Professional Documents

Culture Documents

100%(1)100% found this document useful (1 vote)

351 viewsPerform Underchassis Preventive Maintenance

Perform Underchassis Preventive Maintenance

Uploaded by

Alex J RoblesThis document outlines the learning outcomes, content, activities, assessment, and self-reflection for a module on performing underchassis preventive maintenance. The module covers 8 learning outcomes related to checking fluid levels and components under the vehicle such as the clutch, brakes, transmission, power steering, and tires. Learning activities include reading materials, lectures, demonstrations, practice, and feedback. Assessment includes a written exam, observation with oral questioning, and demonstration with oral questioning. The teacher will reflect on student strengths, weaknesses, feedback, and ways to improve instruction delivery.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- AURLTE102 Diagnose and Repair Light Vehicle EnginesDocument29 pagesAURLTE102 Diagnose and Repair Light Vehicle EnginesRoma RajaNo ratings yet

- Arjes Impaktor 250 - 28 - Carro InferiorDocument62 pagesArjes Impaktor 250 - 28 - Carro InferiorSergio UrquizoNo ratings yet

- Toyota Forklift 7fg FGK FDK Fga FDA 35 50 Operator ManualDocument20 pagesToyota Forklift 7fg FGK FDK Fga FDA 35 50 Operator Manualsamantha100% (56)

- CBLM Backhoe Loader Unit 2 Lo1docx CompressDocument67 pagesCBLM Backhoe Loader Unit 2 Lo1docx CompressCarmen GuevaraNo ratings yet

- Manual Tractor Comet 3 - 08F023948 - eDocument88 pagesManual Tractor Comet 3 - 08F023948 - eTina Manz100% (1)

- Flight Test: the Discipline: A Comprehensive Exploration of the Basic Tenets of Flight Test as a Discipline and Profession.From EverandFlight Test: the Discipline: A Comprehensive Exploration of the Basic Tenets of Flight Test as a Discipline and Profession.No ratings yet

- Passage Planning: To Be Used During Toolbox Meeting As A Guide For DiscussionDocument2 pagesPassage Planning: To Be Used During Toolbox Meeting As A Guide For Discussionsukhjit78100% (2)

- Rig Inspection CourseDocument1 pageRig Inspection CourseMohsenNo ratings yet

- ST 330-74-1974 Chevrolet Light Truck Service ManualDocument978 pagesST 330-74-1974 Chevrolet Light Truck Service Manualkkg4782100% (4)

- M T10000FS 02 05Document104 pagesM T10000FS 02 05Lari Simi100% (1)

- Vauxhall 2003 Zafira ManualDocument283 pagesVauxhall 2003 Zafira Manualtapusoa60% (5)

- 6) Perform Underchassis Preventive MaintenanceDocument52 pages6) Perform Underchassis Preventive MaintenanceROSAN YUMANGNo ratings yet

- Nrs Training Plan TemplateDocument15 pagesNrs Training Plan TemplateZulu198005No ratings yet

- Res 203Document2 pagesRes 203Marl Adam S CababasadaNo ratings yet

- SQE Marine Fumigation 2018 - 09Document2 pagesSQE Marine Fumigation 2018 - 09sailorsuraj3No ratings yet

- API 510demoDocument6 pagesAPI 510demoChiheb KaanicheNo ratings yet

- Session Plan-5-Clean Public Areas Facilities and EquipmentDocument2 pagesSession Plan-5-Clean Public Areas Facilities and EquipmentScarlette Beauty EnriquezNo ratings yet

- Institutional Assessment Instrument - Carry Out Minor Vehicle Maintenance and ServicingDocument8 pagesInstitutional Assessment Instrument - Carry Out Minor Vehicle Maintenance and ServicingClarissa Albor100% (1)

- Session Plan Final AssignmentDocument9 pagesSession Plan Final Assignmentabellajun61No ratings yet

- ASSESSMENT Q and ADocument4 pagesASSESSMENT Q and Ajohn wickNo ratings yet

- HvacDocument20 pagesHvacJoy CelestialNo ratings yet

- SESSION-PLAN - Driving NC IIDocument43 pagesSESSION-PLAN - Driving NC IIAllan Q Venus100% (2)

- Modul Praktik Aircraft Structure 1 20170220 - DipakeDocument47 pagesModul Praktik Aircraft Structure 1 20170220 - DipaketmarizNo ratings yet

- Learner'S Record Book: T I (T TI)Document7 pagesLearner'S Record Book: T I (T TI)Anjanette JestreNo ratings yet

- Plan Training SessionDocument4 pagesPlan Training SessionSon VertucioNo ratings yet

- Tesda Portfolio OrderDocument2 pagesTesda Portfolio OrderLuis S Alvarez Jr100% (1)

- 1table of ContentsDocument2 pages1table of ContentsHestia HDNo ratings yet

- Assessment Service Hydraulic SystemDocument3 pagesAssessment Service Hydraulic SystemEdward RaagasNo ratings yet

- Solano Ist622 ProjectDocument24 pagesSolano Ist622 Projectapi-338466351No ratings yet

- Perform Pre and Post Operation Procedures On Vehicles Under Lto Restricition Codes 6 To 8Document7 pagesPerform Pre and Post Operation Procedures On Vehicles Under Lto Restricition Codes 6 To 8Jason MandelaNo ratings yet

- Assessing Your Own Work: Information and Communication Technology Computer System Servicing Grade 9Document28 pagesAssessing Your Own Work: Information and Communication Technology Computer System Servicing Grade 9Bernadeth Irma Sawal Caballa100% (6)

- SESSION PLAN CORE - Plan Training SessionDocument8 pagesSESSION PLAN CORE - Plan Training SessionRomz ATNo ratings yet

- Session Plan - Observe Procedures, Specifications and Manuals of Instruction - JAR & LMN - v1.1Document4 pagesSession Plan - Observe Procedures, Specifications and Manuals of Instruction - JAR & LMN - v1.1Edward RaagasNo ratings yet

- Project Audit Check List WQTDocument2 pagesProject Audit Check List WQTFarhani YaakonNo ratings yet

- Course Syllabus SampleDocument10 pagesCourse Syllabus Samplececil josef liganNo ratings yet

- Form 5 6Document4 pagesForm 5 6Klowee SalasNo ratings yet

- Assessment Service Charging and StartingDocument3 pagesAssessment Service Charging and StartingEdward RaagasNo ratings yet

- New Quality Evidence Plan of QualityDocument8 pagesNew Quality Evidence Plan of QualityTedo MekonnenNo ratings yet

- Foreword: Aeronautical Institute of Bangladesh Maintenance Training Organization ExpositionDocument15 pagesForeword: Aeronautical Institute of Bangladesh Maintenance Training Organization ExpositionAib BDNo ratings yet

- OG TOGAF91 Accreditation Checklist v3.1Document27 pagesOG TOGAF91 Accreditation Checklist v3.1Oscar Bermudez GarciaNo ratings yet

- Self-Check No. 6.1-1Document11 pagesSelf-Check No. 6.1-1Exilda capinpinNo ratings yet

- Perform Basic BenchworkDocument45 pagesPerform Basic BenchworkrayNo ratings yet

- Syllabus Tracker AZ-500Document35 pagesSyllabus Tracker AZ-500Hazal AltinNo ratings yet

- US Environmental Protection Agency Office of Pesticide ProgramsDocument10 pagesUS Environmental Protection Agency Office of Pesticide ProgramsJeji HirboraNo ratings yet

- 1 Session Plan - PTSDocument12 pages1 Session Plan - PTSRoNnie RonNieNo ratings yet

- Maintain Training FacilitiesDocument19 pagesMaintain Training FacilitiesNheedz Bawa JuhailiNo ratings yet

- Chapter One 12320 A STUDY ON THE EFFICIENCY AND EFFECTIVENESS OF TOOL STORES TO MEET MAINTENANCE REQUIREMENT IN SLAF FLYING FORMATIONSDocument7 pagesChapter One 12320 A STUDY ON THE EFFICIENCY AND EFFECTIVENESS OF TOOL STORES TO MEET MAINTENANCE REQUIREMENT IN SLAF FLYING FORMATIONSStena NadishaniNo ratings yet

- Maintain Session PlanDocument5 pagesMaintain Session PlanRazonable Morales RommelNo ratings yet

- Tabbing CBLMDocument2 pagesTabbing CBLMSharmaine GonzalesNo ratings yet

- Syllabus Tracker AZ-104Document40 pagesSyllabus Tracker AZ-104Hazal AltinNo ratings yet

- Don Bosco Tvet Center-Calauan, Inc.: Session PlanDocument6 pagesDon Bosco Tvet Center-Calauan, Inc.: Session PlanJuliet N. CoronadoNo ratings yet

- TLIB107C - Check and Assess Operational Capabilities of Equipment - Learner GuideDocument34 pagesTLIB107C - Check and Assess Operational Capabilities of Equipment - Learner GuideromerofredNo ratings yet

- FLS and CCA GuidelinesDocument6 pagesFLS and CCA GuidelinesEllory James LintagNo ratings yet

- Session PlanDocument4 pagesSession PlanJohn BuenaaguaNo ratings yet

- 3 - Session PlanDocument3 pages3 - Session PlanNeil DuyagNo ratings yet

- TESDA Post Test With Answers ReviewerDocument12 pagesTESDA Post Test With Answers ReviewerScribdTranslations0% (1)

- CBCS4103 QuestionDocument11 pagesCBCS4103 Questionwas asdNo ratings yet

- Assessment Task 1 Cover Sheet: Student DeclarationDocument7 pagesAssessment Task 1 Cover Sheet: Student DeclarationManish Uprety0% (1)

- Minutes of The Meeting Focused Group Discussion (FGD) : CBT Concerns Discussions Resolutions/AgreementDocument3 pagesMinutes of The Meeting Focused Group Discussion (FGD) : CBT Concerns Discussions Resolutions/AgreementKirsten Q. Caminong100% (2)

- Software VarificationDocument22 pagesSoftware VarificationTHIRUNEELAKANDANNo ratings yet

- Coc 2Document62 pagesCoc 2Rommel PatoritoNo ratings yet

- Assessment Validation TemplateDocument4 pagesAssessment Validation TemplateUmesh Banga100% (1)

- CBLM - 1 - Planning - 2 - L (Session Plan)Document5 pagesCBLM - 1 - Planning - 2 - L (Session Plan)Oliver CalledoNo ratings yet

- Core CompetenciesDocument17 pagesCore CompetenciesChamsonNo ratings yet

- FORM 1.2 Evidences Proof of Current CompetenciesDocument4 pagesFORM 1.2 Evidences Proof of Current CompetenciesRochelle Cunanan LaurzanoNo ratings yet

- Lesson Plan Worksite Hazard Analysis 1-Hour ModuleDocument2 pagesLesson Plan Worksite Hazard Analysis 1-Hour ModuleWanMardziyyahNo ratings yet

- 1-5 Using and Applying Lubricants and Coolants PDFDocument34 pages1-5 Using and Applying Lubricants and Coolants PDFAlex J Robles100% (1)

- Performing Mensuration and CalculationDocument31 pagesPerforming Mensuration and CalculationAlex J Robles100% (1)

- Servicing Differential & Front AxleDocument38 pagesServicing Differential & Front AxleAlex J RoblesNo ratings yet

- Service Ignition SystemDocument38 pagesService Ignition SystemAlex J RoblesNo ratings yet

- Servicing Manual Steering SystemDocument79 pagesServicing Manual Steering SystemAlex J Robles100% (1)

- Working Title Citation CJ4: Quick Reference ChecklistDocument4 pagesWorking Title Citation CJ4: Quick Reference ChecklisttomrachNo ratings yet

- Relief Valve (Torque Converter)Document5 pagesRelief Valve (Torque Converter)Steven Y.MNo ratings yet

- 4x4 Australia Magazine EditorialDocument2 pages4x4 Australia Magazine EditorialopytnymoryakNo ratings yet

- Braking Systems - Past Present & FutureDocument6 pagesBraking Systems - Past Present & FutureAkshat SharmaNo ratings yet

- Paver Finisher: F 161 W / F 161-6W F 161-8WDocument145 pagesPaver Finisher: F 161 W / F 161-6W F 161-8WМихаил КудряшовNo ratings yet

- TM 10-3930-256-10 Mhe-198 Baker Model Ftd-060-Ee Forklift TruckDocument30 pagesTM 10-3930-256-10 Mhe-198 Baker Model Ftd-060-Ee Forklift TruckAdvocateNo ratings yet

- General Information ChassisDocument28 pagesGeneral Information ChassisKada Ben youcefNo ratings yet

- HysterDocument20 pagesHysterSales Ganatra Heavy LiftersNo ratings yet

- Chery Arauca Panel InstrumentosDocument1 pageChery Arauca Panel InstrumentosJose Luis Velasquez RomeroNo ratings yet

- Volvo Op Manual VNL & VNM 2001Document353 pagesVolvo Op Manual VNL & VNM 2001Thomas S Fulford IIINo ratings yet

- UrusDocument48 pagesUrusPIWONo ratings yet

- Spare Parts For Peougeot 306 Part No. Part Name QTYDocument188 pagesSpare Parts For Peougeot 306 Part No. Part Name QTYyared abebeNo ratings yet

- Spare Parts Gatalogue Getman Parte 1Document310 pagesSpare Parts Gatalogue Getman Parte 1EFREN SANCHEZ ROBLESNo ratings yet

- Manual CarroceroDocument78 pagesManual CarroceroPedro LeosNo ratings yet

- 2008 2010 Rhino 700fi Manual PDFDocument503 pages2008 2010 Rhino 700fi Manual PDFBaciu NicolaeNo ratings yet

- Forklift Vocabulary 1Document2 pagesForklift Vocabulary 1Alexandra KogukharNo ratings yet

- Hand Brake or Parking Brake (Automobile)Document5 pagesHand Brake or Parking Brake (Automobile)Ravi TarunNo ratings yet

- RW 1019Document109 pagesRW 1019Jerônimo RafaelNo ratings yet

- 510 SFC TT Sales Pitch BS6Document20 pages510 SFC TT Sales Pitch BS6Ankur MestryNo ratings yet

- Manitou MT 625 HA (EN)Document4 pagesManitou MT 625 HA (EN)ManitouNo ratings yet

- Ranger Over Sport L 494 Vehicle Handling GuideDocument56 pagesRanger Over Sport L 494 Vehicle Handling GuideTraveller100% (1)

- 4s Re Compact Bs4 SPCDocument89 pages4s Re Compact Bs4 SPCjai aroraNo ratings yet

- Breaks and PneumaticsDocument20 pagesBreaks and PneumaticsN.r. SaravananNo ratings yet

- Full Manual Peugeot 208Document352 pagesFull Manual Peugeot 208diseo2mx100% (1)

Perform Underchassis Preventive Maintenance

Perform Underchassis Preventive Maintenance

Uploaded by

Alex J Robles100%(1)100% found this document useful (1 vote)

351 views5 pagesThis document outlines the learning outcomes, content, activities, assessment, and self-reflection for a module on performing underchassis preventive maintenance. The module covers 8 learning outcomes related to checking fluid levels and components under the vehicle such as the clutch, brakes, transmission, power steering, and tires. Learning activities include reading materials, lectures, demonstrations, practice, and feedback. Assessment includes a written exam, observation with oral questioning, and demonstration with oral questioning. The teacher will reflect on student strengths, weaknesses, feedback, and ways to improve instruction delivery.

Original Description:

Original Title

perform underchassis preventive maintenance

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the learning outcomes, content, activities, assessment, and self-reflection for a module on performing underchassis preventive maintenance. The module covers 8 learning outcomes related to checking fluid levels and components under the vehicle such as the clutch, brakes, transmission, power steering, and tires. Learning activities include reading materials, lectures, demonstrations, practice, and feedback. Assessment includes a written exam, observation with oral questioning, and demonstration with oral questioning. The teacher will reflect on student strengths, weaknesses, feedback, and ways to improve instruction delivery.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

100%(1)100% found this document useful (1 vote)

351 views5 pagesPerform Underchassis Preventive Maintenance

Perform Underchassis Preventive Maintenance

Uploaded by

Alex J RoblesThis document outlines the learning outcomes, content, activities, assessment, and self-reflection for a module on performing underchassis preventive maintenance. The module covers 8 learning outcomes related to checking fluid levels and components under the vehicle such as the clutch, brakes, transmission, power steering, and tires. Learning activities include reading materials, lectures, demonstrations, practice, and feedback. Assessment includes a written exam, observation with oral questioning, and demonstration with oral questioning. The teacher will reflect on student strengths, weaknesses, feedback, and ways to improve instruction delivery.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 5

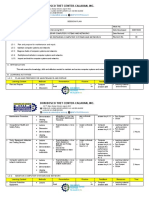

Sector : AUTOMOTIVE LAND TRANSPORTATION

Qualification Title : AUTOMOTIVE SERVICING NCII

Unit of Competency : PERFORM UNDERCHASSIS PREVENTIVE MAINTENANCE

Module: : PERFORMING UNDERCHASSIS PREVENTIVE MAINTENANCE

Learning Outcomes:

LO1. Check clutch fluid and lines

LO2. Inspect brake systems

LO3. Inspect/change transmission/differential gear oil

LO4. Inspect/replace power steering fluid

LO5. Check/re-fill automatic transmission fluid

LO6. Inspect/bleed air tank

LO7. Check tires and tire pressures

LO8. Check under-chassis body bolts and nuts

C. Introduction

This unit deals with the checking, replaceing of fluids and minor repair of underchassis components including tires

D. Learning Activities

LO1. CHECK CLUTCH FLUID AND LINES

Learning Content Presentation Practice Feedback Resources Time

A. Checking and maintaining clutch fluid > Read information sheet > Self-check (answer > Compare to answer > Information sheet

level between minimum and maximum > Lecture - demonstration written question) key > Job sheet

> Participate in group > Perform instruction > Instructor check > Instructor Aid

B. Checking clutch lines for twists and discussion on job sheet evaluation and > Materials

bends > Read job sheet > Return demonstratio recommendation > Tools and equipment

> Personal protective

C. Fitting clutch cover in the cap equipment

> Pens

D. Using clutch fluid > Notepads

LO2. INSPECT BRAKE SYSTEM

Learning Content Presentation Practice Feedback Resources Time

A. Checking and maintaining brake > Read Infomration sheet > Self-check (answer > Compare to answer > Information

fluid level between minimum and > Lecture written question) key > Job Sheet

maximum, andd using clear, undiluted demonstration > Perform instruction >Instructor check > Instructor Aid

fluid > Participation in group on job sheet evaluation and > Tools and equipment

discussion > Return demonstratio recommendation > Personal protective

B. Checking and freeing brake lines or > Read job Sheet equipment

hises of twist and bends

C. Specifying brake pedal free play

D. Checking and testing brake operation

E. Using/changing hydraulic fluid without

spillage and at specified level

F. Checking and adjusting brake pedal,

brake height and brake pre play

G. Bleeding hydraulic brake

H. Checking emergency brake functions

I. Identifying points for adjustments of

emergency brake

LO3. INSPECT?CHANGE TRANSMISSION/DIFFERENTIAL GEAR OIL

Learning Content Presentation Practice Feedback Resources Time

A. Inspecting gear oil > Read Infomration sheet > Self-check (answer > Compare to answer > Information

> Lecture written question) key > Job Sheet

B. Positioning vehicle demonstration > Perform instruction >Instructor check > Instructor Aid

> Participation in group on job sheet evaluation and > Tools and equipment

C. Selecting and using transmission discussion > Return demonstratio recommendation > Personal protective

gear oil which is clear and undiluted > Read job Sheet equipment

with other substances

D. Using grade/classification and level

of gear oil in accordance with

manufacturer's specification

LO4. INSPECT/REPLACE POWER STEERING FLUID

Learning Content Presentation Practice Feedback Resources Time

A. Inspecting power steering linkages > Read Infomration sheet > Self-check (answer > Compare to answer > Information

and connections > Lecture written question) key > Job Sheet

demonstration > Perform instruction >Instructor check > Instructor Aid

B. Parking vehicle and running engine > Participation in group on job sheet evaluation and > Tools and equipment

is at idle speed discussion > Return demonstratio recommendation > Personal protective

> Read job Sheet equipment

C. Inspecting/replacing fluid

LO5. CHECK/REFILL AUTOMATIC TRANSMISSION FLUID

Learning Content Presentation Practice Feedback Resources Time

A. Checking and repleneshing ATF to > Read Infomration sheet > Self-check (answer > Compare to answer > Information

required level > Lecture written question) key > Job Sheet

demonstration > Perform instruction >Instructor check > Instructor Aid

> Participation in group on job sheet evaluation and > Tools and equipment

discussion > Return demonstratio recommendation > Personal protective

> Read job Sheet equipment

LO6. INSPECTED/BLEED AIR TANK

Learning Content Presentation Practice Feedback Resources Time

A. Inspecting and bleeding air tank > Read Infomration sheet > Self-check (answer > Compare to answer > Information

> Lecture written question) key > Job Sheet

demonstration > Perform instruction >Instructor check > Instructor Aid

> Participation in group on job sheet evaluation and > Tools and equipment

discussion > Return demonstratio recommendation > Personal protective

> Read job Sheet equipment

LO7. CHECK TIRES AND TIRE PRESSURES

Learning Content Presentation Practice Feedback Resources Time

A. Inspecting tires for damage or > Read Infomration sheet > Self-check (answer > Compare to answer > Information

deformities and free of solid object > Lecture written question) key > Job Sheet

demonstration > Perform instruction >Instructor check > Instructor Aid

B. Checking and maintaining tire > Participation in group on job sheet evaluation and > Tools and equipment

pressure discussion > Return demonstratio recommendation > Personal protective

> Read job Sheet equipment

C. Performing tire rotation

LO8. CHECK UNDERCHASSIS BODY BOLTS AND NUTS

Learning Content Presentation Practice Feedback Resources Time

A. Checking bolts/nuts including tire > Read Infomration sheet > Self-check (answer > Compare to answer > Information

studs bolts/nuts > Lecture written question) key > Job Sheet

demonstration > Perform instruction >Instructor check > Instructor Aid

B. Checking and maintaining body bolts > Participation in group on job sheet evaluation and > Tools and equipment

and nuts torque discussion > Return demonstratio recommendation > Personal protective

> Read job Sheet equipment

C. Checking procedure according to

manufacturer's specifications

D. Determining the tightness of the

bolts by the sound by tapping bolts/nuts

lightly with pointed hammer

C. ASSESSMENT PLAN

> Written Examination

> Observation with oral questioning

> Demonstration with oral questioning

As the above activities are completed, the student will document the action performed in the progress chart

D. TEACHERS SELF-REFLECTION OF THE SESSION

> Identify the strong points/ineterest of the students

> Identify the weakness of the students

> Ask the student for their feedback with regards of the procedure performed

Ask the student on how they want the trainer to deliver the next competency in order for them to understand it more clearly

You might also like

- AURLTE102 Diagnose and Repair Light Vehicle EnginesDocument29 pagesAURLTE102 Diagnose and Repair Light Vehicle EnginesRoma RajaNo ratings yet

- Arjes Impaktor 250 - 28 - Carro InferiorDocument62 pagesArjes Impaktor 250 - 28 - Carro InferiorSergio UrquizoNo ratings yet

- Toyota Forklift 7fg FGK FDK Fga FDA 35 50 Operator ManualDocument20 pagesToyota Forklift 7fg FGK FDK Fga FDA 35 50 Operator Manualsamantha100% (56)

- CBLM Backhoe Loader Unit 2 Lo1docx CompressDocument67 pagesCBLM Backhoe Loader Unit 2 Lo1docx CompressCarmen GuevaraNo ratings yet

- Manual Tractor Comet 3 - 08F023948 - eDocument88 pagesManual Tractor Comet 3 - 08F023948 - eTina Manz100% (1)

- Flight Test: the Discipline: A Comprehensive Exploration of the Basic Tenets of Flight Test as a Discipline and Profession.From EverandFlight Test: the Discipline: A Comprehensive Exploration of the Basic Tenets of Flight Test as a Discipline and Profession.No ratings yet

- Passage Planning: To Be Used During Toolbox Meeting As A Guide For DiscussionDocument2 pagesPassage Planning: To Be Used During Toolbox Meeting As A Guide For Discussionsukhjit78100% (2)

- Rig Inspection CourseDocument1 pageRig Inspection CourseMohsenNo ratings yet

- ST 330-74-1974 Chevrolet Light Truck Service ManualDocument978 pagesST 330-74-1974 Chevrolet Light Truck Service Manualkkg4782100% (4)

- M T10000FS 02 05Document104 pagesM T10000FS 02 05Lari Simi100% (1)

- Vauxhall 2003 Zafira ManualDocument283 pagesVauxhall 2003 Zafira Manualtapusoa60% (5)

- 6) Perform Underchassis Preventive MaintenanceDocument52 pages6) Perform Underchassis Preventive MaintenanceROSAN YUMANGNo ratings yet

- Nrs Training Plan TemplateDocument15 pagesNrs Training Plan TemplateZulu198005No ratings yet

- Res 203Document2 pagesRes 203Marl Adam S CababasadaNo ratings yet

- SQE Marine Fumigation 2018 - 09Document2 pagesSQE Marine Fumigation 2018 - 09sailorsuraj3No ratings yet

- API 510demoDocument6 pagesAPI 510demoChiheb KaanicheNo ratings yet

- Session Plan-5-Clean Public Areas Facilities and EquipmentDocument2 pagesSession Plan-5-Clean Public Areas Facilities and EquipmentScarlette Beauty EnriquezNo ratings yet

- Institutional Assessment Instrument - Carry Out Minor Vehicle Maintenance and ServicingDocument8 pagesInstitutional Assessment Instrument - Carry Out Minor Vehicle Maintenance and ServicingClarissa Albor100% (1)

- Session Plan Final AssignmentDocument9 pagesSession Plan Final Assignmentabellajun61No ratings yet

- ASSESSMENT Q and ADocument4 pagesASSESSMENT Q and Ajohn wickNo ratings yet

- HvacDocument20 pagesHvacJoy CelestialNo ratings yet

- SESSION-PLAN - Driving NC IIDocument43 pagesSESSION-PLAN - Driving NC IIAllan Q Venus100% (2)

- Modul Praktik Aircraft Structure 1 20170220 - DipakeDocument47 pagesModul Praktik Aircraft Structure 1 20170220 - DipaketmarizNo ratings yet

- Learner'S Record Book: T I (T TI)Document7 pagesLearner'S Record Book: T I (T TI)Anjanette JestreNo ratings yet

- Plan Training SessionDocument4 pagesPlan Training SessionSon VertucioNo ratings yet

- Tesda Portfolio OrderDocument2 pagesTesda Portfolio OrderLuis S Alvarez Jr100% (1)

- 1table of ContentsDocument2 pages1table of ContentsHestia HDNo ratings yet

- Assessment Service Hydraulic SystemDocument3 pagesAssessment Service Hydraulic SystemEdward RaagasNo ratings yet

- Solano Ist622 ProjectDocument24 pagesSolano Ist622 Projectapi-338466351No ratings yet

- Perform Pre and Post Operation Procedures On Vehicles Under Lto Restricition Codes 6 To 8Document7 pagesPerform Pre and Post Operation Procedures On Vehicles Under Lto Restricition Codes 6 To 8Jason MandelaNo ratings yet

- Assessing Your Own Work: Information and Communication Technology Computer System Servicing Grade 9Document28 pagesAssessing Your Own Work: Information and Communication Technology Computer System Servicing Grade 9Bernadeth Irma Sawal Caballa100% (6)

- SESSION PLAN CORE - Plan Training SessionDocument8 pagesSESSION PLAN CORE - Plan Training SessionRomz ATNo ratings yet

- Session Plan - Observe Procedures, Specifications and Manuals of Instruction - JAR & LMN - v1.1Document4 pagesSession Plan - Observe Procedures, Specifications and Manuals of Instruction - JAR & LMN - v1.1Edward RaagasNo ratings yet

- Project Audit Check List WQTDocument2 pagesProject Audit Check List WQTFarhani YaakonNo ratings yet

- Course Syllabus SampleDocument10 pagesCourse Syllabus Samplececil josef liganNo ratings yet

- Form 5 6Document4 pagesForm 5 6Klowee SalasNo ratings yet

- Assessment Service Charging and StartingDocument3 pagesAssessment Service Charging and StartingEdward RaagasNo ratings yet

- New Quality Evidence Plan of QualityDocument8 pagesNew Quality Evidence Plan of QualityTedo MekonnenNo ratings yet

- Foreword: Aeronautical Institute of Bangladesh Maintenance Training Organization ExpositionDocument15 pagesForeword: Aeronautical Institute of Bangladesh Maintenance Training Organization ExpositionAib BDNo ratings yet

- OG TOGAF91 Accreditation Checklist v3.1Document27 pagesOG TOGAF91 Accreditation Checklist v3.1Oscar Bermudez GarciaNo ratings yet

- Self-Check No. 6.1-1Document11 pagesSelf-Check No. 6.1-1Exilda capinpinNo ratings yet

- Perform Basic BenchworkDocument45 pagesPerform Basic BenchworkrayNo ratings yet

- Syllabus Tracker AZ-500Document35 pagesSyllabus Tracker AZ-500Hazal AltinNo ratings yet

- US Environmental Protection Agency Office of Pesticide ProgramsDocument10 pagesUS Environmental Protection Agency Office of Pesticide ProgramsJeji HirboraNo ratings yet

- 1 Session Plan - PTSDocument12 pages1 Session Plan - PTSRoNnie RonNieNo ratings yet

- Maintain Training FacilitiesDocument19 pagesMaintain Training FacilitiesNheedz Bawa JuhailiNo ratings yet

- Chapter One 12320 A STUDY ON THE EFFICIENCY AND EFFECTIVENESS OF TOOL STORES TO MEET MAINTENANCE REQUIREMENT IN SLAF FLYING FORMATIONSDocument7 pagesChapter One 12320 A STUDY ON THE EFFICIENCY AND EFFECTIVENESS OF TOOL STORES TO MEET MAINTENANCE REQUIREMENT IN SLAF FLYING FORMATIONSStena NadishaniNo ratings yet

- Maintain Session PlanDocument5 pagesMaintain Session PlanRazonable Morales RommelNo ratings yet

- Tabbing CBLMDocument2 pagesTabbing CBLMSharmaine GonzalesNo ratings yet

- Syllabus Tracker AZ-104Document40 pagesSyllabus Tracker AZ-104Hazal AltinNo ratings yet

- Don Bosco Tvet Center-Calauan, Inc.: Session PlanDocument6 pagesDon Bosco Tvet Center-Calauan, Inc.: Session PlanJuliet N. CoronadoNo ratings yet

- TLIB107C - Check and Assess Operational Capabilities of Equipment - Learner GuideDocument34 pagesTLIB107C - Check and Assess Operational Capabilities of Equipment - Learner GuideromerofredNo ratings yet

- FLS and CCA GuidelinesDocument6 pagesFLS and CCA GuidelinesEllory James LintagNo ratings yet

- Session PlanDocument4 pagesSession PlanJohn BuenaaguaNo ratings yet

- 3 - Session PlanDocument3 pages3 - Session PlanNeil DuyagNo ratings yet

- TESDA Post Test With Answers ReviewerDocument12 pagesTESDA Post Test With Answers ReviewerScribdTranslations0% (1)

- CBCS4103 QuestionDocument11 pagesCBCS4103 Questionwas asdNo ratings yet

- Assessment Task 1 Cover Sheet: Student DeclarationDocument7 pagesAssessment Task 1 Cover Sheet: Student DeclarationManish Uprety0% (1)

- Minutes of The Meeting Focused Group Discussion (FGD) : CBT Concerns Discussions Resolutions/AgreementDocument3 pagesMinutes of The Meeting Focused Group Discussion (FGD) : CBT Concerns Discussions Resolutions/AgreementKirsten Q. Caminong100% (2)

- Software VarificationDocument22 pagesSoftware VarificationTHIRUNEELAKANDANNo ratings yet

- Coc 2Document62 pagesCoc 2Rommel PatoritoNo ratings yet

- Assessment Validation TemplateDocument4 pagesAssessment Validation TemplateUmesh Banga100% (1)

- CBLM - 1 - Planning - 2 - L (Session Plan)Document5 pagesCBLM - 1 - Planning - 2 - L (Session Plan)Oliver CalledoNo ratings yet

- Core CompetenciesDocument17 pagesCore CompetenciesChamsonNo ratings yet

- FORM 1.2 Evidences Proof of Current CompetenciesDocument4 pagesFORM 1.2 Evidences Proof of Current CompetenciesRochelle Cunanan LaurzanoNo ratings yet

- Lesson Plan Worksite Hazard Analysis 1-Hour ModuleDocument2 pagesLesson Plan Worksite Hazard Analysis 1-Hour ModuleWanMardziyyahNo ratings yet

- 1-5 Using and Applying Lubricants and Coolants PDFDocument34 pages1-5 Using and Applying Lubricants and Coolants PDFAlex J Robles100% (1)

- Performing Mensuration and CalculationDocument31 pagesPerforming Mensuration and CalculationAlex J Robles100% (1)

- Servicing Differential & Front AxleDocument38 pagesServicing Differential & Front AxleAlex J RoblesNo ratings yet

- Service Ignition SystemDocument38 pagesService Ignition SystemAlex J RoblesNo ratings yet

- Servicing Manual Steering SystemDocument79 pagesServicing Manual Steering SystemAlex J Robles100% (1)

- Working Title Citation CJ4: Quick Reference ChecklistDocument4 pagesWorking Title Citation CJ4: Quick Reference ChecklisttomrachNo ratings yet

- Relief Valve (Torque Converter)Document5 pagesRelief Valve (Torque Converter)Steven Y.MNo ratings yet

- 4x4 Australia Magazine EditorialDocument2 pages4x4 Australia Magazine EditorialopytnymoryakNo ratings yet

- Braking Systems - Past Present & FutureDocument6 pagesBraking Systems - Past Present & FutureAkshat SharmaNo ratings yet

- Paver Finisher: F 161 W / F 161-6W F 161-8WDocument145 pagesPaver Finisher: F 161 W / F 161-6W F 161-8WМихаил КудряшовNo ratings yet

- TM 10-3930-256-10 Mhe-198 Baker Model Ftd-060-Ee Forklift TruckDocument30 pagesTM 10-3930-256-10 Mhe-198 Baker Model Ftd-060-Ee Forklift TruckAdvocateNo ratings yet

- General Information ChassisDocument28 pagesGeneral Information ChassisKada Ben youcefNo ratings yet

- HysterDocument20 pagesHysterSales Ganatra Heavy LiftersNo ratings yet

- Chery Arauca Panel InstrumentosDocument1 pageChery Arauca Panel InstrumentosJose Luis Velasquez RomeroNo ratings yet

- Volvo Op Manual VNL & VNM 2001Document353 pagesVolvo Op Manual VNL & VNM 2001Thomas S Fulford IIINo ratings yet

- UrusDocument48 pagesUrusPIWONo ratings yet

- Spare Parts For Peougeot 306 Part No. Part Name QTYDocument188 pagesSpare Parts For Peougeot 306 Part No. Part Name QTYyared abebeNo ratings yet

- Spare Parts Gatalogue Getman Parte 1Document310 pagesSpare Parts Gatalogue Getman Parte 1EFREN SANCHEZ ROBLESNo ratings yet

- Manual CarroceroDocument78 pagesManual CarroceroPedro LeosNo ratings yet

- 2008 2010 Rhino 700fi Manual PDFDocument503 pages2008 2010 Rhino 700fi Manual PDFBaciu NicolaeNo ratings yet

- Forklift Vocabulary 1Document2 pagesForklift Vocabulary 1Alexandra KogukharNo ratings yet

- Hand Brake or Parking Brake (Automobile)Document5 pagesHand Brake or Parking Brake (Automobile)Ravi TarunNo ratings yet

- RW 1019Document109 pagesRW 1019Jerônimo RafaelNo ratings yet

- 510 SFC TT Sales Pitch BS6Document20 pages510 SFC TT Sales Pitch BS6Ankur MestryNo ratings yet

- Manitou MT 625 HA (EN)Document4 pagesManitou MT 625 HA (EN)ManitouNo ratings yet

- Ranger Over Sport L 494 Vehicle Handling GuideDocument56 pagesRanger Over Sport L 494 Vehicle Handling GuideTraveller100% (1)

- 4s Re Compact Bs4 SPCDocument89 pages4s Re Compact Bs4 SPCjai aroraNo ratings yet

- Breaks and PneumaticsDocument20 pagesBreaks and PneumaticsN.r. SaravananNo ratings yet

- Full Manual Peugeot 208Document352 pagesFull Manual Peugeot 208diseo2mx100% (1)