Professional Documents

Culture Documents

Electrode Guide

Electrode Guide

Uploaded by

jayasimhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrode Guide

Electrode Guide

Uploaded by

jayasimhaCopyright:

Available Formats

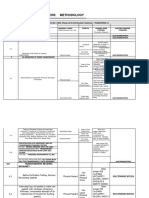

Sr Problem Probable Cause Confirmation-1 Confirmation-2 Confirmation-3 Confirmation-4 Action -1 Action -2 Action -3

Breakage occurred during See Run Time Graph. Sudden See Run Time Graph. Sudden Regulation Check for Overcurrent

Heavy Scrap Collapse Initial few minutes Of Rise in Currents just before Drop in Voltage just before Setting and Column Speed during

Melting Breakage Breakage Arcing

Run Time Graph of Currents

Breakage occurred during Run Time Graph of Hyd Operation Practice ,

1 Electrode Socket Breakages Non Conducting Charge for sudden reduction & Electrode Saver Alarm

Initial few minutes Of Pressure for sudden Fall just Check Electrode Saver Setting Change in Arcing

/ Skull Voltage for sudden Rise just before Brk

Melting before Breakage Pattern

before Breakage

Comparitively Higher No. of Breaks with LOW AD (<1.67)

Electrode Quality Lot Specific / Plant Specific

Breakages Stocks

Reduce the Joining Torque by 15 -

Transition Joint Centre Shear

20% during Transition

Gap in Joint confirmed by

Stop Water Cooling

Within initial 2 -3 Heats after Molten Pitch , Water Oxidation Gap in Middle / Lower Joint of

Machining Tolerances Prefit Nipple loosening for 2 Hours after New

2 Nipple Breakage Addition , Arcing on Faces of Broken Broken Column

Addition

Electrodes

Grind Broken Nip

Within initial 2 -3 Heats after Broken Nipple Sample to be sent

Nipple Quality Even in Flat Bath Lot Specific / Plant Specific Sample to see

Addition to Nsk for Testing

Lamination / Coring

If Inter-Plant

Within initial 2 -3 Heats after Reduce the Joining Torque by 15 -

Transition Joint Transition, consult

Addition 20% during Transition

Plant

In Flat Bath Dip E-1, Current in

Clock-wise Phase Gap in Middle / Lower Joint of Cos-F between Request Customer for Changing

3 Slippage Without Nipple Clockwise Flat Bath Rotation E1 & E-3 should rise, E2 should

Rotation Slipped Column 0.7 to 0.85 the Phase Sequence

remain constant

Stop Water Cooling

Within initial 2 -3 Heats after Gap in Middle / Lower Joint of

Machining Tolerances Last 3 -4 Threads intact Prefit Nipple loosening for 2 Hours after New

Addition Slipped Column

Addition

Gap in Middle / Lower Joint Nipple Lossening during End

4 Slippage With Nipple Nipple Prefittig Lot Specific / Plant Specific Prefit Niple Tightening

of Slipped Column Cap Removal

Gap in Joint confirmed by

Machining Tolerances + Match Mark Reverse Error Column Severe

Some times Nipple Breakages & Molten Pitch , Water Gap in Middle / Lower Joint of Regulation Testing , Electrode

5 Column Vibrations during usage after 10 - 12 Vibrations during Initial

Some times Slippages Oxidation , Arcing on Faces Slipped Column Arcing Speed will be much Higher

(E+M) Heats Period of Arcing

of Broken Electrodes

Long & Deep Cracks upto Cracks more with Low AD Change in Melt Profile to use

Short Arc Operation Increrase in DRI %

Joint Stocks Higher Voltage Tap

6 Tip Cracks

Cracks below and Above Reduce the Joining Torque by 15 Increase in Water

Higher Electrode CTE(L) UHP-LF / HP-Dp Stocks

Lower Joint % Cooling Qty.

You might also like

- Lab Photoelectric Effect PhET Simulation KeyDocument5 pagesLab Photoelectric Effect PhET Simulation KeyAnil KrishnanNo ratings yet

- Grade 7 Entrance ExamDocument5 pagesGrade 7 Entrance Examlyniel john solitario100% (1)

- Colorfastness To Perspiration: AATCC Test Method 15-2009Document3 pagesColorfastness To Perspiration: AATCC Test Method 15-2009Milagros Wieczorek100% (1)

- Rotor Earth Fault ProtectionDocument17 pagesRotor Earth Fault ProtectionchambaywaliNo ratings yet

- Lube Oil Flushing Procedure - Rev 0Document22 pagesLube Oil Flushing Procedure - Rev 0Yusuf67% (3)

- Information On Status of Nuclear Power Plants in Fukushima: Japan Atomic Industrial Forum, IncDocument6 pagesInformation On Status of Nuclear Power Plants in Fukushima: Japan Atomic Industrial Forum, IncJason ChanNo ratings yet

- Information On Status of Nuclear Power Plants in Fukushima: Japan Atomic Industrial Forum, IncDocument6 pagesInformation On Status of Nuclear Power Plants in Fukushima: Japan Atomic Industrial Forum, IncDiego RiveraNo ratings yet

- Information On Status of Nuclear Power Plants in Fukushima: Japan Atomic Industrial Forum, IncDocument6 pagesInformation On Status of Nuclear Power Plants in Fukushima: Japan Atomic Industrial Forum, IncJason ChanNo ratings yet

- Information On Status of Nuclear Power Plants in Fukushima: Japan Atomic Industrial Forum, IncDocument6 pagesInformation On Status of Nuclear Power Plants in Fukushima: Japan Atomic Industrial Forum, IncKwanghoon SeokNo ratings yet

- API 571 20chart Uday XLSXMMMMDocument8 pagesAPI 571 20chart Uday XLSXMMMMMahmoud HagagNo ratings yet

- Vax Consultants Pvt. LTD.Document4 pagesVax Consultants Pvt. LTD.mohana tNo ratings yet

- Sr. No. Item Effects Causes Functions / Requirements Failure ModeDocument6 pagesSr. No. Item Effects Causes Functions / Requirements Failure ModeAtul DahiyaNo ratings yet

- Problem Cases - English PPDocument20 pagesProblem Cases - English PPsaeedNo ratings yet

- FR 4Document1 pageFR 401fe19bme028No ratings yet

- C-KOD PSS Summary report-132KV-MP-2020-21Document3 pagesC-KOD PSS Summary report-132KV-MP-2020-21ddhruvalpNo ratings yet

- AmeronDocument4 pagesAmerontahatekriNo ratings yet

- MBR1535CT, MBR1545CT Switchmode Power Rectifier: Schottky Barrier Rectifiers 15 Amperes 35 and 45 VOLTSDocument3 pagesMBR1535CT, MBR1545CT Switchmode Power Rectifier: Schottky Barrier Rectifiers 15 Amperes 35 and 45 VOLTSNallbellausNo ratings yet

- Risk Assessment - GROUNDINGDocument5 pagesRisk Assessment - GROUNDINGkarla.adamesNo ratings yet

- Cable Sizing Design CriteriaDocument1 pageCable Sizing Design Criteriamuhammad ridwanNo ratings yet

- Maintenancetools 04Document14 pagesMaintenancetools 04siyankallar100% (1)

- B1545Document4 pagesB1545Jef NxtorNo ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- Metal Enclosed MV Capacitor BankDocument5 pagesMetal Enclosed MV Capacitor BankZAHEER ABBASNo ratings yet

- mbrp20035l TestDocument2 pagesmbrp20035l TestfrufruNo ratings yet

- Abu QairDocument12 pagesAbu QairMohamedRezkNo ratings yet

- Datasheet 2Document4 pagesDatasheet 2gigabytestore2015No ratings yet

- Instrument Transformer Testing Brochure ENUDocument36 pagesInstrument Transformer Testing Brochure ENUJayakumar JNo ratings yet

- Instrument Transformer TestingDocument36 pagesInstrument Transformer TestingChowdhury, A Hasib100% (2)

- Baker DX Series Static Motor AnalyzersDocument8 pagesBaker DX Series Static Motor AnalyzersjuanmalegreNo ratings yet

- Z Z Z Z: General RemarksDocument11 pagesZ Z Z Z: General Remarksadi nu100% (1)

- Lubrication and Oil Analysis 1698237450Document114 pagesLubrication and Oil Analysis 1698237450mariustresor997No ratings yet

- 道康宁Dow DOWSIL™ SE 4430白色 导热硅脂 导热胶-附TDS下载Document3 pages道康宁Dow DOWSIL™ SE 4430白色 导热硅脂 导热胶-附TDS下载walter karl Nuñez AngoNo ratings yet

- Chapter 8: Mechanical Failure Ductile Versus Brittle FractureDocument6 pagesChapter 8: Mechanical Failure Ductile Versus Brittle Fracturezerimar33No ratings yet

- Lighting HandbookDocument16 pagesLighting HandbookpthanhcanhNo ratings yet

- 5 Induction Motor ProtectionDocument10 pages5 Induction Motor Protectionknowledge engineeringNo ratings yet

- C.P.O Box 2810 Seoul, Korea (H.Q) Automotive & Component DivisionDocument4 pagesC.P.O Box 2810 Seoul, Korea (H.Q) Automotive & Component DivisionAcero MariaNo ratings yet

- WoundRotorTips 1112Document3 pagesWoundRotorTips 1112andres monederoNo ratings yet

- Maintain Water Quality and Throughput: Cooling Tower Health MonitoringDocument4 pagesMaintain Water Quality and Throughput: Cooling Tower Health Monitoringbudi budihardjoNo ratings yet

- 7.UT (Sewage, Voltex Impeller)Document2 pages7.UT (Sewage, Voltex Impeller)sandy yudhaNo ratings yet

- 4.2 - RB FGC Sootblower Data SheetDocument1 page4.2 - RB FGC Sootblower Data SheetAuilias DiasNo ratings yet

- Trouble Shooting: Quality Is Our MessageDocument9 pagesTrouble Shooting: Quality Is Our MessageMaya MenanNo ratings yet

- Solar System CalculationDocument1 pageSolar System CalculationVinod Gupta100% (2)

- Rotating Machines Testing and Monitoring Brochure ENU PDFDocument28 pagesRotating Machines Testing and Monitoring Brochure ENU PDFC.S.VENKATESWARANNo ratings yet

- Shear Strength by Direct Shear (Small Shear Box) : Client Lab Ref Project Job Borehole Sample Test DetailsDocument10 pagesShear Strength by Direct Shear (Small Shear Box) : Client Lab Ref Project Job Borehole Sample Test DetailsEvonYongNo ratings yet

- Shear Strength by Direct Shear (Small Shear Box) : Client Lab Ref Project Job Borehole Sample Test DetailsDocument10 pagesShear Strength by Direct Shear (Small Shear Box) : Client Lab Ref Project Job Borehole Sample Test DetailsEvonYongNo ratings yet

- Thermal Fatigue Case StudiesDocument22 pagesThermal Fatigue Case StudiesTrương Ngọc SơnNo ratings yet

- Reactor Status and Major Events Update 17 - NPPs in Fukushima As of 10:00 MarchDocument4 pagesReactor Status and Major Events Update 17 - NPPs in Fukushima As of 10:00 MarchmrwonkishNo ratings yet

- Damage Mechanism Temperature Deg C Affected Materials Appearance Prevention What HappensDocument2 pagesDamage Mechanism Temperature Deg C Affected Materials Appearance Prevention What HappensBilalNo ratings yet

- ITRZA 1789a 1000kVA 98.08.28Document4 pagesITRZA 1789a 1000kVA 98.08.28Karim RahmaniNo ratings yet

- 3 Introduction PDFDocument4 pages3 Introduction PDFcafegrNo ratings yet

- Inverter-Wiring-Diagram-Distribution-Board-DB-AC-Split-Circuits-Essential-LoadsDocument1 pageInverter-Wiring-Diagram-Distribution-Board-DB-AC-Split-Circuits-Essential-LoadsFarhan MugalNo ratings yet

- RCM - Fmeca Work Sheet Tb4:: TB4-800: 0: Ah, Ai, GR: TP: WD Document No. Revision Prepared by Checked by Approved byDocument2 pagesRCM - Fmeca Work Sheet Tb4:: TB4-800: 0: Ah, Ai, GR: TP: WD Document No. Revision Prepared by Checked by Approved byAldy Eka SetyawanNo ratings yet

- Heat Exchangers Part 6 - Common Tube DefectsDocument13 pagesHeat Exchangers Part 6 - Common Tube DefectsBaher ElsheikhNo ratings yet

- 6B DegradationDocument19 pages6B DegradationThanapaet RittirutNo ratings yet

- Vs 30cpu04pDocument7 pagesVs 30cpu04p208020No ratings yet

- Partial Discharge PaperDocument6 pagesPartial Discharge Papernutzy1967No ratings yet

- Work Methodology GlorietaDocument6 pagesWork Methodology GlorietaLeo TabitaNo ratings yet

- Chapter 7 Typical Troubles and TroubleshootingDocument13 pagesChapter 7 Typical Troubles and TroubleshootingLuigi PortugalNo ratings yet

- Hot Tub Panels Sa00308001eDocument2 pagesHot Tub Panels Sa00308001ePat WarNo ratings yet

- Periodic Table and Periodicity of Properties: Major ConceptsDocument14 pagesPeriodic Table and Periodicity of Properties: Major ConceptsAbdullah AdeelNo ratings yet

- Form - Izin Kerja Panas (Rev.3)Document2 pagesForm - Izin Kerja Panas (Rev.3)Moch AnwarNo ratings yet

- NDT - Penetrant TestDocument42 pagesNDT - Penetrant TestRidho KurniawanNo ratings yet

- Thermol-D DescriptionDocument4 pagesThermol-D Descriptionajeeit8No ratings yet

- Bulletin New Refrigerant R1234yfDocument10 pagesBulletin New Refrigerant R1234yfYudha SetiawanNo ratings yet

- Ebashi 1969Document35 pagesEbashi 1969NICOLAS KARIM ELTIT ELSACANo ratings yet

- Report On Pervaporation 2Document15 pagesReport On Pervaporation 2merveNo ratings yet

- Science: Quarter 2 - Module 8: Mole ConceptDocument24 pagesScience: Quarter 2 - Module 8: Mole ConceptKc Kirsten Kimberly Malbun75% (4)

- Leaching ProcessesDocument65 pagesLeaching ProcessesSegundo Colorado VillarNo ratings yet

- Viia GroupDocument30 pagesViia GroupTarun SharmaNo ratings yet

- Understanding Valve Design and AlloysDocument6 pagesUnderstanding Valve Design and Alloysmuki10No ratings yet

- IIT JEE Advanced Sample Question Paper With Detailed Solutions 2Document35 pagesIIT JEE Advanced Sample Question Paper With Detailed Solutions 2Manish PilaniaNo ratings yet

- Science of The Total EnvironmentDocument10 pagesScience of The Total EnvironmentMELIZA TATIANA TORRES QUINAYASNo ratings yet

- MM Aqua Technologies LTD.: TubedekDocument47 pagesMM Aqua Technologies LTD.: TubedekSourabh Manuja100% (1)

- Article WJPR 1588155568Document11 pagesArticle WJPR 1588155568Syed Iftekhar AlamNo ratings yet

- Experimental Comparison of Chemical Migration From Petrochemical Plastic and Bioplastic Bottles Into Drinking WaterDocument135 pagesExperimental Comparison of Chemical Migration From Petrochemical Plastic and Bioplastic Bottles Into Drinking WaterRichard Copa AliNo ratings yet

- IIT JEE 2009 Paper-1 Questions and SolutionsDocument39 pagesIIT JEE 2009 Paper-1 Questions and SolutionsResonance Kota50% (2)

- SandCasting by Yaser ElkelawyDocument12 pagesSandCasting by Yaser ElkelawyYaserElkelawyNo ratings yet

- Biochemistry MITDocument5 pagesBiochemistry MITAngga RyanNo ratings yet

- VizagSteel MgmtTRAINEEDocument28 pagesVizagSteel MgmtTRAINEERaghu88% (16)

- Toluene (010822004)Document1 pageToluene (010822004)Harry SitumorangNo ratings yet

- 2020 2021 Intake CHE 450 ASSGN 2Document3 pages2020 2021 Intake CHE 450 ASSGN 2Lad SlasNo ratings yet

- Astm B187-20Document9 pagesAstm B187-20Gregory Alan Francisco IINo ratings yet

- Safety and Health in The Protective Coatings Industry: Daniel P. Adley and Stanford T. LiangDocument21 pagesSafety and Health in The Protective Coatings Industry: Daniel P. Adley and Stanford T. LiangNgô Trung NghĩaNo ratings yet

- Impact of Coal Based Thermal Power Plant On Environment and Its Mitigation MeasureDocument6 pagesImpact of Coal Based Thermal Power Plant On Environment and Its Mitigation MeasureAnirudh KalliNo ratings yet

- B.tech PaintsDocument14 pagesB.tech Paintsluthor26No ratings yet