Professional Documents

Culture Documents

Chapter 1 - Stainless Steel

Chapter 1 - Stainless Steel

Uploaded by

Zuhaila MohammadCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Test 2 Jj512 Pneumatic and Hydraulic Answers All Question in Part A and Part BDocument5 pagesTest 2 Jj512 Pneumatic and Hydraulic Answers All Question in Part A and Part BZuhaila MohammadNo ratings yet

- Litar Topic 3 Dec 2019Document99 pagesLitar Topic 3 Dec 2019Zuhaila MohammadNo ratings yet

- Presentation Djj3213 - Material Science Student Name: Reg - NumberDocument1 pagePresentation Djj3213 - Material Science Student Name: Reg - NumberZuhaila MohammadNo ratings yet

- Eoc 2-Litar-SoalanDocument4 pagesEoc 2-Litar-SoalanZuhaila MohammadNo ratings yet

- Practical Task 1 Pneumatik June 2018Document20 pagesPractical Task 1 Pneumatik June 2018Zuhaila MohammadNo ratings yet

- Course Outline DJJ5123 Jun 2020 QrcodeDocument5 pagesCourse Outline DJJ5123 Jun 2020 QrcodeZuhaila MohammadNo ratings yet

- Djj5123 - Hydraulic - End of Chapter 2Document3 pagesDjj5123 - Hydraulic - End of Chapter 2Zuhaila MohammadNo ratings yet

- Buehler Vibratory Polisher Application Guide - PolishingDocument8 pagesBuehler Vibratory Polisher Application Guide - PolishingNathan T Nesbitt100% (1)

- Working Capital Management and Stores Inventory AnalysisDocument76 pagesWorking Capital Management and Stores Inventory Analysisagr_belaNo ratings yet

- EngineeringDocument208 pagesEngineeringvins4u100% (1)

- Tig Filler Rods: Iller OdsDocument1 pageTig Filler Rods: Iller Odsamir moniriNo ratings yet

- 014 ToolSteelDocument36 pages014 ToolSteelramptechNo ratings yet

- United States Patent (19) : Daly Et Al. 11) 4,436,836Document9 pagesUnited States Patent (19) : Daly Et Al. 11) 4,436,836arif thoha bariklanaNo ratings yet

- TurningDocument64 pagesTurningSerhat DoğandemirNo ratings yet

- 300 60 Komatiite High-Mg BasaltDocument3 pages300 60 Komatiite High-Mg Basalthugoluis_hNo ratings yet

- Union Galvasteel CorporatiofinalDocument13 pagesUnion Galvasteel CorporatiofinalNill Patrick Ulat Dulce100% (1)

- Chemistry Exam Form 5Document35 pagesChemistry Exam Form 5Tan Phei LingNo ratings yet

- BGTECH-1 - Topic 1-Concrete and MasonryDocument7 pagesBGTECH-1 - Topic 1-Concrete and MasonryChristian Sam VillegasNo ratings yet

- Past Paper Electrochemistry LQDocument15 pagesPast Paper Electrochemistry LQapi-3739994100% (1)

- Ar924 PDFDocument2 pagesAr924 PDFMario Mariochi ContardoNo ratings yet

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- Different Types of Pipes & TubesDocument8 pagesDifferent Types of Pipes & TubesSMSMNo ratings yet

- All About EPOXYDocument13 pagesAll About EPOXYEllen Kay CacatianNo ratings yet

- Eoi Kiocl Bolani SailDocument8 pagesEoi Kiocl Bolani Sailkselvan_1No ratings yet

- Welding of Stainless SteelsDocument31 pagesWelding of Stainless SteelsEswarNo ratings yet

- HSEDocument7 pagesHSEElah PalaganasNo ratings yet

- Building Design Construction SystemsDocument287 pagesBuilding Design Construction SystemsRalph SpinelliNo ratings yet

- Crucible and High-Frequency MethodsDocument6 pagesCrucible and High-Frequency Methodsmaanka tuduNo ratings yet

- ElectrochemistryDocument87 pagesElectrochemistryMohit Agrawal50% (2)

- Alphabetical List of AATCC Test Methods & Evaluation ProceduresDocument5 pagesAlphabetical List of AATCC Test Methods & Evaluation ProceduresShalahuddin TukuNo ratings yet

- Chap9 StudentDocument22 pagesChap9 StudentIsabel GohNo ratings yet

- Vocabulary and DefinitionsDocument14 pagesVocabulary and DefinitionsMurugananthamParamasivamNo ratings yet

- Bio Corrosion 2Document20 pagesBio Corrosion 2Kezhakkekarammal Puthiyedattu Sandeep92% (12)

- Problems On HardnessDocument24 pagesProblems On HardnessAdilaAnbreen100% (1)

- PrELIM EXAM CHEMISTRYDocument9 pagesPrELIM EXAM CHEMISTRYrudycamay100% (1)

- Advance Welding TechnologyDocument90 pagesAdvance Welding TechnologyRajib MandalNo ratings yet

- Tema 7 - Enlace MetalicoDocument39 pagesTema 7 - Enlace MetalicoLuchinPozo100% (2)

Chapter 1 - Stainless Steel

Chapter 1 - Stainless Steel

Uploaded by

Zuhaila MohammadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 1 - Stainless Steel

Chapter 1 - Stainless Steel

Uploaded by

Zuhaila MohammadCopyright:

Available Formats

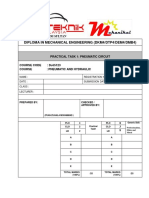

STAINLESS STEEL

MATERIAL TECHNOLOGY (DJF 5062)

What is Stainless Steel?

• Stainless steel are characterized primarily by their corrosion

resistance, high strength and ductility and high chromium content.

• It is highly resistant to corrosion in a variety of environments,

especially the ambient atmosphere.

• It has excellent resistant to stain and rust due to its chromium (Cr)

content, usually from 12 to 20 percent of the alloy or at least 10.5%

chromium.

Effect of Chromium in Plain Carbon Steel:

• Forms hard and stable carbide • Increase hardenability

• Raises critical temperature • Increase wear and corrosion resistance

• Stabilized the ferrite structure in carbon steel • Increase strength and hardness

2% Cr 12% Cr

• Still known as carbon steel • Increase corrosion resistance

• Increase mechanical properties-tensile strength • Increase the strength and hardness

increase until 980MPa and elongation until 15%. • From hard and stable carbides

• Form hard and strength properties. • Raises critical temperature

• Critical temperature increase. • Tend to stabilize the ferrite structure

• Content of Cr dissolve with ferrite in BCC form and

increase the strength, hardenability and

toughness.

• Can cold and hot work to give the good structure

and mechanic properties.

What Makes Stainless Steel Stainless?

• In order to make stainless steel Carbon Steel + O2 = Rust

stainless, there must be at least

12% of Cr in the steel.

• This level of chromium is the Rust

minimum level of chromium to Carbon Steel

ensure there are continuous stable

layer of protective chromium–rich

oxide forms on the surface. Stainless Steel + O2 = Cr Oxide Layer

• Stainless steel are called ‘stainless’

because in the presence of oxygen

(air) they develop a thin, hard

adherent film of chromium oxide Stainless Steel

that protects the metal from

corrosion.

Passive Film in Stainless Steel

• Chromium imparts a special Stainless Steel Cr oxide layer

property to the iron that makes it

corrosion resistant. Surface damaged

• When the chromium is in excess of Stainless Steel Cr oxide layer

12% the corrosion barrier changes

Surface healed

from an active film to passive film.

• The passive layer extremely thin, in

Cr oxide layer

Stainless Steel

the order of 10 to 100 atom thick,

and is composed mainly of Self-healing effect of Stainless Steel Chromium

chromium oxide which prevents oxide is a thin and transparent passive layer of

further diffusion of oxygen into the chromium oxide that allow the natural beauty of

stainless steel to remain intact. It is also self-healing

base metal. and forms readily in air.

Benefit of Stainless Steel

• Corrosion resistance

• Heat resistance

• Hygiene

• Aesthetic appearance

• Ease of fabrication

Classes of Stainless Steel

• Ferritic Stainless Steel

• Martensitic Stainless Steel

• Austenitic Stainless Steel

• Duplex Stainless Steel

• Precipitation Hardening Stainless

Steel

The classes of stainless steel is based The ferritic stainless steel on the left has a body

centered cubic (BCC) crystal structure. By adding

on crystal structure and strengthening nickel to this stainless steel the structure changes

from BCC to face centered cubic (FCC), which is called

mechanism. austenitic.

Classes of Stainless Steel

• Classified by composition of

chromium, carbon and nickel in

that steel.

• Show either stainless steel have

magnetic properties or not.

• Different in mechanical properties

(hardness, toughness, corrosion

resistance)

• Show the structure of stainless

steel. Provides a graphical overview of these groups

with respect to chromium and nickel content.

Classes of Stainless Steel

Ferritic Stainless Steel

• Content : Fe, 12 - 30% Cr, 0.08 - 0.2% C.

• Others name : Chromium steel.

• They are called ferritic since their structure remains mostly ferritic at

normal heat treatment conditions.

• These steel can contain other element such as titanium and niobium

(use to stabilize the structure) and sulfur which is added to improve

machinability.

• BCC structure.

Ferritic Stainless Steel

Properties :

• Magnetic properties, with proper precaution they can be weld.

• Have good strength and moderate ductility (lower ductility than ASS).

• Cannot be heat treated but may be strengthened by work hardening.

• Have excellent corrosion resistance and are relatively inexpensive (do

not contain nickel).

Ferritic Stainless Steel

Application :

• Kitchen equipment

• Washing machine

• High temperature application:

heaters, combustion chamber,

exhaust system, hot water tank,

automotive trim

Ferritic Stainless

Steel

Ferritic Stainless Steel

Grade Cr Mo Ni Mn N Cu Others Pre Pren

430 17 0 0 0 0 17 17

434 18 1 0 0 0 Ti, Nb 22 22

444 19 2 0 0 0 Ti, Nb 26 26

Yield Strength Hardness

Tensile Strength Elongation in (%

Grade 0.2% Proof Rockwell B

(MPa) in 50 mm) Brinell (HB)

(MPa) (HRB)

430 451 206 22 83 183

434 517 345 25 164

Austenitic Stainless Steel

• Content : Fe, 16 - 25% Cr, 7 - 20% Ni, 0.03 - 0.1% C).

• Known as Chromium – Nickel Steel.

• These alloys are called austenitic since their structures remain

austenitic (FCC) at normal heat treating temperature.

• The presence of the nickel, which has an FCC crystal structure enables

the FCC structure to be retained at room temperature.

• 70% of stainless steel production is austenitic stainless steel

Austenitic Stainless Steel

Properties :

• Non magnetic.

• Have excellent ductility, formability (the high formability of the ASS is due

to the FCC crystal) and corrosion resistance (better corrosion resistance

than FSS and MSS because the carbides can be retained in solid solution by

rapid cooling from high temperature).

• Hardened by cold working.

• Expensive.

• Austenitic stainless steel that are for welding contain small stabilizing

addition of titanium or niobium that prevent the inter-crystalline corrosion

and weld decay.

Austenitic Stainless Steel

Application :

• Chemical and food processing equipment

• Biomedical implants (orthopedic application)

• Furnace and heat exchanger

• Welded construction

• Watch casing

• Exterior architecture (roofing)

Austenitic

Stainless Steel

Austenitic Stainless Steel

Grade Cr Mo Ni Mn N Cu Others Pre Pren

304L 18 0 9 1 0 18 18

316L 17 2 11 1 0 24 24

904LN 20 4 25 1 0.1 1.5 32 36

Yield Strength Hardness

Tensile Strength Elongation in (%

Grade 0.2% Proof Rockwell B

(MPa) in 50 mm) Brinell (HB)

(MPa) (HRB)

304 515 205 40 92 201

304L 485 170 40 92 201

304H 515 205 40 92 201

Martensitic Stainless Steel

• Content : Fe, 12 - 17% Cr, 0.15 - 1% C

• Others name : Chromium steel

• These alloys are called martensitic because they are capable of

developing a martensitic structure after an austenizing and quenching

heat treatment.

Martensitic Stainless Steel

Properties :

• Magnetic properties.

• Hardenable by heat treatment.

• Have high strength and hardness (the highest strength among the stainless

steel).

• Its high hardness is due to a hard martensitic matrix and to the presence of

a large concentration of primary carbides.

• Corrosion resistance of these steels is relatively poor compared to the

ferritic and austenitic type.

• Good ductility.

Martensitic Stainless Steel

Application :

• Cutlery

• Surgical tools

• Bearing

• Pump shafts

• Valves

• Instrument tools

• Razor blade

• Fastener

• Turbine blade

• Spring

Martensitic

Stainless Steel

Duplex Stainless Steel

• Duplex stainless steels have a mixed microstructure of austenite and

ferrite (aim usually being to produce a 50/50 mix, although in

commercial alloys the ratio may be 40/60).

• Duplex stainless steels have roughly twice the strength compared to

austenitic stainless steels and also improved resistance to localized

corrosion, particularly pitting, crevice corrosion and stress corrosion

cracking.

• They are characterized by high chromium (19 - 32%) and

molybdenum (up to 5%) and lower nickel contents than austenitic

stainless steels.

• Main composition: 26% Cr, 3.5 to 8% Ni, 4.5% Mo

Duplex Stainless Steel

The properties of duplex stainless steels are achieved with an overall lower

alloy content than similar-performing super-austenitic grades, making their

use cost-effective for many applications

Properties :

• Good Strength

• High ductility

• Good ability to absorb energy

• High tensile strength

• High fatigue strength in the base metal

• Magnetic

Duplex Stainless Steel

Application:

• Common used in marine applications

• Chemical processing, transport and

storage

• Oil and gas exploration and offshore

rigs

• Oil and gas refining, pollution control

equipment, petrochemical plant, heat

exchanger, pulp & papermaking

industry

Duplex Stainless Steel

Grade Cr Mo Ni Mn N Cu Others Pre Pren

2101 21 0 2 5 0.2 21 24

2205 22 3 6 1 0.17 32 35

2304 23 0 4 1 0.13 23 25

2507 25 3.5 7 1 0.25 37 41

Yield Strength Hardness

Tensile Strength Elongation in (%

Grade 0.2% Proof Rockwell B

(MPa) in 50 mm) Brinell (HB)

(MPa) (HRB)

2205 620 450 25 31 293

2507 795 550 15 32 310

Precipitation Hardening Stainless Steel

• Main composition: 6.5% to 7.8% Ni

• Precipitation hardening (PH) results when heat aging treatment

causes hard intermetallic compounds to precipitate from crystal

lattice as the martensite is tempered.

• Austenitic grades are converted to martensitic grades through heat

treatment before precipitation hardening can be done.

• Ferromagnetic

Precipitation Hardening Stainless Steel

APPLICATION

• For use in fasteners and air frame

parts

• For use in high strength high

temperature applications

• Chemical processing equipment

• Heat exchanger

Precipitation Hardening Stainless Steel

Grade Cr Si Ni Mn P S C Others

6.5 –

17-7PH 16 - 18 <1.00 <1.00 <0.040 <0.030 <0.09 Al: 0.75 – 1.50

7.75

6.50 – Cu: 0.04 – 1.00

15-7PH 16 - 18 <1.00 <1.00 <0.040 <0.030 <0.09

7.75 Ti: 0.20 – 0.65

Yield Strength Hardness

Tensile Strength Elongation in (%

Grade 0.2% Proof Rockwell B

(MPa) in 50 mm) Brinell (HB)

(MPa) (HRB)

17-7PH 1380 1210 1 378

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Test 2 Jj512 Pneumatic and Hydraulic Answers All Question in Part A and Part BDocument5 pagesTest 2 Jj512 Pneumatic and Hydraulic Answers All Question in Part A and Part BZuhaila MohammadNo ratings yet

- Litar Topic 3 Dec 2019Document99 pagesLitar Topic 3 Dec 2019Zuhaila MohammadNo ratings yet

- Presentation Djj3213 - Material Science Student Name: Reg - NumberDocument1 pagePresentation Djj3213 - Material Science Student Name: Reg - NumberZuhaila MohammadNo ratings yet

- Eoc 2-Litar-SoalanDocument4 pagesEoc 2-Litar-SoalanZuhaila MohammadNo ratings yet

- Practical Task 1 Pneumatik June 2018Document20 pagesPractical Task 1 Pneumatik June 2018Zuhaila MohammadNo ratings yet

- Course Outline DJJ5123 Jun 2020 QrcodeDocument5 pagesCourse Outline DJJ5123 Jun 2020 QrcodeZuhaila MohammadNo ratings yet

- Djj5123 - Hydraulic - End of Chapter 2Document3 pagesDjj5123 - Hydraulic - End of Chapter 2Zuhaila MohammadNo ratings yet

- Buehler Vibratory Polisher Application Guide - PolishingDocument8 pagesBuehler Vibratory Polisher Application Guide - PolishingNathan T Nesbitt100% (1)

- Working Capital Management and Stores Inventory AnalysisDocument76 pagesWorking Capital Management and Stores Inventory Analysisagr_belaNo ratings yet

- EngineeringDocument208 pagesEngineeringvins4u100% (1)

- Tig Filler Rods: Iller OdsDocument1 pageTig Filler Rods: Iller Odsamir moniriNo ratings yet

- 014 ToolSteelDocument36 pages014 ToolSteelramptechNo ratings yet

- United States Patent (19) : Daly Et Al. 11) 4,436,836Document9 pagesUnited States Patent (19) : Daly Et Al. 11) 4,436,836arif thoha bariklanaNo ratings yet

- TurningDocument64 pagesTurningSerhat DoğandemirNo ratings yet

- 300 60 Komatiite High-Mg BasaltDocument3 pages300 60 Komatiite High-Mg Basalthugoluis_hNo ratings yet

- Union Galvasteel CorporatiofinalDocument13 pagesUnion Galvasteel CorporatiofinalNill Patrick Ulat Dulce100% (1)

- Chemistry Exam Form 5Document35 pagesChemistry Exam Form 5Tan Phei LingNo ratings yet

- BGTECH-1 - Topic 1-Concrete and MasonryDocument7 pagesBGTECH-1 - Topic 1-Concrete and MasonryChristian Sam VillegasNo ratings yet

- Past Paper Electrochemistry LQDocument15 pagesPast Paper Electrochemistry LQapi-3739994100% (1)

- Ar924 PDFDocument2 pagesAr924 PDFMario Mariochi ContardoNo ratings yet

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- Different Types of Pipes & TubesDocument8 pagesDifferent Types of Pipes & TubesSMSMNo ratings yet

- All About EPOXYDocument13 pagesAll About EPOXYEllen Kay CacatianNo ratings yet

- Eoi Kiocl Bolani SailDocument8 pagesEoi Kiocl Bolani Sailkselvan_1No ratings yet

- Welding of Stainless SteelsDocument31 pagesWelding of Stainless SteelsEswarNo ratings yet

- HSEDocument7 pagesHSEElah PalaganasNo ratings yet

- Building Design Construction SystemsDocument287 pagesBuilding Design Construction SystemsRalph SpinelliNo ratings yet

- Crucible and High-Frequency MethodsDocument6 pagesCrucible and High-Frequency Methodsmaanka tuduNo ratings yet

- ElectrochemistryDocument87 pagesElectrochemistryMohit Agrawal50% (2)

- Alphabetical List of AATCC Test Methods & Evaluation ProceduresDocument5 pagesAlphabetical List of AATCC Test Methods & Evaluation ProceduresShalahuddin TukuNo ratings yet

- Chap9 StudentDocument22 pagesChap9 StudentIsabel GohNo ratings yet

- Vocabulary and DefinitionsDocument14 pagesVocabulary and DefinitionsMurugananthamParamasivamNo ratings yet

- Bio Corrosion 2Document20 pagesBio Corrosion 2Kezhakkekarammal Puthiyedattu Sandeep92% (12)

- Problems On HardnessDocument24 pagesProblems On HardnessAdilaAnbreen100% (1)

- PrELIM EXAM CHEMISTRYDocument9 pagesPrELIM EXAM CHEMISTRYrudycamay100% (1)

- Advance Welding TechnologyDocument90 pagesAdvance Welding TechnologyRajib MandalNo ratings yet

- Tema 7 - Enlace MetalicoDocument39 pagesTema 7 - Enlace MetalicoLuchinPozo100% (2)