Professional Documents

Culture Documents

ROFIN SC SERIES. Basic. Strong. Precise PDF

ROFIN SC SERIES. Basic. Strong. Precise PDF

Uploaded by

Maria TzagarakiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ROFIN SC SERIES. Basic. Strong. Precise PDF

ROFIN SC SERIES. Basic. Strong. Precise PDF

Uploaded by

Maria TzagarakiCopyright:

Available Formats

LASER MACRO LASER MACRO

We are where you are!

ROFIN has sales and service teams in about 40 countries

around the world. From planning through implementation, to fast

and reliable service - our staff members are available in every

phase of your project.

To learn more about the various locations of ROFIN, visit us at

www.rofin.com/worldwide ROFIN SC SERIES

ROFIN-SINAR Laser GmbH · Data subject to change without notice · 03/2010

Basic. Strong. Precise.

ROFIN-SINAR Laser GmbH

Berzeliusstraße 87

22113 Hamburg

Germany

Tel.: +49- (0)- 40 - 7 33 63 - 0

Fax.: +49- (0)- 40 - 7 33 63 4100

ROFIN-SINAR, Inc.

40984 Concept Drive

Plymouth, MI 48170

USA

For industrial use – excellent and precise cutting qualities.

Tel.: +1-734-455-5400

Fax.: +1-734-455 2741

info@rofin.com

www.rofin.com

THE POWER OF LIGHT THE POWER OF LIGHT

ROFIN SC SERIES ROFIN SC SERIES ROFIN SC SERIES

LASER MACRO

THE PRODUCT THE PRINCIPLE THE BENEFIT

Precision and Power Revolutionary Compact, Reliable and Maintenance Friendly

The revolutionary Slab-principle of the SC Series, with output powers from 100 up to 600 watts, rounds down A CO2 laser without gas recirculation – how does this involving roots blowers or turbines are not required. The

the powerful spectrum of the CO2 laser range available from ROFIN. The SC lasers are completely sealed off so work in detail? The secret for this technology is in the two crucial advantage of this laser principle is that the laser Very low gas consumption due to its diffusion-cooled

there is no need for gas recirculation equipment such as vaccum pumps or pressure control systems. As gas water-cooled electrodes (slabs). High frequency between gas no longer needs to be circulated and it does not need design

exchange is unnecessary before 16,000 operational hours, the running, maintenance and service costs are these electrodes leads to stimulation of the laser gas. The to be renewed. This means that turbines and blowers,

minimal. The complete range of SC lasers use a single resonator design producing laser light with a linear optical resonator is formed by the front and rear mirrors which are susceptible to deterioration and service, are Light weight, for uncomplicated integration into

polarization. This linearly polarized beam enables protection against back reflection and makes the use in and the two electrodes. The heat generated in the gas is eliminated. Thus, optics integrated into the resonator, processing systems or for mounting on robot arms

cutting machines particularly easy. dissipated by the water-cooled electrodes (diffusion cool- which are contaminated by flowing laser gas (especially

Easy integration of the OEM version

ing). Thus, the conventional gas circulation systems the out-coupling windows), are a thing of the past. Less service requirements thanks to the robust and

Power and precision are defining characteristics of the SC Series and their application is widespread and maintenance friendly construction, no moving parts

include: processing of paper, glass, wood, thin sheet metal and plastics. The lasers are light weight and

extremly robust, making integration with mechanical handling equipment straight forward. Their light weight Highest reliability – ideal for industrial applications

makes these lasers ideal candidates for robotic applications.

High quality application processing as a result of the

system’s high beam quality (K > 0.8) – this results in

Cooling water precise cuts, the highest possible processing speeds

RF excitation

and an increased productivity

Rear mirror

Cooling water

No external gas installation Small and compact: ROFIN SC x10 and SC x20

RF-excited discharge

ROFIN SC x60 Minimal running costs

Output mirror

Waveguiding electrodes

Very low energy consumption in the power saving

Beam shaping unit standby mode

Laser beam

High flexible cutting of polymers

THE POWER OF LIGHT

ROFIN SC SERIES ROFIN SC SERIES ROFIN SC SERIES

LASER MACRO

THE PRODUCT THE PRINCIPLE THE BENEFIT

Precision and Power Revolutionary Compact, Reliable and Maintenance Friendly

The revolutionary Slab-principle of the SC Series, with output powers from 100 up to 600 watts, rounds down A CO2 laser without gas recirculation – how does this involving roots blowers or turbines are not required. The

the powerful spectrum of the CO2 laser range available from ROFIN. The SC lasers are completely sealed off so work in detail? The secret for this technology is in the two crucial advantage of this laser principle is that the laser Very low gas consumption due to its diffusion-cooled

there is no need for gas recirculation equipment such as vaccum pumps or pressure control systems. As gas water-cooled electrodes (slabs). High frequency between gas no longer needs to be circulated and it does not need design

exchange is unnecessary before 16,000 operational hours, the running, maintenance and service costs are these electrodes leads to stimulation of the laser gas. The to be renewed. This means that turbines and blowers,

minimal. The complete range of SC lasers use a single resonator design producing laser light with a linear optical resonator is formed by the front and rear mirrors which are susceptible to deterioration and service, are Light weight, for uncomplicated integration into

polarization. This linearly polarized beam enables protection against back reflection and makes the use in and the two electrodes. The heat generated in the gas is eliminated. Thus, optics integrated into the resonator, processing systems or for mounting on robot arms

cutting machines particularly easy. dissipated by the water-cooled electrodes (diffusion cool- which are contaminated by flowing laser gas (especially

Easy integration of the OEM version

ing). Thus, the conventional gas circulation systems the out-coupling windows), are a thing of the past. Less service requirements thanks to the robust and

Power and precision are defining characteristics of the SC Series and their application is widespread and maintenance friendly construction, no moving parts

include: processing of paper, glass, wood, thin sheet metal and plastics. The lasers are light weight and

extremly robust, making integration with mechanical handling equipment straight forward. Their light weight Highest reliability – ideal for industrial applications

makes these lasers ideal candidates for robotic applications.

High quality application processing as a result of the

system’s high beam quality (K > 0.8) – this results in

Cooling water precise cuts, the highest possible processing speeds

RF excitation

and an increased productivity

Rear mirror

Cooling water

No external gas installation Small and compact: ROFIN SC x10 and SC x20

RF-excited discharge

ROFIN SC x60 Minimal running costs

Output mirror

Waveguiding electrodes

Very low energy consumption in the power saving

Beam shaping unit standby mode

Laser beam

High flexible cutting of polymers

THE POWER OF LIGHT

ROFIN SC SERIES ROFIN SC SERIES ROFIN SC SERIES

LASER MACRO

THE PRODUCT THE PRINCIPLE THE BENEFIT

Precision and Power Revolutionary Compact, Reliable and Maintenance Friendly

The revolutionary Slab-principle of the SC Series, with output powers from 100 up to 600 watts, rounds down A CO2 laser without gas recirculation – how does this involving roots blowers or turbines are not required. The

the powerful spectrum of the CO2 laser range available from ROFIN. The SC lasers are completely sealed off so work in detail? The secret for this technology is in the two crucial advantage of this laser principle is that the laser Very low gas consumption due to its diffusion-cooled

there is no need for gas recirculation equipment such as vaccum pumps or pressure control systems. As gas water-cooled electrodes (slabs). High frequency between gas no longer needs to be circulated and it does not need design

exchange is unnecessary before 16,000 operational hours, the running, maintenance and service costs are these electrodes leads to stimulation of the laser gas. The to be renewed. This means that turbines and blowers,

minimal. The complete range of SC lasers use a single resonator design producing laser light with a linear optical resonator is formed by the front and rear mirrors which are susceptible to deterioration and service, are Light weight, for uncomplicated integration into

polarization. This linearly polarized beam enables protection against back reflection and makes the use in and the two electrodes. The heat generated in the gas is eliminated. Thus, optics integrated into the resonator, processing systems or for mounting on robot arms

cutting machines particularly easy. dissipated by the water-cooled electrodes (diffusion cool- which are contaminated by flowing laser gas (especially

Easy integration of the OEM version

ing). Thus, the conventional gas circulation systems the out-coupling windows), are a thing of the past. Less service requirements thanks to the robust and

Power and precision are defining characteristics of the SC Series and their application is widespread and maintenance friendly construction, no moving parts

include: processing of paper, glass, wood, thin sheet metal and plastics. The lasers are light weight and

extremly robust, making integration with mechanical handling equipment straight forward. Their light weight Highest reliability – ideal for industrial applications

makes these lasers ideal candidates for robotic applications.

High quality application processing as a result of the

system’s high beam quality (K > 0.8) – this results in

Cooling water precise cuts, the highest possible processing speeds

RF excitation

and an increased productivity

Rear mirror

Cooling water

No external gas installation Small and compact: ROFIN SC x10 and SC x20

RF-excited discharge

ROFIN SC x60 Minimal running costs

Output mirror

Waveguiding electrodes

Very low energy consumption in the power saving

Beam shaping unit standby mode

Laser beam

High flexible cutting of polymers

THE POWER OF LIGHT

LASER MACRO LASER MACRO

We are where you are!

ROFIN has sales and service teams in about 40 countries

around the world. From planning through implementation, to fast

and reliable service - our staff members are available in every

phase of your project.

To learn more about the various locations of ROFIN, visit us at

www.rofin.com/worldwide ROFIN SC SERIES

ROFIN-SINAR Laser GmbH · Data subject to change without notice · 03/2010

Basic. Strong. Precise.

ROFIN-SINAR Laser GmbH

Berzeliusstraße 87

22113 Hamburg

Germany

Tel.: +49- (0)- 40 - 7 33 63 - 0

Fax.: +49- (0)- 40 - 7 33 63 4100

ROFIN-SINAR, Inc.

40984 Concept Drive

Plymouth, MI 48170

USA

For industrial use – excellent and precise cutting qualities.

Tel.: +1-734-455-5400

Fax.: +1-734-455 2741

info@rofin.com

www.rofin.com

THE POWER OF LIGHT THE POWER OF LIGHT

LASER MACRO LASER MACRO

We are where you are!

ROFIN has sales and service teams in about 40 countries

around the world. From planning through implementation, to fast

and reliable service - our staff members are available in every

phase of your project.

To learn more about the various locations of ROFIN, visit us at

www.rofin.com/worldwide ROFIN SC SERIES

ROFIN-SINAR Laser GmbH · Data subject to change without notice · 03/2010

Basic. Strong. Precise.

ROFIN-SINAR Laser GmbH

Berzeliusstraße 87

22113 Hamburg

Germany

Tel.: +49- (0)- 40 - 7 33 63 - 0

Fax.: +49- (0)- 40 - 7 33 63 4100

ROFIN-SINAR, Inc.

40984 Concept Drive

Plymouth, MI 48170

USA

For industrial use – excellent and precise cutting qualities.

Tel.: +1-734-455-5400

Fax.: +1-734-455 2741

info@rofin.com

www.rofin.com

THE POWER OF LIGHT THE POWER OF LIGHT

You might also like

- SDR for Beginners Using the SDRplay and SDRuno: Amateur Radio for Beginners, #4From EverandSDR for Beginners Using the SDRplay and SDRuno: Amateur Radio for Beginners, #4No ratings yet

- Ophthalmic LensesDocument224 pagesOphthalmic LensesPaul Rivera100% (2)

- Principles of IlluminationDocument39 pagesPrinciples of IlluminationMark Lorenz Diolata100% (5)

- SC Eng 03-2010 A4 PDFDocument6 pagesSC Eng 03-2010 A4 PDFMaria TzagarakiNo ratings yet

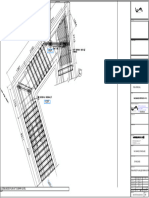

- Column Layout @landing Level of Staircase: S PRO ARDocument1 pageColumn Layout @landing Level of Staircase: S PRO ARMd Mukarram RezaNo ratings yet

- Marsurf: Mobile Surface Roughness Measuring InstrumentsDocument40 pagesMarsurf: Mobile Surface Roughness Measuring InstrumentsDoti Tri PrasetioNo ratings yet

- View-A 02: S PRO ARDocument1 pageView-A 02: S PRO ARMd Mukarram RezaNo ratings yet

- Vibrafoam Product OverviewDocument1 pageVibrafoam Product Overviewhouba gammalNo ratings yet

- October 2017Document88 pagesOctober 2017Treatment Plant Operator MagazineNo ratings yet

- Common Mikrotik Ospf Mistakes: and How To Avoid ThemDocument95 pagesCommon Mikrotik Ospf Mistakes: and How To Avoid ThemfabeltranmNo ratings yet

- Pak CV Ri b11Document2 pagesPak CV Ri b11rizikijanhNo ratings yet

- For Additional Details and Information. Please See Consult With Diebold Installation/Service BranchDocument4 pagesFor Additional Details and Information. Please See Consult With Diebold Installation/Service BranchDNSXNo ratings yet

- Remote Car Key and Smart Remote Programmer BrochureDocument6 pagesRemote Car Key and Smart Remote Programmer Brochurejunior jrNo ratings yet

- S PRO AR: For ApprovalDocument1 pageS PRO AR: For ApprovalMd Mukarram RezaNo ratings yet

- Enlarged Plan at 5180Mm Level 01: S PRO ARDocument1 pageEnlarged Plan at 5180Mm Level 01: S PRO ARMd Mukarram RezaNo ratings yet

- 2-Channel Amplifiers Operation & Installation: FanaticsDocument48 pages2-Channel Amplifiers Operation & Installation: FanaticsNémeth ÁdámNo ratings yet

- Atac Blowing Film Machines Catalogue 2022Document22 pagesAtac Blowing Film Machines Catalogue 2022Leonardo LiraNo ratings yet

- Service Schematics: Exploded View and Component DisposalDocument11 pagesService Schematics: Exploded View and Component Disposalosmar rafael monsalve valenciaNo ratings yet

- Powerline e Air 10Document78 pagesPowerline e Air 10Miguel DíazNo ratings yet

- FllsjebDocument1 pageFllsjebRamces AsisiNo ratings yet

- The Easy To Use, Affordable and High Quality Desktop Scanner For Whole Slide ImagingDocument3 pagesThe Easy To Use, Affordable and High Quality Desktop Scanner For Whole Slide Imagingابو حميد ابو حميدNo ratings yet

- The FPSO Contractors GuidebookDocument20 pagesThe FPSO Contractors Guidebookaarivalagan100% (2)

- Care & Maintenance of Printer Shuttles - TheMRPsolutionDocument6 pagesCare & Maintenance of Printer Shuttles - TheMRPsolutionTarra Ramakrishna RaoNo ratings yet

- CoatingsDocument5 pagesCoatingsLAKIS PAVNo ratings yet

- February 2018Document64 pagesFebruary 2018Treatment Plant Operator MagazineNo ratings yet

- Kawasaki K-ROSET BrochureDocument4 pagesKawasaki K-ROSET BrochureDanilo BritoNo ratings yet

- MOD-09-983 Radio Manager Release Notes For R1.5.2 - Issue 1Document26 pagesMOD-09-983 Radio Manager Release Notes For R1.5.2 - Issue 11012268087No ratings yet

- Microcontroller Microcontroller: Fujitsu Semiconductor Limited Fujitsu Semiconductor LimitedDocument29 pagesMicrocontroller Microcontroller: Fujitsu Semiconductor Limited Fujitsu Semiconductor LimitedJosé Moisés Rafael OstenNo ratings yet

- Meopta Tactical Optics 2014 en PDFDocument38 pagesMeopta Tactical Optics 2014 en PDFBrad HepperNo ratings yet

- Nordson EFD 797PCP Operating ManualDocument30 pagesNordson EFD 797PCP Operating ManualAlberto ValverdeNo ratings yet

- VapR XR Dissolvable Frac Plug Operations ManualDocument12 pagesVapR XR Dissolvable Frac Plug Operations ManualGermanPersicoNo ratings yet

- D6P00301G0Document4 pagesD6P00301G0Hieu NguyenNo ratings yet

- Letter To HomelinkDocument1 pageLetter To HomelinkClayton MutsenekiNo ratings yet

- MPX Magnetostrictive Level Sensors User Manual: For The MPX-FDocument40 pagesMPX Magnetostrictive Level Sensors User Manual: For The MPX-FFaisalNo ratings yet

- Length: Foundation Plan Roof Framing Plan Column Footing DetailDocument1 pageLength: Foundation Plan Roof Framing Plan Column Footing DetailZyrose Jardiolin GuevarraNo ratings yet

- Makro Black Friday 2018 DealsDocument20 pagesMakro Black Friday 2018 DealsBusinessTech90% (20)

- Inbound 6527519127766154016Document15 pagesInbound 6527519127766154016Axel Dave OrcuseNo ratings yet

- Consumers - Oep - 11th Floor Redo - Install Docs 11x17 - 08-01-18Document16 pagesConsumers - Oep - 11th Floor Redo - Install Docs 11x17 - 08-01-18api-277033985No ratings yet

- Section B-B View A-A: Dimensional Detail Section of Retaining WallDocument1 pageSection B-B View A-A: Dimensional Detail Section of Retaining WallShivam SharmaNo ratings yet

- Flyer Robot MPX3500 E 11.2015Document4 pagesFlyer Robot MPX3500 E 11.2015eeNo ratings yet

- (IAC) Vorzrwy13: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 08'WDocument1 page(IAC) Vorzrwy13: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 08'WFábio KastelamaryNo ratings yet

- Palfinger Corporate BroucherDocument10 pagesPalfinger Corporate BrouchersmilewithbalajithNo ratings yet

- A-A-17323 MF Activa 7340-7344 Brochure Eng V7 UBDocument11 pagesA-A-17323 MF Activa 7340-7344 Brochure Eng V7 UBRana Awais AhmadNo ratings yet

- Enlarged Plan at 7400Mm Level Where Staircase Connecting Existing Slab 01Document1 pageEnlarged Plan at 7400Mm Level Where Staircase Connecting Existing Slab 01Md Mukarram RezaNo ratings yet

- Cover Static Port - FinalDocument1 pageCover Static Port - FinalMohammad NorouzzadehNo ratings yet

- TBP Report 2024 WEC R01 QatarDocument6 pagesTBP Report 2024 WEC R01 QatarYuji IdeNo ratings yet

- Grafix Powder Extraction P-Abs 4101 83894Document1 pageGrafix Powder Extraction P-Abs 4101 83894assistante embNo ratings yet

- December 2017Document80 pagesDecember 2017Treatment Plant Operator MagazineNo ratings yet

- Katara Hospitality: Q17017-0100D-SK-T5-400Document1 pageKatara Hospitality: Q17017-0100D-SK-T5-400mohannad.aldahakNo ratings yet

- Sig Sauer LR-2021 Le Catlog Final 5-5-2021Document42 pagesSig Sauer LR-2021 Le Catlog Final 5-5-2021Damion CampbellNo ratings yet

- Classwise Timetable SE 2024Document8 pagesClasswise Timetable SE 2024O and A Level TutorNo ratings yet

- Peta Geologi RegionalDocument1 pagePeta Geologi Regionaldifa sri batenamNo ratings yet

- 04 PotonganDocument1 page04 PotonganIvan AsdianaNo ratings yet

- Sahajanand Laser Technology Ltd. Industry Laser Corporate BrochureDocument2 pagesSahajanand Laser Technology Ltd. Industry Laser Corporate BrochureSLTL GroupNo ratings yet

- 062410Document56 pages062410swapsheetNo ratings yet

- Brother MFC L27rangeDocument10 pagesBrother MFC L27rangemsmith61No ratings yet

- Téchne - Edição 110 (14-05-2006)Document2 pagesTéchne - Edição 110 (14-05-2006)RafaelNo ratings yet

- Time Table 2023-24 ODD SEMDocument1 pageTime Table 2023-24 ODD SEMAnkita Lp Shady IglesiasNo ratings yet

- Marantz SR110Document32 pagesMarantz SR110Rolando perezNo ratings yet

- MT 7610 OnePageDocument2 pagesMT 7610 OnePagesaikyawhtikeNo ratings yet

- Material For Session #14 Ing Ii-2021bDocument5 pagesMaterial For Session #14 Ing Ii-2021bEdinson SNNo ratings yet

- Informacion Sobre El CO2 PDFDocument56 pagesInformacion Sobre El CO2 PDFMaria TzagarakiNo ratings yet

- PS REIS ROBOTICS-1-Robot&system High PDFDocument14 pagesPS REIS ROBOTICS-1-Robot&system High PDFMaria TzagarakiNo ratings yet

- Max1487 Max491Document17 pagesMax1487 Max491Ricardo UrioNo ratings yet

- SC Eng 03-2010 A4 PDFDocument6 pagesSC Eng 03-2010 A4 PDFMaria TzagarakiNo ratings yet

- Product Focus: Visit Us in Hall A2 - Booth 405Document32 pagesProduct Focus: Visit Us in Hall A2 - Booth 405Maria TzagarakiNo ratings yet

- AMKASYN Ac Servo and Main Servo Motors PDFDocument23 pagesAMKASYN Ac Servo and Main Servo Motors PDFMaria Tzagaraki0% (1)

- Tcom - 600 Low Loss Low Passive Intermod Coax: TimesDocument4 pagesTcom - 600 Low Loss Low Passive Intermod Coax: TimesMaria TzagarakiNo ratings yet

- Sony VPL-FW41L PDFDocument61 pagesSony VPL-FW41L PDFMaria TzagarakiNo ratings yet

- SWS-L Series: Compact and High-Power AC/DC Power SupplyDocument20 pagesSWS-L Series: Compact and High-Power AC/DC Power SupplyMaria TzagarakiNo ratings yet

- Schneider Electric Altivar DTM Library V12.8.0 - Release NotesDocument3 pagesSchneider Electric Altivar DTM Library V12.8.0 - Release NotesMaria TzagarakiNo ratings yet

- MRF2800 PDFDocument12 pagesMRF2800 PDFMaria TzagarakiNo ratings yet

- MRF2800 PDFDocument12 pagesMRF2800 PDFMaria TzagarakiNo ratings yet

- MAX803/MAX809/ MAX810 3-Pin Microprocessor Reset Circuits: General Description Benefits and FeaturesDocument8 pagesMAX803/MAX809/ MAX810 3-Pin Microprocessor Reset Circuits: General Description Benefits and FeaturesMaria TzagarakiNo ratings yet

- Technical Information: Recommendations For EMC-compliant Wiring of Servo Drivers and MotorsDocument10 pagesTechnical Information: Recommendations For EMC-compliant Wiring of Servo Drivers and MotorsMaria TzagarakiNo ratings yet

- HCPL 061aDocument19 pagesHCPL 061aMaria TzagarakiNo ratings yet

- Sot89 NPN Silicon Planar Medium Power Transistors BCX54 BCX55 BCX56Document1 pageSot89 NPN Silicon Planar Medium Power Transistors BCX54 BCX55 BCX56Maria TzagarakiNo ratings yet

- Sximatiko RotatedDocument1 pageSximatiko RotatedMaria TzagarakiNo ratings yet

- Parameters ListDocument11 pagesParameters ListMaria TzagarakiNo ratings yet

- DiffDocument1 pageDiffMaria TzagarakiNo ratings yet

- YASKAWA AC Drive V1000: Quick Start GuideDocument46 pagesYASKAWA AC Drive V1000: Quick Start GuideMaria TzagarakiNo ratings yet

- Product Functional Specification 17 Inch WXGA+ Color TFT LCD Module Model Name: B170PW01 V.0Document26 pagesProduct Functional Specification 17 Inch WXGA+ Color TFT LCD Module Model Name: B170PW01 V.0Maria TzagarakiNo ratings yet

- Specification FOR Approval: 15.4" Wxga TFT LCD TitleDocument31 pagesSpecification FOR Approval: 15.4" Wxga TFT LCD TitleMaria TzagarakiNo ratings yet

- Appnote 15Document6 pagesAppnote 15meteohrNo ratings yet

- What Is Lithography?: Li Thog Ra PhyDocument2 pagesWhat Is Lithography?: Li Thog Ra PhystansilawNo ratings yet

- E-Chrom Tech Co., LTD.: B01-CT-8 Series Double Beam UV/Vis SpectrophotometerDocument13 pagesE-Chrom Tech Co., LTD.: B01-CT-8 Series Double Beam UV/Vis SpectrophotometerdernivaljrNo ratings yet

- 5OM Ni DMG PDFDocument6 pages5OM Ni DMG PDFPrabhu Prasad NayakNo ratings yet

- BSC Physics Curriculum and Syllabus CbcsDocument98 pagesBSC Physics Curriculum and Syllabus CbcsRajalearn1 Ramlearn1No ratings yet

- Give Reason WhyDocument3 pagesGive Reason WhySiddharth KothariNo ratings yet

- Science10 Q2 Mod3 QualitativeCharacteristicsOfImages V4Document27 pagesScience10 Q2 Mod3 QualitativeCharacteristicsOfImages V4Stephanie DajaoNo ratings yet

- Optical Fiber CommunicationDocument18 pagesOptical Fiber CommunicationSaurav sharmaNo ratings yet

- Solucion Deteccion Temperatura AXXTEC - PreciosDocument1 pageSolucion Deteccion Temperatura AXXTEC - PreciosLuis Maldonado GuzmanNo ratings yet

- Lighting SystemDocument10 pagesLighting SystempycondaNo ratings yet

- Checklist For Science Students by Bharat PanchalDocument5 pagesChecklist For Science Students by Bharat PanchalArush GautamNo ratings yet

- P-24-09 13th Paper-2Document6 pagesP-24-09 13th Paper-2Raju SinghNo ratings yet

- Tokina Lens Catalog PDFDocument32 pagesTokina Lens Catalog PDFGeorge VassilogluNo ratings yet

- 3D Metrology: Forth Dimension DisplaysDocument4 pages3D Metrology: Forth Dimension DisplaysNathan DrakeNo ratings yet

- Labman 2018-19Document44 pagesLabman 2018-19Puhazh SelvanNo ratings yet

- I. Thin LensesDocument9 pagesI. Thin LensesVijayRagguNo ratings yet

- Csec Lenses 22Document3 pagesCsec Lenses 22ashNo ratings yet

- Instruction Manual Olympus Polarizing MicroscopeDocument14 pagesInstruction Manual Olympus Polarizing MicroscopebambangNo ratings yet

- Comptonization: Photon eDocument25 pagesComptonization: Photon eDavidNo ratings yet

- Update 5-11-19 - Pricelist TRL APP NoveMBER 2019Document20 pagesUpdate 5-11-19 - Pricelist TRL APP NoveMBER 2019Slamet RinaldiNo ratings yet

- Brochure Breuckmann SmartSCAN enDocument4 pagesBrochure Breuckmann SmartSCAN enumutdogan100% (1)

- Total StationDocument22 pagesTotal Stationsagar_srNo ratings yet

- 07A1BS03 - Engineering PhysicsDocument10 pages07A1BS03 - Engineering PhysicsNizam Institute of Engineering and Technology LibraryNo ratings yet

- C. UUVis - TermsDocument11 pagesC. UUVis - Termsharsheen kaurNo ratings yet

- Arihant IndexDocument3 pagesArihant IndexShreya LakhangireNo ratings yet

- Kuliah NMRDocument92 pagesKuliah NMRDedi saputraNo ratings yet

- Lasers in Electronic WarfareDocument3 pagesLasers in Electronic Warfarebring it onNo ratings yet

- STORYLINE For E-COMICS Science 8-LightDocument3 pagesSTORYLINE For E-COMICS Science 8-LightAlexis IgnacioNo ratings yet