Professional Documents

Culture Documents

European Technical Approval ETA-10/0416: BM TRADA Certification

European Technical Approval ETA-10/0416: BM TRADA Certification

Uploaded by

PaulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

European Technical Approval ETA-10/0416: BM TRADA Certification

European Technical Approval ETA-10/0416: BM TRADA Certification

Uploaded by

PaulCopyright:

Available Formats

BM TRADA Certification

Authorised

Chiltern House And notified according

Stocking Lane To article 10 of the council

Directive of 21 December ...

Hughenden Valley 1988 on the approximation of (Logo of approval body)

High Wycombe the laws regulations and

administrative provision of

United Kingdom the member States

relating to construction

Tel:+44 (0)1494 569700 products (89/106/EEC)

Fax:+44 (0)1494 565487 Member of EOTA

Enquiries@bmtrada.com

http:/www.bmtrada.com

Euro pean Techn ical App ro val ETA- 10/0416

Issue 2

[Original version in English language]

Hollo-Bolt®

Trade name

Lindapter International

Holder of approval Lindsay House

Brackenbeck Road

Bradford

West Yorkshire

BD7 2NF

England

Generic type and use Expanding structural bolting assemblies for use in blind

of construction product fastening to steelwork

Validity: from 28/06/2011

to 14/10/2015

Manufacturing plant(s) Lindapter International

Lindsay House

Brackenbeck Road

Bradford

West Yorkshire

BD7 2NF

England

This Approval contains 20 pages including 11 annexes, which form an integral part of

the document

Eur opean O r ganisati on for Techni cal Appr oval s

Contents

Page

I LEGAL BASIS AND GENERAL CONDITIONS ........................................................... 3

II SPECIFIC CONDITIONS OF THE EUROPEAN TECHNICAL APPROVAL ................ 4

1 Definition of product and intended use........................................................................ 4

1.1 Definition of product ........................................................................................ 4

1.2 Intended use ................................................................................................... 4

2 Characteristics of product and methods of verification ................................................ 4

2.1 Characteristics of product ................................................................................ 4

2.2 Methods of verification .................................................................................... 4

3 Durability and identification ......................................................................................... 5

3.1 Durability ......................................................................................................... 5

3.2 Identification .................................................................................................... 5

4 Evaluation and attestation of conformity and CE marking ........................................... 5

4.1 System of attestation of conformity.................................................................. 5

4.2 Responsibilities ............................................................................................... 6

4.3 CE-Marking ..................................................................................................... 7

5 Assumptions under which the fitness of the product for the intended use was

favourably assessed ................................................................................................... 8

5.1 Manufacturing ................................................................................................. 8

5.2 Installation ....................................................................................................... 8

5.3 Instructions for installation ............................................................................... 8

6 Recommendations...................................................................................................... 8

6.1 Packaging, transport and storage .................................................................... 8

6.2 Use, maintenance, repair ................................................................................ 9

ANNEXES

Annex 1 Hollo-Bolt - Product and intended use (3-part assembly)

Annex 2 Hollo-Bolt - Product and intended use (5-part assembly)

Annex 3 Hollo-Bolt - Dimensions of fastener components

Annex 4 Hollo-Bolt (hexagon head) - Materials and dimensions of fastener components

Annex 5 Hollo-Bolt (hexagon head) - Characteristic values and limiting values

Annex 6 Hollo-Bolt (with button head screw) - Materials dimensions and properties of

fastener components

Annex 7 Hollo-Bolt (alternative countersunk collar) - Dimensions

Annex 8 Hollo-Bolt (alternative countersunk collar) - Materials dimensions and properties

of fastener components

Annex 9 Hollo-Bolt Flush Fit - Dimensions of fastener components

Annex 10 Hollo-Bolt Flush Fit - Materials and dimensions of fastener components

Annex 11 Hollo-Bolt Flush Fit - Characteristic values and limiting values

Page 2 of ETA -10/0416, Re - Issued on 26.06.2011

I LEGAL BASIS AND GENERAL CONDITIONS

1 This European Technical Approval is issued by BM TRADA certification in

accordance with:

Council Directive 89/106/EEC of 21 December 1988 on the approximation of laws,

regulations and administrative provisions of Member States relating to construction

products1, modified by Council Directive 93/68/EEC2 and Regulation (EC) N°

1882/2003 of the European Parliament and of the Council3;

Construction Product Regulations 1991 and the subsequent Construction Product

(Amendment) Regulations 1994.

Common Procedural Rules for Requesting, Preparing and the Granting of European

Technical Approvals set out in the Annex to Commission Decision 94/23/EC4;

Procedure for issuing ETA without an ETA Guideline in accordance with point 3.2 of

the Common Procedural Rules, pursuant to Article 9(2) of the CPD).

2 BM TRADA Certification is authorised to check whether the provisions of this

European Technical Approval are met. Checking may take place in the manufacturing

plant(s). Nevertheless, the responsibility for the conformity of the products to the

European Technical Approval and for their fitness for the intended use remains with

the holder of the European Technical Approval.

3 This European Technical Approval is not to be transferred to manufacturers or agents

of manufacturers other than those recorded in a comprehensive list maintained by BM

TRADA and copied to EOTA.

4 This European Technical Approval may be withdrawn by BM TRADA Certification, in

particular pursuant to information by the Commission according to Article 5(1) of

Council Directive 89/106/EEC.

5 Reproduction of this European Technical Approval including transmission by

electronic means shall be in full. However, partial reproduction can be made with the

written consent of BM TRADA Certification. In this case partial reproduction has to be

designated as such. Texts and drawings of advertising brochures shall not contradict

or misuse the European Technical Approval.

6 The European Technical Approval is issued by the approval body in its official

language. This version corresponds fully to the version circulated in EOTA.

Translations into other languages have to be designated as such.

1

Official Journal of the European Communities N° L 40, 11.2.1989, p. 12

2

Official Journal of the European Communities N° L 220, 30.8.1993, p. 1

3

Official Journal of the European Union N° L 284, 31.10.2003, p. 1

4

Official Journal of the European Communities N° L 17, 20.1.1994, p. 34

Page 3 of ETA -10/0416, Re - Issued on 26.06.2011

II SPECIFIC CONDITIONS OF THE EUROPEAN TECHNICAL

APPROVAL

1 Definition of product and intended use

1.1 Definition of product

The Hollo-Bolt fastener is a steel bolting assembly that is fastened to steelwork by

insertion into a predrilled hole from one face and secured on the far side by the

expansion of one part of the assembly after insertion. The expansion is achieved by

tightening operations on the near side only; no access is required to the far side.

For sizes M8, M10 and M12, the Hollo-Bolt assembly comprises three components:

bolt; slotted sleeve, with integral washer; conical nut.

For sizes M16 and M20, the Hollo-Bolt assembly comprises five components: bolt;

slotted sleeve; steel washer; compressible rubber washer; conical nut.

Sizes M8, M10 and M12 are available with hexagonal head screw, hexagon socket

button head screw or security button head screw, or with countersunk head screw

and flared sleeve.

Size M16 is available with hexagonal head screw or countersunk head screw.

Size M20 is available with hexagonal head screw only.

For the form of installed assembly, see Annex 1 and Annex 2.

1.2 Intended use

The product is intended to fasten together two steel structural components, or a

structural steel component and a non-structural component, when the far face of the

steelwork is inaccessible; such a situation commonly occurs when a bolted

connection is required to a structural hollow section. The connection may be required

to resist shear force, tensile force or a combination of shear and tensile forces.

The provisions in this European Technical Approval are based on an intended

working life of the product of 50 years. This working life should not be interpreted as

a guarantee given by the manufacturer but should be regarded as an economically

reasonable working life that is compatible with the expected working life of the

structure.

2 Characteristics of product and methods of verification

2.1 Characteristics of product

The forms of the fastener assemblies and their characteristic properties are given in

Annex 3 to Annex 11. The characteristic material values, dimensions and tolerances

of the fastener assemblies not indicated in the Annexes shall correspond to the

respective values stated in the technical documentation5 of this European Technical

Approval.

2.2 Methods of verification

The assessment of the product for the intended use in the sense of Essential

Requirements 1, 2 and 3 has been made in accordance with the “Common

5

The technical documentation of this European Technical Approval is deposited at BMTRADA and, as far as relevant for the

tasks of the approved bodies involved in the attestation of conformity procedure, is handed over to the approved bodies.

Page 4 of ETA -10/0416, Re - Issued on 26.06.2011

Understanding of Assessment Procedure for expanding structural bolting assemblies

for blind fastening” (ETA request 06.02/11).

3 Durability and identification

3.1 Durability

The durability of the product shall be achieved either by coating or by use of stainless

steel. The durability of the product in environmental conditions corresponding to

corrosivity classifications defined in ISO 9223 are given below:

Corrosivity Galvanized Electro-plated Steel with Stainless steel

class steel steel sheraplex finish

C1 more than 50 more than 50 more than 50 more than 50

years years years years

C2 more than 50 more than 20 more than 50 more than 50

years years years years

C3 more than 20 more than 10 more than 20 more than 50

years years years years

3.2 Identification

The components shall be marked. Details of the marking are given in the technical

documentation of this European Technical Approval.

4 Evaluation and attestation of conformity and CE marking

4.1 System of attestation of conformity

According to Decision 98/214/EC of the European Commission6, System 2+ of the

attestation of conformity applies.

This system is defined as follows.

System 2+: Declaration of conformity of the product by the manufacturer on the basis

of:

a) Tasks for the manufacturer:

(1) initial type testing of the product;

(2) factory production control;

(3) testing of samples taken from the factory in accordance with a prescribed

test plan.

b) Tasks for the notified body:

(4) certification of factory production control on the basis of:

- initial inspection of factory and of factory production control;

- continuous surveillance, assessment and approval of factory production

control.

6

Official Journal of the European Communities

Page 5 of ETA -10/0416, Re - Issued on 26.06.2011

4.2 Responsibilities

4.2.1 Tasks for the manufacturer

4.2.1.1 Initial type-testing of the product

For initial type-testing the results of the tests performed as part of the assessment for

the European Technical Approval shall be used unless there are changes in the

production line or plant. In such cases the necessary initial type-testing has to be

agreed between the manufacturer and the notified bodies involved.

4.2.1.2 Factory production control

The manufacturer shall exercise permanent internal control of production. All the

elements, requirements and provisions adopted by the manufacturer shall be

documented in a systematic manner in the form of written policies and procedures.

This production control system shall ensure that the product is in conformity with this

European Technical Approval.

The manufacturer shall only use raw materials supplied with the relevant inspection

documents. The incoming raw materials shall be subject to controls and tests by the

manufacturer before acceptance. Check of incoming materials such as nuts, washers,

material for sleeves, shall include control of the inspection documents presented by

suppliers (comparison with nominal values) by verifying dimensions and determining

material properties, e.g. tensile strength, hardness, surface finish.

The manufactured components of the fastener assemblies shall be subjected to the

following tests, in accordance with the prescribed test plan7:

− Dimensions of component parts:

bolt (diameter, length, marking);

sleeve (length, internal and external diameters, geometry of the slots, geometry

of the integral washer, where applicable);

rubber washer (diameter, thickness);

conical nut (diameters, length, geometry of surface);

washer (diameters, thickness, where applicable).

− Material properties:

bolt (ultimate tensile strength)

sleeve (ultimate tensile strength)

rubber washer (material composition, Shore hardness)

conical nut (proof load),

washer (hardness, where separate).

− Thickness of the protective coating (where applicable).

− Visual control of correct assembly and of completeness of the fastener assembly.

4.2.1.3 Further testing of samples

Samples of the complete assemblies shall be tested in tension in accordance with the

prescribed test plan.

7

The prescribed test plan has been deposited at BMTRADA and is only made available to the approved bodies involved in the

conformity attestation procedure.

Page 6 of ETA -10/0416, Re - Issued on 26.06.2011

4.2.1.4 Frequency of controls and recording of results

The results of factory production control shall be recorded and evaluated. The records

include at least the following information:

− designation of the product, basic material and components;

− type of control or testing;

− date of manufacture of the product and date of testing of the product or basic

material and components;

− result of control and testing and, if appropriate, comparison with requirements;

− signature of person responsible for factory production control.

The records shall be presented to the enforcing authority during the continuous

surveillance.

Details of the extent, nature and frequency of testing and controls to be performed

within the factory production control shall correspond to the prescribed test plan.

4.2.2 Tasks of approved bodies

4.2.2.1 Initial inspection of factory and of factory production control

The notified body shall ascertain that, in accordance with the prescribed test plan, the

factory and the factory production control are suitable to ensure continuous and

orderly manufacturing of the fastener assembly according to the specifications

mentioned in 2.1, as well as to the Annexes to this European Technical Approval.

4.2.2.2 Continuous surveillance

The notified body shall visit the factory at least twice a year (unless agreed otherwise

between the manufacturer and the notified body) for regular inspection. It shall be

verified that the system of factory production control in accordance with this European

Technical Approval is maintained,

Continuous surveillance and assessment of factory production control shall be

performed according to the prescribed test plan.

The results of product certification and continuous surveillance shall be made

available on demand by the enforcing authority. In cases where the provisions of this

European Technical Approval and the prescribed test plan are no longer fulfilled, the

conformity certificate shall be withdrawn.

4.3 CE-Marking

The CE marking shall be affixed on each packaging of fastener assemblies. The

symbol « CE » shall be accompanied by the following information:

− identification number of the certification body;

− name or identifying mark of the producer and manufacturing plant;

− the last two digits of the year in which the CE-marking was first affixed;

− number of the EC certificate of conformity;

− number of the European Technical Approval;

− size and type of fastener assembly.

Page 7 of ETA -10/0416, Re - Issued on 26.06.2011

5 Assumptions under which the fitness of the product for the

intended use was favourably assessed

5.1 Manufacturing

The fastener assembly is manufactured in accordance with the provisions of this

European Technical Approval using the production process assessed during

inspection of the plant by the notified body.

5.2 Installation

The fitness of the fastener assembly for the intended use is given under the

conditions that installation complies with the manufacturer’s instructions. In particular

that the fastener is installed in a hole whose dimensions are within the stated

tolerance on hole diameter; that faces of the components to be fastened together are

brought into contact before the assembly is tightened; that the tightening torque is at

least the minimum stated value.

5.3 Instructions for installation

It is the manufacturer’s responsibility to ensure that the specific instructions for

installation are provided to the purchaser. This information may be made by

reproduction of the respective parts of the European Technical Approval. In addition

all installation data shall be shown clearly on the package and/or on an enclosed

instruction sheet, preferably using illustration(s).

The minimum information required is:

• The fastener is to be installed in pre-drilled holes.

• The steelwork and attached component is to be brought into good contact and the

holes aligned before inserting the fastener.

• Illustration of the method of gripping the collar.

• Illustration of the method of attaching the torque wrench and statement of the

torque to be applied.

All information shall be presented in a clear and explicit form.

5.3.1 Design of connections using the product

The characteristic values of material resistance given in Annexes 4 to 11 may be

used as characteristic values when verifying structural adequacy in accordance with

Eurocode 3.

It is important to note that these characteristic values are valid for the assembly itself

but in any connection detail the design resistance of the connection may be limited to

a lesser value (than the sum of the resistances of the fasteners) by the structural

components that are connected. For example, when the thickness of the connected

component is small, pull-out failure may occur before failure of any of the assemblies,

6 Recommendations

6.1 Packaging, transport and storage

The products should be packed in boxes bearing the manufacturer’s name, product

type, nominal size, quantity, date of manufacture and batch reference details.

Page 8 of ETA -10/0416, Re - Issued on 26.06.2011

6.2 Use, maintenance, repair

The assessment of the fitness for use is based on the assumption that maintenance

is not required during the assumed intended working life.

Should repair prove necessary, fasteners should be replaced.

Page 9 of ETA -10/0416, Re - Issued on 26.06.2011

Hollo-Bolt structural bolting assembly (3-part assembly)

Pre-installation

Post installation

This form of the assembly is used for sizes M8, M10 and M12

Note: The fastener is illustrated with a hexagon head setscrew. A button head setscrew

may alternatively be used.

Hollo-Bolt Annex 1

Product and intended use (3-part assembly) of ETA 10/0416

Page 10 of ETA -10/0416, Re - Issued on 26.06.2011

Hollo-Bolt structural bolting assembly (5-part assembly)

Pre-installation

Post installation

This form of the assembly is used for sizes M16 and M20

Note: The fastener is illustrated with a hexagon head setscrew.

Hollo-Bolt Annex 2

Product and intended use (5-part assembly) of ETA 10/0416

Page 11 of ETA -10/0416, Re - Issued on 26.06.2011

Hollo-Bolt structural bolting assembly (pre-installation)

d e

k l s

Figure 3.1 Hexagon head screw

dc

lc

Figure 3.2 Conical nut

ds2 ds1

h ls

Figure 3.3 Sleeve with integral collar (3-part assembly)

ds2 ds1

h ls

Figure 3.4 Sleeve and separate collar (5 -part assembly)

dw2 dw1

hw

Figure 3.5 Rubber washer (5-part assembly)

Hollo-Bolt Annex 3

Dimensions of fastener components of ETA 10/0416

Page 12 of ETA -10/0416, Re - Issued on 26.06.2011

Table 4.1 Material specification and reference standards

Steel Stainless steel

Designation HB HBST

Hexagon head screw Property class 8.8, EN ISO 898-1 Austenitic grade A4,property class 70,

EN ISO 3506

Sleeve with integral Free cutting carbon steel, type Austenitic stainless steel, number,

collar, 11SMn30, EN 10087:1999 or 1.4404, EN 10088-3:2005 (minimum

sleeve (without collar), 11SMnPb30, EN 10087:1999 with a tensile strength 500 N/mm2 according to

2

collar (separate) minimum tensile strength of 430 N/mm Standard)

2

Conical Nut (sizes up to HB16) or 390 N/mm (size

HB20)

or

Cold drawn steel AISI 1021, grade

C10B21 (minimum tensile strength

2

470 N/mm according to Standard)

Coating (of cone, Electrodeposited coating, EN ISO 2081 (not applicable)

sleeve, collar and + JS500

screw) (see technical documentation)

or

hot dip galvanizing to EN ISO 1461:2009

or

sherardizing to BS 4921:1988, class 1 +

sheraplex coating

Rubber washer (see technical documentation) (see technical documentation)

Table 4.2 Dimensions

M8 M10 M12 M16 M20

Nominal diameter d mm 8 10 12 16 20

Max dia of cone dc mm 13 17.46 19.05 25.4 31.75

Outer dia of sleeve ds1 mm 13.75 17.75 19.75 25.75 32.75

Inner dia of sleeve ds2 mm 9 12 14 17 21

height of collar h mm 5 6 7 8 10

Outer dia of washer dw1 mm 26 31

Inner dia of washer dw2 mm 16 20

Washer thickness hw mm 5 5

Size 1 l mm 50 55 60 75 90

Length of

Size 2 l mm 70 70 80 100 120

screw

Size 3 l mm 90 90 100 120 150

Size 1 ls mm 30 30 35 41.5 50

Length of

Size 2 ls mm 49 48 57 63 76

sleeve

Size 3 ls mm 68 67 79 84 102

For thread dimensions and tolerances, see EN ISO 4017 (steel assemblies) or EN ISO 3506

(stainless steel assemblies).

For other dimensions and tolerances, see technical documentation

Hollo-Bolt (hexagon head) Annex 4

Materials and dimensions of fastener components of ETA 10/0416

Page 13 of ETA -10/0416, Re - Issued on 26.06.2011

Table 5.1 Characteristic values of tensile and shear resistances

Nominal Tensile resistance Shear resistance Material strength

size Ft,Rk (kN) Fv,Rk (kN) of sleeve (N/mm2)

Designation

HB08 M8 23.1 32.9 430

HB10 M10 39.6 54.2 430

HB12 M12 45.8 71.0 430

HB16 M16 84.3 139 430

HB20 M20 124 211 390

HBST08 M8 26.8 30.7 500

HBST10 M10 46.0 51.0 500

HBST12 M12 53.3 65.0 500

HBST16 M16 98.0 128 500

HBST20 M20 154 205 500

The characteristic values are valid when the assemblies are installed in holes in steel

components within the tabulated range of hole size and when the total thickness of the

components into which the assemblies are installed are within the tabulated range of

thickness.

Table 5.2 Limiting values of hole size and grip

Nominal Hole diameter Clamped length (mm)

size (mm) Size 1 Size 2 Size 3

Designation min max min max min max min max

HB 08 M8 13.8 15.0 3 22 22 41 41 60

HB 10 M10 17.8 19.0 3 22 22 41 41 60

HB 12 M12 19.8 21.0 3 25 25 47 47 69

HB 16 M16 25.8 28.0 12 29 29 50 50 71

HB 20 M20 32.8 35.0 12 34 34 60 60 86

In addition, the outer ply (i.e. the ply directly under the collar) must be at least 8 mm thick for

sizes HB16 and HB20.

Table 5.3 Minimum values of installation torque

Torque

(Nm)

Designation

HB08 and HBST08 23

HB10 and HBST10 45

HB12 and HBST12 80

HB16 and HBST16 190

HB20 and HBST20 300

Hollo-Bolt (hexagon head) Annex 5

Characteristic values and limiting values of ETA 10/0416

Page 14 of ETA -10/0416, Re - Issued on 26.06.2011

Hollo-Bolt structural bolting assemblies - alternative set screws

dk d

k l

Figure 6.1 Hexagon socket button head screw

Note: In addition, ‘security head’ screws are produced to the same dimensions but with a

different shape of socket in the head.

Table 6.1 Material specification and reference standards

Steel Stainless steel

Designation HBBH (with hexagon socket (not applicable)

HBFT or HBPR (with security socket)

Hexagon socket button Property class 10.9, EN ISO 7380:2004

head screw

Button head security Property class 10.9, EN ISO 7380:2004

screw

Coating of screw Electrodeposited coating, EN ISO 2081

+ JS500

(see technical documentation)

or

sherardizing to BS 4921:1988, class 1 +

sheraplex coating

Table 6.2 Dimensions

M8 M10 M12

Nominal diameter d mm 8 10 12

Size 1 l mm 50 55 60

Length of

Size 2 l mm 70 75 90

screw

Size 3 l mm 90 90 110

For thread dimensions and tolerances, see EN ISO 4017 (steel assemblies).

The material specifications and dimensions of the conical nut, sleeve and washer used with

the button head screw are the same as those for the hexagon head assembly.

Characteristic values of assemblies with button head screws

The characteristic values, limiting hole sizes and minimum installation torque values are all

the same as for the Hollo-Bolts with hexagon heads.

Hollo-Bolt (with button head screw) Annex 6

of ETA 10/0416

Materials dimensions and properties of fastener

components

Page 15 of ETA -10/0416, Re - Issued on 26.06.2011

Hollo-Bolt structural bolting assemblies –alternative countersunk collars

ds2 ds1

h ls

Figure 7.1 Countersunk collar and sleeve for 3-part assembly

Figure 7.2 Countersunk collar for 5-part assembly

For the dimensions of the countersinking, see the technical documentation.

Hollo-Bolt (alternative countersunk collar) Annex 7

of ETA 10/0416

Dimensions of sleeve and collar

Page 16 of ETA -10/0416, Re - Issued on 26.06.2011

Hollo-Bolt structural bolting assemblies –alternative countersunk collars

Table 8.1 Material specification and reference standards

Steel Stainless steel

Designation HBCSK HBSTCSK

Sleeve with integral Free cutting carbon steel, type Austenitic stainless steel, number,

collar, 11SMn30, EN 10087:1999 or 1.4404, EN 10088-3:2005 (minimum

2

separate collar 11SMnPb30, EN 10087:1999 with a tensile strength 500 N/mm according to

2

minimum tensile strength of 430 N/mm Standard)

or

Cold drawn steel AISI 1012, grade

C10B21 (minimum tensile strength 470

N/mm2 according to standard)

Countersunk head Property class 10.9, EN ISO 10642 Austenitic grade A4, property class 70,

screw EN ISO 3506

Dimensions in accordance with EN ISO

10642

Coating (of cone, Electrodeposited coating, EN ISO 2081 (not applicable)

sleeve, collar and + JS500

screw) (see technical documentation)

or

sherardizing to BS 4921:1988, class 1 +

sheraplex coating

Table 8.2 Dimensions of countersunk screws

M8 M10 M12 M16

Nominal diameter d mm 8 10 12 16

Size 1 l mm 50 50 55 70

Length of

Size 2 l mm 70 70 80 100

screw

Size 3 l mm 90 90 100 120

For thread dimensions and tolerances, see EN ISO 4017 (steel assemblies) or EN ISO 3506

(stainless steel assemblies).

The dimensions of the conical nut, sleeve, collar and washer (for the 5-part assembly) are

the same as those for the hexagon head assembly.

Characteristic values of assemblies with countersunk collars

The characteristic values, limiting hole sizes and minimum installation torque values are all

the same as for the Hollo-Bolts with hexagon heads.

Hollo-Bolt (alternative countersunk collar) Annex 8

of ETA 10/0416

Materials, dimensions and properties of fastener

components

Page 17 of ETA -10/0416, Re - Issued on 26.06.2011

Hollo-Bolt Flush Fit structural bolting assemblies

dk d

k

l

Figure 9.1 Countersunk head screw

ds2 ds1 dk

90°

h

ls

Figure 9.2 Flush fit sleeve

The dimensions of the conical nuts are the same as for corresponding nominal size of the

hexagon head assemblies

Hollo-Bolt Flush Fit Annex 9

Dimensions of fastener components of ETA 10/0416

Page 18 of ETA -10/0416, Re - Issued on 26.06.2011

Table 10.1 Material specification and reference standards

Steel Stainless steel

Designation HBFF HBSTFF

Countersunk head Property class 10.9, EN ISO 10642 Austenitic grade A4, property class 70,

screw EN ISO 3506

Dimensions in accordance with EN ISO

10642

Flush fit sleeve and Free cutting carbon steel, type Austenitic stainless steel, number,

Conical Nut 11SMn30, EN 10087:1999 or 1.4404, EN 10088-3:2005 (minimum

2

11SMnPb30, EN 10087:1999 with a tensile strength 500 N/mm according to

2

minimum tensile strength of 430 N/mm Standard)

or

Cold drawn steel AISI C10B21

(minimum tensile strength 470 N/mm2

according to Standard)

Coating (of nut, sleeve, Electrodeposited coating, EN ISO 2081 (not applicable)

collar and screw) + JS500

(see technical documentation)

or

sherardizing to BS 4921:1988, class 1 +

sheraplex coating

Table 10.2 Dimensions

M8 M10 M12

Nominal diameter d mm 8 10 12

Max dia of cone dc mm 13 17.46 19.05

Outer dia of sleeve ds1 mm 13.75 17.75 19.75

Inner dia of sleeve ds2 mm 9 12 14

Outer dia of tapered portion dk mm 23.7 29.6 32.7

Lengths

Length of screw – Size 1 l mm 50 50 55

Length of screw – Size 2 l mm 70 70 80

Length of screw – Size 3 l mm 90 90 100

Length of sleeve – Size 1 ls mm 35 36 42

Length of sleeve – Size 2 ls mm 54 54 64

Length of sleeve – Size 3 ls mm 73 73 86

Length of tapered portion h mm 5 6 7

For thread dimensions and tolerances, see EN ISO 4017 (steel assemblies) or EN ISO 3506

(stainless steel assemblies).

For other dimensions and tolerances, see technical documentation

Hollo-Bolt Flush Fit Annex 10

Materials and dimensions of fastener components of ETA 10/0416

Page 19 of ETA -10/0416, Re - Issued on 26.06.2011

Table 11.1 Characteristic values of tensile and shear resistances

Nominal Tensile resistance Shear resistance Material strength

size Ft,Rk (kN) Fv,Rk (kN) of sleeve

2

(N/mm )

Designation

HBFF08 M8 23.1 32.9 430

HBFF10 M10 39.6 54.2 430

HBFF12 M12 45.8 71.0 430

HBSTFF08 M8 26.8 30.7 500

HBSTFF10 M10 46.0 51.0 500

HBSTFF12 M12 53.3 65.5 500

The characteristic values are valid when the assemblies are installed in holes in steel

components within the tabulated range of hole size and when the total thickness of the

components into which the assemblies are installed are within the tabulated range of

thickness.

Table 11.2 Limiting values of hole size and grip

Nominal Hole diameter Clamped length (mm)

size (mm) Size 1 Size 2 Size 3

Designation min max min max min max min max

HBFF08 and HBSTFF08 M8 13.8 15.0 10 27 27 45 45 64

HBFF10 and HBSTFF10 M10 17.8 19.0 12 27 27 45 45 64

HBFF12 and HBSTFF12 M12 19.8 21.0 12 30 30 52 52 74

In addition, the outer ply (i.e. the ply directly under the collar) must be at least 8 mm thick for

M8 size and 10 mm for M10 and M12 sizes.

Table 11.3 Minimum values of installation torque

Torque

(Nm)

Designation

HBFF08 and HBSTFF08 23

HBFF10 and HBSTFF10 45

HBFF12 and HBSTFF12 80

Hollo-Bolt Flush Fit Annex 11

Characteristic values and limiting values of ETA 10/0416

Page 20 of ETA -10/0416, Re - Issued on 26.06.2011

You might also like

- BS EN 13022-2-2014 by BSIDocument44 pagesBS EN 13022-2-2014 by BSIBranescu FlorinNo ratings yet

- BS en 840-2-2012Document22 pagesBS en 840-2-2012Jerry BeanNo ratings yet

- BS en 13285 - 2010 Unbound Mixtures - SpecsDocument26 pagesBS en 13285 - 2010 Unbound Mixtures - SpecsselcukxNo ratings yet

- 2016 National Construction EstimatorDocument302 pages2016 National Construction EstimatorportalmanNo ratings yet

- BS en 1096-4-2018 - (2022-08-18 - 04-11-19 Am)Document38 pagesBS en 1096-4-2018 - (2022-08-18 - 04-11-19 Am)Free MouseNo ratings yet

- BS en 10202-2001 (2003)Document48 pagesBS en 10202-2001 (2003)Federico De MartiniNo ratings yet

- Bs-En 14879-6 - 2009Document56 pagesBs-En 14879-6 - 2009Patricio G. ArrienNo ratings yet

- BS en 13502-2002Document28 pagesBS en 13502-2002Miroslav RakicNo ratings yet

- BS en 124-2 - 2015Document36 pagesBS en 124-2 - 2015Design Frame Cover100% (4)

- BS en 50618-2014Document34 pagesBS en 50618-2014Giang KhuongNo ratings yet

- BS en 682-2002 Elastomeric Seals-Materials Requirements For Seals Used in PipesDocument22 pagesBS en 682-2002 Elastomeric Seals-Materials Requirements For Seals Used in PipesM Alim Ur RahmanNo ratings yet

- Nen-En 1825-1 2004Document30 pagesNen-En 1825-1 2004Alexandros TountasNo ratings yet

- Frey Ss I Bar Eta 090169Document34 pagesFrey Ss I Bar Eta 090169Amal HajarNo ratings yet

- ETA 09-0169 FreyssiBars enDocument34 pagesETA 09-0169 FreyssiBars enjeff_5650% (2)

- Guidance On Factory Production Control For The CE Marking (Attestation of Conformity 2+) of Designed Masonry MortarsDocument16 pagesGuidance On Factory Production Control For The CE Marking (Attestation of Conformity 2+) of Designed Masonry MortarsmanojballaNo ratings yet

- NB-CPD SG02 04 011r1 - Certification of The FPC of Building Limes To EN 459-1 2010Document8 pagesNB-CPD SG02 04 011r1 - Certification of The FPC of Building Limes To EN 459-1 2010Taha HusNo ratings yet

- Eta 08-0339Document9 pagesEta 08-0339MihaelaBeatriceVladNo ratings yet

- Eta 09-0013 TTM Multistrand enDocument56 pagesEta 09-0013 TTM Multistrand enjasamnaj100% (1)

- BS en 12952-10 - 2002Document14 pagesBS en 12952-10 - 2002Azima Zalfa AuliyakNo ratings yet

- European Technical Approval ETA-98/0001: Hilti Stud Anchor HST, HST-R and HST-HCRDocument23 pagesEuropean Technical Approval ETA-98/0001: Hilti Stud Anchor HST, HST-R and HST-HCRHemang KhandelwalNo ratings yet

- EN 13395-1-2002 - enDocument10 pagesEN 13395-1-2002 - enoptbestoreNo ratings yet

- CD044002Document45 pagesCD044002Laury CHBNo ratings yet

- NB-CPD SG02 04 010 - Aggregates PDFDocument45 pagesNB-CPD SG02 04 010 - Aggregates PDFntemou100% (2)

- BS en 10300-2005 (2006)Document54 pagesBS en 10300-2005 (2006)leila eslamiNo ratings yet

- SRR30SAB CE HlklemoveDocument5 pagesSRR30SAB CE HlklemoveManohar T MNo ratings yet

- Approved - Guidance: GNB-CPDDocument17 pagesApproved - Guidance: GNB-CPDAnonymous G6ceYCzwtNo ratings yet

- BS en 14022-2010Document16 pagesBS en 14022-2010osamatqm9No ratings yet

- MSA Certificate 3 M Cable PFLDocument2 pagesMSA Certificate 3 M Cable PFLAlexanderGabrielMendozaVelásquezNo ratings yet

- BS en 12079-2 2006Document18 pagesBS en 12079-2 2006Carlos Roberto Ferreira JuniorNo ratings yet

- En CPR Guidance For Aluminium Doors Windows and Curtain Walls 2018Document22 pagesEn CPR Guidance For Aluminium Doors Windows and Curtain Walls 2018Mehul VoraNo ratings yet

- DSI DYWIDAG ETA-09-0068 DYWIDAG External Strand Post-Tensioning System For 3 To 37 Strands e 01Document47 pagesDSI DYWIDAG ETA-09-0068 DYWIDAG External Strand Post-Tensioning System For 3 To 37 Strands e 01suvraNo ratings yet

- ETA 13-0163 PERINSUL HL Final 13-6-2013Document16 pagesETA 13-0163 PERINSUL HL Final 13-6-2013Attila SiklodiNo ratings yet

- A130607 - ETA 08-0012 - June2013Document55 pagesA130607 - ETA 08-0012 - June2013Mark El RamyNo ratings yet

- DD Cen TS 1992-4-2-2009 144 PDFDocument34 pagesDD Cen TS 1992-4-2-2009 144 PDFGinoNo ratings yet

- Iso 10204 Tipos de Certificados de Inspeccion - OcrDocument14 pagesIso 10204 Tipos de Certificados de Inspeccion - OcrMarco VeraNo ratings yet

- PD Cen TR 14245-2020Document44 pagesPD Cen TR 14245-2020Sadek SadNo ratings yet

- ETAG 030: Guideline For European Technical Approval ofDocument41 pagesETAG 030: Guideline For European Technical Approval ofAli KerimzadeNo ratings yet

- BS en 50214-2006 (2007)Document30 pagesBS en 50214-2006 (2007)Dung PhamNo ratings yet

- BBA Cert For Landmark Wall System For Rienf Soil Ret WallsDocument10 pagesBBA Cert For Landmark Wall System For Rienf Soil Ret WallssandycastleNo ratings yet

- Slurry Surfacing - Test Methods - : Part 3: ConsistencyDocument10 pagesSlurry Surfacing - Test Methods - : Part 3: ConsistencyMurat AtmacaNo ratings yet

- BS en 13888-2009Document18 pagesBS en 13888-2009abualamal100% (2)

- NB-CPD SG02 03 002r2 - EN 934 series-FPC Cert - Admixtures For Concrete Mortar and Grout PDFDocument15 pagesNB-CPD SG02 03 002r2 - EN 934 series-FPC Cert - Admixtures For Concrete Mortar and Grout PDFAlban TabakuNo ratings yet

- Unbound Mixtures. SpecificationsDocument36 pagesUnbound Mixtures. SpecificationseeeNo ratings yet

- Design of Fastenings For Use in Concrete - DD CEN TS 1992-4!5!2009Document28 pagesDesign of Fastenings For Use in Concrete - DD CEN TS 1992-4!5!2009Abdul Hamid HamatNo ratings yet

- BS 00030-1-1-1998 (2006)Document10 pagesBS 00030-1-1-1998 (2006)Balaji NaikNo ratings yet

- Latest Date For Receipt of Comments: 28 October 2023: Form 36Document131 pagesLatest Date For Receipt of Comments: 28 October 2023: Form 36J MrNo ratings yet

- Precast Concrete Products. Normal Weight and LightweightDocument48 pagesPrecast Concrete Products. Normal Weight and Lightweighttony.slash.pageNo ratings yet

- Dudek ETA 14 0181 Dudek I Beams ENDocument20 pagesDudek ETA 14 0181 Dudek I Beams ENJoseph BookerNo ratings yet

- 15534-6-2015 - BS enDocument26 pages15534-6-2015 - BS enVan Thu DangNo ratings yet

- BS en 15498-2008Document56 pagesBS en 15498-2008Amer AmeryNo ratings yet

- EN 13892-4-2002 - enDocument12 pagesEN 13892-4-2002 - enAndré VenturaNo ratings yet

- BS en 480-11-2005Document22 pagesBS en 480-11-2005dcd1980No ratings yet

- ETAG 007: Guideline For European Technical Approval ofDocument46 pagesETAG 007: Guideline For European Technical Approval ofMatt MacDonaghNo ratings yet

- PD Cen TR 10364-2018Document10 pagesPD Cen TR 10364-2018navaronefraNo ratings yet

- Eta 06-0226 Freyssinet Post-Tensioning SystemDocument104 pagesEta 06-0226 Freyssinet Post-Tensioning SystemМихајло МиленковићNo ratings yet

- Eta 040013 - Simpson NailsDocument13 pagesEta 040013 - Simpson NailsGuillaumeHNONo ratings yet

- BS en 01015-18-2002 Wetting CapilarDocument12 pagesBS en 01015-18-2002 Wetting CapilarClaudia CarhuaniNo ratings yet

- BS en 1011-8 - 2004 PDFDocument24 pagesBS en 1011-8 - 2004 PDFrezaNo ratings yet

- BS en 1559-2 2014Document28 pagesBS en 1559-2 2014umur kaçamaklı100% (1)

- Automotive Paints and CoatingsFrom EverandAutomotive Paints and CoatingsHans-Joachim StreitbergerNo ratings yet

- On The Blast Resistance of Laminat - 2012 - International Journal of Solids andDocument20 pagesOn The Blast Resistance of Laminat - 2012 - International Journal of Solids andPaulNo ratings yet

- Tractive Rolling Contact Mechanics of - 2012 - International Journal of SolidsDocument17 pagesTractive Rolling Contact Mechanics of - 2012 - International Journal of SolidsPaulNo ratings yet

- Supplement To AGRD Part 6B Roadside EnvironmentDocument9 pagesSupplement To AGRD Part 6B Roadside EnvironmentPaulNo ratings yet

- CRN-SPC-CVL-713026361-377 - Boundary Fences PDFDocument17 pagesCRN-SPC-CVL-713026361-377 - Boundary Fences PDFPaulNo ratings yet

- Building Enclosure Commissioning: What's The Big Deal?Document44 pagesBuilding Enclosure Commissioning: What's The Big Deal?PaulNo ratings yet

- Modeling of MIG MAG Welding With Experimental Validation - 2010 - Applied MathemDocument17 pagesModeling of MIG MAG Welding With Experimental Validation - 2010 - Applied MathemPaulNo ratings yet

- Stick Electrode Welding GuideDocument44 pagesStick Electrode Welding GuidePaulNo ratings yet

- Industry Alert - VBA - Feb 2016Document6 pagesIndustry Alert - VBA - Feb 2016PaulNo ratings yet

- FLIR T810441-En-Us gUIDEDocument39 pagesFLIR T810441-En-Us gUIDEPaulNo ratings yet

- Safety Factor For StoneDocument4 pagesSafety Factor For StonePaulNo ratings yet

- Applied Mathematical Modelling: Junli Liu, Tailei ZhangDocument12 pagesApplied Mathematical Modelling: Junli Liu, Tailei ZhangPaulNo ratings yet

- Editorial Board - 2010 - Applied Mathematical ModellingDocument1 pageEditorial Board - 2010 - Applied Mathematical ModellingPaulNo ratings yet

- Influences of Longitudinal Magnetic Field On Wave Propa - 2010 - Applied MathemaDocument12 pagesInfluences of Longitudinal Magnetic Field On Wave Propa - 2010 - Applied MathemaPaulNo ratings yet

- Bolted Conn. With Hot-Dip Galv. Steel Memb.Document14 pagesBolted Conn. With Hot-Dip Galv. Steel Memb.PaulNo ratings yet

- 5.9 Anti Graffiti Coatings and TreatmentsDocument5 pages5.9 Anti Graffiti Coatings and TreatmentsPaulNo ratings yet

- FISCHER Anchor Design-Pages-192-261Document71 pagesFISCHER Anchor Design-Pages-192-261PaulNo ratings yet

- Anchor Bolt FAZ: Approved ForDocument6 pagesAnchor Bolt FAZ: Approved ForPaulNo ratings yet

- Bolted Joint Design: Home Screws Index PageDocument5 pagesBolted Joint Design: Home Screws Index PagePaulNo ratings yet

- Waterloo Station PDFDocument9 pagesWaterloo Station PDFPaul100% (1)

- VetraFin Glass Fin SystemDocument24 pagesVetraFin Glass Fin SystemPaulNo ratings yet

- ChangingMarkets Bostick PDFDocument7 pagesChangingMarkets Bostick PDFPaulNo ratings yet

- Architectural Powder - Mike WithersDocument36 pagesArchitectural Powder - Mike WithersPaulNo ratings yet

- Preventing Coastal Corrosion (Tea Staining) : Technical BulletinDocument4 pagesPreventing Coastal Corrosion (Tea Staining) : Technical BulletinPaulNo ratings yet

- Peer Review: Auckland Council Civic Administration BuildingDocument25 pagesPeer Review: Auckland Council Civic Administration BuildingPaulNo ratings yet

- Monthly Project HSE Dashboard - December-2020Document25 pagesMonthly Project HSE Dashboard - December-2020saqibNo ratings yet

- Mohammed FARID: Career ObjectivesDocument3 pagesMohammed FARID: Career ObjectivesRohan Dutt SharmaNo ratings yet

- Preparation of Implementation Schedule: 5.1 Study of Contract Package ArrangementDocument326 pagesPreparation of Implementation Schedule: 5.1 Study of Contract Package ArrangementAl Patrick Dela CalzadaNo ratings yet

- Lean Construction - A Guide For Financial ManagersDocument27 pagesLean Construction - A Guide For Financial Managersprasmyth6897No ratings yet

- 5 Steps To Select Right Excavator For Construction Applications For Construction ProsDocument14 pages5 Steps To Select Right Excavator For Construction Applications For Construction ProsThomas FederuikNo ratings yet

- Amana Steel Buildings Contracting LLCDocument108 pagesAmana Steel Buildings Contracting LLCrexNo ratings yet

- Renovation Works FrameDocument1 pageRenovation Works FrameAdrian DyNo ratings yet

- Method Statement of AbutmentDocument8 pagesMethod Statement of AbutmentSaeed Ahmed SoomroNo ratings yet

- BOQ For The Propose Residence For MR Gihan AmarasekaraDocument75 pagesBOQ For The Propose Residence For MR Gihan AmarasekaraRamith De SilvaNo ratings yet

- Segmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureDocument4 pagesSegmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureAmar Babu ChNo ratings yet

- Contract Agreement20230311 ZDocument5 pagesContract Agreement20230311 ZChuan TianNo ratings yet

- 50 000m JITI FACILITY REACHES PRACTICAL COMPLETION PCLDocument5 pages50 000m JITI FACILITY REACHES PRACTICAL COMPLETION PCLJDANo ratings yet

- Cap 6 Site Layout PDFDocument10 pagesCap 6 Site Layout PDFPeter WachiraNo ratings yet

- PDF 04 Pneumatic Testing Procedure Shell Ok 4 DLDocument6 pagesPDF 04 Pneumatic Testing Procedure Shell Ok 4 DLAmin ThabetNo ratings yet

- Top Steel Fabrication Companies in DubaiDocument5 pagesTop Steel Fabrication Companies in DubaiRashid AlminNo ratings yet

- Valuations - Quantity Surveyors - Quantity SurveyingDocument2 pagesValuations - Quantity Surveyors - Quantity SurveyingrachuNo ratings yet

- Formtiles Brochures 2Document2 pagesFormtiles Brochures 2Joseph ValenciaNo ratings yet

- Front Elevation Escalator Section: General NoteDocument1 pageFront Elevation Escalator Section: General NoteHabibulla BavajiNo ratings yet

- As 7Document5 pagesAs 7Rajiv JhaNo ratings yet

- "Implementing Lean Construction in Ashghal ": Ciht 19 February 2019Document54 pages"Implementing Lean Construction in Ashghal ": Ciht 19 February 2019Mohammed MuzakkirNo ratings yet

- LTCC Easy 2Document2 pagesLTCC Easy 2alyNo ratings yet

- Architectural Design QuestionnairesDocument3 pagesArchitectural Design QuestionnairesJay PamotonganNo ratings yet

- Ce CV 2Document10 pagesCe CV 2miran sayyedNo ratings yet

- Nepomuceno Reaction PaperDocument9 pagesNepomuceno Reaction PaperAngelo NepomucenoNo ratings yet

- Tile Estimate Template For Bathroom RenovationDocument2 pagesTile Estimate Template For Bathroom Renovationchris j ChavezNo ratings yet

- An Assessment of Maintenance Culture On Public Buildings in Nigeria (A Case Study of Osun State) 1Document6 pagesAn Assessment of Maintenance Culture On Public Buildings in Nigeria (A Case Study of Osun State) 1Nsikak XavierNo ratings yet

- PF CFVG June 2021Document78 pagesPF CFVG June 2021Cherry’s ChannelNo ratings yet

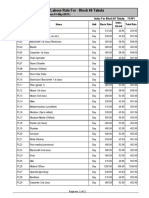

- Block 66 Takula - ResourceRate - LabourDocument2 pagesBlock 66 Takula - ResourceRate - LabourManojNo ratings yet

- Gunawardena Etal. ICSBE2016Document9 pagesGunawardena Etal. ICSBE2016Rajih RamadanNo ratings yet