Professional Documents

Culture Documents

DRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019

DRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019

Uploaded by

SamerCopyright:

Available Formats

You might also like

- Pas96 2017 PDFDocument58 pagesPas96 2017 PDFCristalina Do Oeste75% (4)

- Shell Safety in Drilling ManualDocument147 pagesShell Safety in Drilling ManualJacob KeeminkNo ratings yet

- ReportDocument57 pagesReportkasun123745982% (11)

- Checklist For Lifting Plan: S/N Items YES NO RemarksDocument1 pageChecklist For Lifting Plan: S/N Items YES NO RemarksAndrianoNo ratings yet

- Health, Safety & EnvironmentDocument27 pagesHealth, Safety & EnvironmentbilouNo ratings yet

- Fall Protection Survey of RIG 40Document3 pagesFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- Isand Drilling HSE Case Nov 08 Rev A02lDocument310 pagesIsand Drilling HSE Case Nov 08 Rev A02lSalim Muftah100% (5)

- SoBo - Site Inspection ChecklistDocument5 pagesSoBo - Site Inspection ChecklistAndrada Roxana IonescuNo ratings yet

- HACCP ValidationDocument9 pagesHACCP ValidationNurhadi EdogawaNo ratings yet

- World Food Safety Guidelines 2010Document91 pagesWorld Food Safety Guidelines 2010Len Villamoya SimpasNo ratings yet

- Valeura Hse Management System PDFDocument19 pagesValeura Hse Management System PDFAbdelkarimNo ratings yet

- Safety Campaign Poster Topic 2 - Confined Space (Eng)Document1 pageSafety Campaign Poster Topic 2 - Confined Space (Eng)Muhammad TohirNo ratings yet

- Are You in The Line of Fire?: Examples of Hazardous EnergyDocument2 pagesAre You in The Line of Fire?: Examples of Hazardous EnergyMuhammad TohirNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IDocument3 pagesPro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IMohammed Hamza100% (1)

- Short Service Employees ProcedureDocument7 pagesShort Service Employees ProcedureMuhammad Usman100% (1)

- Hazard Hunt Status 26-08-2017Document28 pagesHazard Hunt Status 26-08-2017Yaqoob IbrahimNo ratings yet

- Rig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickDocument5 pagesRig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickMalik Muhammad Nauman ZiaNo ratings yet

- Harc TLC Kd-1revisiDocument2 pagesHarc TLC Kd-1revisitanjungkasri rayaNo ratings yet

- IADC Gin Pole Guidelines Rig Pass.75140439Document22 pagesIADC Gin Pole Guidelines Rig Pass.75140439Hashimi Juni100% (1)

- Breaking Containment Check ListDocument4 pagesBreaking Containment Check Listromedic36No ratings yet

- NB2 HSE Case Part 5 - Emergency Response Rev 1Document36 pagesNB2 HSE Case Part 5 - Emergency Response Rev 1George MedeirosNo ratings yet

- Hse PlanDocument240 pagesHse PlanWaleed KhalidNo ratings yet

- 01 Introductory Module Admin ManualDocument34 pages01 Introductory Module Admin ManualTaymoor Malek100% (1)

- Monthly Hse Rig InspectionDocument7 pagesMonthly Hse Rig InspectionHidacio Da LimiaNo ratings yet

- Rig - LOUISIANA - JSA-IN-HAL-DF-402 CLEANING OF MIXING TANK 2018.10.28Document7 pagesRig - LOUISIANA - JSA-IN-HAL-DF-402 CLEANING OF MIXING TANK 2018.10.28Aziz AndriyantoNo ratings yet

- F0810 - Pre-Post Rig Move Meetings FormsDocument18 pagesF0810 - Pre-Post Rig Move Meetings FormsPaulNo ratings yet

- Drilling Safety: David Calvert, True Oil Enterprises IncDocument16 pagesDrilling Safety: David Calvert, True Oil Enterprises Inccall_mustafas2361No ratings yet

- Safty BookletDocument8 pagesSafty Bookletjinyuan74No ratings yet

- Rajda Industries & Exports Pvt. LTD Fire Safety Checklist SA8000:2014Document6 pagesRajda Industries & Exports Pvt. LTD Fire Safety Checklist SA8000:2014AVISEK GHOSHNo ratings yet

- 07.03.09 Rig Move (Working at Height)Document1 page07.03.09 Rig Move (Working at Height)Hamdi RafiekNo ratings yet

- 7c - IOGP 432 Table 1 Draft v3 04062016Document32 pages7c - IOGP 432 Table 1 Draft v3 04062016Idada Ezekiel100% (1)

- Hydrogen Sulphide (H2S) & Escape Breathing Apparatus (BA)Document91 pagesHydrogen Sulphide (H2S) & Escape Breathing Apparatus (BA)Wahid Husain0% (1)

- Safety Campaign Poster Topic 2 - Zero Harm (Eng)Document1 pageSafety Campaign Poster Topic 2 - Zero Harm (Eng)Muhammad TohirNo ratings yet

- SP2000 Road Safety StandardDocument120 pagesSP2000 Road Safety StandardSunder TrichyNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- #101 - Oilfield HSE Inspection HandbookDocument30 pages#101 - Oilfield HSE Inspection HandbookEagle EyeNo ratings yet

- PR001 HSE Auditing ProcedureDocument19 pagesPR001 HSE Auditing ProcedureThien NguyenNo ratings yet

- Confined-Sop - Qatar SteelDocument28 pagesConfined-Sop - Qatar SteelUnais RahmanNo ratings yet

- Objectives: CareerDocument14 pagesObjectives: CareerHedi Ben MohamedNo ratings yet

- Tennin HAZOPDocument4 pagesTennin HAZOPMohamed SamirNo ratings yet

- Cp-122 Hse ManualDocument1 pageCp-122 Hse ManualAnonymous IeFbdsfCoNo ratings yet

- H2S Contingency PlanDocument33 pagesH2S Contingency PlanAnonymous JMuM0E5YO100% (1)

- Well Handover DocumentDocument1 pageWell Handover DocumentCadiffNo ratings yet

- OIl Rig Safety ChecklistDocument10 pagesOIl Rig Safety ChecklistTom TaoNo ratings yet

- Apprisk Assessment HAZOPDocument1 pageApprisk Assessment HAZOPHakim YahiaouiNo ratings yet

- Hsem-Sp-0014 Nidaa Journey ManagementDocument6 pagesHsem-Sp-0014 Nidaa Journey ManagementAhmed Imtiaz RaoNo ratings yet

- Dragon OilDocument34 pagesDragon OilDavinNo ratings yet

- Emergency Response & Contigency Planning StandardDocument15 pagesEmergency Response & Contigency Planning Standardbilou100% (1)

- Nipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01Document1 pageNipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01cmrig74No ratings yet

- 2 32 2 1 13 01-CS-ProcedureDocument30 pages2 32 2 1 13 01-CS-ProcedureMahmoud SaiedNo ratings yet

- UEP-HL Stop Cards Feb - 2017Document59 pagesUEP-HL Stop Cards Feb - 2017Yaqoob Ibrahim100% (1)

- Checklist For Safe UseDocument33 pagesChecklist For Safe UseShahpour SotoudehNo ratings yet

- Safety Performance Indicators - Motor Vehicle Crash Data - 2008-2019Document56 pagesSafety Performance Indicators - Motor Vehicle Crash Data - 2008-2019TFattahNo ratings yet

- Visible Safety and Induction: Hse Management Visit ChecklistDocument6 pagesVisible Safety and Induction: Hse Management Visit ChecklistHARSHALNo ratings yet

- SIPP Training - 064413Document11 pagesSIPP Training - 064413Ndi FlavourNo ratings yet

- Daily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryDocument5 pagesDaily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- Well Operations Crew Resource ManagementDocument2 pagesWell Operations Crew Resource ManagementJassieNo ratings yet

- 01.01. HSE ManagementDocument64 pages01.01. HSE ManagementHussainNo ratings yet

- HSE MS Training Feb 2019Document17 pagesHSE MS Training Feb 2019Tatak Bay AhmedNo ratings yet

- Road & Traffic Safety Procedure: Pars Oil & Gas CompanyDocument29 pagesRoad & Traffic Safety Procedure: Pars Oil & Gas CompanyKostan Abdillah100% (1)

- MIM1185.001 MIMs Numerical IndexDocument4 pagesMIM1185.001 MIMs Numerical IndexGeorge Zormpas100% (1)

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- DRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019Document35 pagesDRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019SamerNo ratings yet

- Attachment 3 - Mog-Hseq-F-292 Rev A1 - GHG - 4yp - FormDocument20 pagesAttachment 3 - Mog-Hseq-F-292 Rev A1 - GHG - 4yp - FormSamerNo ratings yet

- MOG-CIMS-P-112 Rev A2 Corporate PPE ManagementfdfdDocument55 pagesMOG-CIMS-P-112 Rev A2 Corporate PPE ManagementfdfdSamerNo ratings yet

- Attachment 1 - Water, Waste & Spill DATA - Environmental ReportDocument25 pagesAttachment 1 - Water, Waste & Spill DATA - Environmental ReportSamerNo ratings yet

- MOG-HSEQ-H-P-116 Rev A1 Corporate Standards For Local Medical FacilitiesDocument75 pagesMOG-HSEQ-H-P-116 Rev A1 Corporate Standards For Local Medical FacilitiesSamerNo ratings yet

- MOG-HSEQ-H-P-019 Rev A1 Fitness To Work & Health SurveillanceDocument33 pagesMOG-HSEQ-H-P-019 Rev A1 Fitness To Work & Health SurveillanceSamerNo ratings yet

- MOG-HSEQ-E-P-113 Rev A1 Corporate Air Emissions Management PorocedureDocument85 pagesMOG-HSEQ-E-P-113 Rev A1 Corporate Air Emissions Management PorocedureSamerNo ratings yet

- MOG-HSEQ-E-P-113 Rev A1 Corporate Air Emissions Management PorocedureDocument85 pagesMOG-HSEQ-E-P-113 Rev A1 Corporate Air Emissions Management PorocedureSamerNo ratings yet

- Food Delivery Truck Inspection Form2016Document2 pagesFood Delivery Truck Inspection Form2016Samer100% (1)

- MOG-CIMS-P-112 Rev A1 Corporate PPE ManagementDocument57 pagesMOG-CIMS-P-112 Rev A1 Corporate PPE ManagementSamerNo ratings yet

- Case Study 01-16 - ENDocument6 pagesCase Study 01-16 - ENSamerNo ratings yet

- Case Study 03-16 - ENDocument8 pagesCase Study 03-16 - ENSamerNo ratings yet

- Food Delivery Truck Inspection 21-9-2016Document2 pagesFood Delivery Truck Inspection 21-9-2016SamerNo ratings yet

- 10SF.15 MOG HSEQ SF P 0110 A1 Confined Space ProcedureDocument38 pages10SF.15 MOG HSEQ SF P 0110 A1 Confined Space ProcedureSamerNo ratings yet

- Weld Inspection ReportDocument12 pagesWeld Inspection ReportSamerNo ratings yet

- 10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetyDocument21 pages10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetySamerNo ratings yet

- Paint Inspection ReportDocument2 pagesPaint Inspection ReportSamerNo ratings yet

- Separator Data SheetDocument2 pagesSeparator Data SheetSamerNo ratings yet

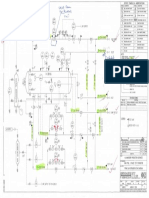

- As Built DrawingDocument3 pagesAs Built DrawingSamerNo ratings yet

- Dimentional ReportDocument1 pageDimentional ReportSamerNo ratings yet

- MOG-HSEQ-P-xxx Rev P1 PPE ManagementDocument47 pagesMOG-HSEQ-P-xxx Rev P1 PPE ManagementSamerNo ratings yet

- Mellitah Oil & Gas BV: Libyan BranchDocument8 pagesMellitah Oil & Gas BV: Libyan BranchSamerNo ratings yet

- MOG-CIMS-P-112 Rev A1 Corporate PPE ManagementDocument55 pagesMOG-CIMS-P-112 Rev A1 Corporate PPE ManagementSamerNo ratings yet

- ﺘﯿﻠﻣ ــ ﻔﻨﻠﻟ ﺔـ ــ ـﻐﻟاو ﻂـ ــ ﻲﺑ زﺎ - ﭬ ﻲ Mellitah Oil &Gas B.V Libyan BrancDocument2 pagesﺘﯿﻠﻣ ــ ﻔﻨﻠﻟ ﺔـ ــ ـﻐﻟاو ﻂـ ــ ﻲﺑ زﺎ - ﭬ ﻲ Mellitah Oil &Gas B.V Libyan BrancSamerNo ratings yet

- Mog-Cims-P-112 Rev A1 Ppe ManagementDocument56 pagesMog-Cims-P-112 Rev A1 Ppe ManagementSamerNo ratings yet

- Calendar 2017 enDocument14 pagesCalendar 2017 enSamerNo ratings yet

- HACCP in The Chocolate Industry: J.-L. CordierDocument5 pagesHACCP in The Chocolate Industry: J.-L. CordierMauro Antonio Villalobos KramNo ratings yet

- Fishbone Cause and Effect DiagramDocument1 pageFishbone Cause and Effect DiagramsitimaezyarohNo ratings yet

- Neogen - Effective Testing Components of An Environmental Monitoring Program PDFDocument12 pagesNeogen - Effective Testing Components of An Environmental Monitoring Program PDFAngga PrasetyoNo ratings yet

- Cocu 2 (Sweet and Savoury Filling Preparation)Document14 pagesCocu 2 (Sweet and Savoury Filling Preparation)Fadilah MazlanNo ratings yet

- Principles of Haccp SystemDocument4 pagesPrinciples of Haccp SystemLider Castillo0% (1)

- RA 10611 or The Food Safety Act 2013Document33 pagesRA 10611 or The Food Safety Act 2013jercherwinNo ratings yet

- 10 Gabriel Mainer Albiac - Principles Haccp Oil RefiningDocument38 pages10 Gabriel Mainer Albiac - Principles Haccp Oil RefiningMuhammad WaseemNo ratings yet

- Haccp, Ssop and GMPDocument49 pagesHaccp, Ssop and GMPManantan Ma. KatherinaNo ratings yet

- Final Operation MGM Report-LibreDocument16 pagesFinal Operation MGM Report-LibressimisimiNo ratings yet

- Implementation of FSMS ISO 22000:2005 in Small Medium EnterprisesDocument53 pagesImplementation of FSMS ISO 22000:2005 in Small Medium Enterprisesfaisalrafique100% (8)

- Compliance With Food SafetyDocument203 pagesCompliance With Food SafetyHsamb Abm100% (1)

- Departmental Organisation & Staffing: Unit 2Document22 pagesDepartmental Organisation & Staffing: Unit 2Yash SankhlaNo ratings yet

- Tata Steel: Mr. Partha Sengupta Vice President, Raw MaterialsDocument18 pagesTata Steel: Mr. Partha Sengupta Vice President, Raw MaterialsbinumalhotraNo ratings yet

- FDC Organic Virgin Coconut Oil Hazard Analysis and Critical Control Points Plan PDFDocument3 pagesFDC Organic Virgin Coconut Oil Hazard Analysis and Critical Control Points Plan PDFWynona Basilio100% (3)

- Company Profile Intrafood Citarasa Nusantara PDFDocument24 pagesCompany Profile Intrafood Citarasa Nusantara PDFdann yanuar50% (2)

- FF-TNI-001 Rev. 04 Questionnaire - Preparation For ISO 22000 or HACCP PDFDocument13 pagesFF-TNI-001 Rev. 04 Questionnaire - Preparation For ISO 22000 or HACCP PDFRenaldo MoontriNo ratings yet

- Principles of Food SanitationDocument201 pagesPrinciples of Food Sanitationayman shamsNo ratings yet

- ISO 22000 Gap Analysis: Text ChangeDocument8 pagesISO 22000 Gap Analysis: Text ChangeJmy GbuNo ratings yet

- Pesticides, Food Safety, Gaps, Sustainability, and The California Pistachio IndustryDocument12 pagesPesticides, Food Safety, Gaps, Sustainability, and The California Pistachio IndustryDorin BadiuNo ratings yet

- Traditional Fermented MilkDocument5 pagesTraditional Fermented MilkPraveen KumarNo ratings yet

- Hazard Analysis Critical Control Point (HACCP) Plan Submission Guidelines PDFDocument8 pagesHazard Analysis Critical Control Point (HACCP) Plan Submission Guidelines PDFThuyền TháiNo ratings yet

- Notice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsDocument2 pagesNotice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsJustia.com100% (1)

- 2021 Food Safety Officer Book - SWA EducationDocument552 pages2021 Food Safety Officer Book - SWA EducationMaritza Mercedes Zambrano IntriagoNo ratings yet

- Codex AlimentariusDocument18 pagesCodex AlimentariusprincessicyjulietNo ratings yet

- Plant Manager Operations in Rochester NY Resume Mark AsbrandDocument3 pagesPlant Manager Operations in Rochester NY Resume Mark AsbrandMark AsbrandNo ratings yet

- Food Safety Alerts - A Case Study On An Advanced Rapid Alert SystemDocument8 pagesFood Safety Alerts - A Case Study On An Advanced Rapid Alert Systemdijana9No ratings yet

DRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019

DRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019

Uploaded by

SamerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019

DRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019

Uploaded by

SamerCopyright:

Available Formats

HSE AUDIT REPORT

HSE

eni north africa b.v.

TITLE:

Joint HSE Audit Report - NWD Drilling Rig 11 ,Well A 58, Wafa Field 27 & 28 Oct.2019

NOTES:

This HSE Audit report represents an HSE technical feedback on NWD Drilling Rig 11, Well A 58,

WAFA Field, to ensure the implementation of the HSE operational control procedures.

DATE OF ISSUE: EFFECTIVE DATE:

20/11/2019 20/11/2019

PREPARED BY: CHECKED BY: APPROVED BY:

Abdalla DREBEIKA Walid BENZEGLAM Abdulmonem ARIFI

Safety Coordinator HSE Ops. and JV MANAGER MANAGING DIRECTOR

Jamal ARAFA Norbert JALLAIS

HSE & SD DIV. MANAGER

Medical Services Adviser

1 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

CONTENTS

1. HSE AUDIT SUMMARY......................................................................................3

2. AUDIT CHECKLIST AND ACTION PLAN................................................................7

3. AUDIT CONCLUSION......................................................................................22

4. REVIEWED DOCUMENTATION..........................................................................22

5. ATTACHMENTS..............................................................................................23

a) Opening & Closing out Meeting attendees list and interviewed Reference

Figures.................................................................................................................................................23

b) Audit Photos................................................................................................................................24

2 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

1. HSE AUDIT SUMMARY

Scope / Boundary / NWD Drilling Rig 11 ,Well A 58, Wafa Field

Extent

Audit Date & Duration Start: 27.October.2019 End: 28.October.2019

- Coordination Agreement between Eni NA and MOG;

Nr.117/CPM/GO/2018-2019

- NWD HSE Management System and HSE Plan;

- MOG HSE IMS

Audit Criteria

- Eni NA HSE policy & sister’s policies, Eni NA HSE IMS Procedures &

Operating Instructions

- ISO 45001:2018 and ISO 14001:2015 standards;

- Libyan legal requirements, International legal requirements (IMO,

SOLAS, MARPOL, STCW, ISM Code, etc.) and OGP best practices.

MOG Company Man, NWD Tool pusher, NWD RSTC, NWD Medic,

Auditee

camp boss Responsible, Eni NA Representatives (Geologists).

Audit Objectives Audit Team

- Verify the respect of Coordination Agreement Lead Auditor: Adalla DREBEIKA - Eni NA

for HSE part; Safety Coordinator;

- Verify the level of implementation of NWD HSE Auditor: Jamal ARAFA - Eni NA Medical

Management System; Services Adviser;

- Verify the Compliance vs. Libyan legislation and Auditor: Milad ELFAZAA – NWD HSE

international other requirements; Manager;

- Identify HSE areas for improvement and Auditor: Saliem MUAIN - MOG HSE dept.

recommendations;

- Verify Implementation of Health requirements

Audit Execution Methodology

- Documents review, Interview of Key personnel, and site visit.

Summary of Main Audit Findings

3 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Audit Global Appreciation

Eni NA along together with its main stockholders; MOG and NWD have participated in a joint HSE

audit activity on NWD Drilling Rig 11, Well A58, WAFA Field, on the period 27-28 Oct. 2019. It is

crucial to early engage the main stakeholders at the operational level in such activity in order to

ensure an effective, smooth and rapid enhancement/improvement of the HSE performance

throughout the entire lifecycle of this drilling campaign.

Although this Audit was conducted during critical circumstances in the country, but three parties

represented great level of welling and enthusiasm to carry it out despite of all encountered security

adversities.

NWD Rig 11 is Oil Well With 2000 HP Electrical Operating System (SCR) Ross Hill Powered With 3 each

3512 Generator Set, Refurbished by DRECO in 1992, Mast Clear Height 140 ft., API Nominal Load

Capacity 1,330,000 lbs., Hook Load Rating 1,000,000 lbs. Using 1 ½” Drilling line, it can reach 20,000 ft.

Rig certified with DSL Cat III till June 7 th 2020.

The opening meeting was conducted on 27 th Oct. 2019 at NWD, Rig 11’s meeting room and attended

by all auditee as per attached attendees list. Audit methodology, Criteria and Objective were

represented and discussed during the opening meeting.

Close-out meeting was held on 28th Oct. 2019 at NWD, Rig 11’s meeting room, in which all findings

were discussed with MOG Company Man, NWD Tool pusher and NWD senior crew. Additionally,

auditee were eager to start of sorting out those findings can be managed at the site level in order to

meet Eni NA and MOG goals and to maintain their company HSE level in the continues improvement

framework.

During audit execution, the following findings were encountered which merit attention and follow-up;

Positive Findings

Commitment of MOG Company Man and NWD Rig crew during auditing period, in addition to

the prompt response to close-out/ sort some findings that can be managed at the site level;

Well-structured inspection Campaign on the period 15 Jul. to 16 Aug. 2019 for lifting equipment

& accessories; validity 6 M / 1 year;

Regular inspections of catering and food provision facilities were carried out by Medilink doctor.

It is recently launched by first week of October 2019;

Availability of subcontractor “Medilink” doctor and ambulance at 24 hours;

Proper housekeeping and well-organized Laundry room and Washing Machines.

Areas for improvement:

Lack of NWD RIG Crew HSE leadership and commitment;

Inadequate HSE induction was introduced /delivered;

Absence of fixed H2S, fire and smoke detection systems;

Absence of own NWD Occupational Health, Safety and environmental guidelines;

Incompetent / unqualified NWD HSE officer;

Improper implementation of NWD HSE operational controls; PTW, Risk assessment

,TBT, lifting ops and working at height;

Lack of adequate maintenance management system and procedure;

Lack of HSE emergency preparedness;

Poor management of electrical cables, connections, extensions and junctions.

4 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Improper management of lifting appliances i.e. lack of segregation between

certified and rejected lifting appliances;

Poor management of environmental aspects i.e. spillages, wastes...etc. at Rig site

and camp;

Lack of level 1 HSE emergency drills and exercises;

Improper management of sewage Pits in terms of; Inappropriate location and

Health & safety precautionary measures;

Absence of Protection barriers and precautionary safety signs around the Water

pit;

Poor condition and erosion of Mud pit basin containment (the soil embankment

around the bit perimeter);

Malfunctioning of controlled descent device escape line at the Derrick;

Unsafe handling and storing of pressurized cylinders i.e. Oxygen, Nitrogen and

helium cylinders;

Poor adherence to Smoking policy at rig site, offices and accommodation rooms;

Unsafe practice of diesel storing and refueling process;

Lack of service sub-contractors engagement in HSE aspects at rig site by NWD;

No evidence of HSE meetings;

Lack of HSE training to rig crew including HSE officer;

Absence of rig site HSE risk assessment register;

Inadequate Fitness to Work process of NWD RIG Crew and catering staff;

Poor level of housekeeping at rig sit and minicamp;

No implementation of Hazard Analysis and Critical Control Points (HACCP) system

procedures, records and food handler certification;

Lack of formal hygiene education of catering staff;

Lack of supervision by certified hygienist;

Frozen store lacks protective clothing (PPE) when accessing low temperature zone

and handing meat;

Lack of properly stocked first aid kits;

Lack of pest control implemented.

5 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

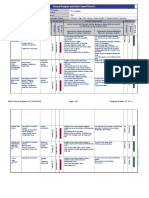

2. AUDIT CHECKLIST AND ACTION PLAN

2

1 Type of Proposed

No Requirement Finding(s) Suggested Action(s)

Finding Deadline

NWD Rig Crew has represented a poor level of HSE NC NWD has to reinforce the HSE lead ship

leadership and commitment during the interview initiative at rig site through their

and safety walkthrough at rig site. Nevertheless, Toolpusher & HSE officer as they shall

NWD Toolpusher & HSE officer showed a great act as a good safety leaders and

level of satisfaction and confidant despite of the leading by example to encourage and

poor level of HSE performance at rig sit. drive other rig crew. Additionally, they

Additionally, stop authority is not well-illustrated shall ensure that everyone well-

as none of rig crew has intervene / interact as a understood the concept of “stop Continues

1 HSE leadership

safety leader whenever observed an unsafe authority” by intervening whenever

act/unsafe condition during our site tour. there is an HSE violations or HSE

breaching rules.

Simultaneously, it is crucial that MOG

company has to strongly adhere the

safety leadership initiative and stop

authority concept to NWD rig crew.

Although NWD HSE policy was displayed at O NWD rig crew staff shall be informed

minicamp area and endorsed by NWD chairman on about the HSE policy and its aim, goal

Jan. 2016, but it was not well communicated or and objectives. This can be achieved

2 HSE Policy

through awareness sessions covering

introduced to NWD Rig crew as part of crew never

all rig crew. Relevant record shall be

heard about the HSE policy. retained.

3 Presence of

documented HSE In spite of that fact that NWD QHSE Manual NC Ensure that all relevant operation

Management

6 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

revision Aug. 2018 was made available during the

audit period, but there were no evidence of instruction procedures i.e. PTW, risk

dedicated operation instruction procedures i.e. assessment, working at height,

PTW , risk assessment, working at height, H2S….etc. are available at rig site and

H2S….etc. well understood by all rig crew.

O

System The Presented QHSE Manual at Rig site was wade An Arabic version of QHSE Manual and

in English language version rather than Arabic one, relevant operation instruction

and the crucial concern is that; NWD HSE officer procedures shall be guaranteed as

and Toolpusher are not well aware and understood most of rig crew are not English

it is content as they facing difficulties to speakers. Additionally, NWD has to

understand English language. ensure that said documents are well

understood by all rig crew.

4 NWD HSE officer has to ensure the

Implementation Although NWD HSE officer has delivered an HSE NC delivery of a good and well-structured

HSE operational induction to auditing team upon arrival at rig site, HSE induction to rig visitors. HSE

controls (PTW, risk but it was very week as it didn’t include the induction shall include and not limited

assessment,

follows; NWD HSE policy, smoking policy, to the follows; NWD HSE policy,

working at height,

H2S….etc.) associated risks & hazards to operations at site, smoking policy, associated risks &

evacuation procedure, available emergency hazards to operations at site,

equipment, mandatory PPE requirements…etc. evacuation procedure, available

emergency equipment, mandatory

PPE requirements…etc.

In spite of the fact that NWD is using two PTW O

NWD is recommended to enhance and

forms “Cold & Hot” to control ongoing activities at restructure own PTW forms to be in

rig site , but the form is lacking the follows; line with the international standards, in

7 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

proper identification of associated risks & hazards , order to ensure all essential elements

relevant control measures, , work are guaranteed i.e. proper

suspensions/stop for any safety concern, and identification of associated risks &

mandatory PPE requirements. Additionally, PTW hazards, relevant control measures,

form is written only in English language and most work suspensions/stop for any safety

of rig crew are not capable to understand English concern, and mandatory PPE

language. requirements. Additionally, an Arabic

version of NWD PTW forms shall be

guaranteed and well-understood by rig

crew as most of them are not English

speakers.

NC Reinforce to implementation of PTW

logbook to register to ensure a better

Although NWD has a dedicated PTW logbook to

management of PTWs “opened and

register for opened and closed PTWs, but there is

closed “.

no evidence of it is implementation.

Reinforce the implementation of the

Tool box talk practice in prior to start

NC

any task controlled by a PTW during

No evidence of any Tool box talk conducted in

the current well A58.

prior to start any task controlled by a PTW during

the current well A58. NC NWD is recommended to enhance and

restructure own Job Risk assessment

Although NWD has own Job Risk assessment form,

form to be in line with the international

but it is lacking to risk evaluation & rankling,

standards, in order to ensure all

existing control measure and additional required

essential elements are guaranteed i.e.

control measures “if any”. Additionally, no

risk evaluation & rankling, existing

evidence of any conducted JRA for current well

8 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

A58 activities.

control measure and additional

required control measures “if any”.

Additionally NWD has to reinforce the

implementation of JRA practice to all

tasks controlled by a PTW during the

current well A58.

NWD has to develop a Risk assessment

and register that includes all risk and

NC

No Risk assessment and register in place. hazardous associated to the activity at

current well A58 i.e lifting ops, welding

working at height, fire and exposition,

presence of H2S, blowout...etc.

Reinforce a proper implementation of

In spite of the fact that NWD has in place a Stop Stop card practice in a systematic way

card system ,but it is not properly implemented as O by tracking , follow-up and monitor

there is no a systematic mechanism in place to those raised observation in order to be

track , follow-up and monitor those raised sorted-out and close in due time.

observation in order to be sorted-out and close.

Ensure that all non-routine lifting

No evidence of any prepared lifting plan for operations shall be properly planned in

NC advance and a dedicated lifting plan

previously conducted lifting activities during this

was prepared and discussed endorsed.

drilling campaign.

6 Well-structured inspection Campaign on the period

Application of lifting 15 Jul. to 16 Aug. 2019 for the lifting equipment & C

gear and lifting accessories “Crane, Fork Lift, baskets, Slings and

9 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

shackles”. Relevant certificates with Validity of 6 M

/ 1 year ahead.

During the audit, Also there is no evidence NWD Shall manage their lifting

showing how NWD is managing/ logging those O equipment and accessories in a proper

certificates i.e. “log sheet for the lifting inventory”. way. i.e. “log sheet for the lifting

inventory, quarantine place for rejected

slings and shackles, etc.

Colour code system is not implemented.

O Color code system for all lifting gears

equipment and skips shall be implemented and

inspection and communicated.

Improper management, storing and handling of

certification scheme

slings i.e. No dedicated area for certified & Reinforce a proper management of

inspected or junk & rejected slings, part of slings by segregation and identifying

certified slings were thrown on the ground, mixing NC different labelled areas for certified /

between certified and rejected slings and no inspected slings and rejected/ junk

slings.

dedicated sign.

Ensure that relevant data plats on

Lacking/ missing of data plats on some baskets baskets and slings which indicates

and slings which indicates some important data of NC some important data of the safe load

the safe load. are available.

7 Presence of H2S, NC

Smoke, and fire Although NWD has a fixed H2S detection and alarm NWD shall ensure the reconnecting of

protection & system installed at rig site but is not the fixed H2S detection and alarm

prevention

Program based on a

working/disconnected. NC system, as well as ensure it is well-

risk assessment. functioning, regularly inspected &

Fire diesel pump battery is not recharged. tested.

Consequently, it was not available to start during

10 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Ensure that the fire pump in a good

operating condition and it is reliable

audit period. when needed. Additionally, ensure a

good inspection, test and maintenance

program in place.

Ensure all Fire extinguishers at rig site

Some of Fire extinguishers at rig site are are inspected and well maintained

depressurized with no inspection program or NC through a dedicated maintenance &

maintenance. inspection program.

No presence of smoke & fire detection and alarm

NWD shall ensure rig site is well

system in place. protected by a reliable smoke & fire

NC detection and alarm system.

NWD shall protect the diesel storage

Diesel storage and refueling area not protected by area with a sufficient no. of fire

fire extinguishers. NC extinguishers “Powder and foam

extinguishers”.

There is no dedicated fire team. Additionally, no

firefighting training for rig crew. NWD shall ensure a sufficient no. of rig

crew has received firefighting training.

NC Apparently, MOG wafa filed HSE Dept.

has proposed to provide a practical

training for rig crew at wafa firefighting

station.

8 General Safety Insufficient no of safety signs at rig site. For NC Ensure a sufficient no. of safety signs

practices instant, at diesel thanks, generators, chemical are installed through all rig site

11 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

storage area, drilling mud shaker, and mud hopper according to areas

/mixing barrel …etc. presented/associated risks and

hazardous.

Pipe racks lacking pipe stopper. NC

Ensure to install Pipe stoppers to all

Pipe racks at rig site.

Unsafe handling & storing of compressed

cylinders; Oxygen, nitrogen, acetylene and CO2 at NC Ensure the safe handling and storing of

rig site. I.e. not secured with a chain or strap in a compressed cylinders I.e. Compressed

proper cylinder cart, and no cylinder cap mixing cylinders shall be secured with a chain

empty cylinders with full ones and mixing different or strap in a proper cylinder cart/rigid

type of gas cylinders together. frame, cylinder cap shall be installed,

proper segregation between empty

cylinders and full ones, and proper

segregation between different types

of gas cylinders.

Body harness located at rig floor are improperly

stored and not inspected. NC Body harness shall be stored in an

ordinary way and a way from oil, water

and sun in dedicated area. Additionally,

ensure they are frequently inspected

using a dedicated inspection form.

Unsafe practice of diesel refueling process i.e. no

earthing while refueling, no maneuvering while NC NWD shall issue a dedicated safe work

truck attempting to approach diesel tanks, no instruction for refueling process, and

secure pipe connections and diesel leaking. this instruction shall be we well-

explained to relevant workers to

ensure an effective implementation.

Work instruction shall grantee all

relevant safety practices i.e. earthing,

safe maneuvering, secured pipe

connections with no leaks,,,etc.

Electrical cables are laying everywhere on the

12 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

ground along rig site & minicamp, also some of NC NWD shall Reassess the status Electrical

their coating defected and wearied. Additionally, cables switches, extensions and

part of electrical, switches, extensions and junctions by electrician accompanied by

junctions are damaged. on HSE officer. In order to ensure the

rig site is free from electrical, slips and

No evidence of any maintenance and inspection trips hazardous.

program or records for all Rig equipment and tools NWD shall develop a dedicated

NC

i.e. Crane, forklift, lifting devices and accessories, maintenance and inspection program

vehicles, fire pump, emergency equipment … etc. for all Rig equipment and tools i.e.

Absence of Protection barriers and precautionary Crane, forklift, lifting devices and

safety signs around the Water pit “1.8 m depth”. accessories, vehicles, fire pump,

Malfunctioning of controlled descent device at the emergency equipment … etc.

derrick. NC Controlled descent device at the

Derrick shall be inspected and tested to

Unsafe Storing condition of some heavy items guarantee it is proper functioning.

(used/ damaged spare parts) on the roof surface NC

of the electrical workshop container. Ensure a safe storing of items in a

proper and dedicated area for storing.

Additionally, heavy items (used/

damaged spare parts) on the roof

The Outlet H.P. Vent line of Poor Boy Degasser surface of the electrical workshop

(Mud Gas Separator) is unsafely located at container shall be removed.

NC Ensure a safe distance between the

distance less than 2 meters from mud logging unit.

Outlet H.P. Vent line of Poor Boy

Degasser (Mud Gas Separator) and the

Lacking of some safety pins at rig substructure. mud logging unit.

NC A survey and inspection has to be done

to identify missing safety pins. Then,

No material safety data sheet for all chemicals ensure missing safety pins are

13 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

stored at rig site. installed.

O MOG to reinforce all contractor to

provide MSDS for All chemicals stored

Outlet flare vent line was placed unsafely out of at rig site.

burning pit.

Lacking of Safety hose restraining device at all Relocate outlet flare vent line to be at

pressurized hoses lines i.e. Air compressed lines, burning pit.

O

cementing H.P. lines….etc.

Ensure all pressurized hoses lines i.e.

Air compressed lines, cementing H.P.

O lines….etc. are safely secured by a

Water suction pump was unsafely located at the Safety hose restraining device.

top of the water pit basin containment “pith depth

1.6 m”, whenever there is a need to star it up a Relocate the Water suction pump in a

worker shall reach at the top of pit basin safer place a way from top of the water

containment taking the risk of falling into the O pit basin containment to avoid the risk

water pit “depth 1.6 m”. of falling into the water pit.

Some of stairs are bended and might cause

tripping hazards i.e. Rig floor stairs, shale shaker

stairs, mud hopper stairs…etc. A survey and inspection has to be done

to identify and fix all bended stairs to

Poor distribution of eye wash stations /units at rig avoid the risk of slips, trip and falling.

O

site i.e. Rig floor and chemical storage area.

Reassess the distribution of eye wash

stations /units to ensure concerned

area are covered i.e. Rig floor and

O

Although NWD has always an HSE officer available chemical storage area.

on shift, but the person always changed as there

are no fixed/ dedicated HSE officers whom NWD shall appoint/ assign fixed HSE

permanently working in back 2 back shifts and officer whom dedicated to work back 2

O

appointed for this rig & well A58. back for this drilling campaign.

14 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

9 Management of Improper management of Environmental aspects

Environmental at Rig site as follows:

aspects NWD shall ensure no diesel spillage

A Significant quantity of spilled diesel at diesel during refueling process. Additionally,

storage area resulted from poor refueling NC

reinforce the implementation of

process.

precautionary measures to prevent any

solid contamination in case of spillage

i.e. secondary containment, spill kit,

plastic sheets barriers…etc.

Mud chemicals i.e. bentonite, barite, calcium

chloride, soda, and sodium chloride are NC MOG shall reinforce precautionary

improperly managed and stored in non- measures to manage Mud chemicals in

environmentally-friendly manner at rig site i.e. environmentally-friendly manner at the

no containment, no segregation, no labeling, no rig site i.e. proper containment, proper

MSDS, improper handling and dispose-of segregation, labeling, MSDS, proper

damaged/ opened Packages and no Caution handling and dispose-of damaged/

signs. opened Packages, Caution signs…etc.

Lack of waste management plan at Rig site

MOG and NWD shall develop a waste

management plan, and ensure its

NC proper implementation.

Continues leaking of water-based drilling mud

due Poor condition and erosion of water-based MOG shall fix the water-based drilling

drilling mud pit basin containment (the soil mud pit basin containment to prevent

embankment around the bit perimeter); any leak form the pit.

O

A Significant quantity of spilled cement at

MOG shall give clear instructions to it is

Schlumberger pumping cementing unit.

sub-contractor Schlumberger to prohibit

any cement spillage at the rig site.

15 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

NWD shall properly store lubricant Oil

A moderate quantity of lubricant Oil drums at drums in a safety and environmentally-

rig site are improperly stored with no friendly manner and enforce

secondary containment, no spill kit and no NC precautionary measures i.e.

labeling. Secondary containment, spill kit,

labeling…etc.

NWD shall develop and implement

Poor management of hazardous generated waste management pan to ensure the

NC

wastes i.e. oil filters, oily rags, exhausted oil proper management of hazardous

and damaged chemical damaged/ opened generated wastes.

Packages.

MOG shall ensure the implementation

of all relevant precautionary measures

Improper management of sewage Pits in terms NC for sewage Pits i.e. Hard barricades,

of; inappropriate location and Health & safety Precaution signs, Proper distance away

precautionary measures. from mini-camp & main camp in terms

of health precaution.

10 HSE training

program and No evidence showing the delivery of HSE training NWD shall develop an HSE training

Competent HSE courses to NWD rig crew including HSE officer and NC plan for all rig crew and insure its

personnel Tool pusher i.e. fire-fighting, first aid, hazard implementation. Training plan shall

identification & risk management, waste handling& cover all HSE essential courses i.e.

management and emergency preparedness. Fire-fighting, first aid, hazard

identification & risk management,

waste handling& management and

emergency preparedness.

Interviewed NWD HSE officer in-charge has not a NWD shall assign HSE officer with an

sufficient level of HSE knowledge and working adequate level of HSE knowledge and

experience in HSE IMS ”HSE key elements and NC working experience in HSE IMS ”HSE

aspects”. key elements and aspects”.

16 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

MOG and NWD shall establish a good

HSE communication between MOG, NWD and sub-

HSE communication with sub-

contractors (SLB, Aljof…,etc) is not well

contractors (SLB, Aljof…,etc), this can

established, where there is no dedicated HSE

be achieved through dedicated

meeting to discuss and address relevant HSE NC

frequent HSE meetings to discuss to

aspects concerns at rig site. For instant, waste

discuss and address relevant HSE

management, housekeeping, storing and handling

aspects concerns at rig site i.e. Waste

of chemicals, general risks and hazardous...etc.

HSE meetings and management, housekeeping, storing

11 and handling of chemicals, general

Communications

risks and hazardous...etc.

During audit opening meeting, auditing team

NWD shall enhance internal

observed a lack of internal communication O

communications between NWD head

between NWD head offices in Tripoli and rig site

offices in Tripoli and rig site

management, where NWD Tool pusher and HSE

management to avoid any

officer were not duly informed in advance about

miscommunication and lack of

this joint HSE Audit.

information.

MOG and NWD shall put in place the

No evidence of emergency response plan for the

Emergency emergency response plan that

well A58 containing emergency responsibilities,

12 preparedness NC approved in well A58 coordination

actions, scenarios contacts, no emergency drills

and response agreement. Additionally, emergency

were conducted. drills and exercises shall be frequently

conducted to ensure the readiness of

rig crew.

13 Occupational Health NWD and its Catering sub-contractor do not own NC

guidelines Occupational Health guidelines. MOG shall Engage NWD and Catering

sub-contractor to adopt Occupational

Health guidelines in line with

17 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

international standard / MOG/Eni NA.

Poor management of first Aid boxes i.e. lack of

All First Aid boxes shall be mounted to

properly stocked first aid kits inside the kitchen, two

the wall, and need regular inspection

14 First Aid boxes were not re-stocked and fixed on the

First Aid boxes O and re-stocked.

designated areas (nearer to the kitchen area).

Additionally, first aid boxes were not regularly

inspected.

Assessed FTW certificates were not meeting the

local regulations requirement, MOG & Eni NA NWD shall ensure the issuance of the

NC

standards. Fitness to Work occupational health

screening certificates from an accredited

Libyan authorities as per Libyan law.

Fitness to work

15 Lack of adequate follow up and documentation FTW

documentation & NC NWD shall apply systemic approach for

health surveillance certification process.

follow up and documentation FTW

certification process.

Not all NWD and sub-contractors staff were having NC NWD shall ensue all own staff and sub-

valid fitness to work certificates.

contractor have valid fitness to work

certificates.

16 Industrial hygiene

Black water and grey water discharged through NC MOG shall ensure the implementation

pipes and disposed into open untreated sewage pits of all relevant precautionary measures

for sewage Pits i.e. Hard barricades,

situated few meters away from sleeping quarters, Precaution signs, Proper distance away

from mini-camp & main camp in terms

18 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

of health precaution.

kitchen, and food storage areas.

Conformation to the highest applicable

Catering staff lack formal hygiene education i.e. no O

records of food handler training, and food handlers standards with regard to local and

international hygiene regulations and

do not have training appropriate to their level of O

responsibility. guidelines.

A hazard analysis and critical control

No implementation of Hazard Analysis and Critical

Control Points (HACCP) system procedures, records points (HACCP) system in place.

and food handler certification. O

No records of water testing, sampling for analysis Water sampling for analysis to be done.

Lighting; need regular proper

were undone.

O maintenance.

Frozen store lacks protective clothing (PPE) when NWD shall provide protective clothing

accessing low temperature zone and handing meat. O (PPE) when accessing low temperature

zone and handing meat.

Poor conditions and bad welfare facilities for Rig NWD shall enhance/improve the

crew at minicamp/rig site. welfare facilities for Rig crew at

minicamp/rig site.

1

Findings: If there is no audit evidence about the deviation – there is no nonconformity. If there is evidence about the deviation – it must be documented as nonconformity

2

Type of Finding:

- NC: Non-Conformity

o Major NC: when the minimum requirements for this element are not fulfilled or numerous deficiencies have been found for more requirements of the element.

o Minor NC: when the requirements for this element are partially fulfilled or not serious deficiencies have been found for some requirements.

- O: Observation / Opportunities for Improvement / Recommendation: when all requirements for this element are fulfilled but it is better to define improvement actions in order to strengthen the level of compliance and to

prevent the occurrence of deficiencies in the future.

- C: Compliance

- P: Positive Practice / Strength Point

19 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

20 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

3. AUDIT CONCLUSION

To be accomplished once

feedback and comments received

from Auditing team members and

MOG wafa filled concerned

parties.

4. REVIEWED DOCUMENTATION

Document Title Reference Review

Date

NWD Quality, Health and safety management system NWD-QHSM rev. 03 17.10.2019

Manual

Coordination Agreement between Eni NA and MOG Nr.117/CPM/GO/2018-2019 07.10.2019

NWD PTW forms -------

Job Risk assessment & Tool box risk assessment Card ------- 17.10.2019

21 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Document Title Reference Review

Date

NWD - Rig 11 Lifting equipment inspection reports 17.10.2019

-------

5. ATTACHMENTS

a) Opening & Closing-out meeting attendees list and interviewed reference figures

22 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

b) Audit Photos

23 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 01: Improper management of lifting accessories

slings

Figure# 02: Drilling Pipe rack lacking pipe stopper of lifting

accessories slings

24 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 03: Lacking of some safety pins at rig substructure

25 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 04: Disconnected H2S and gas detection & alarm system

26 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 05: Unsafe handling of compressed gas cylinders

Figure# 06: Outlet flare vent line unsafely placed out of burning pit

27 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 07: Poor management of diesel refueling and storage process

Figure# 08: Improper storing condition of lubricant oil drums “filled”.

28 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 09: Poor environmental & safety condition at Schlumberger pumping cementing

unit.

Figure# 10: Poor condition and erosion of water-based drilling mud pit

basin containment (the soil embankment around the bit perimeter).

Figure# 11: Llack of safety precaution measures around water pit (1.8 m depth)

i.e. no hard barricade, no precaution sign…etc.

29 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 12: Poor management of chemicals at rig site

30 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 13: Unsafe location of water suction pump (on the top of water

pit basin containment #1.8 m depth)

Figure# 14: Poor operating condition of fire pump i.e.

no maintenance & inspection and uncharged battery.

Figure# 15: Unsafe storage of heavy items on the container’s roof

31 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 16: V. poor condition of electrical cables, sockets, conjunction boxes

Figure# 18: Damaged safe guards

Figure# 17: Poor management

of body harnesses at SLB cementing unit

32 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

Figure# 18: Poor level of housekeeping

Figure# 19: V. Poor condition of swage pits ssituated

close to

minicamp and main camp (less than 11 meters distance)

33 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

HSE AUDIT REPORT

HSE

eni north africa b.v.

34 / 34

REC-HSE-11-enina rev02

This document is the property of eni North Africa B.V.. All rights reserved.

- Warning! This document is uncontrolled when printed -

You might also like

- Pas96 2017 PDFDocument58 pagesPas96 2017 PDFCristalina Do Oeste75% (4)

- Shell Safety in Drilling ManualDocument147 pagesShell Safety in Drilling ManualJacob KeeminkNo ratings yet

- ReportDocument57 pagesReportkasun123745982% (11)

- Checklist For Lifting Plan: S/N Items YES NO RemarksDocument1 pageChecklist For Lifting Plan: S/N Items YES NO RemarksAndrianoNo ratings yet

- Health, Safety & EnvironmentDocument27 pagesHealth, Safety & EnvironmentbilouNo ratings yet

- Fall Protection Survey of RIG 40Document3 pagesFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- Isand Drilling HSE Case Nov 08 Rev A02lDocument310 pagesIsand Drilling HSE Case Nov 08 Rev A02lSalim Muftah100% (5)

- SoBo - Site Inspection ChecklistDocument5 pagesSoBo - Site Inspection ChecklistAndrada Roxana IonescuNo ratings yet

- HACCP ValidationDocument9 pagesHACCP ValidationNurhadi EdogawaNo ratings yet

- World Food Safety Guidelines 2010Document91 pagesWorld Food Safety Guidelines 2010Len Villamoya SimpasNo ratings yet

- Valeura Hse Management System PDFDocument19 pagesValeura Hse Management System PDFAbdelkarimNo ratings yet

- Safety Campaign Poster Topic 2 - Confined Space (Eng)Document1 pageSafety Campaign Poster Topic 2 - Confined Space (Eng)Muhammad TohirNo ratings yet

- Are You in The Line of Fire?: Examples of Hazardous EnergyDocument2 pagesAre You in The Line of Fire?: Examples of Hazardous EnergyMuhammad TohirNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IDocument3 pagesPro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IMohammed Hamza100% (1)

- Short Service Employees ProcedureDocument7 pagesShort Service Employees ProcedureMuhammad Usman100% (1)

- Hazard Hunt Status 26-08-2017Document28 pagesHazard Hunt Status 26-08-2017Yaqoob IbrahimNo ratings yet

- Rig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickDocument5 pagesRig 812-A-001-Jha Prepare and Lower The Rig Floor & DerrickMalik Muhammad Nauman ZiaNo ratings yet

- Harc TLC Kd-1revisiDocument2 pagesHarc TLC Kd-1revisitanjungkasri rayaNo ratings yet

- IADC Gin Pole Guidelines Rig Pass.75140439Document22 pagesIADC Gin Pole Guidelines Rig Pass.75140439Hashimi Juni100% (1)

- Breaking Containment Check ListDocument4 pagesBreaking Containment Check Listromedic36No ratings yet

- NB2 HSE Case Part 5 - Emergency Response Rev 1Document36 pagesNB2 HSE Case Part 5 - Emergency Response Rev 1George MedeirosNo ratings yet

- Hse PlanDocument240 pagesHse PlanWaleed KhalidNo ratings yet

- 01 Introductory Module Admin ManualDocument34 pages01 Introductory Module Admin ManualTaymoor Malek100% (1)

- Monthly Hse Rig InspectionDocument7 pagesMonthly Hse Rig InspectionHidacio Da LimiaNo ratings yet

- Rig - LOUISIANA - JSA-IN-HAL-DF-402 CLEANING OF MIXING TANK 2018.10.28Document7 pagesRig - LOUISIANA - JSA-IN-HAL-DF-402 CLEANING OF MIXING TANK 2018.10.28Aziz AndriyantoNo ratings yet

- F0810 - Pre-Post Rig Move Meetings FormsDocument18 pagesF0810 - Pre-Post Rig Move Meetings FormsPaulNo ratings yet

- Drilling Safety: David Calvert, True Oil Enterprises IncDocument16 pagesDrilling Safety: David Calvert, True Oil Enterprises Inccall_mustafas2361No ratings yet

- Safty BookletDocument8 pagesSafty Bookletjinyuan74No ratings yet

- Rajda Industries & Exports Pvt. LTD Fire Safety Checklist SA8000:2014Document6 pagesRajda Industries & Exports Pvt. LTD Fire Safety Checklist SA8000:2014AVISEK GHOSHNo ratings yet

- 07.03.09 Rig Move (Working at Height)Document1 page07.03.09 Rig Move (Working at Height)Hamdi RafiekNo ratings yet

- 7c - IOGP 432 Table 1 Draft v3 04062016Document32 pages7c - IOGP 432 Table 1 Draft v3 04062016Idada Ezekiel100% (1)

- Hydrogen Sulphide (H2S) & Escape Breathing Apparatus (BA)Document91 pagesHydrogen Sulphide (H2S) & Escape Breathing Apparatus (BA)Wahid Husain0% (1)

- Safety Campaign Poster Topic 2 - Zero Harm (Eng)Document1 pageSafety Campaign Poster Topic 2 - Zero Harm (Eng)Muhammad TohirNo ratings yet

- SP2000 Road Safety StandardDocument120 pagesSP2000 Road Safety StandardSunder TrichyNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- #101 - Oilfield HSE Inspection HandbookDocument30 pages#101 - Oilfield HSE Inspection HandbookEagle EyeNo ratings yet

- PR001 HSE Auditing ProcedureDocument19 pagesPR001 HSE Auditing ProcedureThien NguyenNo ratings yet

- Confined-Sop - Qatar SteelDocument28 pagesConfined-Sop - Qatar SteelUnais RahmanNo ratings yet

- Objectives: CareerDocument14 pagesObjectives: CareerHedi Ben MohamedNo ratings yet

- Tennin HAZOPDocument4 pagesTennin HAZOPMohamed SamirNo ratings yet

- Cp-122 Hse ManualDocument1 pageCp-122 Hse ManualAnonymous IeFbdsfCoNo ratings yet

- H2S Contingency PlanDocument33 pagesH2S Contingency PlanAnonymous JMuM0E5YO100% (1)

- Well Handover DocumentDocument1 pageWell Handover DocumentCadiffNo ratings yet

- OIl Rig Safety ChecklistDocument10 pagesOIl Rig Safety ChecklistTom TaoNo ratings yet

- Apprisk Assessment HAZOPDocument1 pageApprisk Assessment HAZOPHakim YahiaouiNo ratings yet

- Hsem-Sp-0014 Nidaa Journey ManagementDocument6 pagesHsem-Sp-0014 Nidaa Journey ManagementAhmed Imtiaz RaoNo ratings yet

- Dragon OilDocument34 pagesDragon OilDavinNo ratings yet

- Emergency Response & Contigency Planning StandardDocument15 pagesEmergency Response & Contigency Planning Standardbilou100% (1)

- Nipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01Document1 pageNipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01cmrig74No ratings yet

- 2 32 2 1 13 01-CS-ProcedureDocument30 pages2 32 2 1 13 01-CS-ProcedureMahmoud SaiedNo ratings yet

- UEP-HL Stop Cards Feb - 2017Document59 pagesUEP-HL Stop Cards Feb - 2017Yaqoob Ibrahim100% (1)

- Checklist For Safe UseDocument33 pagesChecklist For Safe UseShahpour SotoudehNo ratings yet

- Safety Performance Indicators - Motor Vehicle Crash Data - 2008-2019Document56 pagesSafety Performance Indicators - Motor Vehicle Crash Data - 2008-2019TFattahNo ratings yet

- Visible Safety and Induction: Hse Management Visit ChecklistDocument6 pagesVisible Safety and Induction: Hse Management Visit ChecklistHARSHALNo ratings yet

- SIPP Training - 064413Document11 pagesSIPP Training - 064413Ndi FlavourNo ratings yet

- Daily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryDocument5 pagesDaily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- Well Operations Crew Resource ManagementDocument2 pagesWell Operations Crew Resource ManagementJassieNo ratings yet

- 01.01. HSE ManagementDocument64 pages01.01. HSE ManagementHussainNo ratings yet

- HSE MS Training Feb 2019Document17 pagesHSE MS Training Feb 2019Tatak Bay AhmedNo ratings yet

- Road & Traffic Safety Procedure: Pars Oil & Gas CompanyDocument29 pagesRoad & Traffic Safety Procedure: Pars Oil & Gas CompanyKostan Abdillah100% (1)

- MIM1185.001 MIMs Numerical IndexDocument4 pagesMIM1185.001 MIMs Numerical IndexGeorge Zormpas100% (1)

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- DRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019Document35 pagesDRAFT# HSE Audit Report NWD - Rig 11 - Well A 58 - Wafa Field 27-28. Oct. 2019SamerNo ratings yet

- Attachment 3 - Mog-Hseq-F-292 Rev A1 - GHG - 4yp - FormDocument20 pagesAttachment 3 - Mog-Hseq-F-292 Rev A1 - GHG - 4yp - FormSamerNo ratings yet

- MOG-CIMS-P-112 Rev A2 Corporate PPE ManagementfdfdDocument55 pagesMOG-CIMS-P-112 Rev A2 Corporate PPE ManagementfdfdSamerNo ratings yet

- Attachment 1 - Water, Waste & Spill DATA - Environmental ReportDocument25 pagesAttachment 1 - Water, Waste & Spill DATA - Environmental ReportSamerNo ratings yet

- MOG-HSEQ-H-P-116 Rev A1 Corporate Standards For Local Medical FacilitiesDocument75 pagesMOG-HSEQ-H-P-116 Rev A1 Corporate Standards For Local Medical FacilitiesSamerNo ratings yet

- MOG-HSEQ-H-P-019 Rev A1 Fitness To Work & Health SurveillanceDocument33 pagesMOG-HSEQ-H-P-019 Rev A1 Fitness To Work & Health SurveillanceSamerNo ratings yet

- MOG-HSEQ-E-P-113 Rev A1 Corporate Air Emissions Management PorocedureDocument85 pagesMOG-HSEQ-E-P-113 Rev A1 Corporate Air Emissions Management PorocedureSamerNo ratings yet

- MOG-HSEQ-E-P-113 Rev A1 Corporate Air Emissions Management PorocedureDocument85 pagesMOG-HSEQ-E-P-113 Rev A1 Corporate Air Emissions Management PorocedureSamerNo ratings yet

- Food Delivery Truck Inspection Form2016Document2 pagesFood Delivery Truck Inspection Form2016Samer100% (1)

- MOG-CIMS-P-112 Rev A1 Corporate PPE ManagementDocument57 pagesMOG-CIMS-P-112 Rev A1 Corporate PPE ManagementSamerNo ratings yet

- Case Study 01-16 - ENDocument6 pagesCase Study 01-16 - ENSamerNo ratings yet

- Case Study 03-16 - ENDocument8 pagesCase Study 03-16 - ENSamerNo ratings yet

- Food Delivery Truck Inspection 21-9-2016Document2 pagesFood Delivery Truck Inspection 21-9-2016SamerNo ratings yet

- 10SF.15 MOG HSEQ SF P 0110 A1 Confined Space ProcedureDocument38 pages10SF.15 MOG HSEQ SF P 0110 A1 Confined Space ProcedureSamerNo ratings yet

- Weld Inspection ReportDocument12 pagesWeld Inspection ReportSamerNo ratings yet

- 10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetyDocument21 pages10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetySamerNo ratings yet

- Paint Inspection ReportDocument2 pagesPaint Inspection ReportSamerNo ratings yet

- Separator Data SheetDocument2 pagesSeparator Data SheetSamerNo ratings yet

- As Built DrawingDocument3 pagesAs Built DrawingSamerNo ratings yet

- Dimentional ReportDocument1 pageDimentional ReportSamerNo ratings yet

- MOG-HSEQ-P-xxx Rev P1 PPE ManagementDocument47 pagesMOG-HSEQ-P-xxx Rev P1 PPE ManagementSamerNo ratings yet

- Mellitah Oil & Gas BV: Libyan BranchDocument8 pagesMellitah Oil & Gas BV: Libyan BranchSamerNo ratings yet

- MOG-CIMS-P-112 Rev A1 Corporate PPE ManagementDocument55 pagesMOG-CIMS-P-112 Rev A1 Corporate PPE ManagementSamerNo ratings yet

- ﺘﯿﻠﻣ ــ ﻔﻨﻠﻟ ﺔـ ــ ـﻐﻟاو ﻂـ ــ ﻲﺑ زﺎ - ﭬ ﻲ Mellitah Oil &Gas B.V Libyan BrancDocument2 pagesﺘﯿﻠﻣ ــ ﻔﻨﻠﻟ ﺔـ ــ ـﻐﻟاو ﻂـ ــ ﻲﺑ زﺎ - ﭬ ﻲ Mellitah Oil &Gas B.V Libyan BrancSamerNo ratings yet

- Mog-Cims-P-112 Rev A1 Ppe ManagementDocument56 pagesMog-Cims-P-112 Rev A1 Ppe ManagementSamerNo ratings yet

- Calendar 2017 enDocument14 pagesCalendar 2017 enSamerNo ratings yet

- HACCP in The Chocolate Industry: J.-L. CordierDocument5 pagesHACCP in The Chocolate Industry: J.-L. CordierMauro Antonio Villalobos KramNo ratings yet

- Fishbone Cause and Effect DiagramDocument1 pageFishbone Cause and Effect DiagramsitimaezyarohNo ratings yet

- Neogen - Effective Testing Components of An Environmental Monitoring Program PDFDocument12 pagesNeogen - Effective Testing Components of An Environmental Monitoring Program PDFAngga PrasetyoNo ratings yet

- Cocu 2 (Sweet and Savoury Filling Preparation)Document14 pagesCocu 2 (Sweet and Savoury Filling Preparation)Fadilah MazlanNo ratings yet

- Principles of Haccp SystemDocument4 pagesPrinciples of Haccp SystemLider Castillo0% (1)

- RA 10611 or The Food Safety Act 2013Document33 pagesRA 10611 or The Food Safety Act 2013jercherwinNo ratings yet

- 10 Gabriel Mainer Albiac - Principles Haccp Oil RefiningDocument38 pages10 Gabriel Mainer Albiac - Principles Haccp Oil RefiningMuhammad WaseemNo ratings yet

- Haccp, Ssop and GMPDocument49 pagesHaccp, Ssop and GMPManantan Ma. KatherinaNo ratings yet

- Final Operation MGM Report-LibreDocument16 pagesFinal Operation MGM Report-LibressimisimiNo ratings yet

- Implementation of FSMS ISO 22000:2005 in Small Medium EnterprisesDocument53 pagesImplementation of FSMS ISO 22000:2005 in Small Medium Enterprisesfaisalrafique100% (8)

- Compliance With Food SafetyDocument203 pagesCompliance With Food SafetyHsamb Abm100% (1)

- Departmental Organisation & Staffing: Unit 2Document22 pagesDepartmental Organisation & Staffing: Unit 2Yash SankhlaNo ratings yet

- Tata Steel: Mr. Partha Sengupta Vice President, Raw MaterialsDocument18 pagesTata Steel: Mr. Partha Sengupta Vice President, Raw MaterialsbinumalhotraNo ratings yet

- FDC Organic Virgin Coconut Oil Hazard Analysis and Critical Control Points Plan PDFDocument3 pagesFDC Organic Virgin Coconut Oil Hazard Analysis and Critical Control Points Plan PDFWynona Basilio100% (3)

- Company Profile Intrafood Citarasa Nusantara PDFDocument24 pagesCompany Profile Intrafood Citarasa Nusantara PDFdann yanuar50% (2)

- FF-TNI-001 Rev. 04 Questionnaire - Preparation For ISO 22000 or HACCP PDFDocument13 pagesFF-TNI-001 Rev. 04 Questionnaire - Preparation For ISO 22000 or HACCP PDFRenaldo MoontriNo ratings yet

- Principles of Food SanitationDocument201 pagesPrinciples of Food Sanitationayman shamsNo ratings yet

- ISO 22000 Gap Analysis: Text ChangeDocument8 pagesISO 22000 Gap Analysis: Text ChangeJmy GbuNo ratings yet

- Pesticides, Food Safety, Gaps, Sustainability, and The California Pistachio IndustryDocument12 pagesPesticides, Food Safety, Gaps, Sustainability, and The California Pistachio IndustryDorin BadiuNo ratings yet

- Traditional Fermented MilkDocument5 pagesTraditional Fermented MilkPraveen KumarNo ratings yet

- Hazard Analysis Critical Control Point (HACCP) Plan Submission Guidelines PDFDocument8 pagesHazard Analysis Critical Control Point (HACCP) Plan Submission Guidelines PDFThuyền TháiNo ratings yet

- Notice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsDocument2 pagesNotice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsJustia.com100% (1)

- 2021 Food Safety Officer Book - SWA EducationDocument552 pages2021 Food Safety Officer Book - SWA EducationMaritza Mercedes Zambrano IntriagoNo ratings yet

- Codex AlimentariusDocument18 pagesCodex AlimentariusprincessicyjulietNo ratings yet

- Plant Manager Operations in Rochester NY Resume Mark AsbrandDocument3 pagesPlant Manager Operations in Rochester NY Resume Mark AsbrandMark AsbrandNo ratings yet

- Food Safety Alerts - A Case Study On An Advanced Rapid Alert SystemDocument8 pagesFood Safety Alerts - A Case Study On An Advanced Rapid Alert Systemdijana9No ratings yet