Professional Documents

Culture Documents

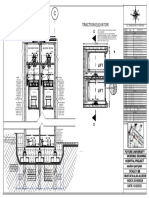

Section B - B Section C - C Section D - D: Scale 1:5 Scale 1:5 Scale 1:5

Section B - B Section C - C Section D - D: Scale 1:5 Scale 1:5 Scale 1:5

Uploaded by

luis marcelino chuquimango muñozCopyright:

Available Formats

You might also like

- 70180-2530-HRSG-RFQ-FT1 Rev.01 PDFDocument75 pages70180-2530-HRSG-RFQ-FT1 Rev.01 PDFluis marcelino chuquimango muñozNo ratings yet

- Newton Raphson MethodDocument29 pagesNewton Raphson Methodfaizankhan23100% (1)

- Caregiving TG - 10Document31 pagesCaregiving TG - 10Amer Dalanda100% (2)

- Chapter 4Document79 pagesChapter 4Clarizza0% (1)

- Rev EDocument1 pageRev EAli EynieNo ratings yet

- Length: Site Welds Details of Left Face Site Welds Details of Right FaceDocument1 pageLength: Site Welds Details of Left Face Site Welds Details of Right Faceluis marcelino chuquimango muñozNo ratings yet

- MRT2 SEM DrawingDocument1 pageMRT2 SEM DrawingqinxuekunNo ratings yet

- Bellary Hiriyur: Hiriyuru BypassDocument12 pagesBellary Hiriyur: Hiriyuru BypassSettipalli Ram Surya100% (1)

- Set EstructuralDocument53 pagesSet EstructuralNelson DaherNo ratings yet

- 3829 HQ SHD ME HVAC 003 Rev 07 PDFDocument1 page3829 HQ SHD ME HVAC 003 Rev 07 PDFemadNo ratings yet

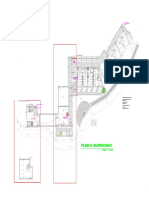

- Planta Semisotano: 13 EstacionamientosDocument1 pagePlanta Semisotano: 13 EstacionamientosGiordano Tuanama YapoNo ratings yet

- OT3073-20 L3 LAB Condenseur R3Document1 pageOT3073-20 L3 LAB Condenseur R3becemNo ratings yet

- المصعدDocument1 pageالمصعدmustafamoharamNo ratings yet

- Spare Part List 5587258891Document2 pagesSpare Part List 5587258891Ndikumasabo EtienneNo ratings yet

- Sector Delineation Plan - Zone LDocument1 pageSector Delineation Plan - Zone LGirija UmathNo ratings yet

- MPC2550 P2PDocument17 pagesMPC2550 P2PCristian TempyNo ratings yet

- Sdi - Sub Sotano Area RojoDocument1 pageSdi - Sub Sotano Area RojoClenin Huacho AyalaNo ratings yet

- Fire Water Pump Cont. (SB) : HydrantDocument1 pageFire Water Pump Cont. (SB) : HydrantBindimNo ratings yet

- D104/D106 Point To Point Diagram (1/2) : IPU (PCB4)Document18 pagesD104/D106 Point To Point Diagram (1/2) : IPU (PCB4)Esdras Paes100% (1)

- London Tube MapDocument1 pageLondon Tube MapleprincecNo ratings yet

- MP6002 p2p Model mt-c5 PtopDocument25 pagesMP6002 p2p Model mt-c5 PtopMario GermanNo ratings yet

- Bizhub: Overall Wiring DiagramDocument56 pagesBizhub: Overall Wiring DiagramHugo Luis Escalante100% (1)

- Wiring Diagram (FS-527)Document1 pageWiring Diagram (FS-527)Emerson Fonte Dos Santos Freire0% (1)

- Coventry WEB PDFDocument1 pageCoventry WEB PDFdsamuNo ratings yet

- Bombeo 1%: Documentos de ReferenciaDocument4 pagesBombeo 1%: Documentos de Referenciajose luisNo ratings yet

- P034-DSF-AB-EL-108A Factory Ground Floor Lighting LayoutDocument1 pageP034-DSF-AB-EL-108A Factory Ground Floor Lighting Layoutahmad aldaliNo ratings yet

- DrainageNetworkMap 127Document1 pageDrainageNetworkMap 127Sudipta N SinghaNo ratings yet

- USB Hub DemoDocument3 pagesUSB Hub DemoMaiquel HorstNo ratings yet

- Etihad Rail Network: Layout PlanDocument1 pageEtihad Rail Network: Layout PlanShabir AhmadNo ratings yet

- IPE-MEK-E-EL-DSL-0003 - 06 - Main Connection & Protection Diagram (Both SSE & Clients)Document1 pageIPE-MEK-E-EL-DSL-0003 - 06 - Main Connection & Protection Diagram (Both SSE & Clients)sreeagile.esNo ratings yet

- Plano de Detalles de Planta General - PG-01Document1 pagePlano de Detalles de Planta General - PG-01Morbo Orgus DoverNo ratings yet

- Edgevpldt Legazpi - Ee As-Built 121922Document10 pagesEdgevpldt Legazpi - Ee As-Built 121922Debussy PanganibanNo ratings yet

- G1D DPS-205CP Power Supply Sony MA2Document3 pagesG1D DPS-205CP Power Supply Sony MA2VintikNo ratings yet

- Wiring Diagram For Main Body - A3Document4 pagesWiring Diagram For Main Body - A3Emerson Fonte Dos Santos FreireNo ratings yet

- FTML - Unit-1 - Plant LayoutDocument1 pageFTML - Unit-1 - Plant Layoutdr.afroza1875No ratings yet

- 18 723500 1100001344 Asb SRV SHD 106003 - 01Document1 page18 723500 1100001344 Asb SRV SHD 106003 - 01mahmudulalam konokNo ratings yet

- SÑ 02 PDFDocument1 pageSÑ 02 PDFC.O. INGENIERIA Y CONSTRUCCIONNo ratings yet

- Outdoor Lounge Area: Open To BelowDocument1 pageOutdoor Lounge Area: Open To BelowTimmy BarnuevoNo ratings yet

- Sameen RiziviDocument1 pageSameen RiziviSameen RizviNo ratings yet

- Site Development Plan: T W O - W A Y D R I V E W A YDocument1 pageSite Development Plan: T W O - W A Y D R I V E W A Yar.arvinarceNo ratings yet

- Espe Mep SQ SD R.sump.r2-3Document1 pageEspe Mep SQ SD R.sump.r2-3Tri SafrilNo ratings yet

- 5.4.6 077154C-1825-DW-1622-001 - C-Electrical Cable Routing Guide DrawingDocument2 pages5.4.6 077154C-1825-DW-1622-001 - C-Electrical Cable Routing Guide DrawingmondaldgpNo ratings yet

- L-02 - PPT - URBANIZACION POPULAR COOVITIOMAR-ModelDocument1 pageL-02 - PPT - URBANIZACION POPULAR COOVITIOMAR-ModelArccon sacNo ratings yet

- Module M-04: EquipmentDocument1 pageModule M-04: EquipmentRobles DreschNo ratings yet

- Bottom Face (View From Below) : SCALE 1:25Document1 pageBottom Face (View From Below) : SCALE 1:25luis marcelino chuquimango muñozNo ratings yet

- BC Hydro Transmission SystemDocument1 pageBC Hydro Transmission Systemapi-559082385No ratings yet

- TER30004Document1 pageTER30004luis marcelino chuquimango muñozNo ratings yet

- Mapa Fisico Turistico Frontal PDFDocument1 pageMapa Fisico Turistico Frontal PDFfenixcpcsaNo ratings yet

- L1 Brick and Tile Setting Out - 16062022Document1 pageL1 Brick and Tile Setting Out - 16062022SENG ZHeng CHIEWNo ratings yet

- Served BY HC-7E-01 Served BY HC-7E-01: State of Kuwait Ministry of HealthDocument1 pageServed BY HC-7E-01 Served BY HC-7E-01: State of Kuwait Ministry of HealthHoneywell KCCNo ratings yet

- Served BY HC-9E-01 Served BY HC-9E-01: State of Kuwait Ministry of HealthDocument1 pageServed BY HC-9E-01 Served BY HC-9E-01: State of Kuwait Ministry of HealthHoneywell KCCNo ratings yet

- EXTERNAL ELECTRICAL ROUTING (1) (1) - ModelDocument1 pageEXTERNAL ELECTRICAL ROUTING (1) (1) - ModellogeshNo ratings yet

- Sonaglia - PLANOS FEBRERO2022Document2 pagesSonaglia - PLANOS FEBRERO2022romdreNo ratings yet

- Bomba KordelioDocument1 pageBomba KordelioVasilis PanagiotidisNo ratings yet

- Bomb 4 XartisDocument1 pageBomb 4 XartisThousandnews GrNo ratings yet

- Arquitectura P.General FINALDocument1 pageArquitectura P.General FINALEdinson David Merel VillarrealNo ratings yet

- Itr Fob PDFDocument1 pageItr Fob PDFAlok Kumar100% (1)

- T260XW02 VS Bn07-00638a T-ConDocument11 pagesT260XW02 VS Bn07-00638a T-ConTran Van Thien50% (2)

- PP 6001Document23 pagesPP 6001maxchelasNo ratings yet

- Petite FleurDocument2 pagesPetite FleurDanielle MurrayNo ratings yet

- 2 Anchoring PlanDocument1 page2 Anchoring PlanPhú Vũ TrươngNo ratings yet

- Del DesembarcoDocument1 pageDel DesembarcoPeterRomeroNo ratings yet

- Termocandelaria Combined Cycle Conversion ProjectDocument2 pagesTermocandelaria Combined Cycle Conversion Projectluis marcelino chuquimango muñozNo ratings yet

- Termocandelaria Combined Cycle Conversion ProjectDocument2 pagesTermocandelaria Combined Cycle Conversion Projectluis marcelino chuquimango muñozNo ratings yet

- Termocandelaria Combined Cycle Conversion ProjectDocument2 pagesTermocandelaria Combined Cycle Conversion Projectluis marcelino chuquimango muñozNo ratings yet

- TER33006Document1 pageTER33006luis marcelino chuquimango muñozNo ratings yet

- Length: Site Welds Details of Left Face Site Welds Details of Right FaceDocument1 pageLength: Site Welds Details of Left Face Site Welds Details of Right Faceluis marcelino chuquimango muñozNo ratings yet

- Bottom Face (View From Below) : SCALE 1:25Document1 pageBottom Face (View From Below) : SCALE 1:25luis marcelino chuquimango muñozNo ratings yet

- TER30004Document1 pageTER30004luis marcelino chuquimango muñozNo ratings yet

- TER30006Document1 pageTER30006luis marcelino chuquimango muñozNo ratings yet

- Cityscope Sports and LeisureDocument7 pagesCityscope Sports and LeisurePD HoàngNo ratings yet

- Unit 2 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep RaghavDocument72 pagesUnit 2 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep Raghavavikool1708No ratings yet

- Open Source Tools For Measuring The Internal Quality of Java Software Products A SurveyDocument12 pagesOpen Source Tools For Measuring The Internal Quality of Java Software Products A SurveyStanley UmohNo ratings yet

- Immunomodulators: By: Payal Suthar Department of PharmacognosyDocument26 pagesImmunomodulators: By: Payal Suthar Department of PharmacognosyHely Patel100% (1)

- CV - Muhammad Fazli - Deck Cadet TrainingDocument1 pageCV - Muhammad Fazli - Deck Cadet TrainingfazliNo ratings yet

- Salesforce Pages Developers GuideDocument810 pagesSalesforce Pages Developers GuideanynameNo ratings yet

- PreliminariesDocument11 pagesPreliminariesGhabbFloresPalNo ratings yet

- Engine RT-flex Operation Practical AdvancedDocument3 pagesEngine RT-flex Operation Practical AdvancedPiotr StankiewiczNo ratings yet

- Automation of Watering System Using MicrocontrollerDocument3 pagesAutomation of Watering System Using MicrocontrollerVinduja KarthikaNo ratings yet

- Dobor Rezystorow B628xx StepUp Chip - vbc-VB9208-v1.0Document9 pagesDobor Rezystorow B628xx StepUp Chip - vbc-VB9208-v1.0asdfNo ratings yet

- Record Keeping MisconceptionsDocument9 pagesRecord Keeping MisconceptionsPeaceNo ratings yet

- 01 DTMDocument2 pages01 DTMMauro BorgesNo ratings yet

- The Limitations of Medium in A Communication AmongDocument4 pagesThe Limitations of Medium in A Communication AmongChristine MarieNo ratings yet

- Timber Frame Solutions 03Document20 pagesTimber Frame Solutions 03sertackcdgNo ratings yet

- Bandas PDFDocument3 pagesBandas PDFClaudia DiazNo ratings yet

- THE LAW PERTAINING TO PRIVATE PERSONAL & COMML RELATIONS - AdDU Bar NotesDocument54 pagesTHE LAW PERTAINING TO PRIVATE PERSONAL & COMML RELATIONS - AdDU Bar NotesDevilleres Eliza DenNo ratings yet

- PCK303 Understanding The Lesson 9Document2 pagesPCK303 Understanding The Lesson 9Japhet BagsitNo ratings yet

- ManSci ReviewDocument7 pagesManSci ReviewCathleen TenaNo ratings yet

- List of Society Latest PDFDocument42 pagesList of Society Latest PDFDr Tilak Raj MeenaNo ratings yet

- Fussion3000 MackieDocument8 pagesFussion3000 MackieMarco BruceNo ratings yet

- Greenhills Mining Corp vs. Office of The PresidentDocument1 pageGreenhills Mining Corp vs. Office of The PresidentJAMNo ratings yet

- On The Job Evaluation SheetDocument2 pagesOn The Job Evaluation Sheetmoonbright27No ratings yet

- 6th Grade Worksheet BundleDocument65 pages6th Grade Worksheet BundleLisa Ward0% (1)

- Application of Negative Stiffness Devices For Seismic Protection of Bridge StructuresDocument10 pagesApplication of Negative Stiffness Devices For Seismic Protection of Bridge StructuresganeshNo ratings yet

- Multithreaded Airport Simulation SystemsDocument6 pagesMultithreaded Airport Simulation Systemsphanikrishnajagadesh666No ratings yet

- AnalogyDocument11 pagesAnalogydamuNo ratings yet

- Ministry Planning Made EasyDocument48 pagesMinistry Planning Made Easym28181920No ratings yet

Section B - B Section C - C Section D - D: Scale 1:5 Scale 1:5 Scale 1:5

Section B - B Section C - C Section D - D: Scale 1:5 Scale 1:5 Scale 1:5

Uploaded by

luis marcelino chuquimango muñozOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section B - B Section C - C Section D - D: Scale 1:5 Scale 1:5 Scale 1:5

Section B - B Section C - C Section D - D: Scale 1:5 Scale 1:5 Scale 1:5

Uploaded by

luis marcelino chuquimango muñozCopyright:

Available Formats

N

K

V

A

W

B

L

J

T

I

1. STEEL

6 100 1.1. Steel according Euro Norm EN 10025-1 & EN 10025-2. EN10025-2/S235JR

15295 Minimum yield point in compliance with table 7 from EN10025-2.

The subgrades are determined based on table 2-1 from EN 1993-1-10 and are specified 69025_30E01, drawings and

4 item list.

INSIDE

PL10x100

520 3850 3800 2800 4000 319 1.2. All connection plates welded to stiffeners members in steel S235JR will also be made of S235JR.

OUTSIDE

4

2. WELDING

6 100 2.1. Weld material must be equal to base material.

230 PANEL=3390 230 PANEL=3340 230 PANEL=2340 230 PANEL=3540 230

6 100 2.2. Unless indicated otherwise, all welds are minimum: a = 5mm and are continuous.

230 230 230 4

2.3. All given welds dimensions are as European way: throat dimensions. 11

OUTSIDE

INSIDE

11

4

For leg size, multiply throat dimension by 1.42.

100 525 525 520 520 525 525 100 100 555 555 560 560 555 555 100

OUTSIDE

INSIDE

6 2.4. All welding must be in compliance with ITP 69025_96E01.

2.5. Symbolic representation on drawing to EN 22553. The correspondences between representation according to

50

100 530 530 535 535 530 530 100 100 535 535 535 535 100 EN and symbolic representation according to AWS are given in the connection books 69025_50F04 and

69025_50F07.

50

4 Joint preparation according to AWS.

TOP OF CASING +27565 4 4 3. BOLT

TOP OF CASING +27565 PL10x100 CA.4

4 30 3.1. Information about bolts (quantities, sizes, material,..) has to be determined following John Cockerill

4 PL10x100

engineering drawings.

PL6x75 3.2. Bolts are referenced in the manufacturing bolt list 69025_30E25.

200

1325

1325

4 3.3. Tightening method is described in the bolt tightening procedure 69025_50M01.

CA.9

25

3.4. Mechanical properties of fasteners according to EN 14399 for bolts 10.9 and EN 15048 for bolts 8.8.

20

+26240 PL10x100 PL6x300

HEB300 HEB300 HEB240 HEB240 +26240 4 4. FABRICATION, ERECTION AND TOLERANCES

25

4.1. Fabrication must be in compliance with all requirements of John Cockerill specifications 99000_30E01 and

4 69025_30E01.

50

10

50

20

4.2. Erection must be in compliance with all requirements of John Cockerill erection procedures 69025_88E01.

10

25

6 4.3. Tolerances of manufacturing and erection must be in compliance with all requirements of John Cockerill

4

50

specifications 69025_99E99.

4 4 4.4. Coating must be in compliance with all requirements of John Cockerill specification 69025_49E01.

4

2880

2890

4 4.5. Manufacturing and quality control must be in compliance with all requirements of John Cockerill ITP

PL10x100 4 69025_96E01.

4 PL10x100

4 4.6. Panels, studs, insulation and liner installation must be in compliance with all requirements of John Cockerill

4 4 method statements 69025_63E61 and 69025_63E63 and in compliance with all requirements of specification

69025_63E01.

+23360 +23350 SECTION B - B 4

4

PL10x100 4.7. Panels shop welds positions must be located/adapted by the manufacturer according to its shop cutting

drawings.

SCALE 1:5 SECTION C - C 5. GENERAL

5.1. All dimensions are in mm on drawings 300XX and in inches on drawings 300XX-I.

4 4 4

SCALE 1:5 SECTION D - D 6.

5.2. For section with possibility of water accumulation, holes for dewatering must be drilled, refer to 69025_30E01.

ABREVIATIONS

2410

6.1. TOC: Top Of Concrete

2420

SCALE 1:5 6.2. TOS: Top Of Steel

9

9

4 4 4 4

PANEL=12584

PANEL=12584

PLATE=12578

PLATE=12578

6.3. BOS: Bottom Of Steel

CC.48

CC.33

CC.23

CC.31

+20950 4

+20930

5

5

2410

2420

5 4 WELDING SYMBOL REPRESENTATION

(According to EN 22553)

5

4

+18540 4 WELD ON ARROW SIDE FIELD WELD WELD ALL AROUND

+18510

IPE240 TYP IPE240 TYP IPE240 TYP IPE240 TYP

WELD ON OTHER SIDE 8

8

BACK WELD FLUSH or FLAT CONVEX CONCAVE

PL10x100 TYP

PL10x100 TYP

PL10x100 TYP

PL10x100 TYP

H9

2410

2420

SECTION E - E 60° A

A

H8 B

B

+16130

C SCALE 1:5 SECTION F - F 2 2

+16090

DISTANCE BETWEEN PLATES

DISTANCE BETWEEN PLATES

2

SCALE 1:5

2

A

60°

B C

2

A

2410

2420

25

25

A 2

7

7

4 4 4 4

B

2

2

a

5 BE CAREFUL :

+13720 +13670 THROAT DIMENSION IS GIVEN

4 FOR ALL WELD SYMBOLS

45°

REAR 5

FACE 4

REFERENCE DRAWINGS

2410

2420

5

4 DRW No. TITLE

69025_30008 LATERAL FACES CONNECTION DETAILS

5 69025_30009 LATERAL FACES CONNECTION DETAILS (PART 2)

+11310 +11250

H7 6

4

6

4 4

SECTION G - G

4

2410

PANEL=10686

PLATE=10636

SCALE 1:5

2420

S

4 4 4 4 H6

CC.40

4

SECTION H - H KEY PLAN E W

PANEL=12631

PLATE=12575

+8900 +8830

5

SCALE 1:5

CC.47

CC.71

CC.22

OTHERS JOHN COCKERILL

N

NORTH

LEFT FACE

PLANT

JOHN COCKERILL Ref.

X= 0

5 Y= 0

2410

HA

2420

4 Z= 0

REAR FACE

Y

FRONT FACE

LP DRUM

X 5

HP DRUM

STACK

IP DRUM

5

HB

A +6490

A GAS FLOW

+6410

HC

E E F F G G H H I I

OUTSIDE CASING

H5 H0 H1 H2 H3 H4 H5 H6 H7 H8 H9 H10

DISTANCE BETWEEN PLATES

SECTION I - I

2880

2890

D 4

RIGHT FACE

SCALE 1:5 PLANT COORDINATE

200

1035 2355 470 1150 1720 OF HRSG ORIGIN (JOHN COCKERILL Ref.)

HRSG COORDINATES SYSTEM

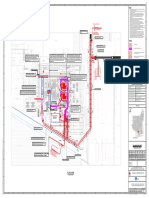

+3610 HEB300 HEB300 HEB240 +3520 HRSG 10 : EAST = 718558 mm ( 2357Ft 5'50/73) HRSG ORIGIN COORDINATES (X= 0; Y= 0; Z= 0)

HEB240 4

NORTH = 224656 mm (737Ft 21/29) ARE LOCATED AT CENTERLINE OF HRSG

4

5 ELEVATION = 0 mm(GRADE LEVEL, Top of Grouting (TR)

D EXPANSION JOINT INLET (FRONT SIDE) AND

4

5

1675

AT TOP OF GROUTING ELEVATION LEVEL.

4

1235

PANEL=3070

HRSG 20 : EAST = 718558 mm (2357Ft 5'50/73)

PLATE=3064

DET. A NORTH = 184256 mm (604Ft 6'9/52)

CASING = 2470

ELEVATION = 0 mm(GRADE LEVEL, Top of Grouting (TR)

5

5

J J

OUTSIDE

BOTTOM OF CASING +2375 CC.39 K K

CASING = 2375

4

4

4

OUTSIDE

BOTTOM OF CASING +1050

H6 H5

0.00 SECTION J - J SECTION K - K B 29.05.2020 Update BEL AGa PSh

3

3

SCALE 1:5 SCALE 1:5 A 24.04.2020 First issue BEL AGa PSh

3850 3800 2800 4000

REV. DATE DESCRIPTION DRWN CHKD APPD

H9 H8 H7 H6 H5

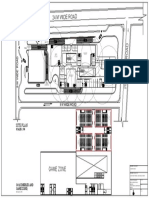

ELEVATION VIEW - LEFT FACE PANELS

SCALE 1:50

HEB300

1150

520 250 250 250 250 250 250 250

R

25 TERMOCANDELARIA COMBINED CYCLE CONVERSION PROJECT

2

2

PL10x100 TYP

6

50

6

481 6

STATUS REVISIONS

B004E.00098 Fmt :

6

594

PRELIMINARY A

IPE240 TYP

240

FLANGE CUTTING FOR FOR LAYOUT

HA DOOR PASSAGE ORDER N°

324

FOR CONSTRUCTION B ISO

DET. H6

R

FOR CONSTRUCTION EXCEPT HOLD

DET. H8 DET. H7 DET. H5

25

AS BUILT

DET. H9 Engineer P. SHANKAR

3850 3800 2800 4000 Destination Checker A. GARCIA

TERMOCANDELARIA

H9 H8 H7 H6 H5 DETAIL A Colombia

Draftman A. GIORDANO

Name Signature

SCALE 1:10

SECTION A - A Designation

HRSG CASING

SCALE 1:50 LEFT FACE

1

1

N Draw

This drawing and the design it covers are the property of John Cockerill Energy. They

are merely loaned on the borrower's express agreement that they will not be reproduced, 69025 _ 30002

copied, loaned, exhibited or used, except in the limited way and private use permitted by

any written consent given by John Cockeri lI Energy to the borrower. Scale : Sheet : 1/1

W V U T S R Q P O N M L K J I H G F E D C B A

You might also like

- 70180-2530-HRSG-RFQ-FT1 Rev.01 PDFDocument75 pages70180-2530-HRSG-RFQ-FT1 Rev.01 PDFluis marcelino chuquimango muñozNo ratings yet

- Newton Raphson MethodDocument29 pagesNewton Raphson Methodfaizankhan23100% (1)

- Caregiving TG - 10Document31 pagesCaregiving TG - 10Amer Dalanda100% (2)

- Chapter 4Document79 pagesChapter 4Clarizza0% (1)

- Rev EDocument1 pageRev EAli EynieNo ratings yet

- Length: Site Welds Details of Left Face Site Welds Details of Right FaceDocument1 pageLength: Site Welds Details of Left Face Site Welds Details of Right Faceluis marcelino chuquimango muñozNo ratings yet

- MRT2 SEM DrawingDocument1 pageMRT2 SEM DrawingqinxuekunNo ratings yet

- Bellary Hiriyur: Hiriyuru BypassDocument12 pagesBellary Hiriyur: Hiriyuru BypassSettipalli Ram Surya100% (1)

- Set EstructuralDocument53 pagesSet EstructuralNelson DaherNo ratings yet

- 3829 HQ SHD ME HVAC 003 Rev 07 PDFDocument1 page3829 HQ SHD ME HVAC 003 Rev 07 PDFemadNo ratings yet

- Planta Semisotano: 13 EstacionamientosDocument1 pagePlanta Semisotano: 13 EstacionamientosGiordano Tuanama YapoNo ratings yet

- OT3073-20 L3 LAB Condenseur R3Document1 pageOT3073-20 L3 LAB Condenseur R3becemNo ratings yet

- المصعدDocument1 pageالمصعدmustafamoharamNo ratings yet

- Spare Part List 5587258891Document2 pagesSpare Part List 5587258891Ndikumasabo EtienneNo ratings yet

- Sector Delineation Plan - Zone LDocument1 pageSector Delineation Plan - Zone LGirija UmathNo ratings yet

- MPC2550 P2PDocument17 pagesMPC2550 P2PCristian TempyNo ratings yet

- Sdi - Sub Sotano Area RojoDocument1 pageSdi - Sub Sotano Area RojoClenin Huacho AyalaNo ratings yet

- Fire Water Pump Cont. (SB) : HydrantDocument1 pageFire Water Pump Cont. (SB) : HydrantBindimNo ratings yet

- D104/D106 Point To Point Diagram (1/2) : IPU (PCB4)Document18 pagesD104/D106 Point To Point Diagram (1/2) : IPU (PCB4)Esdras Paes100% (1)

- London Tube MapDocument1 pageLondon Tube MapleprincecNo ratings yet

- MP6002 p2p Model mt-c5 PtopDocument25 pagesMP6002 p2p Model mt-c5 PtopMario GermanNo ratings yet

- Bizhub: Overall Wiring DiagramDocument56 pagesBizhub: Overall Wiring DiagramHugo Luis Escalante100% (1)

- Wiring Diagram (FS-527)Document1 pageWiring Diagram (FS-527)Emerson Fonte Dos Santos Freire0% (1)

- Coventry WEB PDFDocument1 pageCoventry WEB PDFdsamuNo ratings yet

- Bombeo 1%: Documentos de ReferenciaDocument4 pagesBombeo 1%: Documentos de Referenciajose luisNo ratings yet

- P034-DSF-AB-EL-108A Factory Ground Floor Lighting LayoutDocument1 pageP034-DSF-AB-EL-108A Factory Ground Floor Lighting Layoutahmad aldaliNo ratings yet

- DrainageNetworkMap 127Document1 pageDrainageNetworkMap 127Sudipta N SinghaNo ratings yet

- USB Hub DemoDocument3 pagesUSB Hub DemoMaiquel HorstNo ratings yet

- Etihad Rail Network: Layout PlanDocument1 pageEtihad Rail Network: Layout PlanShabir AhmadNo ratings yet

- IPE-MEK-E-EL-DSL-0003 - 06 - Main Connection & Protection Diagram (Both SSE & Clients)Document1 pageIPE-MEK-E-EL-DSL-0003 - 06 - Main Connection & Protection Diagram (Both SSE & Clients)sreeagile.esNo ratings yet

- Plano de Detalles de Planta General - PG-01Document1 pagePlano de Detalles de Planta General - PG-01Morbo Orgus DoverNo ratings yet

- Edgevpldt Legazpi - Ee As-Built 121922Document10 pagesEdgevpldt Legazpi - Ee As-Built 121922Debussy PanganibanNo ratings yet

- G1D DPS-205CP Power Supply Sony MA2Document3 pagesG1D DPS-205CP Power Supply Sony MA2VintikNo ratings yet

- Wiring Diagram For Main Body - A3Document4 pagesWiring Diagram For Main Body - A3Emerson Fonte Dos Santos FreireNo ratings yet

- FTML - Unit-1 - Plant LayoutDocument1 pageFTML - Unit-1 - Plant Layoutdr.afroza1875No ratings yet

- 18 723500 1100001344 Asb SRV SHD 106003 - 01Document1 page18 723500 1100001344 Asb SRV SHD 106003 - 01mahmudulalam konokNo ratings yet

- SÑ 02 PDFDocument1 pageSÑ 02 PDFC.O. INGENIERIA Y CONSTRUCCIONNo ratings yet

- Outdoor Lounge Area: Open To BelowDocument1 pageOutdoor Lounge Area: Open To BelowTimmy BarnuevoNo ratings yet

- Sameen RiziviDocument1 pageSameen RiziviSameen RizviNo ratings yet

- Site Development Plan: T W O - W A Y D R I V E W A YDocument1 pageSite Development Plan: T W O - W A Y D R I V E W A Yar.arvinarceNo ratings yet

- Espe Mep SQ SD R.sump.r2-3Document1 pageEspe Mep SQ SD R.sump.r2-3Tri SafrilNo ratings yet

- 5.4.6 077154C-1825-DW-1622-001 - C-Electrical Cable Routing Guide DrawingDocument2 pages5.4.6 077154C-1825-DW-1622-001 - C-Electrical Cable Routing Guide DrawingmondaldgpNo ratings yet

- L-02 - PPT - URBANIZACION POPULAR COOVITIOMAR-ModelDocument1 pageL-02 - PPT - URBANIZACION POPULAR COOVITIOMAR-ModelArccon sacNo ratings yet

- Module M-04: EquipmentDocument1 pageModule M-04: EquipmentRobles DreschNo ratings yet

- Bottom Face (View From Below) : SCALE 1:25Document1 pageBottom Face (View From Below) : SCALE 1:25luis marcelino chuquimango muñozNo ratings yet

- BC Hydro Transmission SystemDocument1 pageBC Hydro Transmission Systemapi-559082385No ratings yet

- TER30004Document1 pageTER30004luis marcelino chuquimango muñozNo ratings yet

- Mapa Fisico Turistico Frontal PDFDocument1 pageMapa Fisico Turistico Frontal PDFfenixcpcsaNo ratings yet

- L1 Brick and Tile Setting Out - 16062022Document1 pageL1 Brick and Tile Setting Out - 16062022SENG ZHeng CHIEWNo ratings yet

- Served BY HC-7E-01 Served BY HC-7E-01: State of Kuwait Ministry of HealthDocument1 pageServed BY HC-7E-01 Served BY HC-7E-01: State of Kuwait Ministry of HealthHoneywell KCCNo ratings yet

- Served BY HC-9E-01 Served BY HC-9E-01: State of Kuwait Ministry of HealthDocument1 pageServed BY HC-9E-01 Served BY HC-9E-01: State of Kuwait Ministry of HealthHoneywell KCCNo ratings yet

- EXTERNAL ELECTRICAL ROUTING (1) (1) - ModelDocument1 pageEXTERNAL ELECTRICAL ROUTING (1) (1) - ModellogeshNo ratings yet

- Sonaglia - PLANOS FEBRERO2022Document2 pagesSonaglia - PLANOS FEBRERO2022romdreNo ratings yet

- Bomba KordelioDocument1 pageBomba KordelioVasilis PanagiotidisNo ratings yet

- Bomb 4 XartisDocument1 pageBomb 4 XartisThousandnews GrNo ratings yet

- Arquitectura P.General FINALDocument1 pageArquitectura P.General FINALEdinson David Merel VillarrealNo ratings yet

- Itr Fob PDFDocument1 pageItr Fob PDFAlok Kumar100% (1)

- T260XW02 VS Bn07-00638a T-ConDocument11 pagesT260XW02 VS Bn07-00638a T-ConTran Van Thien50% (2)

- PP 6001Document23 pagesPP 6001maxchelasNo ratings yet

- Petite FleurDocument2 pagesPetite FleurDanielle MurrayNo ratings yet

- 2 Anchoring PlanDocument1 page2 Anchoring PlanPhú Vũ TrươngNo ratings yet

- Del DesembarcoDocument1 pageDel DesembarcoPeterRomeroNo ratings yet

- Termocandelaria Combined Cycle Conversion ProjectDocument2 pagesTermocandelaria Combined Cycle Conversion Projectluis marcelino chuquimango muñozNo ratings yet

- Termocandelaria Combined Cycle Conversion ProjectDocument2 pagesTermocandelaria Combined Cycle Conversion Projectluis marcelino chuquimango muñozNo ratings yet

- Termocandelaria Combined Cycle Conversion ProjectDocument2 pagesTermocandelaria Combined Cycle Conversion Projectluis marcelino chuquimango muñozNo ratings yet

- TER33006Document1 pageTER33006luis marcelino chuquimango muñozNo ratings yet

- Length: Site Welds Details of Left Face Site Welds Details of Right FaceDocument1 pageLength: Site Welds Details of Left Face Site Welds Details of Right Faceluis marcelino chuquimango muñozNo ratings yet

- Bottom Face (View From Below) : SCALE 1:25Document1 pageBottom Face (View From Below) : SCALE 1:25luis marcelino chuquimango muñozNo ratings yet

- TER30004Document1 pageTER30004luis marcelino chuquimango muñozNo ratings yet

- TER30006Document1 pageTER30006luis marcelino chuquimango muñozNo ratings yet

- Cityscope Sports and LeisureDocument7 pagesCityscope Sports and LeisurePD HoàngNo ratings yet

- Unit 2 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep RaghavDocument72 pagesUnit 2 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep Raghavavikool1708No ratings yet

- Open Source Tools For Measuring The Internal Quality of Java Software Products A SurveyDocument12 pagesOpen Source Tools For Measuring The Internal Quality of Java Software Products A SurveyStanley UmohNo ratings yet

- Immunomodulators: By: Payal Suthar Department of PharmacognosyDocument26 pagesImmunomodulators: By: Payal Suthar Department of PharmacognosyHely Patel100% (1)

- CV - Muhammad Fazli - Deck Cadet TrainingDocument1 pageCV - Muhammad Fazli - Deck Cadet TrainingfazliNo ratings yet

- Salesforce Pages Developers GuideDocument810 pagesSalesforce Pages Developers GuideanynameNo ratings yet

- PreliminariesDocument11 pagesPreliminariesGhabbFloresPalNo ratings yet

- Engine RT-flex Operation Practical AdvancedDocument3 pagesEngine RT-flex Operation Practical AdvancedPiotr StankiewiczNo ratings yet

- Automation of Watering System Using MicrocontrollerDocument3 pagesAutomation of Watering System Using MicrocontrollerVinduja KarthikaNo ratings yet

- Dobor Rezystorow B628xx StepUp Chip - vbc-VB9208-v1.0Document9 pagesDobor Rezystorow B628xx StepUp Chip - vbc-VB9208-v1.0asdfNo ratings yet

- Record Keeping MisconceptionsDocument9 pagesRecord Keeping MisconceptionsPeaceNo ratings yet

- 01 DTMDocument2 pages01 DTMMauro BorgesNo ratings yet

- The Limitations of Medium in A Communication AmongDocument4 pagesThe Limitations of Medium in A Communication AmongChristine MarieNo ratings yet

- Timber Frame Solutions 03Document20 pagesTimber Frame Solutions 03sertackcdgNo ratings yet

- Bandas PDFDocument3 pagesBandas PDFClaudia DiazNo ratings yet

- THE LAW PERTAINING TO PRIVATE PERSONAL & COMML RELATIONS - AdDU Bar NotesDocument54 pagesTHE LAW PERTAINING TO PRIVATE PERSONAL & COMML RELATIONS - AdDU Bar NotesDevilleres Eliza DenNo ratings yet

- PCK303 Understanding The Lesson 9Document2 pagesPCK303 Understanding The Lesson 9Japhet BagsitNo ratings yet

- ManSci ReviewDocument7 pagesManSci ReviewCathleen TenaNo ratings yet

- List of Society Latest PDFDocument42 pagesList of Society Latest PDFDr Tilak Raj MeenaNo ratings yet

- Fussion3000 MackieDocument8 pagesFussion3000 MackieMarco BruceNo ratings yet

- Greenhills Mining Corp vs. Office of The PresidentDocument1 pageGreenhills Mining Corp vs. Office of The PresidentJAMNo ratings yet

- On The Job Evaluation SheetDocument2 pagesOn The Job Evaluation Sheetmoonbright27No ratings yet

- 6th Grade Worksheet BundleDocument65 pages6th Grade Worksheet BundleLisa Ward0% (1)

- Application of Negative Stiffness Devices For Seismic Protection of Bridge StructuresDocument10 pagesApplication of Negative Stiffness Devices For Seismic Protection of Bridge StructuresganeshNo ratings yet

- Multithreaded Airport Simulation SystemsDocument6 pagesMultithreaded Airport Simulation Systemsphanikrishnajagadesh666No ratings yet

- AnalogyDocument11 pagesAnalogydamuNo ratings yet

- Ministry Planning Made EasyDocument48 pagesMinistry Planning Made Easym28181920No ratings yet