Professional Documents

Culture Documents

Safe Work Plan For Erection of Steel Structure

Safe Work Plan For Erection of Steel Structure

Uploaded by

Ye YintOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safe Work Plan For Erection of Steel Structure

Safe Work Plan For Erection of Steel Structure

Uploaded by

Ye YintCopyright:

Available Formats

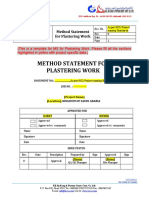

KMA-SUZUE LOGISTICS CENTER EXTENSION PROJECT

Safe Work Plan for Erection of Steel Structure

General Safety

All working crew shall go through with MBL / SIT in-house rules and regulation by SIT's HSE team

before commencing of works. (Refer. ATT 1)

HOT Work Safety

Every of modification or newly fabricated job in the plant, contractor shall be followed which has

been issued on safety Memo as per KSL - Construction Safety Memorandum (Hot Work Safety) . (Refer. ATT 2)

Shall brief to working crew before commencing of work.

Working At Heigth Safety

All working at height work shall be comply with KSL - Construction Safety Memorandum ( Working at Height

Safety ) . (Refer. ATT 3)

PPEs

- Safety Helmet

- Fully body harness

- Safety Shoe

- Hand Glove

- Ear Plug

Housekeeping & Waste Disposal

- Any Construction waste such as pieces of metal plate, used welding electrode, used grinding disc,

welding sludge, grinding particles shall be contain and properly house keep is required to control

and prevent for client's working enviroment and good for hygiene of daily working enviroment as

well.

Page 1 of 3 Prepared by SIT

KMA-SUZUE LOGISTICS CENTER EXTENSION PROJECT

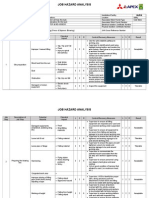

SCOPE OF WORK AND MAJOR Scaffold Erection / Dismantling for steel structure installation work at

TASK bucket elevator.

EQUIPMENT INVOLVED Scaffolding Material and necessary tools

WORK ACTIVITY To carry out scaffold material to erect scaffolding at bucket elevator.

Vehicular accident, Blockage access, Falling object, Falling from height,

HAZARD

Damaged to client facilities.

Long Sleeve, Long Pant, Hard Hat, Safety Shoe, Safety Harness, Hand

PPE

Glove.

LOTO NA

To prevent the accident:-

¨ Ensure Daily tools box talk must be done by SIT's HSE team.

¨ Contractor to apply PTW one day in advance for SIT PIC to review and approval.

¨ Ensure working shall attend the toolbox talk before start work.

¨ Beaware of truck and forklift movement when delivering the scaffold material crossing road to

working area.

¨ Cordon off the working area with suitable warning sign must provided.

¨ All scaffold members must be fastened with effective couplers and right to use as per equipment.

(Eg. Fixed coupler, Swivel coupler).

¨ The couplers, Sole plate, base plate, joint pin and other scaffold material free from defect.

¨ The planks/Toe board should free from defect and damage such as cracks, splits, etc.

¨ The access ladders free from corrosion, cracks, rusts, oil and other damage.

¨ Make sure to check all scaffold material are in good conditions before erecting.

¨ Contractor to submit scaffold inspection checklist every week.

¨ The scaffold tag shall be available and visible to indicate scaffold safe for use after erection.

¨ Only authorized scaffold builder to do erection and modification of scaffolding.

¨ Only competence and trained person to do erection and modification of scaffold.

¨ Shall STOP work any work deviated from original plan and do proper investigate before

resuming work.

Page 2 of 3 Prepared by SIT

KMA-SUZUE LOGISTICS CENTER EXTENSION PROJECT

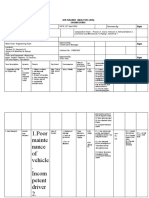

SCOPE OF WORK AND MAJOR

Using mobile crane to erection of steel structure

TASK

EQUIPMENT INVOLVED Mobile crane

WORK ACTIVITY Using mobile crane to install steel column, member and beam

May collapse crane, Failure crane during lifting, Broken off webbing sling

HAZARD

of steel rope, Slip of load, hitting by load to other facilities or human

LOTO NA

To prevent the accident:-

¨ Ensure Daily tools box talk must be done by SIT's HSE team.

¨ Make sure apply the lifting permit and approved by SIT.

¨ Ensure worker shall attend the daily tool box talk before start work.

¨ All lifiting activity shall be comply with lifiting plan.

¨ Contractor engineer or supervisor must explained approved MOS and JSRA to their co-follow

worker such as crane operator, lifting supervisor, rigger man and signal man.

¨ Make sure to use tag line to prevent for the swinging of load.

¨ All lifiting crews such as crane operator, lifiting supervisor, rigger man and signal man and signal

man, they shall have quilified certificate and competence to perform lifiting activities.

¨ Crane operator to check crane condition daily and control by crane checklist prior to start lifiting

operation.

¨ Ensure to check soil condition prior to travel in to gravel area.

¨ Outrigger must be fully extended with suitable outrigger mats.

¨ Crane operator ensure to check crane limit switch is in good functioning.

¨ Anchor point of Chain block shall enough stronger point to hook.

¨ Ensure that chain block capacity must be more than load capacity.

¨ All lifiting gear and appliance shall be inspected and safe for lifiting operation.

¨ Cordon off the lifiting operation area with suitable warning sign.

¨ Mobile crane shall be inspected and safe to use by crane company.

¨ All lifiting activity shall be under control by competence lifiting supervisor.

¨ Beaware of truck and forklift movement around lifiting area.

¨ To do proper housekeeping after work done.

¨ Shall STOP work any work deviated from original plan and do proper investigate before

resuming work.

Page 3 of 3 Prepared by SIT

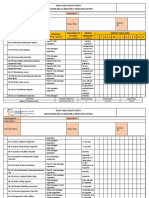

Project : KMA-SUZUE LOGISTICS CENTER EXTENSION PROJECT ATTACHEMENT - 1

Client : KMA-SUZUE MYANMAR LOGISTICS

Date : 23-Jun-2019

TO : All Project Members, Contractors and Sub-contractors

RE : Construction Safety Memorandum # 1 : Working at height safety

Working at height is the largest single cause among serious acciendents in the construction industry therefore risk

control shall be carried out for all works more than 1.8 meters above the ground level from which workers or

materials could possibly fall.

Please pay serious attension and comply with safety instructions mentioned below before you start working in

KMA-SUZUE Logistics Center Extension Project Construction Site.

· All Scaffold should be erected and dismentled by those who are adequately experienced and

competent in the erection and dismentling of scaffolding.

· A competent person should inspect all scaffolds at least three days after erection. The outcomes

of inspections must be recorded, documented and kept available.

· Tages shall be fitted to all scaffolds to indicate whether they are safe for use or not.

Scaffolding Foreman (or) Supervisor shall sign all “Safe for Use” Green Tags.

· Make sure to access the soil condition prior to the commencement of any scaffold erection works.

· Ensure to use standard base plates on the scaffolding foundation.

· All the employees must ware the safety harness whenever working at height 1.8 m and above.

· Always hook up at the anchorage point (above shoulder).

· Provide safe access, guard rail, hand rail for prevention of fall and to install safety net or toe

board for prevention of falling objects.

· Secure all the tools, devices and equipment of installation work to avoid the following objects.

· Provide the "Life Line" if the working platform is insufficient or working at roof area.

· Must comply with basic ladder safety requirement while using A-frame ladder or straight ladder.

· Assit one person ro hold the ladder to maintain balance of the ladder and "Top 3 Rungs" of ladder

is not allowed to use to prevent over reaching.

If you have any concern about the clarification on facts mentioned above, please feel free to contact me.

Thank you for your cooperation.

Memo#1 Safety Memo SIT

You might also like

- Method Statement-Erosion ControlDocument22 pagesMethod Statement-Erosion ControlGad100% (1)

- SAFE WORK PROCEDURE Road WorkDocument6 pagesSAFE WORK PROCEDURE Road WorkMuhammad RidwanNo ratings yet

- Workplace Inspection Checklist For Construction Works - KenyaDocument20 pagesWorkplace Inspection Checklist For Construction Works - KenyaWinstone Audi100% (1)

- Safe Work ProcedureDocument19 pagesSafe Work Procedureshihab67% (3)

- JSA - Mechanical-Excavation PDFDocument1 pageJSA - Mechanical-Excavation PDFAhmed GomaaNo ratings yet

- Activity Hazard AnalysisDocument7 pagesActivity Hazard AnalysisAnthony MacatangayNo ratings yet

- EAP Grammar in Context: Reading & WritingDocument27 pagesEAP Grammar in Context: Reading & WritingMónica Coirolo50% (2)

- Appointment of Formwork & Support Work SupervisorDocument1 pageAppointment of Formwork & Support Work SupervisorRickesh Nunkoo100% (1)

- Temp Fencing & GateDocument12 pagesTemp Fencing & GateMark Fash0% (1)

- COSHH Assessment RegisterDocument4 pagesCOSHH Assessment Registeranon_529779409No ratings yet

- CP 601S CP 601S: Elastomeric Firestop SealantDocument4 pagesCP 601S CP 601S: Elastomeric Firestop Sealantrichard_qrNo ratings yet

- NCP Altered Thermoregulation HypothermiaDocument2 pagesNCP Altered Thermoregulation HypothermiaMaila Joy Pring Fuentes100% (10)

- Turkish AirlinesDocument16 pagesTurkish AirlinesChris Gb100% (1)

- Octopus Jsa For ExcavationDocument1 pageOctopus Jsa For ExcavationOgunwa EmmanuelNo ratings yet

- Method Statement With Job Safety Analysis For Road Drains Culverts Road Crossover Final 16 07 2019Document32 pagesMethod Statement With Job Safety Analysis For Road Drains Culverts Road Crossover Final 16 07 2019Imranuddin SyedNo ratings yet

- Sample Checklist For FormworkDocument2 pagesSample Checklist For FormworkDaniel JulianNo ratings yet

- Daily Site DiaryDocument2 pagesDaily Site DiaryShivaraj Subramaniam100% (2)

- Safety Plan: A) Personal Protective Equipment (Ppe)Document4 pagesSafety Plan: A) Personal Protective Equipment (Ppe)Navneet SoniNo ratings yet

- Job Hazard AnalysisDocument5 pagesJob Hazard AnalysisShamel Jen FacundoNo ratings yet

- Method Statement For Excavation Compaction and BackfillingDocument8 pagesMethod Statement For Excavation Compaction and BackfillingIna RoseNo ratings yet

- Traffic Management Plan of KitimeDocument21 pagesTraffic Management Plan of KitimeBiniyam TseguNo ratings yet

- Excavation and BackfillingDocument2 pagesExcavation and BackfillingyasserNo ratings yet

- L019 - OHSE Shaft Work Permit FormatDocument1 pageL019 - OHSE Shaft Work Permit FormatRajib MondalNo ratings yet

- SS JSP - 017 Backfilling and CompactionDocument6 pagesSS JSP - 017 Backfilling and CompactionSn Ahsan100% (1)

- Presentation 1 Demolition Work (Edited)Document17 pagesPresentation 1 Demolition Work (Edited)imah4152100% (2)

- Safe Work Method Statement Slab Concreting PurposeDocument4 pagesSafe Work Method Statement Slab Concreting Purposeyogesh shindeNo ratings yet

- Site Inspection ReportDocument45 pagesSite Inspection ReportAhmad HasnanNo ratings yet

- Mathod Stetement. SafetyDocument17 pagesMathod Stetement. Safetymangeshshinde124No ratings yet

- Scaffolding SafetyDocument51 pagesScaffolding SafetySatya NaiduNo ratings yet

- C0329C-SOW-00-M-0005 - Scope of Work For Scaffolding RentDocument9 pagesC0329C-SOW-00-M-0005 - Scope of Work For Scaffolding RentReza Furqon100% (1)

- Work Method Statement: BNPP-HSE-JHA-2014-210 6Document8 pagesWork Method Statement: BNPP-HSE-JHA-2014-210 6Karthik babuNo ratings yet

- Construction Site Safety Plan Template (EXAMPLE)Document25 pagesConstruction Site Safety Plan Template (EXAMPLE)roland magoNo ratings yet

- Curriculum Vitae: With Industrial Fire & Safety Services As A Safety SupervisorDocument4 pagesCurriculum Vitae: With Industrial Fire & Safety Services As A Safety SupervisorIssac JohnNo ratings yet

- HIRAC Julz 021722Document5 pagesHIRAC Julz 021722JulzNo ratings yet

- Mobilization, Temporary Facilities and ControlsDocument9 pagesMobilization, Temporary Facilities and ControlsFikreyesus Demeke CherkosNo ratings yet

- Block Wall - Risk AssessmentDocument19 pagesBlock Wall - Risk Assessmentfziza100% (3)

- Excavation Checklist PDFDocument4 pagesExcavation Checklist PDFPageduesca RouelNo ratings yet

- Method Statement of ExcavationDocument9 pagesMethod Statement of ExcavationAmit kumar thakurNo ratings yet

- Daily Construction Inspection ReportDocument2 pagesDaily Construction Inspection ReportVirgilio ValmonteNo ratings yet

- Procedure Installation of Lighting - LABUAN BAJO PDFDocument6 pagesProcedure Installation of Lighting - LABUAN BAJO PDFWika Djoko ONo ratings yet

- SG-12 Safety Guideline For Demolition of Building and Structure-Final NewDocument39 pagesSG-12 Safety Guideline For Demolition of Building and Structure-Final NewrajiNo ratings yet

- Site Organisation and ManagementDocument20 pagesSite Organisation and ManagementMohit Rajoriya100% (1)

- Excavation Safety Policy: City of LincolnDocument11 pagesExcavation Safety Policy: City of LincolnMianNo ratings yet

- 5-Monthly Environment ReportDocument2 pages5-Monthly Environment ReportMohamed RizwanNo ratings yet

- Pre-Demolition Checklist: Lancaster Safety Consulting, IncDocument5 pagesPre-Demolition Checklist: Lancaster Safety Consulting, InctonyNo ratings yet

- HUP & LUP CCS C64A HDB Housekeeping & Safety Audit Report 13.01.2011Document9 pagesHUP & LUP CCS C64A HDB Housekeeping & Safety Audit Report 13.01.2011Shahid AliNo ratings yet

- JHA Blowing PressDocument5 pagesJHA Blowing PressLuqman OsmanNo ratings yet

- Block Work MS (Sample)Document18 pagesBlock Work MS (Sample)jones100% (1)

- Site Storage PlanDocument28 pagesSite Storage PlanSimamora Samuel Hansen100% (1)

- Job Hazard Analysis Engineering Site Inspection 2Document5 pagesJob Hazard Analysis Engineering Site Inspection 2Nonsoufo ezeNo ratings yet

- Unsafe Act Form: Unsafe Acts Require A Written Warning and Re-Training Before The Employee Resumes Work Date DateDocument2 pagesUnsafe Act Form: Unsafe Acts Require A Written Warning and Re-Training Before The Employee Resumes Work Date DateGunturMasihAristaNo ratings yet

- Construction & Demolition WasteDocument7 pagesConstruction & Demolition WastefaridkhanNo ratings yet

- MOS Template - Plastering WorkDocument18 pagesMOS Template - Plastering WorkAnantha PadmanabhanNo ratings yet

- 07 Method Sytatement For Drilling MachineDocument5 pages07 Method Sytatement For Drilling MachineNishar Balkavade100% (1)

- NCR RepairDocument4 pagesNCR RepairPanruti S SathiyavendhanNo ratings yet

- 1.1 Site Daily DiaryDocument1 page1.1 Site Daily DiaryNwe OoNo ratings yet

- Contractors Guide To Work Method StatementsDocument6 pagesContractors Guide To Work Method StatementsMuhammed AliNo ratings yet

- Piling Works Mos RevisedDocument4 pagesPiling Works Mos RevisedPrince Car-chang50% (2)

- Method Statement For Cement Board Dry Wall PartitionsDocument10 pagesMethod Statement For Cement Board Dry Wall PartitionsComet GroupNo ratings yet

- Ohs-Pr-09-09-F01 (A) Plant and Facility Register and InspectionDocument4 pagesOhs-Pr-09-09-F01 (A) Plant and Facility Register and InspectionSiddiquiNo ratings yet

- BargeDocument4 pagesBargeanon_222140886No ratings yet

- Construction of Burhani Park, Neral: Checklist For ExcavationDocument2 pagesConstruction of Burhani Park, Neral: Checklist For Excavationyash shahNo ratings yet

- Construction Site ChecklistDocument5 pagesConstruction Site ChecklistKutbuddin J TunkiwalaNo ratings yet

- SWP-07 Excavation WorksDocument7 pagesSWP-07 Excavation WorksMd Shahin100% (1)

- Method Statement For Excavation & Backfilling (SAMPLE)Document14 pagesMethod Statement For Excavation & Backfilling (SAMPLE)Hasann MaawiaNo ratings yet

- Water Tank For Minn Tun's Project - 1Document7 pagesWater Tank For Minn Tun's Project - 1Ye YintNo ratings yet

- TKIC-Document Transmittal-012Document12 pagesTKIC-Document Transmittal-012Ye YintNo ratings yet

- Cell GroupDocument15 pagesCell GroupYe YintNo ratings yet

- Note 3Document3 pagesNote 3Ye YintNo ratings yet

- Number FormatDocument4 pagesNumber FormatYe YintNo ratings yet

- Mathematical Operators & Formula CalculationDocument2 pagesMathematical Operators & Formula CalculationYe YintNo ratings yet

- Conditional FormatDocument5 pagesConditional FormatYe YintNo ratings yet

- Table StyleDocument5 pagesTable StyleYe YintNo ratings yet

- Font & AlignmentDocument6 pagesFont & AlignmentYe YintNo ratings yet

- Find & ReplaceDocument13 pagesFind & ReplaceYe YintNo ratings yet

- Risk Assessment Plan For - Site-Clearing-EarthworksDocument2 pagesRisk Assessment Plan For - Site-Clearing-EarthworksYe YintNo ratings yet

- Example Risk Assessment For Contract Bricklayers - HSE For Northern Ireland962188620220321Document8 pagesExample Risk Assessment For Contract Bricklayers - HSE For Northern Ireland962188620220321Ye YintNo ratings yet

- Concrete Breaker Instructions For Use: When OperatingDocument1 pageConcrete Breaker Instructions For Use: When OperatingYe YintNo ratings yet

- Ko Ye Yint (Level Result)Document1 pageKo Ye Yint (Level Result)Ye YintNo ratings yet

- Sterling Myanmar Mail - NYSH - Cement Material SubmissionDocument2 pagesSterling Myanmar Mail - NYSH - Cement Material SubmissionYe YintNo ratings yet

- Sterling's Machinery and Equipment ListDocument2 pagesSterling's Machinery and Equipment ListYe YintNo ratings yet

- Display Isolation Tag (Isolation Close/open)Document1 pageDisplay Isolation Tag (Isolation Close/open)Ye YintNo ratings yet

- Site Visit ReportDocument1 pageSite Visit ReportYe YintNo ratings yet

- See Detail in Fabrication Work Schedule: (Overall)Document1 pageSee Detail in Fabrication Work Schedule: (Overall)Ye YintNo ratings yet

- Concrete Blocks Layout & Elevation For 4th Floor (Part-A)Document10 pagesConcrete Blocks Layout & Elevation For 4th Floor (Part-A)Ye YintNo ratings yet

- AutoCAD Operator - Emergent - 20171005Document2 pagesAutoCAD Operator - Emergent - 20171005Ye YintNo ratings yet

- 20ft Long Angle 3.00 NosDocument8 pages20ft Long Angle 3.00 NosYe YintNo ratings yet

- Typical Drawing For Concrete Block Installation (Rev-03)Document1 pageTypical Drawing For Concrete Block Installation (Rev-03)Ye YintNo ratings yet

- INSPECTION SHEET (Rebar)Document3 pagesINSPECTION SHEET (Rebar)Ye YintNo ratings yet

- Coreflor: (Non-Metallic Monolithic Surface Hardening Compound)Document2 pagesCoreflor: (Non-Metallic Monolithic Surface Hardening Compound)Ye YintNo ratings yet

- WM-CPP-Rebar Record As of 23.aprilDocument9 pagesWM-CPP-Rebar Record As of 23.aprilYe YintNo ratings yet

- Historia de La OrtodonciaDocument9 pagesHistoria de La Ortodonciacarmonao.carina94No ratings yet

- Patient InfoDocument2 pagesPatient InfoJoshua AysonNo ratings yet

- KIS MYP Summative Assessment - Grade 7 C ADocument4 pagesKIS MYP Summative Assessment - Grade 7 C AAahan ShahNo ratings yet

- Fit For Frailty Part 1Document22 pagesFit For Frailty Part 1or1da2sa3No ratings yet

- Let's Talk About HealthDocument1 pageLet's Talk About HealthAlma Lorena Alonso LinaresNo ratings yet

- Homoeopathic & Biochemic Instant PrescriberDocument369 pagesHomoeopathic & Biochemic Instant Prescriberdevilcobra68No ratings yet

- Social Work Dissertation Substance MisuseDocument5 pagesSocial Work Dissertation Substance MisuseWebsitesThatWritePapersForYouCanada100% (1)

- Histeroctomy PDFDocument6 pagesHisteroctomy PDFsanta_pangaribuan_1No ratings yet

- Medical Terminology Chapter 2 With Complete Solutions 100%Document10 pagesMedical Terminology Chapter 2 With Complete Solutions 100%Gregg ProducerNo ratings yet

- Trung Tâm Ngoại Ngữ Nq Education Tầng 3, Tòa nhà 29T2 - N05 Hoàng Đạo Thúy - 0961 976 968 1Document6 pagesTrung Tâm Ngoại Ngữ Nq Education Tầng 3, Tòa nhà 29T2 - N05 Hoàng Đạo Thúy - 0961 976 968 1HAnhh TrầnnNo ratings yet

- Project ProposalDocument9 pagesProject Proposalafsar izafNo ratings yet

- Digital Studio: Course DescriptionDocument12 pagesDigital Studio: Course DescriptionCornNo ratings yet

- Textbook Gen64 125Document76 pagesTextbook Gen64 125Jiraporn AekkhamphanNo ratings yet

- Sample SyllabusDocument9 pagesSample SyllabusRolalen Joyce C PaitonNo ratings yet

- LSU STUDENT LOG BOOK MarketingDocument46 pagesLSU STUDENT LOG BOOK MarketingJOSPHAT NYASHA GORONGANo ratings yet

- Sustainable Development Goal 2 - Zero HungerDocument11 pagesSustainable Development Goal 2 - Zero HungeralomerdenisNo ratings yet

- Teaching Organizational Diagnosis As A Practice Theory-WeisbordDocument7 pagesTeaching Organizational Diagnosis As A Practice Theory-WeisbordOscar Daniel Hernández OlveraNo ratings yet

- Final Exam Schedule-StudentsDocument2 pagesFinal Exam Schedule-StudentsBLESSEDNo ratings yet

- DG Du Diabète Type 1Document1 pageDG Du Diabète Type 1Daoud IssaNo ratings yet

- ResumescDocument2 pagesResumescapi-662191303No ratings yet

- Simulacro de Seguimiento Académico Simulacro de Seguimiento AcadémicoDocument6 pagesSimulacro de Seguimiento Académico Simulacro de Seguimiento Académicoalessa garciaNo ratings yet

- Snakes Are Needed in Our World For ManyDocument18 pagesSnakes Are Needed in Our World For Manyapi-600442421No ratings yet

- HNTR BDN EmailDocument6 pagesHNTR BDN EmailEd Robinson100% (1)

- Lesson Plan Death CareDocument19 pagesLesson Plan Death CareLoma Waghmare (Jadhav)No ratings yet

- Clinical 3 Dump Dusting Chimozi 3Document8 pagesClinical 3 Dump Dusting Chimozi 3Miriward ZimbaNo ratings yet