Professional Documents

Culture Documents

Metal Bellows Coupling I: Series KM

Metal Bellows Coupling I: Series KM

Uploaded by

Ismael Rios0 ratings0% found this document useful (0 votes)

17 views1 pageThe document describes the Metal Bellows Coupling I Series KM, a low-cost standard metal bellows coupling. It has a 6-corrugation bellows and simple radial clamping hub allowing for easy installation. The series comes in various standard sizes ranging from 20Nm to 1300Nm torque capacity. Key specifications are provided like dimensions, material properties, torque limits, spring rates and more. It can operate in temperatures from -40°C to 200°C.

Original Description:

manual de cople tipo muelle KM

Original Title

Datasheet_KM

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes the Metal Bellows Coupling I Series KM, a low-cost standard metal bellows coupling. It has a 6-corrugation bellows and simple radial clamping hub allowing for easy installation. The series comes in various standard sizes ranging from 20Nm to 1300Nm torque capacity. Key specifications are provided like dimensions, material properties, torque limits, spring rates and more. It can operate in temperatures from -40°C to 200°C.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

17 views1 pageMetal Bellows Coupling I: Series KM

Metal Bellows Coupling I: Series KM

Uploaded by

Ismael RiosThe document describes the Metal Bellows Coupling I Series KM, a low-cost standard metal bellows coupling. It has a 6-corrugation bellows and simple radial clamping hub allowing for easy installation. The series comes in various standard sizes ranging from 20Nm to 1300Nm torque capacity. Key specifications are provided like dimensions, material properties, torque limits, spring rates and more. It can operate in temperatures from -40°C to 200°C.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Metal Bellows Coupling I Series KM

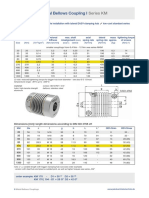

6-corrugation bellows simple installation with radial EASY-clamping hub low-cost standard series

technical data:

KM TN moment torsional max. shaft axial lateral mass tightening torque

of inertia stiffness misalignment (mm) spring rate spring rate approx. of screws

Size [Nm] [10-3kgm2] [Nm/arcmin] axial ± lateral [N/mm] [N/mm] [kg] [Nm] (*)

smaller couplings from 0,4 Nm - 12 Nm see series MKM

20 20 0,14 5,2 0,8 0,25 51 190 0,3 14

35 35 0,14 5,8 0,8 0,25 51 190 0,3 14

60 60 0,29 8,7 0,9 0,3 49 260 0,5 35 (30)*

80 80 0,79 14 1 0,3 45 280 0,8 65 (50)*

170 170 0,83 17 1 0,3 80 470 0,8 65 (50)*

270 270 2,2 32 1 0,3 70 450 1,4 115 (90)*

400 400 2,4 47 1 0,3 100 640 1,5 115 (90)*

600 600 5,3 67 1 0,3 100 980 2,4 180 (140)*

900 900 9 105 1 0,3 145 1000 3,3 180 (140)*

1300 1300 14 170 1 0,3 130 920 4,2 290 (240*)

(*) note: reduced tightening torque for bigger hub bore diameter - see also Ø D 1/2max!

material:

bellows: stainless steel

hubs: high-tensile strength

aluminum

screws: ISO 4762 / 12.9

temperature range: -40°C

up to +200°C

update version

Dimensions [mm]: length dimensions according to DIN ISO 2768 cH

KM Øa c f g h L L* ØD1/2min ØD1/2max

20 56 19 M6 30 8 70 81 8 32 -

35 56 19 M6 30 8 70 81 10 32 -

60 66 22 M8 33 9 77 87 13 28 (35)

80 82 28,5 M 10 38 11,5 90 102 16 32 (43)

170 82 28,5 M 10 40 11,5 92 104 18 32 (43)

270 101 35 M 12 42 13 100 106 25 42 (55)

400 101 35 M 12 48 13 106 112 28 42 (55)

600 122 42 M 14 52 16 120 - 32 55 (68)

900 133 47 M 14 53 18,5 143 - 40 65 (75)

1300 157 54 M 16 55 20 145 - 48 70 (85)

note: L* ≙ variable length with bigger clamping hub size (see order example)

. version with steel hub and plasma welded joint, as well as higher torques see series „KG“

order example: KM 170 - D1 = 30 G7 D2 = 35 H6

KM 170 | 104 - D1 = 28 G6 D2 = 42 G6

9 Metal Bellows Couplings www.jakobantriebstechnik.de

You might also like

- Torque Details-Hex Bolt DIN 933Document2 pagesTorque Details-Hex Bolt DIN 933coolkaisy100% (3)

- Datasheet KMDocument1 pageDatasheet KMAlexander DíazNo ratings yet

- Datasheet KMDocument1 pageDatasheet KMFrancisco SanchezNo ratings yet

- Datasheet KPPDocument1 pageDatasheet KPPRogelio LiceaNo ratings yet

- Installation Instructions Input/Output Chokes (FSD To FSF)Document2 pagesInstallation Instructions Input/Output Chokes (FSD To FSF)Uno MariconNo ratings yet

- Catalog Standard Motor LTS PDFDocument20 pagesCatalog Standard Motor LTS PDFYogesh BadheNo ratings yet

- Butterfly Valve DatasheetDocument2 pagesButterfly Valve DatasheetKanthan DevanNo ratings yet

- ISO 7089 (Washer)Document1 pageISO 7089 (Washer)anks_raNo ratings yet

- Serie 523 - ISO 15552Document69 pagesSerie 523 - ISO 15552NixiusNo ratings yet

- Hotrolled BeamDocument2 pagesHotrolled BeamWawaNo ratings yet

- Steel For BridgeDocument2 pagesSteel For BridgeDennis SsempebwaNo ratings yet

- SAMPAG ANCHOR CHANELS CatalogueNo.8 PDFDocument40 pagesSAMPAG ANCHOR CHANELS CatalogueNo.8 PDFKemo TufoNo ratings yet

- Abb Con Fusible GG Directo Coord 2 PesadoDocument1 pageAbb Con Fusible GG Directo Coord 2 PesadoIto SalvadorNo ratings yet

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocument2 pages2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNo ratings yet

- Hydraulic Cylinders CHDocument8 pagesHydraulic Cylinders CHStoianovici CristianNo ratings yet

- DIN Flange 2502-2503 PDFDocument2 pagesDIN Flange 2502-2503 PDFHeru Agus SetyawanNo ratings yet

- K91.31 Fig T302-M3 B302-S13 en FinalDocument1 pageK91.31 Fig T302-M3 B302-S13 en FinaladrianioantomaNo ratings yet

- Europian Standard ChannelsDocument1 pageEuropian Standard Channelsrimew42878No ratings yet

- Rotary Cylinder, Series TRR: Technical DataDocument5 pagesRotary Cylinder, Series TRR: Technical DataFernando GómezNo ratings yet

- Din Standard FlangesDocument5 pagesDin Standard FlangesMARKETING SIGMANo ratings yet

- Industrial Silos: Technical SheetDocument31 pagesIndustrial Silos: Technical Sheetred patriotNo ratings yet

- Viga IPEDocument2 pagesViga IPEHelmer MeloNo ratings yet

- Starco Elevator Buckets Made of Steel/stainless Steel (Parameters in MM)Document1 pageStarco Elevator Buckets Made of Steel/stainless Steel (Parameters in MM)Zerpa Rodriguez YancarlosNo ratings yet

- τεχνικά χαρακτηριστικά τριφασικών ασύγχρονων κινητήρων βραχυκυκλωμένου δρομέα (κέλυφος χυτοσιδήρου) (Κατάλογος Βαλιάδη)Document32 pagesτεχνικά χαρακτηριστικά τριφασικών ασύγχρονων κινητήρων βραχυκυκλωμένου δρομέα (κέλυφος χυτοσιδήρου) (Κατάλογος Βαλιάδη)jkgrNo ratings yet

- Flange Dim EN1092-1Document18 pagesFlange Dim EN1092-1Santi Puente CosmesNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- Three Phase Squirrel Cage Induction Motors: Maa Series 63 - 160 SIZESDocument6 pagesThree Phase Squirrel Cage Induction Motors: Maa Series 63 - 160 SIZESsugirinNo ratings yet

- Chain Din766 PDFDocument5 pagesChain Din766 PDFMiguelRagas100% (1)

- Technical Data For All PilgersDocument4 pagesTechnical Data For All PilgersTushar PachlangiaNo ratings yet

- BOM of TankDocument4 pagesBOM of TankArvind ShuklaNo ratings yet

- Pro 787426Document5 pagesPro 787426Mohamed ElmakkyNo ratings yet

- Ks Jis Standard Ks Jis Standard Flanges Slip On Jis 5kgcm2 Jis 10kgcm2Document15 pagesKs Jis Standard Ks Jis Standard Flanges Slip On Jis 5kgcm2 Jis 10kgcm2JeromeNo ratings yet

- Apostila Flange 02Document3 pagesApostila Flange 02Mauro BrajãoNo ratings yet

- 3.2 - 5 Ton Low Head RoomDocument1 page3.2 - 5 Ton Low Head Roomafshin dadvarNo ratings yet

- TurnbucklesDocument4 pagesTurnbucklesFunda TuranNo ratings yet

- Flange Dim EN1092 1 BS4504 PDFDocument18 pagesFlange Dim EN1092 1 BS4504 PDFSathykumar Murugesan100% (1)

- Metal Bellows Coupling Series KGEDocument1 pageMetal Bellows Coupling Series KGEDani GhNo ratings yet

- 1091 Bombas CentrifugasDocument17 pages1091 Bombas CentrifugasEugenio GomezNo ratings yet

- Flange-Dim-EN1092-1-BS4504_unlockedDocument7 pagesFlange-Dim-EN1092-1-BS4504_unlockedWagdy GomaaNo ratings yet

- World Tractor Products PDFDocument12 pagesWorld Tractor Products PDFAshraf MostafaNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- Standard Sectional Dimension of I-Steel and Its Sectional Area, Unit Weight and Sectional CharacteristicDocument2 pagesStandard Sectional Dimension of I-Steel and Its Sectional Area, Unit Weight and Sectional CharacteristicEndar SudarnoNo ratings yet

- RHS Pipe Clamps and Supports ENGDocument5 pagesRHS Pipe Clamps and Supports ENGramzi5ben5ahmedNo ratings yet

- Acoples FalkDocument3 pagesAcoples FalkluispereirapNo ratings yet

- Hebei Shengtian Pipe-Fitting Group Co., LTD - Dimensions, Sizg Flanges PDFDocument6 pagesHebei Shengtian Pipe-Fitting Group Co., LTD - Dimensions, Sizg Flanges PDFHamed FarajpourNo ratings yet

- Channels PFC PDFDocument1 pageChannels PFC PDFviswanathanNo ratings yet

- British Parallel Flange Channels PFCDocument1 pageBritish Parallel Flange Channels PFCdarinnavilNo ratings yet

- Z-Core: System: Pressure Range: Temperature: Chemical BarrierDocument16 pagesZ-Core: System: Pressure Range: Temperature: Chemical BarrierjeovanNo ratings yet

- En 13121-3 Bridas Pn10Document1 pageEn 13121-3 Bridas Pn10Ricardo BustamanteNo ratings yet

- TIEIG 2023 - Twin Washers & Disc SpringsDocument24 pagesTIEIG 2023 - Twin Washers & Disc SpringsHülya Kula ÇİÇEKÇİNo ratings yet

- BS EN 1092 PN16 Flange Dimensions - Roy MechDocument4 pagesBS EN 1092 PN16 Flange Dimensions - Roy MechpriyankaNo ratings yet

- Sisa TekanDocument6 pagesSisa Tekaneko bari wNo ratings yet

- E Starco Steel Elevator BucketDocument1 pageE Starco Steel Elevator BucketAhmed SadekNo ratings yet

- Tyre Coupling With Spacer UNEFLEX SD SeriesDocument3 pagesTyre Coupling With Spacer UNEFLEX SD SeriesGabriel MoreiraNo ratings yet

- BYG Master Catalog en LRS Classicwearparts 01Document169 pagesBYG Master Catalog en LRS Classicwearparts 01Niten GuptaNo ratings yet

- Type S Starco™: Pressed Seamless Steel / Stainless Steel / GalvanisedDocument1 pageType S Starco™: Pressed Seamless Steel / Stainless Steel / GalvanisedCristian Vicente Irigoyen AlvaradoNo ratings yet

- Process Datasheet For Relief ValveDocument3 pagesProcess Datasheet For Relief Valvemadhu8087No ratings yet

- Expansion: JointDocument40 pagesExpansion: JointVignesh NadimuthuNo ratings yet

- HPLA Linear Actuator - User Guide: Mounting, Start-Up, Maintenance, RepairDocument55 pagesHPLA Linear Actuator - User Guide: Mounting, Start-Up, Maintenance, RepairIsmael RiosNo ratings yet

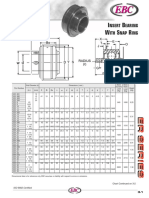

- I B W S R: Nsert Earing ITH NAP INGDocument2 pagesI B W S R: Nsert Earing ITH NAP INGIsmael RiosNo ratings yet

- Unidad Lineal ParkerDocument14 pagesUnidad Lineal ParkerIsmael RiosNo ratings yet

- Thrust Bearings: 53210 29430 E U210 M 81110 TN P5Document20 pagesThrust Bearings: 53210 29430 E U210 M 81110 TN P5Ismael RiosNo ratings yet

- Lexium 62 ILM - ILM1003P11F0000Document2 pagesLexium 62 ILM - ILM1003P11F0000Ismael RiosNo ratings yet

- Catalogo Reductor DinaboxDocument20 pagesCatalogo Reductor DinaboxIsmael RiosNo ratings yet

- Manual Tecnico de DriveDocument2 pagesManual Tecnico de DriveIsmael RiosNo ratings yet

- Standard Specification Piping Fabrication and Installation Spec - 00 - P - 02Document12 pagesStandard Specification Piping Fabrication and Installation Spec - 00 - P - 02tsaigoneseNo ratings yet

- CentaFlex - Assembly and Operating InstructionsDocument68 pagesCentaFlex - Assembly and Operating InstructionsbogdanostinNo ratings yet

- B-313 Series E-1510 Technical BrochureDocument8 pagesB-313 Series E-1510 Technical BrochureAnonymous 7xHNgoKE6eNo ratings yet

- Auma India GearboxesDocument40 pagesAuma India GearboxesGuillermo Damian100% (1)

- Tech Specs - 11 - EquipmentDocument62 pagesTech Specs - 11 - Equipmentjkhgvdj mnhsnjkhgNo ratings yet

- FLOWSERVE LNN Training CustomerDocument44 pagesFLOWSERVE LNN Training CustomerPatricia J Ángeles100% (1)

- 300+ TOP THEORY of MACHINES Questions and Answers PDFDocument32 pages300+ TOP THEORY of MACHINES Questions and Answers PDFkrishnaNo ratings yet

- Ductile Iron Pipes General Information PDFDocument15 pagesDuctile Iron Pipes General Information PDFfernandoNo ratings yet

- Uhing ManualDocument28 pagesUhing Manualganon188No ratings yet

- Goulds Vertical Turbine PumpDocument16 pagesGoulds Vertical Turbine PumpAnanto Veryadesa100% (2)

- 35 Project ReportDocument282 pages35 Project ReportGenji Ömer GerezNo ratings yet

- 019 HSC ManualDocument29 pages019 HSC ManualMarvin DuarteNo ratings yet

- Amerigear Gear Couplings: Standard and Modified DesignsDocument52 pagesAmerigear Gear Couplings: Standard and Modified DesignsJose Henrique GuimarãesNo ratings yet

- Manguito de FijaciónDocument39 pagesManguito de FijaciónIndustrial Estrumec Ltda.No ratings yet

- VSH Shurjoint Presentation 2018 PDFDocument66 pagesVSH Shurjoint Presentation 2018 PDFioan cristian cotorobaiNo ratings yet

- Goulds Vertical ReaderDocument20 pagesGoulds Vertical ReaderSonthi MooljindaNo ratings yet

- Design of Machine Elements Two MarksDocument23 pagesDesign of Machine Elements Two MarksManivannan JeevaNo ratings yet

- S-001-M-004 Mechanical Equipment InstallationDocument23 pagesS-001-M-004 Mechanical Equipment InstallationGeoffWilliams1956No ratings yet

- Design of Machine Elements 1 (Web) Faculty Coordinator(s) : 1Document4 pagesDesign of Machine Elements 1 (Web) Faculty Coordinator(s) : 1Umar MajeedNo ratings yet

- Flender FLUDEX CouplingsDocument38 pagesFlender FLUDEX CouplingspablodugalNo ratings yet

- Installation Instructions: For Teekay Pipe CouplingsDocument8 pagesInstallation Instructions: For Teekay Pipe Couplingssami maNo ratings yet

- Ravasiiberica Rotary Limit Switch BaseDocument16 pagesRavasiiberica Rotary Limit Switch BaseAhmad DagamsehNo ratings yet

- Cotter JointsDocument7 pagesCotter JointsVille4everNo ratings yet

- XYZ 200 ManualDocument95 pagesXYZ 200 ManualMShoibNo ratings yet

- BD 5003 PDFDocument59 pagesBD 5003 PDFsuhardiantoNo ratings yet

- SEW Eurodrive GearmotorsDocument23 pagesSEW Eurodrive GearmotorsRhiieeNo ratings yet

- Parts of A PumpDocument5 pagesParts of A Pumpanmn123100% (1)

- Bomba DemingDocument10 pagesBomba Deminghiltonparedes22No ratings yet

- Mech Cat PDFDocument169 pagesMech Cat PDFardi_a0uNo ratings yet

- Manual de OperaçãoDocument46 pagesManual de OperaçãoNeilton Batista GomesNo ratings yet