND

CHEMICAL WASHES

other remarks:

¾ fresh water should be limited to wide shallow casings and where it is more

certain that the hydrocarbon-bearing formation has a minimum clay content

and also when there is no risk of creating emulsions with the formation oil.

¾ brines can be used also when the slurry has been mixed with the same

type of chloride as in the brine (Na Cl, KCl).

¾ Warning: brines can easily create emulsions which in turn create

precipitates in the presence of certain products of the mud.

¾ rather than for dissolving dehydrated clay particles, chemical washes are

designed to alter the polarity which keeps the layers apart (swelling), with

the result of bringing them closer together.

Well Area Operations Drilling Cements RPW2021A 12

Agip KCO Drilling Supervisor Training Course

OTHER REMARKS ABOUT SPACERS, FLUSHES AND

CHEMICAL WASHES

The table below gives the viscosity values, measured using a Fann

Viscosimeter at variable rotation velocity, of the mixtures of a spacer and of a

mud, at the standard concentrations of 75/25, 50/50 and 25/75, as well as the

viscosity of the spacer and mud alone.

The spacer was weighted with barite at 1.54 kg/l and enriched with two

surfactants, while the mud was a traditional OBM at 1.44 kg/l.

Well Area Operations Drilling Cements RPW2021A 13

Agip KCO Drilling Supervisor Training Course

RHEOLOGIES

Mud % Spcr.% Temp oC 300 200 100 6 3 Pv Yp

100 - 27 97 72 45 13 11

75 25 27 119 90 55 15 13

50 50 27 42 34 23 9 7

25 75 27 45 35 24 9 8

- 100 27 32 23 15 5 4

.B.: The RATIO COMPATIBILITY index is calculated by dividing the max value at the viscosimeter

(at 300 RPM) of the mixture of the two fluids, by the max value (at 300 RPM) of the mud alone.

The fluids are considered compatible if this ratio is less than 2.5.

Max viscosity value of the mud and spacer mixture 119

Max viscosity value of the mud alone 97

RCI (Ratio Compatibility Index) = 1.227

Well Area Operations Drilling Cements RPW2021A 14

Agip KCO Drilling Supervisor Training Course

You might also like

- Depositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12From EverandDepositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12No ratings yet

- 1B - Drilling Cost and Drilling RateDocument37 pages1B - Drilling Cost and Drilling RateTu Dang TrongNo ratings yet

- The Use and Misuse of Centrifuges PDFDocument4 pagesThe Use and Misuse of Centrifuges PDFChandrasekar Srinivas MohanNo ratings yet

- A Comparison of High-Viscosity and High-Density Sweeps As Hole CleaningDocument1 pageA Comparison of High-Viscosity and High-Density Sweeps As Hole Cleaningsaa6383No ratings yet

- Welltrain Subsea Vertical Kill Sheet - API Field Units - Revised July 2010Document4 pagesWelltrain Subsea Vertical Kill Sheet - API Field Units - Revised July 2010ElrohirPendragonNo ratings yet

- Mgo LabDocument3 pagesMgo Labapi-336093393No ratings yet

- Drilling Fluid FunctionsDocument28 pagesDrilling Fluid FunctionsChristian Olascoaga MoriNo ratings yet

- Chapter-9 Drilling FluidsDocument8 pagesChapter-9 Drilling FluidsAAADSFDVSDVNo ratings yet

- Section 14C Treatment and DisposalDocument22 pagesSection 14C Treatment and DisposalLazharNo ratings yet

- 17-Section 17 Engineering DataDocument29 pages17-Section 17 Engineering DataLazharNo ratings yet

- PillsDocument3 pagesPillsAhmedMohsenNo ratings yet

- Warning Signs When CirculatingDocument7 pagesWarning Signs When CirculatingDidin DelgadoNo ratings yet

- 14 Contaminants - Part 2 NEWDocument26 pages14 Contaminants - Part 2 NEWLuis CarrilloNo ratings yet

- Stuck Pipe PDFDocument16 pagesStuck Pipe PDFcarlos801No ratings yet

- Depth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Document101 pagesDepth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Roger GuevaraNo ratings yet

- Completion Fluids Displacement and Cementing SpacersDocument18 pagesCompletion Fluids Displacement and Cementing SpacersAnonymous JMuM0E5YONo ratings yet

- IDPT - 08 - Intro To IPM Process and SystemsDocument15 pagesIDPT - 08 - Intro To IPM Process and Systemsnurwinanto01No ratings yet

- Casing andDocument48 pagesCasing andAboZaidNo ratings yet

- Baquiano 1 Reporte de Lodos PDFDocument1 pageBaquiano 1 Reporte de Lodos PDFLenis CeronNo ratings yet

- BP Lost Circulation TechniquesDocument6 pagesBP Lost Circulation TechniquesInderjeet HoodaNo ratings yet

- Section 3B NAF TestingDocument26 pagesSection 3B NAF TestingLazharNo ratings yet

- Completion Fluid ProgramDocument8 pagesCompletion Fluid ProgramMessaoud Amr100% (1)

- Field Fluids QaqcDocument38 pagesField Fluids QaqcscrbdgharaviNo ratings yet

- 2-Drilling Fluids AdidtivesDocument36 pages2-Drilling Fluids AdidtivesHayder AliNo ratings yet

- 09 - Standard WBM TESTING 2013Document45 pages09 - Standard WBM TESTING 2013Slim.BNo ratings yet

- 5 Effect of High Temp On MudsDocument8 pages5 Effect of High Temp On Mudsgplese0No ratings yet

- Drilling Fluid CompressibilityDocument1 pageDrilling Fluid CompressibilityLuisA.HarCórNo ratings yet

- 01-Section 02 Drilling Fluids Functions PDFDocument11 pages01-Section 02 Drilling Fluids Functions PDFLazharNo ratings yet

- 03-Section 3A WBM TestingDocument44 pages03-Section 3A WBM TestingLazharNo ratings yet

- p43 Formation Isolation ValveDocument1 pagep43 Formation Isolation ValvePak RioNo ratings yet

- IPM Bit TechnologyDocument70 pagesIPM Bit Technologyamin peyvandNo ratings yet

- BHA#006 8.5in PDXceed +EcoScope+ TeleScopeDocument1 pageBHA#006 8.5in PDXceed +EcoScope+ TeleScopeKelly Cubillos quirozNo ratings yet

- IWCF WI CH 2 Completion EquipmentDocument59 pagesIWCF WI CH 2 Completion Equipmentseyyid ali lylNo ratings yet

- 2 - DrillingFluidProperties - ESCertification v1 - 1 - 6180305 - 01Document37 pages2 - DrillingFluidProperties - ESCertification v1 - 1 - 6180305 - 01Ricardo VillarNo ratings yet

- Mud Properties and Measurements Revised 02Document42 pagesMud Properties and Measurements Revised 02Mohamed Ahmed AlyNo ratings yet

- Section - 10 Lost CirculationDocument16 pagesSection - 10 Lost CirculationIbrahim DewaliNo ratings yet

- KMC HydraulicDocument1 pageKMC HydraulicHunterNo ratings yet

- Iwcf 2007 Halliburton 11 08Document338 pagesIwcf 2007 Halliburton 11 08daniel abiaNo ratings yet

- Henriksen, VibekeDocument150 pagesHenriksen, VibekeHamed SadeghiNo ratings yet

- Hole Volume Mu-135aDocument8 pagesHole Volume Mu-135afadli.lpgNo ratings yet

- Mud MixDocument2 pagesMud MixscrbdgharaviNo ratings yet

- Wellbore Stability Effect of Mud Weight 1645782860Document27 pagesWellbore Stability Effect of Mud Weight 1645782860Muhammad Husein MahfudzNo ratings yet

- ContaminationDocument30 pagesContaminationSofiane KharchiNo ratings yet

- Rheological Models For Drilling FluidDocument16 pagesRheological Models For Drilling FluidModesty Ekeh100% (1)

- Mud NotesDocument56 pagesMud Notesrainaldy sebastianNo ratings yet

- Section 5B Rheology & HydraulicsDocument10 pagesSection 5B Rheology & HydraulicsLazharNo ratings yet

- Drilling CalculationDocument36 pagesDrilling CalculationYakoub YakoubiNo ratings yet

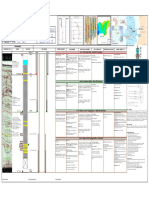

- Banda East Well Montage 28sept08 A4 SizeDocument1 pageBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNo ratings yet

- Determine Hole Cleaning Requirement in Deviated WellsDocument22 pagesDetermine Hole Cleaning Requirement in Deviated WellsCut Fanni Ayutaya100% (1)

- W5D3 - DE - Introduction To Borehole SurveyingDocument65 pagesW5D3 - DE - Introduction To Borehole SurveyingFernandoNo ratings yet

- Wellbore Stability MMBDocument18 pagesWellbore Stability MMBcamel 125No ratings yet

- Wellbore Instability in Oil Well Drillin PDFDocument10 pagesWellbore Instability in Oil Well Drillin PDFAhmed GharbiNo ratings yet

- Cementing Design Liner GeneralDocument5 pagesCementing Design Liner GeneralnkhamidyNo ratings yet

- Appendix-25 Sole-2 Wireline ReportDocument8 pagesAppendix-25 Sole-2 Wireline ReportAustinNo ratings yet

- Sickwellanalysis 2013Document28 pagesSickwellanalysis 2013mts1234No ratings yet

- 05 - SRB Hydraulic ProgramsDocument22 pages05 - SRB Hydraulic ProgramsnelsonhugoNo ratings yet

- 05-Section 5A Drilling Fluids RheologyDocument22 pages05-Section 5A Drilling Fluids RheologyLazhar100% (1)

- Kirksey - Squeeze CementingDocument37 pagesKirksey - Squeeze CementingAquiles CarreraNo ratings yet

- Drill in Fluids 1.0Document29 pagesDrill in Fluids 1.0Long Nhật PhanNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Mocks 2022chem 1Document11 pagesMocks 2022chem 1Pastor Bahemuka EdwardNo ratings yet

- Inzapol TX 6600Document2 pagesInzapol TX 6600New EmailNo ratings yet

- Determining The Biobased Content of Natural Range Materials Using Radiocarbon and Isotope Ratio Mass Spectrometry AnalysisDocument14 pagesDetermining The Biobased Content of Natural Range Materials Using Radiocarbon and Isotope Ratio Mass Spectrometry AnalysisMohanadNo ratings yet

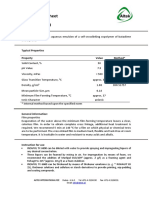

- AGIP ALARIA 3 - EnglishDocument4 pagesAGIP ALARIA 3 - EnglishobongomichelleNo ratings yet

- EPB-2. Wheat Gluten CNC TIo2 El-Wakil 2015Document40 pagesEPB-2. Wheat Gluten CNC TIo2 El-Wakil 2015mohammad9906426240No ratings yet

- Vessels Particulars: (SEP 2.1 / CP 10)Document1 pageVessels Particulars: (SEP 2.1 / CP 10)Pavel ViktorNo ratings yet

- A Comparative Study of Spectral Data and Color Fastness On 100% Linen and 100% Cotton Dyed With Reactive Dye in CPB AND PDPS Dyeing ProcessDocument62 pagesA Comparative Study of Spectral Data and Color Fastness On 100% Linen and 100% Cotton Dyed With Reactive Dye in CPB AND PDPS Dyeing ProcessDesign ZoneNo ratings yet

- BOF Post Combustion PaperDocument7 pagesBOF Post Combustion PaperAvs RamachandraNo ratings yet

- Msds Vaslin Putih WilDocument6 pagesMsds Vaslin Putih Wilprasetyo Ary wibowoNo ratings yet

- Tyfo SCH-7UP Composite: Using Tyfo S EpoxyDocument2 pagesTyfo SCH-7UP Composite: Using Tyfo S Epoxyyusak santosoNo ratings yet

- G7LM Q1W1 4v.6 PDFDocument31 pagesG7LM Q1W1 4v.6 PDFHazen Dominique Caparros MaquintoNo ratings yet

- Technical TextilesDocument13 pagesTechnical TextilesAchal Kanodia0% (2)

- F3 Chapter 4 Reactivity of MetalsDocument11 pagesF3 Chapter 4 Reactivity of MetalsJue Hazea GoldshopNo ratings yet

- Question 1255586Document10 pagesQuestion 1255586subrat swainNo ratings yet

- Chemical Reaction c8Document17 pagesChemical Reaction c8Alina SaraswatNo ratings yet

- The Adsorption of Gold On Minerals and Activated Carbon (Preg-Robbing) in Non-Ammoniacal Thiosulfate SolutionsDocument57 pagesThe Adsorption of Gold On Minerals and Activated Carbon (Preg-Robbing) in Non-Ammoniacal Thiosulfate SolutionsAldoNo ratings yet

- Case Study 1 BTK3813E Sem 2 - 2223Document3 pagesCase Study 1 BTK3813E Sem 2 - 2223nabil FarhaanNo ratings yet

- 08 Selection, Screening, and Analysis of RecombinantsDocument19 pages08 Selection, Screening, and Analysis of Recombinantsbiotic projectNo ratings yet

- Astm A351 A351mDocument5 pagesAstm A351 A351mOscar Franco MNo ratings yet

- Methods For Studying MicroorganismsDocument30 pagesMethods For Studying MicroorganismsAdnan Qureshi80% (5)

- Unit - 4 MCQ'sDocument8 pagesUnit - 4 MCQ'srishavr2001No ratings yet

- Official Confined Space Entry ChecklistDocument2 pagesOfficial Confined Space Entry ChecklistSaim AliNo ratings yet

- Modeling of Advanced Alkaline ElectrolyzersDocument11 pagesModeling of Advanced Alkaline ElectrolyzersAhmedNo ratings yet

- Calcium Silicate Bricks or Sand Lime BricksDocument4 pagesCalcium Silicate Bricks or Sand Lime Bricksmanhal alnoaimyNo ratings yet

- ARP6179-Evaluation of Gas Turbine Engine Lubricant Compatibility With Elastomer O-RingsDocument15 pagesARP6179-Evaluation of Gas Turbine Engine Lubricant Compatibility With Elastomer O-RingsJicheng PiaoNo ratings yet

- 9 EvaporationDocument82 pages9 Evaporationsanjay YadavNo ratings yet

- Food AdulterantDocument5 pagesFood AdulterantprayagaNo ratings yet

- Exxal Alcohols For SurfactantsDocument68 pagesExxal Alcohols For SurfactantsSteve JenkinsNo ratings yet

- Industrial Hazards Due To Fire Accidents, MechanicalDocument33 pagesIndustrial Hazards Due To Fire Accidents, MechanicalAmit Rohit100% (5)