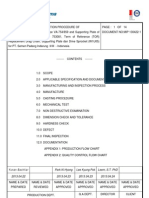

Professional Documents

Culture Documents

Kupdf Welding

Kupdf Welding

Uploaded by

SamayapuramCopyright:

Available Formats

You might also like

- Advanced Coating Solutions For The OilDocument4 pagesAdvanced Coating Solutions For The OilManivannanMudhaliarNo ratings yet

- EnDOtec Welding Cored WireDocument12 pagesEnDOtec Welding Cored WirecriuvosNo ratings yet

- Electrode Converted Into TextDocument14 pagesElectrode Converted Into TextNeha NimbarkNo ratings yet

- BergerMasterFile PDFDocument74 pagesBergerMasterFile PDFSumanta RoyNo ratings yet

- The Light Machine Shop Divided Into The Following SectionDocument5 pagesThe Light Machine Shop Divided Into The Following Sectionyogendra singhNo ratings yet

- Electrode Codes For Use in BoilersDocument4 pagesElectrode Codes For Use in Boilersh_patnaikNo ratings yet

- Advances in Thermal Spray TechnologyDocument3 pagesAdvances in Thermal Spray Technologyinterpon07No ratings yet

- FCAW Electrode DesignationDocument3 pagesFCAW Electrode DesignationthedreampowerNo ratings yet

- Specification Sheet: 2304: (UNS S32304)Document2 pagesSpecification Sheet: 2304: (UNS S32304)Deepak TdNo ratings yet

- AODDocument8 pagesAODPrakash Mishra100% (1)

- VAPOR-JET Venturi BlenderDocument2 pagesVAPOR-JET Venturi BlenderCaterine Jara CeaNo ratings yet

- Resicham Surface Prep GuidelinesDocument4 pagesResicham Surface Prep GuidelinesPJOE81No ratings yet

- FAQ - What Is The Procedure For Welding En24 (Subsequently Known As 817M40 and 1.6582 34CrNiMo6), A 0.4% C, 1.25% CR, 0.3% Mo LowDocument2 pagesFAQ - What Is The Procedure For Welding En24 (Subsequently Known As 817M40 and 1.6582 34CrNiMo6), A 0.4% C, 1.25% CR, 0.3% Mo LowSubhra S SanyalNo ratings yet

- Packing, Preservation and Storage ProcedureDocument9 pagesPacking, Preservation and Storage ProcedureMohamed FarisNo ratings yet

- Alloy Valves PDFDocument4 pagesAlloy Valves PDFYamil Diaz SantosNo ratings yet

- MIG Gas Mix Developed by EdDocument7 pagesMIG Gas Mix Developed by Edc_e_z_a_rNo ratings yet

- (Materiales) Productos CNFDocument18 pages(Materiales) Productos CNFNicolás Felipe Reyes CerdaNo ratings yet

- Brass MachiningDocument68 pagesBrass MachiningVaibhav ShuklaNo ratings yet

- Rotary Kiln Supporting Roll:: Case Histories On Integrity and Failures in Industry (Chifi)Document20 pagesRotary Kiln Supporting Roll:: Case Histories On Integrity and Failures in Industry (Chifi)Ramakrishnan AmbiSubbiahNo ratings yet

- Belzona - Cold Curing WrapsDocument4 pagesBelzona - Cold Curing WrapsNay ThihaNo ratings yet

- Free Fire Risk Assessment Example PDFDocument17 pagesFree Fire Risk Assessment Example PDFFairoza AmalinnaNo ratings yet

- Copper Tubes - ASTM B88MDocument7 pagesCopper Tubes - ASTM B88Myarzar17No ratings yet

- 06 VD Mee-Welding of Super Duplex Stainless SteelsDocument12 pages06 VD Mee-Welding of Super Duplex Stainless SteelsKareem AbdelazizNo ratings yet

- EutecTrode Manual Metal Arc Electrodes PDFDocument12 pagesEutecTrode Manual Metal Arc Electrodes PDFswapneel_kulkarniNo ratings yet

- ABJ PresentationDocument51 pagesABJ PresentationMarvin CastelinoNo ratings yet

- Duplex SSDocument12 pagesDuplex SSTushar PatilNo ratings yet

- CDP 4666 PDFDocument2 pagesCDP 4666 PDFVitor Rigueira de GodoyNo ratings yet

- Firelite 124Document1 pageFirelite 124pamelataboadalozanoNo ratings yet

- New Materials For Sour Gas Drill Pipe: 26 March/April 2002Document2 pagesNew Materials For Sour Gas Drill Pipe: 26 March/April 2002amigofirmNo ratings yet

- Aalco CatalogueDocument92 pagesAalco CatalogueNigin ParambathNo ratings yet

- Glassflake Lining Metal TanksDocument5 pagesGlassflake Lining Metal TanksSimbu ArasanNo ratings yet

- Carbon Steel Pipes - Comparing AmericanDocument2 pagesCarbon Steel Pipes - Comparing AmericanKazi Anwarul Azim SohelNo ratings yet

- 150-600 Gate ValveDocument4 pages150-600 Gate ValveSaquib NishatNo ratings yet

- Common Defects in Gas CuttingDocument14 pagesCommon Defects in Gas CuttingASHVIN YADAVNo ratings yet

- A F E S: Process Piping 670.200Document17 pagesA F E S: Process Piping 670.200puwarin najaNo ratings yet

- Nfa 49 215 Grade Tu 37c Tubes PDFDocument1 pageNfa 49 215 Grade Tu 37c Tubes PDFMitul MehtaNo ratings yet

- Pipe GuideDocument231 pagesPipe GuidegeorgD2010100% (2)

- Rimmed Vs Killed SteelDocument1 pageRimmed Vs Killed SteelMuthuKumarNo ratings yet

- Global Leader in SNG Energy Systems: (Synthetic Natural Gas)Document4 pagesGlobal Leader in SNG Energy Systems: (Synthetic Natural Gas)khairiNo ratings yet

- Mip - Chain Va.754Document16 pagesMip - Chain Va.754Jiggy JickNo ratings yet

- DMR 249 ADocument8 pagesDMR 249 Aasprclms durgapurNo ratings yet

- Specification For 3LPE CoatingDocument32 pagesSpecification For 3LPE Coatinggauravagrawal2010No ratings yet

- Assessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012Document39 pagesAssessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012abhi_luvme03100% (1)

- Cement Plant CorrosionDocument7 pagesCement Plant CorrosionHemlata ChandelNo ratings yet

- Syntho-Glass - OriginalDocument2 pagesSyntho-Glass - Originalkyawhlas5817No ratings yet

- PR8592 Welding TechnologyDocument77 pagesPR8592 Welding TechnologyVijayan VNo ratings yet

- Contrasting Welding Techniques Used On Pipelines and Refinery PipingDocument5 pagesContrasting Welding Techniques Used On Pipelines and Refinery PipingahmedNo ratings yet

- Chemilube E C G X: Description:-Grease For Lubricating Electrical Contacts Customer BenefitsDocument1 pageChemilube E C G X: Description:-Grease For Lubricating Electrical Contacts Customer BenefitssatfasNo ratings yet

- Duplex Stainless Steel DetailDocument12 pagesDuplex Stainless Steel DetailessnelsonNo ratings yet

- INCONEL 686 - INCO-WELD 686CPT Application List For IndiaDocument10 pagesINCONEL 686 - INCO-WELD 686CPT Application List For IndiaBhanu Pratap ChoudhuryNo ratings yet

- En 10028 P355GHDocument2 pagesEn 10028 P355GHEvriMert RüzgArdaNo ratings yet

- Floating Flange Rubber Expansion Joints: Series 980Document8 pagesFloating Flange Rubber Expansion Joints: Series 980Roland Bon IntudNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- Boldrocchi CatalogueDocument19 pagesBoldrocchi Catalogueamitjoshi2002No ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Material Receiving Inspection ReportDocument2 pagesMaterial Receiving Inspection Reportsmsunil12345No ratings yet

- Preview PDFDocument2 pagesPreview PDFLandon SchmidtNo ratings yet

- Heidelberg Client 3.0 The Evolutionary Step Following Our PC Lifecycle ManagementDocument27 pagesHeidelberg Client 3.0 The Evolutionary Step Following Our PC Lifecycle ManagementHoward HutchingsNo ratings yet

- Nature - The Hydrogen RevolutionDocument4 pagesNature - The Hydrogen RevolutionOUSSAMA BEN OMARNo ratings yet

- Product Information: Cordless Screwdriver and NutrunnerDocument96 pagesProduct Information: Cordless Screwdriver and Nutrunneradskñlfjñ kljfsgoiasNo ratings yet

- Sheet Metal Forming - PpsDocument26 pagesSheet Metal Forming - PpsNhan LeNo ratings yet

- Lecture 9-Binary Distillation ProblemsDocument18 pagesLecture 9-Binary Distillation ProblemsWasim NawazNo ratings yet

- Pipe Shop Standard For B31.9 - REV.05-2023Document1 pagePipe Shop Standard For B31.9 - REV.05-2023iplaruffNo ratings yet

- S1 Mcom Research Methodology Full NotesDocument163 pagesS1 Mcom Research Methodology Full Notesjayeshraj0000No ratings yet

- JJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Document9 pagesJJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Ah Tiang100% (1)

- Manufacturing Processes 1Document9 pagesManufacturing Processes 1Kodok SuperNo ratings yet

- Machine Tools Design: InstructorsDocument31 pagesMachine Tools Design: InstructorsAladdin AdelNo ratings yet

- Tsubaki Power Lock Ad N SeriesDocument5 pagesTsubaki Power Lock Ad N SeriesRizal IephoNo ratings yet

- Jamson Flotation CellsDocument10 pagesJamson Flotation CellsErland Yennfred Zegarra MezaNo ratings yet

- Minutes of Meeting: Bekapai-3 Surface Facilities Modification and Dogleg Installation (Epcic)Document13 pagesMinutes of Meeting: Bekapai-3 Surface Facilities Modification and Dogleg Installation (Epcic)Arung IdNo ratings yet

- Pull-Off Test Report - PUB Pedestrian Bridge ProjectDocument2 pagesPull-Off Test Report - PUB Pedestrian Bridge ProjectErin Williams100% (2)

- Questions BankDocument6 pagesQuestions BankSyed KhaleelullahNo ratings yet

- Document BED 330, 2Document8 pagesDocument BED 330, 2phirisimon815No ratings yet

- List Dobi in Sungai BesiDocument9 pagesList Dobi in Sungai BesihermancxNo ratings yet

- I.M Actividad 9Document82 pagesI.M Actividad 9AXEL JUAREZNo ratings yet

- Acceptance Criteria in Welding TableBDocument1 pageAcceptance Criteria in Welding TableBanishk6336No ratings yet

- Types and Characteristics of Common Grinding Circuit Flow SheetsDocument9 pagesTypes and Characteristics of Common Grinding Circuit Flow SheetsJoseluis Campean SedanoNo ratings yet

- 4grinding Polishing Flexible ToolsDocument113 pages4grinding Polishing Flexible ToolsGabriel DobrescuNo ratings yet

- Warehouse Resume ObjectiveDocument5 pagesWarehouse Resume Objectivehjsfixljg100% (1)

- Water-Based Polyurethane Acrylic Hybrid DispersionsDocument6 pagesWater-Based Polyurethane Acrylic Hybrid DispersionsDan RoskeNo ratings yet

- ResumeDocument2 pagesResumeapi-489105449No ratings yet

- QW-196 Resistance Weld Testing: ASME BPVC - IX-2019Document1 pageQW-196 Resistance Weld Testing: ASME BPVC - IX-2019Tahar DabbarNo ratings yet

- Concrete TechnologyDocument214 pagesConcrete Technologycheersbeer01No ratings yet

- WA Hardlite™: Ultra-Thin Composite WearplatesDocument5 pagesWA Hardlite™: Ultra-Thin Composite WearplatesFernando MilmanNo ratings yet

- Pitting-Acceptance or Rejection Pitting-Acceptance or RejectionDocument24 pagesPitting-Acceptance or Rejection Pitting-Acceptance or Rejectionmohammed harrisNo ratings yet

- Material Specification Sheet Saarstahl - 55Cr3: 1.7176 F 1 K BS: Afnor: Sae: Material GroupDocument1 pageMaterial Specification Sheet Saarstahl - 55Cr3: 1.7176 F 1 K BS: Afnor: Sae: Material GrouphdierkeNo ratings yet

- Airless Shot Blasting QuestionnaireDocument2 pagesAirless Shot Blasting Questionnairedonhan91No ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFHardikNo ratings yet

- Unit 7 Drill BushingsDocument24 pagesUnit 7 Drill BushingsRamiro Acosta CepedaNo ratings yet

- Introduction, Casting Process Casting Processes - NoteDocument22 pagesIntroduction, Casting Process Casting Processes - NoteVasantha SudasinghaNo ratings yet

Kupdf Welding

Kupdf Welding

Uploaded by

SamayapuramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kupdf Welding

Kupdf Welding

Uploaded by

SamayapuramCopyright:

Available Formats

Weld Joints

(a) Butt joint (b) Corner joint (c) T joint (d) Lap joint (e) Edge joint

FIGURE 12.1 Examples of welded joints.

e

c

y n

t

i a n

l

i n i

o

e t

t

b n c

a

i s s i e

r t t a p

a r r s s

h V a a e

c y

t M I

n

t P P n i

l f l

g n l a

e r i o a

n g

i l g l b

i e u t

e s a r e l s s s

r

t e m a o e a i o

Method S D S L T R E V C

Arc welding 1 2 3 1 3 1 2 2 2

Resistance welding 1 2 1 1 3 3 3 3 1

Brazing 1 1 1 1 3 1 3 2 3

Bolts and nuts 1 2 3 1 2 1 1 1 3

Riveting 1 2 3 1 1 1 3 1 2

Fasteners 2 3 3 1 2 2 2 1 3

Seaming, crimping 2 2 1 3 3 1 3 1 1

TABLE 12.1 Comparison of various joining

Adhesive bonding 3 1 1 2 3 2 3 3 2 methods.

Note: 1, very good; 2, good; 3, poor.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

General Summary

Joining Skill Level Welding Current Distor- Cost of

Process Operation Advantage Required Position Type tion

∗

Equipment

Shielded Manual Portable High All ac, dc 1 to 2 Low

Lo

metal arc and flexible

Submerged Auto

Autom

mat

atic

ic Hig

igh

h de

depo

possi- Low to Flat and ac, dc 1 to 2 Medium

arc tion medium horizontal

Gas metal Semiautomatic Works with Low to All dc 2 to 3 Meedium to

M

arc or automatic most metals high high

Gas tung- Manual or Works with Low to All ac, dc 2 to 3 Medium

sten arc automatic most metals high

Flux-cored Semiautomatic High deposi- Low to All dc 1 to 3 Medium

arc or automatic tion high

Oxyfuel Manual Portable High All – 2 to 4 Low

and flexible

Electron Semiautomatic Works with Medium to All – 3 to 5 High

beam,, las

beam laser

er or automatic most metals high

beam

∗

1, highest; 5, lowest

TABLE 12.2 General characteristics of joining processes.

processes.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Oxyfuel Gas Welding

2100 C

° 1260 C

°

Outer envelope Acetylene

(3800 F)

° (2300 F)

°

(small and narrow) feather

Inner cone Outer Inner cone Bright luminous Blue

3040 to 3300 C ° envelope (pointed) inner cone envelope

(5500 to 6000 F) °

(a) Neutral flame (b) Oxidizing flame (c) Carburizing (reducing) flame

Gas mixture

Filler rod Welding torch

Molten

Flame

weld metal

Solidified

Base metal weld metal

(d)

FIGURE 12.2 Three basic types of oxyacetylene flames used in oxyfuel gas welding and cutting

operations: (a) neutral flame; (b) oxidizing flame; (c) carburizing, or reducing, flame. (d) The principle of

the oxyfuel gas welding operation.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Pressure

Pressu re Gas Weldi

elding

ng

C2H2 + O2 mixture

Torch

withdrawn

Torch

Flame heating

of surfaces

Upsetting

force

Clamp

(a) (b)

FIGURE 12.3 Schematic illustration of the pressure gas welding

welding process; (a) before, and

(b) after.

after. Note

Note the formation of a flash at the joint, which can later be trimmed off.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Heatt Tran

Hea Transfer

sfer in Weld

Welding

ing

Specific Energy, u

Material J/mm3 BTU/in3

Aluminum and its alloys 2.9 41

Cast irons 7.8 112

Copper 6.1 87 Heat input

Bronze (90Cu-10Sn) 4.2 59 H V I

Magnesium 2.9 42 = e

Nickel 9.8 142 l v

Steels 9.1-10.3 128-146

Stainless steels 9.3-9.6 133-137

Titanium 14.3 204

Welding speed

TABLE 12.3 Approximate specific energy V I

required to melt a unit volume of commonly v = e

welded materials. uA

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Shielded

Shield ed Metal Arc Welding

Welding machine AC or DC

power source and controls Solidified slag

Work Arc Electrode

cable holder Coating

Electrode Electrode

Shielding

Work gas

Base metal

Electrode

cable Weld metal Arc

FIGURE 12.4 (a) Schematic illustration of the shielded metal arc welding process. About one-half of all

large-scale industrial welding operations use this process. (b) Schematic illustration of the shielded

metal arc welding operation.

7

5 4

2

FIGURE 12.5 A weld zone showing

showing the build-up

6 3

sequence of individual weld beads in deep welds.

8

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Submerg

Sub merged

ed Arc Weldi

Welding

ng

Electrode-wire reel

Flux hopper

Voltage and

current control

Unfused-flux

recovery tube

Wire-feed motor

Electrode cable

Contact tube

Workpiece Voltage-pickup

Weld backing leads (optional)

Ground

FIGURE 12.6 Schematic illustration of the submerged arc welding process

process and equipment. Unfused

flux is recovered and reused.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Gas Met

Metal

al Arc Weld

elding

ing

Solid wire electrode

Shielding gas

Current conductor

Travel

Nozzle

Wire guide and

Shielding gas contact tube

Arc

Solidified weld metal

Base metal Molten weld metal

(a)

Feed control

Control system Wire

Gas out

Gun control Gas in

Shielding-gas source

Gun

Workpiece

FIGURE 12.7 (a) Gas metal arc welding process,

Voltage control

formerly known as MIG welding (for metal inert

Wire-feed

drive motor Welding machine gas). (b) Basic equipment used in gas metal arc

welding operations.

Contactor control 110 V supply

(b)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Flux-C

Flu x-Cored

ored Arc Weld

Welding

ing

Current-carrying guide tube

Arc shield composed of Insulated extension tip

vaporized and slag-forming

compounds protects metal

transfer through arc

Powdered metal, vapor-or

gas-forming materials,

Solidified slag deoxidizers and scavengers

Molten slag

Arc

Solidified weld metal Base metal

Metal droplets covered with

thin slag coating forming

Molten molten puddle

weld metal

FIGURE 12.8 Schematic illustration of the flux-cored arc welding process. This

operation is similar to gas metal arc welding.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Electrogas & Electroslag Welding

Power source Control panel

Drive rolls

Electrode conduit Wire reel

Welding wire

Gas

Wire-feed drive

Oscillator

Electrode lead

Welding gun Oscillation (optional)

Water

Gas

Gas box Consumable

Gas guide tube

Water out Water out Molten slag

Welding wire Supplementary Work

shielding gas Molten weld pool

Water in Water in Workpiece

Fixed shoe Moveable shoe Retaining shoe

(ground) lead

Water in

Primary shielding gas

Water out

FIGURE 12.9 Schematic illustration of the

electrogas welding process. FIGURE 12.10 Equipment used for electroslag

welding operations.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Gas Tun

ungs

gste

tenn Arc

Arc Weld

Weldin

ingg

Travel

Electrical conductor

Tungsten electrode

Gas passage

Shielding gas

Filler wire Arc

Solidified weld metal

Molten weld metal

(a)

Inert-gas

ACor DC

Cooling-water supply

welder

supply

Torch

Filler rod

FIGURE 12.11 (a) Gas tungsten arc welding

Drain

Workpiece process, formerly known as TIG welding (for

tungsten inert gas). (b) Equipment for gas

Foot pedal (optional)

tungsten arc welding operations.

(b)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Plasma

Pla sma Arc Weldi

Welding

ng

Tungsten

electrode

– Plasma gas –

Shielding gas

Power Power

supply supply

+

(a) (b)

FIGURE 12.12 Two types of plasma arc welding processes: (a) transferred and (b)

nontransferred. Deep and narrow welds are made by this process at high welding

speeds.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Weld Bead Comparisons

Laser welds

(a) (b)

FIGURE 12.13 Comparison of the size of weld weld beads in (a) FIGURE 12.14 Gillette Sensor razor cartridge,

electron-beam or laser-beam welding with that in (b) with laser-beam welds.

conventional (tungsten arc) welding. Source: American Welding

Society, Welding Handbook, 8th ed., 1991.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Original Fusion zone Heat-affected

structure (weld metal) zone

Fusion

Fusio n Weld Charact

Characteristi

eristics

cs

Base metal

Molten weld metal

e

r

u

t Melting point of base metal

a

r

e

p Temperature at which the (a) (b)

m base-metal microstructure

e

T is affected

Original FIGURE 12.16

12.16 Grain structure

structure in (a) a deep

temperature weld and (b) a shallow weld. Note that the grains

of base metal

in the solidified weld metal are perpendicular to

FIGURE 12.15 Characteristics of a typical fusion their interface with the base metal.

weld zone in oxyfuel gas welding and arc welding

processes. 1 mm

0.1 mm 145 Melt zone

155

0.43 mm 260

330 Heat-affected

zone

355

Hardness (HV)

(a) (b)

FIGURE 12.17 (a) Weld bead on a cold-rolled nickel strip strip

produced by a laser beam. (b) Microhardness profile across the

Manufacturing Processes for Engineering Materials, 5th ed. weld bead. Note the lower hardness of the weld bead as

Kalpakjian • Schmid

© 2008, Pearson Education

compared with the base metal. Source: IIT Research Institute.

Fusion Defects

FIGURE 12.18 Intergranular corrosion

corrosion of a weld

joint in ferritic stainless-steel welded tube, after

exposure to a caustic solution. The weld line

li ne is at

the center of the photograph. Source: Courtesy

of Allegheny

Allegheny Ludlum Corp.

Weld Weld

Weld

FIGURE 12.19 Examples

of various incomplete Base

B

fusion in welds. metal

Incomplete fusion from oxide Incomplete fusion in a

or dross at the center of a joint, groove weld

Incomplete fusion in fillet welds. especially in aluminum

B is often termed bridging

! "

(a) (b) (c)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Defects in Welded Joints

Underfill Crack

Inclusions Base metal

Incomplete

penetration

(a)

FIGURE 12.19

12.19 Examples of various incomplete

Good weld

fusion in welds.

Overlap Undercut

Porosity

Lack of

penetration

(b) (c)

Weld

Toe crack

Transverse

crack

Longitudinal

Crater crack Base metal

cracks

Underbead

crack

FIGURE 12.20 Examples of various defects in

Weld

fusion welds.

Weld

Transverse

crack

Longitudinal

crack Base

metal

Base

metal Toe crack

(a) (b)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Weld Cra

Crack

ck

FIGURE 12.22 Crack in a weld bead, due to the fact that the two components

components

were not allowed to contract after the weld was completed. Source: Courtesy of

Packer Engineering.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Distortion

Distor tion in Welds

Weld FIGURE 12.23 Distortion and

Weld

warping of parts after welding,

caused by differential thermal

Transverse shrinkage Weld Weld

expansion and contraction of

Neutral axis

different regions of the welded

assembly. Warping can be reduced

Angular distortion

Longitudinal or eliminated by proper weld

shrinkage design and fixturing prior to

(a) (b) (c) (d)

welding.

Residual stress

Comp

Compre

ress

ssiv

ive

e Ten

ensi

sile

le

Base

metal FIGURE 12.24 Residual stresses developed in a

straight butt joint. Source: Courtesy of the

American Welding Society.

Weld

(a) (b)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Distortion

Distor tion of Welded Struct

Structures

ures

Rigid frame Hot zone (expanded) Contraction

Internal

Melt

(residual)

(pushed

tensile

out)

stress

No shape Distortion

change

( a) (b) (c)

FIGURE 12.25 Distortion of a welded structure. (a) Before welding;

welding; (b) during welding, with

weld bead placed in joint; (c) after welding, showing distortion in the structure. Source: After

J.A. Schey.

Schey.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Tens

ensio

ion-S

n-Shea

hearr Test

estin

ingg

Root bend

Longitudinal

tension-shear

Clamp

Roller Face bend

Weld

Transverse Side bend

tension-shear

(a) (b) (c)

FIGURE 12.26 (a) Types of specimens for tension-shear testing of welds. (b) Wraparound bend test method.

(c) Three-point bending of welded specimens. (See also Fig. 2.21.)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Tens

ensio

ion-

n-Sh

Shear

ear Tes

Testt of Sp

Spot

ot Wel

elds

ds

(a)

1.

Raised nugget

(b) 2.

Hole left in part

Button diameter

indicates quality

3.

(c) (d)

FIGURE 12.27 (a) Tension-shear test for spot welds; (b) cross-tension

cross-tension test; (c) twist

test; (d) peel test.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Roll Bonding & Ultras

Ultrasonic

onic Welding

Force

Mass

Cladding metal Transducer

Toolholder

Transducer DC

Base metal polarization Roller

Coupling

supply

system

Rolls Workpiece

Tip AC

Direction of power

Workpiece vibration supply

Anvil

FIGURE 12.28 Schematic illustration

of the roll-bonding, or cladding, (a) (b)

process.

FIGURE 12.29 (a) Components of an ultrasonic welding machine for

lap welds. (b) Ultrasonic seam welding using a roller.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Friction

Frict ion Welding

FIGURE 12.30 Sequence of operations in the

friction welding process. (1) The part on the left

Beginning of flash

Force is rotated at high speed. (2) The part on the right

r ight

1.

2.

Force

is brought into contact under an axial force. (3)

Speed increased The axial force is increased, and the part on the

h

t

g 3. left stops rotating; flash begins to form. (4) After

n

e

l

t

a specified upset length or distance is achieved,

e Flash

s

p the weld is completed. The upset length is the

U

,

e

distance the two pieces move inward during

c

r

o

Force 4. welding after their initial contact; thus, the total

F

,

d

e

length after welding is less than the sum of the

e

p Total upset length lengths of the two pieces. If necessary,

necessary, the flash

S e n g t h

U p se t l le

h

can be removed by secondary operations, such

Time

as machining or grinding.

FIGURE 12.31

12.31 Shapes of the fusion zone in

friction welding as a function of the force applied

(a) High pressure (b) Low pressure (c) Optimum

and the rotational speed.

or low speed or high speed

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Friction

Frict ion Stir Welding

Shouldered

non-consumable

tool

Probe

Weld

FIGURE 12.32 The principle of the friction stir welding process. Aluminum-alloy plates

up to 75 mm (3 in.) thick have been welded by this process. Source: TWI, Cambridge,

United Kingdom.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Resistance

Resist ance Spot Welding

Electrodes

Weld nugget

Lap joint

1. Pressure 2. Current 3. Current off, 4. Pressure released

applied on pressure on

(a)

Electrodes

Electrode

Electrode tip

Indentation

Sheet

Weld nugget separation

Workpiece Workpiece

(a) (b)

Heat-affected zone

Electrode

(b)

FIGURE 12.34 Two types of electrode

electrode designs

for easy access in spot welding operations for

complex shapes.

FIGURE 12.33

12.33 (a) Sequence in the resistance

spot welding operation. (b) Cross-section of a

spot weld, showing weld nugget and light

indentation by the electrode on sheet surfaces.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Seam & Resist

Resistance

ance Projection Welding

Electrode wheels

Electrode wheels

Weld nuggets

Weld Weld

Sheet

(a) (b) (c) (d)

FIGURE 12.35 (a) Illustration of the seam

welding process, with rolls acting as electrodes.

(b) Overlapping spots in a seam weld. (c) Cross-

section of a roll spot weld. (d) Mash seam Force

welding.

Flat electrodes Weld

nuggets

Sheet

Product

FIGURE 12.36 Schematic illustration of

Workpiece

resistance projection welding: (a) before and (b)

after. The projections on sheet metal are Projections

produced by embossing operations, as described Force

in Section 7.5.2.

(a) (b)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Flash & Stud Welding

Arc

FIGURE 12.37 Flash welding process for

for end-to-

end welding of solid rods or tubular parts. (a)

Before and (b) after.

(a) (b)

Push Pull Push

FIGURE 12.38 Sequence

of operations in stud arc

Stud

welding, used for welding Molten

bars, threaded rods, and Ceramic weld

ferrule Arc Weld

various fasteners on metal

Workpiece

metal plates. (base metal)

1. 2. 3. 4.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Explosion

Explosi on Welding

Deto

Detona

nato

torr Expl

Explos

osiv

ive

e

Deto

Detona

nato

torr Expl

Explos

osiv

ive

e Clad me

Clad meta

tall Buffer

(flyer) Clad metal FIGURE 12.39 Schematic

Constant- Angular-interface illustration of the explosion

interface A

clearance gap

clearance

welding process: (a) constant

gap interface clearance gap and (b)

Base plate Base plate angular interface clearance gap.

(a) (b)

FIGURE 12.40 Cross-sections of explosion

welded joints: (a) titanium (top) on low-carbon

steel (bottom) and (b) Incoloy 800 (iron-nickel-

base alloy) on low-carbon steel. The wavy

interfaces shown improve the shear strength of

the joint. Some combinations of metals, such as

tantalum and vanadium, produce a much less

wavy interface. If the two metals have little

metallurgical compatibility, an interlayer may be

added that has compatibility with both metals. (a) (b)

{\it Source:} Courtesy

Cour tesy of DuPont Company.

Company.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Diffusion Bonding

Stop off Bonding pressure

1. Core sheet 2. Diffusion bonding

Gas

Die

pressure

for forming

Die

3. Superplastic forming 4. Final structure

FIGURE 12.41 Sequence of operations in diffusion bonding and

superplastic forming of a structure with three flat sheets. See also Fig. 7.46.

Source: After D. Stephen and S.J. Swadling.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

ISBN No. 0-13-227271-7

Brazing

Brazi ng & Braze Welding

T

e

n

Torch Brass filler metal h

s

t i

l

Base Base metal g

e

s

n

metal e

t

r

r S e

t h n

g t

Flux s e a h

t r s

n t r e n

i t h

gt

g

o

Filler J

metal

(a) (b) Joint clearance

FIGURE 12.43 The effect of joint clearance on

FIGURE 12.42 (a) Brazing and (b) braze welding

welding operations. tensile and shear strength of brazed joints. Note

that unlike tensile strength, shear strength

continually decreases as clearance increases.

Base Metal Filler Metal Brazing Temperature ( C) ◦

Aluminum and its alloys Aluminum-silicon 570-620

Magnesium alloys Magnesium-aluminum 580-625

Copper and its alloys Copper-phosphorus 700-925

TABLE 12.4 Typical filler metals for

for brazing Ferro

errous

us and

and nonf

nonfer

erro

rous

us allo

alloys

ys (exc

(excep

eptt Silv

Silver

er and

and coppe

copperr allo

alloys

ys,, 62

620-

0-11

1150

50

various metals and alloys. alum

alumin

inum

um and

and magn

magnesesiu

ium)

m) copp

copper

er-p

-pho

hosp

spho

horu

russ

Iron-, nickel-, and cobalt-base alloys Gold 900-1100

Stainless steels, nickel- and cobalt- Nickel-silver 925-1200

base alloys

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Furnace Brazing & Brazed Joints

Filler FIGURE 12.44 An application

application of

Filler-metal

metal furnace brazing: (a) before and

wire

(b) after. Note that the filler

metal is a shaped wire.

(a) (b)

FIGURE 12.45

12.45 Joint designs

designs commonly used in

brazing operations.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Solder Joints

(a) Flanged T (b) Fl

Flush la

lap (c) Fl

Flanged co

corner (d) Line contact

Bolt

or rivet

FIGURE 12.46 Joint designs commonly used

used for

soldering.

(e) Flat lock seam (f) Flanged bottom (g) Gull wing

Crimp

PC board Wire

(h) Through hole (i) Crimped (j) Twisted

Solder Typical Application

Tin-lead General purp osose

Tin-zinc Aluminum

Lead

Lead-s

-sil

ilve

verr Stre

Streng

ngth

th at high

higher

er than

than room

room tempe

tempera

ratu

ture

re

TABLE 12.5 Types of solders

solder s and their Cadmium-sil

Cadmium-silver ver Strength

Strength at high

high temperatures

temperatures

applications. Zinc-alumin

Zinc-aluminum um Aluminum

Aluminum;; corrosion

corrosion resistance

resistance

Tin-

in-silve

lver Electronics

Tin-

Tin-bi

bism

smut

uth h Elec

Electr

tron

onic

icss

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Soldering for Circuit Boards

Squeegee

Tensioned screen Screen material

Paste

FIGURE 12.47 Screening solder pastepaste onto

onto a

printed circuit board in reflow soldering. Source:

After V.

V. Solberg.

Solb erg.

Paste deposited Emulsion Contact ar

area

on contact area

Copper land

Copper land Wetted solder

Plating or coat

coating Oil or air

Flux

FIGURE 12.48 (a) Schematic

Residues

illustration of the wave soldering

process. (b) SEM image of a wave Turbulent zone

(oil prevents dross)

soldered joint on a surface-mount

device. See also Section 13.13. Oil mixed in

Turbulent zone

(dross formed

in air)

(a) (b)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Adhesive Bonding

Single taper Single

Simple Simple

Beveled Beveled Double taper Double

Radiused Radiused Increased thickness Beveled

(a) (b) (c) (d)

FIGURE 12.49 Various configurations

configurations for adhesively bonded joints: (a) single lap, (b)

double lap, (c) scarf, and (d) strap.

Peeling

force

FIGURE 12.50 Characteristic behavior of (a)

brittle and (b) tough and ductile adhesives in a

peeling test. This test is similar to peeling

adhesive tape from a solid surface.

(a) (b)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Properties

Properties of Adhesive

Adhesivess

Epoxy

Epox y Pol

olyu

yure

reth

than

anee Modi

Modifie

fiedd Ac

Acry

ryli

licc Cyan

Cyanoc

ocry

ryla

late

te Anae

Anaero

robi

bicc

Impact resistance Po or Excellent Go o d Po or Fair

Tension-shear 15-22 12-20 20-30 18.9 17.5

strength, MPa (2.2-3.2) (1.7-2.9) (2.9-4.3) (2.7) (2.5)

(103 psi)

Peel strength , N/m

∗

< 523 (3) 14,000 (80) 5250 (30) < 525 (3) 1750 (10)

(lb/in.)

Substrates b on

onded Most Most smooth, Most smo ot

oth, Most non- Metals, glass,

nonpo

porrous nonpo

porrous porous metals

por thermosets

or plastics

Service temperature -55 to 120 -40 to 90 -70 to 120 -55 to 80 -55 to 150

range, C ( F)

◦ ◦

(-70 to 250) (-250 to 175) (-100 to 250) (-70 to 175) (-70 to 300)

Heat cure or mixing Yes Yes No No No

required

Solvent resistance Excellent Go o d Go o d Go o d Excellent

Moisture resistance Go od-Excellent Fair Go o d Po or Go o d

Gap limitation, mm None None 0.5 (0.02) 0.25 (0.01) 0.60 (0.025)

(in.)

Odor Mild Mild Strong Mo derate Mild

Toxicity Mo derate Mo derate Moderate Low Low

Flammability Low Low High Low Low

Note: Peel strength varies widely depending on surface preparation and quality.

TABLE 12.6 Typical properties and characteristics

characteristics of chemically reactive

reactive structural

adhesives.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Rivets and Stapling

Standard loop Flat clinch

(a) (b)

Nonmetal

Metal channel

(c) (d)

(a) (b) (c) (d)

FIGURE 12.52 Examples of various fastening

FIGURE 12.51 Examples of rivets: (a) (a) solid, (b) tubular,

tubular, (c)

methods. (a) Standard loop staple; (b) flat clinch

split, or bifurcated, and (d) compression.

staple; (c) channel strap; (d) pin strap.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Seams & Crimping

FIGURE 12.53 Stages in forming a double-

lock seam. See also Fig. 7.23.

1. 2. 3. 4.

FIGURE 12.54 Two examples

exampl es of mechanical

mechani cal

joining by crimping.

(a) (b)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Snap Fasteners

Spring clip

Nut

Rod-end attachment Push-on

to sheet-metal part fastener

(a) (b) (c)

Deflected Rigid

Sheet-metal cover Sheet-metal cover Integrated snap fasteners

(d) (e) (f) (g)

FIGURE 12.55 Examples of spring and snap-in fasteners

fasteners to facilitate assembly.

assembly.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Design Guideli

Guidelines

nes for Welding

Poor Good Poor Good

Load

Load

(a) (b)

Cut not Deburred

square Burr edge

90°

(c) (d)

Surface to be machined

(e) (f)

FIGURE 12.56 Design guidelines for welding. Source: Bralla, J.G. (ed.)

Handbook of Product Design for Manufacturing , 2d ed. McGraw-Hill, 1999.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Weld Designs

Poor Go o d

FIGURE 12.57 Design guidelines for flash

welding.

Moment, M 3M

Continuous Intermittent

weld welds

Welds

(a) (b)

Wel

eld

d Ba

Base

se me

meta

tall

FIGURE 12.58 Weld designs for Example 12.7.

Single V groove Double V groove

(c)

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Brazing Designs

Good Poor Comments

Too little joint

area in shear

Improved design

when fatigue

loading is a factor

to be considered

Insufficient

bonding

FIGURE 12.59 Examples of good and

and poor designs for brazing.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Design for Adhesive Bonding

Poor Good Very good

Adhesive

(a) (b) (c)

Adhesive A dhes i v e FIGURE 12.60 Various joint designs in adhesive

bonding. Note that good designs require large

contact areas for better joint strength.

Rivet S po t wel d

(d) Combination joints

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Design for Riveting

Poor

Good

(a) (b) (c) (d)

FIGURE 12.61 Design guidelines for riveting. Source: Bralla, J.G. (ed.)

Handbook of Product Design for Manufacturing , 2nd ed. McGraw-Hill, 1999.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

Case Study: Monost eel® Pistons

Monosteel

Oil gallery

Friction

welds

(a) (b)

Monosteel ® piston. (a) Cutaway view of the piston, showing the oil gallery

FIGURE 12.62 The Monosteel

and friction welded sections; (b) detail of the friction welds before the external flash is removed

by machining; note that this photo is a reverse of the one on the left.

Manufacturing Processes for Engineering Materials, 5th ed.

Kalpakjian • Schmid

© 2008, Pearson Education

You might also like

- Advanced Coating Solutions For The OilDocument4 pagesAdvanced Coating Solutions For The OilManivannanMudhaliarNo ratings yet

- EnDOtec Welding Cored WireDocument12 pagesEnDOtec Welding Cored WirecriuvosNo ratings yet

- Electrode Converted Into TextDocument14 pagesElectrode Converted Into TextNeha NimbarkNo ratings yet

- BergerMasterFile PDFDocument74 pagesBergerMasterFile PDFSumanta RoyNo ratings yet

- The Light Machine Shop Divided Into The Following SectionDocument5 pagesThe Light Machine Shop Divided Into The Following Sectionyogendra singhNo ratings yet

- Electrode Codes For Use in BoilersDocument4 pagesElectrode Codes For Use in Boilersh_patnaikNo ratings yet

- Advances in Thermal Spray TechnologyDocument3 pagesAdvances in Thermal Spray Technologyinterpon07No ratings yet

- FCAW Electrode DesignationDocument3 pagesFCAW Electrode DesignationthedreampowerNo ratings yet

- Specification Sheet: 2304: (UNS S32304)Document2 pagesSpecification Sheet: 2304: (UNS S32304)Deepak TdNo ratings yet

- AODDocument8 pagesAODPrakash Mishra100% (1)

- VAPOR-JET Venturi BlenderDocument2 pagesVAPOR-JET Venturi BlenderCaterine Jara CeaNo ratings yet

- Resicham Surface Prep GuidelinesDocument4 pagesResicham Surface Prep GuidelinesPJOE81No ratings yet

- FAQ - What Is The Procedure For Welding En24 (Subsequently Known As 817M40 and 1.6582 34CrNiMo6), A 0.4% C, 1.25% CR, 0.3% Mo LowDocument2 pagesFAQ - What Is The Procedure For Welding En24 (Subsequently Known As 817M40 and 1.6582 34CrNiMo6), A 0.4% C, 1.25% CR, 0.3% Mo LowSubhra S SanyalNo ratings yet

- Packing, Preservation and Storage ProcedureDocument9 pagesPacking, Preservation and Storage ProcedureMohamed FarisNo ratings yet

- Alloy Valves PDFDocument4 pagesAlloy Valves PDFYamil Diaz SantosNo ratings yet

- MIG Gas Mix Developed by EdDocument7 pagesMIG Gas Mix Developed by Edc_e_z_a_rNo ratings yet

- (Materiales) Productos CNFDocument18 pages(Materiales) Productos CNFNicolás Felipe Reyes CerdaNo ratings yet

- Brass MachiningDocument68 pagesBrass MachiningVaibhav ShuklaNo ratings yet

- Rotary Kiln Supporting Roll:: Case Histories On Integrity and Failures in Industry (Chifi)Document20 pagesRotary Kiln Supporting Roll:: Case Histories On Integrity and Failures in Industry (Chifi)Ramakrishnan AmbiSubbiahNo ratings yet

- Belzona - Cold Curing WrapsDocument4 pagesBelzona - Cold Curing WrapsNay ThihaNo ratings yet

- Free Fire Risk Assessment Example PDFDocument17 pagesFree Fire Risk Assessment Example PDFFairoza AmalinnaNo ratings yet

- Copper Tubes - ASTM B88MDocument7 pagesCopper Tubes - ASTM B88Myarzar17No ratings yet

- 06 VD Mee-Welding of Super Duplex Stainless SteelsDocument12 pages06 VD Mee-Welding of Super Duplex Stainless SteelsKareem AbdelazizNo ratings yet

- EutecTrode Manual Metal Arc Electrodes PDFDocument12 pagesEutecTrode Manual Metal Arc Electrodes PDFswapneel_kulkarniNo ratings yet

- ABJ PresentationDocument51 pagesABJ PresentationMarvin CastelinoNo ratings yet

- Duplex SSDocument12 pagesDuplex SSTushar PatilNo ratings yet

- CDP 4666 PDFDocument2 pagesCDP 4666 PDFVitor Rigueira de GodoyNo ratings yet

- Firelite 124Document1 pageFirelite 124pamelataboadalozanoNo ratings yet

- New Materials For Sour Gas Drill Pipe: 26 March/April 2002Document2 pagesNew Materials For Sour Gas Drill Pipe: 26 March/April 2002amigofirmNo ratings yet

- Aalco CatalogueDocument92 pagesAalco CatalogueNigin ParambathNo ratings yet

- Glassflake Lining Metal TanksDocument5 pagesGlassflake Lining Metal TanksSimbu ArasanNo ratings yet

- Carbon Steel Pipes - Comparing AmericanDocument2 pagesCarbon Steel Pipes - Comparing AmericanKazi Anwarul Azim SohelNo ratings yet

- 150-600 Gate ValveDocument4 pages150-600 Gate ValveSaquib NishatNo ratings yet

- Common Defects in Gas CuttingDocument14 pagesCommon Defects in Gas CuttingASHVIN YADAVNo ratings yet

- A F E S: Process Piping 670.200Document17 pagesA F E S: Process Piping 670.200puwarin najaNo ratings yet

- Nfa 49 215 Grade Tu 37c Tubes PDFDocument1 pageNfa 49 215 Grade Tu 37c Tubes PDFMitul MehtaNo ratings yet

- Pipe GuideDocument231 pagesPipe GuidegeorgD2010100% (2)

- Rimmed Vs Killed SteelDocument1 pageRimmed Vs Killed SteelMuthuKumarNo ratings yet

- Global Leader in SNG Energy Systems: (Synthetic Natural Gas)Document4 pagesGlobal Leader in SNG Energy Systems: (Synthetic Natural Gas)khairiNo ratings yet

- Mip - Chain Va.754Document16 pagesMip - Chain Va.754Jiggy JickNo ratings yet

- DMR 249 ADocument8 pagesDMR 249 Aasprclms durgapurNo ratings yet

- Specification For 3LPE CoatingDocument32 pagesSpecification For 3LPE Coatinggauravagrawal2010No ratings yet

- Assessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012Document39 pagesAssessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012abhi_luvme03100% (1)

- Cement Plant CorrosionDocument7 pagesCement Plant CorrosionHemlata ChandelNo ratings yet

- Syntho-Glass - OriginalDocument2 pagesSyntho-Glass - Originalkyawhlas5817No ratings yet

- PR8592 Welding TechnologyDocument77 pagesPR8592 Welding TechnologyVijayan VNo ratings yet

- Contrasting Welding Techniques Used On Pipelines and Refinery PipingDocument5 pagesContrasting Welding Techniques Used On Pipelines and Refinery PipingahmedNo ratings yet

- Chemilube E C G X: Description:-Grease For Lubricating Electrical Contacts Customer BenefitsDocument1 pageChemilube E C G X: Description:-Grease For Lubricating Electrical Contacts Customer BenefitssatfasNo ratings yet

- Duplex Stainless Steel DetailDocument12 pagesDuplex Stainless Steel DetailessnelsonNo ratings yet

- INCONEL 686 - INCO-WELD 686CPT Application List For IndiaDocument10 pagesINCONEL 686 - INCO-WELD 686CPT Application List For IndiaBhanu Pratap ChoudhuryNo ratings yet

- En 10028 P355GHDocument2 pagesEn 10028 P355GHEvriMert RüzgArdaNo ratings yet

- Floating Flange Rubber Expansion Joints: Series 980Document8 pagesFloating Flange Rubber Expansion Joints: Series 980Roland Bon IntudNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- Boldrocchi CatalogueDocument19 pagesBoldrocchi Catalogueamitjoshi2002No ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Material Receiving Inspection ReportDocument2 pagesMaterial Receiving Inspection Reportsmsunil12345No ratings yet

- Preview PDFDocument2 pagesPreview PDFLandon SchmidtNo ratings yet

- Heidelberg Client 3.0 The Evolutionary Step Following Our PC Lifecycle ManagementDocument27 pagesHeidelberg Client 3.0 The Evolutionary Step Following Our PC Lifecycle ManagementHoward HutchingsNo ratings yet

- Nature - The Hydrogen RevolutionDocument4 pagesNature - The Hydrogen RevolutionOUSSAMA BEN OMARNo ratings yet

- Product Information: Cordless Screwdriver and NutrunnerDocument96 pagesProduct Information: Cordless Screwdriver and Nutrunneradskñlfjñ kljfsgoiasNo ratings yet

- Sheet Metal Forming - PpsDocument26 pagesSheet Metal Forming - PpsNhan LeNo ratings yet

- Lecture 9-Binary Distillation ProblemsDocument18 pagesLecture 9-Binary Distillation ProblemsWasim NawazNo ratings yet

- Pipe Shop Standard For B31.9 - REV.05-2023Document1 pagePipe Shop Standard For B31.9 - REV.05-2023iplaruffNo ratings yet

- S1 Mcom Research Methodology Full NotesDocument163 pagesS1 Mcom Research Methodology Full Notesjayeshraj0000No ratings yet

- JJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Document9 pagesJJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Ah Tiang100% (1)

- Manufacturing Processes 1Document9 pagesManufacturing Processes 1Kodok SuperNo ratings yet

- Machine Tools Design: InstructorsDocument31 pagesMachine Tools Design: InstructorsAladdin AdelNo ratings yet

- Tsubaki Power Lock Ad N SeriesDocument5 pagesTsubaki Power Lock Ad N SeriesRizal IephoNo ratings yet

- Jamson Flotation CellsDocument10 pagesJamson Flotation CellsErland Yennfred Zegarra MezaNo ratings yet

- Minutes of Meeting: Bekapai-3 Surface Facilities Modification and Dogleg Installation (Epcic)Document13 pagesMinutes of Meeting: Bekapai-3 Surface Facilities Modification and Dogleg Installation (Epcic)Arung IdNo ratings yet

- Pull-Off Test Report - PUB Pedestrian Bridge ProjectDocument2 pagesPull-Off Test Report - PUB Pedestrian Bridge ProjectErin Williams100% (2)

- Questions BankDocument6 pagesQuestions BankSyed KhaleelullahNo ratings yet

- Document BED 330, 2Document8 pagesDocument BED 330, 2phirisimon815No ratings yet

- List Dobi in Sungai BesiDocument9 pagesList Dobi in Sungai BesihermancxNo ratings yet

- I.M Actividad 9Document82 pagesI.M Actividad 9AXEL JUAREZNo ratings yet

- Acceptance Criteria in Welding TableBDocument1 pageAcceptance Criteria in Welding TableBanishk6336No ratings yet

- Types and Characteristics of Common Grinding Circuit Flow SheetsDocument9 pagesTypes and Characteristics of Common Grinding Circuit Flow SheetsJoseluis Campean SedanoNo ratings yet

- 4grinding Polishing Flexible ToolsDocument113 pages4grinding Polishing Flexible ToolsGabriel DobrescuNo ratings yet

- Warehouse Resume ObjectiveDocument5 pagesWarehouse Resume Objectivehjsfixljg100% (1)

- Water-Based Polyurethane Acrylic Hybrid DispersionsDocument6 pagesWater-Based Polyurethane Acrylic Hybrid DispersionsDan RoskeNo ratings yet

- ResumeDocument2 pagesResumeapi-489105449No ratings yet

- QW-196 Resistance Weld Testing: ASME BPVC - IX-2019Document1 pageQW-196 Resistance Weld Testing: ASME BPVC - IX-2019Tahar DabbarNo ratings yet

- Concrete TechnologyDocument214 pagesConcrete Technologycheersbeer01No ratings yet

- WA Hardlite™: Ultra-Thin Composite WearplatesDocument5 pagesWA Hardlite™: Ultra-Thin Composite WearplatesFernando MilmanNo ratings yet

- Pitting-Acceptance or Rejection Pitting-Acceptance or RejectionDocument24 pagesPitting-Acceptance or Rejection Pitting-Acceptance or Rejectionmohammed harrisNo ratings yet

- Material Specification Sheet Saarstahl - 55Cr3: 1.7176 F 1 K BS: Afnor: Sae: Material GroupDocument1 pageMaterial Specification Sheet Saarstahl - 55Cr3: 1.7176 F 1 K BS: Afnor: Sae: Material GrouphdierkeNo ratings yet

- Airless Shot Blasting QuestionnaireDocument2 pagesAirless Shot Blasting Questionnairedonhan91No ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFHardikNo ratings yet

- Unit 7 Drill BushingsDocument24 pagesUnit 7 Drill BushingsRamiro Acosta CepedaNo ratings yet

- Introduction, Casting Process Casting Processes - NoteDocument22 pagesIntroduction, Casting Process Casting Processes - NoteVasantha SudasinghaNo ratings yet