Professional Documents

Culture Documents

03 GMP Score Mar 2020

03 GMP Score Mar 2020

Uploaded by

KUSHADITYAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03 GMP Score Mar 2020

03 GMP Score Mar 2020

Uploaded by

KUSHADITYACopyright:

Available Formats

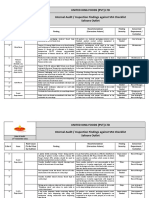

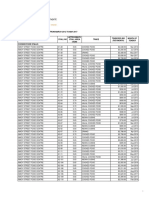

BR INC

GMP Scores

Date 4/8 /2020 Time: 11:30 AM

Product PAPER CUP Plant: Whole Plant

S.No. Location GMP Score REMARKS Corrective action

1 Personal Hygiene

Workers are aware of what they do and

2

follow GMP Policy.

On immediate basis wound has

No worker found with communicalbe One worker found with wound in been covered with proper

0

disease, infection or open cuts wounds hand in RM area. bandange.

Employees wear the proper hair covering,

beard covering, disposable gloves and

uniforms? 2

Uniforms of employees are clean 2

No worker found with any type of

jewelry, rings, watches, fingernail polish 2

or bandages?

No worker found with dirty & long nails 2

2 Hygiene Station

Lockers are properly maintained 2

Change rooms are clean 2

Change rooms are proper illuminated 2

Wash basins are clean 2

Soap solutions and Sanitizers dispensers

2

are fixed and filled.

Hand washing instructions are displayed 2

One of the dustbin in Change on immediate basis dustbin as

Dust bins are clean and covered 0 room not found covered. been covered.

3 Pest Control

Insectecuters are working 2

Insectecuters are placed away from the

2

products

They are clean( No Dust/No Rust/Dead

2

Insects, etc.)

R.B no.09 not found Fixed and on immediate basis Fixing and

Rodaboxes are intact and fixed 0

intact. Intactation has been done.

Identification/Numbering of rodaboxes

2

on walls/boxes.

F/BI/MR/07/05 Issue No.01 Revision No.00 Issue Date: 01/01/2020

BR INC

Approved pesticides are used. 2

No Pest at the time of audit 2

There is a map & monitoring record for

2

the rodent and pest control

4 Floor

Process area floor not found in on immediate basis cleaning

Clean 0

cleaned condition. has been done.

There is no standing water which

2

attracts the pests inside the plant.

No Crevices 2

No product residue spread 2

No unwanted materials 2

5 Windows

Clean (No Dust/No Cobwebs/No Rust

2

etc.)

Windows to the outside have fine mesh

screens to keep out insects if not they 2

are tightly sealed.

Glass/Acrylic pans are intact 2

Windows glass are numbered &

2

monitored

6 Doors

Clean (No Dust/No Cobwebs/No Rust

2

etc.)

There is no gap between door and floor.

(Pass a pencil under the door) 2

No Gaps (Intact Mesh) 2

Self-closing system in place. 2

7 Ceiling

Intact (no leakage) 2

No gap between roof & walls 2

White wash (no flaking) 2

No cobwebs 2

8 Walls

No Flacking of white wash/Paint 2

No Crevices, cracks, wholes etc 2

No Cobwebs 2

No Dust 2

F/BI/MR/07/05 Issue No.01 Revision No.00 Issue Date: 01/01/2020

BR INC

9 Wood Policy

No wooden articles found 2

Raw Material/ Finished Product

10

Storage

RM are placed on Pallets/trays 2

Shelves and/or platforms are separated

2

from floors and walls to allow cleaning.

Segregation of Good and Rejected

2

Material

Proper Ventilation/Adequate Air

2

Circulation

No Irregular Stacking 2

Good/Rejected/Hold Material & other

Labelling is done and seggrigation is 2

RM are stored on a first in, first out basis. 2

Stack card is placed on RM & PM to

ensure a proper rotation of stocks and for 2

internal traceability purposes.

FG/RM are stored atleast 18 inches away Gap is not found between wall On immediate basis the gap has

0

from the wall and material in RM store. been maintained.

Covering of floor with tarpaullin for

2

storing the FG.

Proper illumination. 2

11 Walk Gallery:

Clean(No Product residue/ No product

2

materials/No Dust/No Bags etc)

12 Equipment

All equipment that comes in contact with

product cleaned and sanitized as often as

necessary to prevent contamination of the 2

product.

There are no any build-up or seepage of

cleaning solvents or lubricants on

equipment, which can contaminate 2

product.

All repairs on equipment are of a

permanent nature (e.g., no bobby pins in

place of cotter pins), as temporary repair 2

parts can break or rupture and get in the

product.

No nut-bolts are missing from 2

equipment.

Equipments are designed in a

way for easy cleaning (above and below) 2

and preventive maintenance.

13 Electric Points:

No Broken Switches 2

F/BI/MR/07/05 Issue No.01 Revision No.00 Issue Date: 01/01/2020

BR INC

No Loose Connections/ Wires 2

All the electric panels are remain closed

2

while not in use.

No Gaps Between Switch board and

2

Walls

No Cobwebs 2

14 Lights/Fans:

Few light not working at the FG On immediate basis Replaced

Lights and fans are Working 0

store. with new one.

Clean and No Insect trapped inside/No

2

Dust

Overhead lights covered with shields to

prevent contamination of products by 2

broken glass in case the lamps burst.

15 Cleaning Tools

All the cleaning tools are kept at

2

designated areas while not in use.

Colour coding of cleaning tools is done 2

16 Chemicals:

On immediate basis chemical

One of the chemical found in

All the chemicals are properly stored 0 has been removed and stored

production office.

at mentioned place

All the chemicals are properly labeled 2

Chemicals used in process are food grade 2

Printing ink is food grade. 2

MSDS displayed 2

Lockers are provided for Chemicals 2

17 Machines and Tool

Conveyor condition, no leakage of oil 2

Belt guard facility provided. 2

WI does not displayed on the on immediate basis the

WI dispalyed for Machine operations. 0 production area. instructions has been

displayed.

All the tools are stored at their

2

designated place

18 Safety/Emergency Response

Fire-Extinguisher refilled as per Plan 2

FE are rust free, cobweb free and dust

2

free.

Presure indicator Needle towards Green

2

Area

Emergency Exits are properly marked

2

and illuminated

F/BI/MR/07/05 Issue No.01 Revision No.00 Issue Date: 01/01/2020

BR INC

Emergency Assembly area not On immediate Basis

Emergency Assembly area identified 0

Identified. identifaction has been done.

19 Drainage

Clean(No Algae,Fungal growth/No

2

Stains)

No Foul Smell 2

Drain cover Intact/ No Broken Drain Drain cover not found in the on immediate basis covering

0

Cover external area. has been done.

No Product Material Residue 2

On immediate basis the

No Stagnant Water 0 Drain D1 found choked. Cleaning has been done.

Drains Outlet Seives in Place 2

20 External Area

Are roads are maintained. 2

Grass should be less than 4 inches. 2

There is no standing water which attracts

2

the pests.

Traffic routes should be clearly

2

identified.

Burrow have been filled so as not to

provide hiding places or entry points for 2

pests

21 Security

Vistors register in place. 2

Colour coded Visitor card and visitor

2

pass in place.

Emergency Contact numbers displayed at

2

security office

Securiry staff aware of visitor policy and Security Staff is unaware of on immediate basis training

0

security instruction. Emergency situations. has been provided.

GMP Score 88.000 %

Scoring Criteria Not Complying-0 Partially Complying-1 Completely Complying-2

REMARKS IF ANY -

SIGNATURE OF AUDITEE SIGNATURE OF AUDITOR

F/BI/MR/07/05 Issue No.01 Revision No.00 Issue Date: 01/01/2020

You might also like

- Checklist For Worker CampDocument2 pagesChecklist For Worker CampSatya Naidu100% (1)

- Daily Sanitation Inspection ChecklistDocument3 pagesDaily Sanitation Inspection ChecklistJames Christian Hermetanio Lopez100% (1)

- Supplier Audit ChecklistDocument8 pagesSupplier Audit ChecklistNor Idayu IsmailNo ratings yet

- BRC FACILITY Hygiene InspectionDocument3 pagesBRC FACILITY Hygiene InspectionJaved IqbalNo ratings yet

- Sui Northern Gas Pipelines Limited: Site: Canteen Name Date of MonitoringDocument3 pagesSui Northern Gas Pipelines Limited: Site: Canteen Name Date of Monitoringsaad kamranNo ratings yet

- Sample: Retail Food Establishment Inspection ReportDocument2 pagesSample: Retail Food Establishment Inspection Reportnarasimma8313No ratings yet

- I Design & Facilities of My Premise: S.No. Checklist Item WeightageDocument3 pagesI Design & Facilities of My Premise: S.No. Checklist Item WeightageMAHESH SHAWNo ratings yet

- Observation Report KFCA BA-Tollgate 1 (02-03-2022)Document15 pagesObservation Report KFCA BA-Tollgate 1 (02-03-2022)arainzada807No ratings yet

- Unit No /area: Month:: Criteria For Deciding Level DateDocument2 pagesUnit No /area: Month:: Criteria For Deciding Level DateK K Maharana100% (1)

- SQAC - (March - Area 6) - 1Document86 pagesSQAC - (March - Area 6) - 1Jhazreel BiasuraNo ratings yet

- Food Handling Practice RecordDocument1 pageFood Handling Practice Recordwinnie chanNo ratings yet

- SQAC - (April - Area 6)Document86 pagesSQAC - (April - Area 6)Jhazreel BiasuraNo ratings yet

- I-Beam: Operations and Maintenance Periodic IAQ MaintenanceDocument13 pagesI-Beam: Operations and Maintenance Periodic IAQ MaintenanceKhalid ImamNo ratings yet

- HWC TehnaDocument9 pagesHWC TehnaAnonymous hkWIKjoXFVNo ratings yet

- Onthe4 of June 2022-Cabangani Nyoni Was Trying To Unblock The Dust Cyclones Using ADocument4 pagesOnthe4 of June 2022-Cabangani Nyoni Was Trying To Unblock The Dust Cyclones Using AGcinumuzi SibandaNo ratings yet

- S. No. Audit Question Scoring I Design & Facilities: Meat ProcessingDocument2 pagesS. No. Audit Question Scoring I Design & Facilities: Meat Processingmnegm2890No ratings yet

- Inventory DocumentDocument47 pagesInventory DocumentRichard RamosNo ratings yet

- HWC TehnaDocument41 pagesHWC TehnaDj AsiNo ratings yet

- Inventory 3 Lavender Gardens - July 2021 ReportDocument40 pagesInventory 3 Lavender Gardens - July 2021 Reportsusu.thompson2002No ratings yet

- Corrective Action Plan 09-05-2021 FINALDocument2 pagesCorrective Action Plan 09-05-2021 FINALBirhanu AtnafuNo ratings yet

- 5S Checklists For External Areas HousekeepingDocument5 pages5S Checklists For External Areas HousekeepingkinergyphilippinesNo ratings yet

- Facility Management AuditDocument2 pagesFacility Management AuditIkennaNo ratings yet

- Inspection Balsam BagelsDocument5 pagesInspection Balsam BagelsNews 8 WROCNo ratings yet

- HWC ChandbajaDocument9 pagesHWC ChandbajaAnonymous hkWIKjoXFVNo ratings yet

- Change Rooms RegisterDocument1 pageChange Rooms RegisterMcbride NdjaoNo ratings yet

- Restaurant Rating QuestionsDocument4 pagesRestaurant Rating QuestionsshehzadaminNo ratings yet

- Slaughter House - Meat: S. No. Audit Question ScoringDocument2 pagesSlaughter House - Meat: S. No. Audit Question ScoringShahnawaz PathanNo ratings yet

- Hygiene Ratings - FSSAI ChecklistDocument5 pagesHygiene Ratings - FSSAI ChecklistsendthilNo ratings yet

- Port Kennedy: Per WeekDocument28 pagesPort Kennedy: Per WeekTờ RangNo ratings yet

- 5S TPM Audit FormatDocument3 pages5S TPM Audit Formatmayurbhadra1992No ratings yet

- 009-Environmental and Health ChecklistDocument2 pages009-Environmental and Health ChecklistEffort NkalaNo ratings yet

- January 2021: Contractors Housing Selection Appraisal Tool (COVID-19 Virus Spread Precautions)Document2 pagesJanuary 2021: Contractors Housing Selection Appraisal Tool (COVID-19 Virus Spread Precautions)sampath sunkojiNo ratings yet

- 472821fa-b333-4bf1-bab9-2ddd24a30f9bDocument3 pages472821fa-b333-4bf1-bab9-2ddd24a30f9bSouthern Interscholastic Press AssociationNo ratings yet

- Copy of RC HSEDocument5 pagesCopy of RC HSEAnwar Haji JavedNo ratings yet

- FSSAI Checklist - General ManufacturingDocument3 pagesFSSAI Checklist - General ManufacturingNithya MichaelNo ratings yet

- Quarter 1 - Module 2: CookeryDocument11 pagesQuarter 1 - Module 2: Cookeryroderic v. perezNo ratings yet

- Inspection Checklist - Central Office Feb 2024Document7 pagesInspection Checklist - Central Office Feb 2024Louise Charmaine SuNo ratings yet

- Example Cleaning InstructionDocument3 pagesExample Cleaning Instructionleila lolita leila lilasNo ratings yet

- Proyecto 3S Parte I: Denominacion Del Proyecto Equipo Del Proyecto FechaDocument20 pagesProyecto 3S Parte I: Denominacion Del Proyecto Equipo Del Proyecto FechaJose Miguel Solano RiveraNo ratings yet

- Standard Operating Procedure Pests and Rodents ControlDocument3 pagesStandard Operating Procedure Pests and Rodents ControlDaniel Yves IV Paez100% (2)

- SAAR0119-SE-Fo-07004 Office Inspection Checklist ( Environmental)Document1 pageSAAR0119-SE-Fo-07004 Office Inspection Checklist ( Environmental)Shakir AkashNo ratings yet

- BSV Check: Critical Control PointsDocument13 pagesBSV Check: Critical Control Pointsaiman zamaniNo ratings yet

- Retail Food Establishment Inspection Report: Foodborne Illness Risk Factors & Interventions and Good Retail PracticesDocument4 pagesRetail Food Establishment Inspection Report: Foodborne Illness Risk Factors & Interventions and Good Retail PracticesSouthern Interscholastic Press AssociationNo ratings yet

- Ann-Rose Uhland Myriam Ouardani Serissa SummaryDocument3 pagesAnn-Rose Uhland Myriam Ouardani Serissa SummarypedrooyeNo ratings yet

- PHC KotsukhiaDocument12 pagesPHC KotsukhiaAnonymous hkWIKjoXFVNo ratings yet

- TDS Pioneer-Mighty-Bond 022019Document2 pagesTDS Pioneer-Mighty-Bond 022019Reynee Shaira MatulacNo ratings yet

- Prepare Cleaning Agents: What I Need To KnowDocument5 pagesPrepare Cleaning Agents: What I Need To KnowCherryl Asuque GellaNo ratings yet

- fc8a8094-a8e6-4da8-92ff-0a4072417e3aDocument3 pagesfc8a8094-a8e6-4da8-92ff-0a4072417e3aSouthern Interscholastic Press AssociationNo ratings yet

- Audit Report Safoora Outlet 17th NovemberDocument6 pagesAudit Report Safoora Outlet 17th Novembersajid waqasNo ratings yet

- Laboratory MaintenanceDocument3 pagesLaboratory MaintenanceRoh MerNo ratings yet

- S. No. Audit Question Scoring: CateringDocument3 pagesS. No. Audit Question Scoring: CateringamitNo ratings yet

- Plant Hygiene ProcedureDocument2 pagesPlant Hygiene ProcedureRavi BaghelNo ratings yet

- The NSGCD Clutter Hoarding Scale: Official Organizational Assessment ToolDocument10 pagesThe NSGCD Clutter Hoarding Scale: Official Organizational Assessment ToolnogoodreasonNo ratings yet

- Burger KingDocument2 pagesBurger KingWXYZ-TV Channel 7 DetroitNo ratings yet

- Maintain FacilityDocument19 pagesMaintain FacilityElbertjohn LagundayNo ratings yet

- STD XI Microbiology Practical Manual: Practicals Page. NoDocument26 pagesSTD XI Microbiology Practical Manual: Practicals Page. NogopimicroNo ratings yet

- Covid-19 Inspection PerformaDocument2 pagesCovid-19 Inspection Performaabbasranjha786No ratings yet

- Termites and Borers: A Home-Owner's Guide to their Detection, Prevention and ControlFrom EverandTermites and Borers: A Home-Owner's Guide to their Detection, Prevention and ControlNo ratings yet

- Quality Manual: ISO 9001:2015 Quality Management SystemDocument1 pageQuality Manual: ISO 9001:2015 Quality Management SystemKUSHADITYANo ratings yet

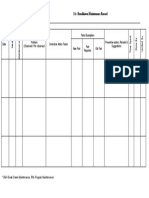

- 4 Breakdown Maintenance RecordDocument1 page4 Breakdown Maintenance RecordKUSHADITYANo ratings yet

- Work Environment & InfrastructureDocument1 pageWork Environment & InfrastructureKUSHADITYANo ratings yet

- Affidavit Proforma For Online RCMCDocument2 pagesAffidavit Proforma For Online RCMCKUSHADITYANo ratings yet

- Column & Footing DetailDocument111 pagesColumn & Footing DetailKUSHADITYANo ratings yet

- The African Essentials - Presentation - O - 2019Document34 pagesThe African Essentials - Presentation - O - 2019Fatima SilvaNo ratings yet

- 25 Duas From The Holy QuranDocument4 pages25 Duas From The Holy QuranKhan Amir Younus KamalNo ratings yet

- Gilbert Clayton PapersDocument37 pagesGilbert Clayton PapersbosLooKiNo ratings yet

- Practical Work 1 EventDocument19 pagesPractical Work 1 EventNur ShakirinNo ratings yet

- ISquare - Setup Guide For Fresh UsersDocument12 pagesISquare - Setup Guide For Fresh UsersWQDNo ratings yet

- L4 02 Causative Verbs Teaching JobDocument4 pagesL4 02 Causative Verbs Teaching JobGeorge VieiraNo ratings yet

- Physical Education - 12th PDFDocument340 pagesPhysical Education - 12th PDFGunal Agarwal100% (1)

- Reactor and Regenerator System of FCCDocument67 pagesReactor and Regenerator System of FCCDai NamNo ratings yet

- Landmark Cases Oposa vs. Factoran, JRDocument7 pagesLandmark Cases Oposa vs. Factoran, JRChristine JungoyNo ratings yet

- Pe 3 2ND QTR W1 Folk DanceDocument41 pagesPe 3 2ND QTR W1 Folk DanceKiesha TataroNo ratings yet

- Experimental Study On GPR Detection of Voids Inside and Behind Tunnel LiningsDocument10 pagesExperimental Study On GPR Detection of Voids Inside and Behind Tunnel LiningsSajid KhanNo ratings yet

- Paper 3 On Stan LeeDocument5 pagesPaper 3 On Stan Leeapi-545773326No ratings yet

- Tender Bids From March 2012 To April 2017Document62 pagesTender Bids From March 2012 To April 2017scribd_109097762No ratings yet

- Sample Thesis 2Document127 pagesSample Thesis 2Carlo Troy AcelottNo ratings yet

- E M II: Synchronous MachineDocument10 pagesE M II: Synchronous MachineAkashman ShakyaNo ratings yet

- TestDocument3 pagesTestPopovska KristinaNo ratings yet

- RMS Infosheet Classic Vehicle Scheme Mou 2016 12Document21 pagesRMS Infosheet Classic Vehicle Scheme Mou 2016 12www.toxiconlineNo ratings yet

- God Will Protect His Church God Will Protect His ChurchDocument17 pagesGod Will Protect His Church God Will Protect His ChurchLaura GarciaNo ratings yet

- (Promotion Policy of APDCL) by Debasish Choudhury: RecommendationDocument1 page(Promotion Policy of APDCL) by Debasish Choudhury: RecommendationDebasish ChoudhuryNo ratings yet

- Communication MatrixDocument1 pageCommunication Matrixrohini kadamNo ratings yet

- Statistical Quality Control PPT 3 2Document18 pagesStatistical Quality Control PPT 3 2Baljeet Singh100% (1)

- Cemex Holdings Philippines Annual Report 2016 PDFDocument47 pagesCemex Holdings Philippines Annual Report 2016 PDFFritz NatividadNo ratings yet

- Reading Passage 1: Succeed in IELTS Volume 8Document16 pagesReading Passage 1: Succeed in IELTS Volume 8Huyền Kiệt thươngNo ratings yet

- Cooling Tower AshraeDocument18 pagesCooling Tower AshraeMAITREE JHANo ratings yet

- Comparison of Alternatives NotesDocument10 pagesComparison of Alternatives NotesLibyaFlowerNo ratings yet

- Satellite CommunicationsDocument57 pagesSatellite Communicationsheritage336No ratings yet

- Karakoram International University: TopicDocument56 pagesKarakoram International University: TopicNoor KhanNo ratings yet

- Comparison of Starbucks With The Coffee BeanDocument16 pagesComparison of Starbucks With The Coffee BeanshaiNo ratings yet

- Blockchain-Enabled Drug Supply Chain: Sheetal Nayak, Prachitee Shirvale, Nihar Naik, Snehpriya Khul, Amol SawantDocument4 pagesBlockchain-Enabled Drug Supply Chain: Sheetal Nayak, Prachitee Shirvale, Nihar Naik, Snehpriya Khul, Amol SawantWaspNo ratings yet

- Ch13. Flexible Budget-AkmDocument44 pagesCh13. Flexible Budget-AkmPANDHARE SIDDHESHNo ratings yet