Professional Documents

Culture Documents

Simulation Assignment: Farah Naz ERP ID: 18535

Simulation Assignment: Farah Naz ERP ID: 18535

Uploaded by

Adnan SiddiqiCopyright:

Available Formats

You might also like

- Operations and Supply Management Simulation Anita Souza Davenport University MGMT757Document22 pagesOperations and Supply Management Simulation Anita Souza Davenport University MGMT757Andrew Neuber90% (10)

- Gillette vs. EnergizerDocument5 pagesGillette vs. EnergizerAshish Singh RainuNo ratings yet

- MCQ Law MidtermDocument81 pagesMCQ Law MidtermkaksdvoNo ratings yet

- Vodites - Mds and SemanticDocument5 pagesVodites - Mds and SemanticAnyone SomeoneNo ratings yet

- Lisa BentonDocument8 pagesLisa BentonShrikant JirapureNo ratings yet

- Payload CIGTC-46639 INVDocument4 pagesPayload CIGTC-46639 INVmbraghumb9019No ratings yet

- IMT - OCEAN ActivityDocument4 pagesIMT - OCEAN ActivityViren BansalNo ratings yet

- Chapter 1 Management and Personnel FeasibilityDocument25 pagesChapter 1 Management and Personnel Feasibility버니 모지코50% (2)

- TechCoop Deck - Short ENG 11.9.22Document10 pagesTechCoop Deck - Short ENG 11.9.22Minh LeNo ratings yet

- BAFI3182-FINANCIAL MARKETS Assignment 3 Research PaperDocument16 pagesBAFI3182-FINANCIAL MARKETS Assignment 3 Research PaperChu Ngoc AnhNo ratings yet

- Global Supply Chain M11207Document4 pagesGlobal Supply Chain M11207Anonymous VVSLkDOAC133% (3)

- Case-3 Vinay Kalra PGFC1948Document5 pagesCase-3 Vinay Kalra PGFC1948Vinay KalraNo ratings yet

- Case Study 27 V2Document10 pagesCase Study 27 V2mrchardNo ratings yet

- Stability, Conglomerate Strategy and VariantsDocument13 pagesStability, Conglomerate Strategy and VariantssukruthiNo ratings yet

- GSCM Sim ManualDocument9 pagesGSCM Sim ManualSana BhittaniNo ratings yet

- Imt 69Document4 pagesImt 69arun1974No ratings yet

- GSCMS PlayermanualDocument15 pagesGSCMS Playermanualhemanthsoni16No ratings yet

- Record Sheet, Year 1 NameDocument5 pagesRecord Sheet, Year 1 NameAbirami AsokkumarNo ratings yet

- GSCMRecord SheetsDocument5 pagesGSCMRecord SheetsJoe HigginsNo ratings yet

- IMT-01 Dec 09Document2 pagesIMT-01 Dec 09Fin CorpNo ratings yet

- Digital Business Innovation - Mannam SreedeviDocument4 pagesDigital Business Innovation - Mannam SreedeviSreedevi MannamNo ratings yet

- Solutions Balancing Process Capacity Simulation Challenge 1 and Challange 2Document29 pagesSolutions Balancing Process Capacity Simulation Challenge 1 and Challange 2Mariam AlraeesiNo ratings yet

- Operations Strategy - Simulation NotesDocument4 pagesOperations Strategy - Simulation NotesOlle Green0% (1)

- A Case Study On JioDocument9 pagesA Case Study On JioAnonymous CwJeBCAXpNo ratings yet

- Simulacion GSCMV2 Instrucciones de JuegoDocument8 pagesSimulacion GSCMV2 Instrucciones de Juegodiego jNo ratings yet

- IMT EverestDocument2 pagesIMT EverestDebasish PattanaikNo ratings yet

- Chapter Ten: ForecastingDocument49 pagesChapter Ten: ForecastingK59 Tran Gia KhanhNo ratings yet

- M4W6 GSCM SoloAssignment RecordSheetsDocument8 pagesM4W6 GSCM SoloAssignment RecordSheetsKai DooeNo ratings yet

- Quality Analytics SimulationDocument2 pagesQuality Analytics SimulationNehir AltıparmakNo ratings yet

- Case Study 20202712Document4 pagesCase Study 20202712rabbi sodhiNo ratings yet

- Random Motors Project Submission: Name - Rohith MuralidharanDocument10 pagesRandom Motors Project Submission: Name - Rohith MuralidharanRohith muralidharanNo ratings yet

- OPSCMProject AnirudhaChakrabortyDocument5 pagesOPSCMProject AnirudhaChakrabortyAnirudha ChakrabortyNo ratings yet

- OPSCMProject AniDocument6 pagesOPSCMProject Anianiket.negi1996No ratings yet

- Global Supply Chain Management SimulationDocument9 pagesGlobal Supply Chain Management SimulationJawadNo ratings yet

- Section D - OSD - Group 5Document6 pagesSection D - OSD - Group 5Chidananda PuriNo ratings yet

- Grid OD: Pramod DhawanDocument13 pagesGrid OD: Pramod DhawanPrabhakar DhavanNo ratings yet

- Quality Talk May 2019Document13 pagesQuality Talk May 2019AnkurNo ratings yet

- Project Management-Case Presentation 1 Assignment Questions: Vertex Pharmaceuticals: R& D Portfolio ManagementDocument1 pageProject Management-Case Presentation 1 Assignment Questions: Vertex Pharmaceuticals: R& D Portfolio ManagementAnubhav JainNo ratings yet

- Imt 24Document3 pagesImt 24subhadipsen52100% (1)

- Group Work 4 Reinventing Performance MGMT DelloiteDocument1 pageGroup Work 4 Reinventing Performance MGMT DelloiteVijay RNo ratings yet

- Assignment 1 Back Bay Battery Simulation Shreya Gupta Final PDFDocument10 pagesAssignment 1 Back Bay Battery Simulation Shreya Gupta Final PDFAditya MohamadNo ratings yet

- Pitch Deck Upgrad UpdatedDocument14 pagesPitch Deck Upgrad UpdatedShivam GuptaNo ratings yet

- Rocinante 36 Marengo 32 Mileage (KM/LTR) Top Speed (KM/HR) Mileage (KM/LTR) Top Speed (KM/HR)Document5 pagesRocinante 36 Marengo 32 Mileage (KM/LTR) Top Speed (KM/HR) Mileage (KM/LTR) Top Speed (KM/HR)dharmendra2271993No ratings yet

- Digital Business InnovationDocument5 pagesDigital Business Innovationanju antonyNo ratings yet

- Sineflex Solutions Partnering For Healthcare InnovationDocument9 pagesSineflex Solutions Partnering For Healthcare InnovationDeblina MitraNo ratings yet

- Leading-Change SU08Document8 pagesLeading-Change SU08harshnvicky123No ratings yet

- HBSP Global SC Decision Record TemplateDocument4 pagesHBSP Global SC Decision Record TemplateIman Christin Wirawan0% (1)

- Assignment 2 Group 4BDocument5 pagesAssignment 2 Group 4BBhumika VishnoiNo ratings yet

- PGP MAJVCG 2019-20 S3 Unrelated Diversification PDFDocument22 pagesPGP MAJVCG 2019-20 S3 Unrelated Diversification PDFBschool caseNo ratings yet

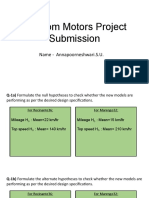

- Random Motors Project Submission: Name - Annapoorneshwari.S.UDocument10 pagesRandom Motors Project Submission: Name - Annapoorneshwari.S.Uannapoorneshwari suNo ratings yet

- IMT - Project Submission - Change ManagementDocument7 pagesIMT - Project Submission - Change ManagementRajesh KommineniNo ratings yet

- Case Study On Blue Ocean StrategyDocument6 pagesCase Study On Blue Ocean Strategyarvind sharmaNo ratings yet

- Ceres Gardening Company Submission TemplateDocument2 pagesCeres Gardening Company Submission TemplateSreyashi GhoshNo ratings yet

- RamkrishnaBhandare Project Submission LeadershipDocument14 pagesRamkrishnaBhandare Project Submission LeadershipAarya BhandareNo ratings yet

- Business Model CanvasDocument1 pageBusiness Model CanvasKiran Kumar MallickNo ratings yet

- Small PDFDocument41 pagesSmall PDFNimisha Palawat100% (1)

- Karandeep - Random MotorDocument10 pagesKarandeep - Random MotorRishabh TiwariNo ratings yet

- OPSCMProject SssDocument3 pagesOPSCMProject SssSudhansu Sekhar SinghNo ratings yet

- Swot AnalysisDocument3 pagesSwot AnalysisYashashvi RastogiNo ratings yet

- Shyam.B RandomMotorsDocument10 pagesShyam.B RandomMotorsShyam StarcNo ratings yet

- OPSCMProjectDocument4 pagesOPSCMProjectRinku SinghNo ratings yet

- Assignment 1 - TerraCogDocument6 pagesAssignment 1 - TerraCogEina GuptaNo ratings yet

- Exercise 3Document5 pagesExercise 3Mikhail Aron GorreNo ratings yet

- Developing A Competitive Strategy 1 CompressedDocument55 pagesDeveloping A Competitive Strategy 1 CompressedneffhbaculodmzNo ratings yet

- Nitin Gupta Synopsis)Document12 pagesNitin Gupta Synopsis)tanishka1981No ratings yet

- REKO DIQ Case (Write-Up)Document1 pageREKO DIQ Case (Write-Up)Adnan SiddiqiNo ratings yet

- The Control of Decision and Liability of The CompanyDocument1 pageThe Control of Decision and Liability of The CompanyAdnan SiddiqiNo ratings yet

- IPE - Adnan - 18508Document7 pagesIPE - Adnan - 18508Adnan SiddiqiNo ratings yet

- Case Brief - Adnan - 18508Document2 pagesCase Brief - Adnan - 18508Adnan Siddiqi0% (1)

- OPM ProjectDocument4 pagesOPM ProjectAdnan SiddiqiNo ratings yet

- Visual Merchandising and DisplayDocument45 pagesVisual Merchandising and Displayrakadimass17No ratings yet

- E-Commerce Manager ResumeDocument3 pagesE-Commerce Manager Resumemuhammed SabryNo ratings yet

- At 31 May 20X7 RobertaDocument6 pagesAt 31 May 20X7 RobertaTrung Anh NguyenNo ratings yet

- Dissertation Final Proposal Patricia ChabataDocument19 pagesDissertation Final Proposal Patricia ChabataPaul Bunhu100% (2)

- A Study On Ratio Analysis at Leading Commercial Banks in IndiaDocument19 pagesA Study On Ratio Analysis at Leading Commercial Banks in IndiaCentral Asian StudiesNo ratings yet

- ĐHTMDocument3 pagesĐHTMNgọc MaiNo ratings yet

- Marris Theory: AssumptionsDocument3 pagesMarris Theory: Assumptionssara100% (1)

- Question 1&2Document21 pagesQuestion 1&2May MansiaNo ratings yet

- Ud, BuanaDocument9 pagesUd, Buanafitrianura04No ratings yet

- Rev v01 Genzyme and Relational Investors - Science and Business CollideDocument5 pagesRev v01 Genzyme and Relational Investors - Science and Business CollideEffendi AndokoNo ratings yet

- Color-Coding:: Step 1 - Enter Info About Your Company in Yellow Shaded Boxes BelowDocument26 pagesColor-Coding:: Step 1 - Enter Info About Your Company in Yellow Shaded Boxes BelowBangesweNo ratings yet

- EMT 301 Lecture 4 - Copy - Copy-1Document31 pagesEMT 301 Lecture 4 - Copy - Copy-1Abraham Temitope AkinnurojuNo ratings yet

- Campus Proposition 2024 ICICI BankDocument31 pagesCampus Proposition 2024 ICICI Bankajith vNo ratings yet

- BTS - Design Thinking Canvasses For Student ProgramsDocument18 pagesBTS - Design Thinking Canvasses For Student ProgramsJoseph CadelinaNo ratings yet

- Business LetterDocument5 pagesBusiness Lettermjpason0425No ratings yet

- 3.3.2 Brand Extension - Brand Reinforcement, Brand RevitalizationDocument12 pages3.3.2 Brand Extension - Brand Reinforcement, Brand RevitalizationKetan MahajanNo ratings yet

- Business Plan Sandwich Queens1Document10 pagesBusiness Plan Sandwich Queens1Alyzza CasinoNo ratings yet

- Adjustments To Reconcile Net Income To Net Cash Provided by Operating ActivitiesDocument4 pagesAdjustments To Reconcile Net Income To Net Cash Provided by Operating ActivitiesTasim IshraqueNo ratings yet

- Year Examination Institution Marks ObtainedDocument2 pagesYear Examination Institution Marks ObtainedTanya SinghNo ratings yet

- Econ2113 PS2Document5 pagesEcon2113 PS2jacky114aaNo ratings yet

- Test Bank For Supply Management 8th Edition David N BurtDocument10 pagesTest Bank For Supply Management 8th Edition David N BurtShamika Bejaran100% (27)

- The B2B Executive Playbook: Achieving Sustainable, Predictable, Profitable GrowthDocument21 pagesThe B2B Executive Playbook: Achieving Sustainable, Predictable, Profitable GrowthSasi KumarNo ratings yet

- Types of Media: Lecture - 3Document21 pagesTypes of Media: Lecture - 3MUHAMMAD ZAINNo ratings yet

- Third Quarter ExamDocument6 pagesThird Quarter ExamRaul Soriano Cabanting100% (4)

- Hfsafety 1 SEM 22-23: Click To Add Text Click To Add TextDocument70 pagesHfsafety 1 SEM 22-23: Click To Add Text Click To Add TextAdrienne CoNo ratings yet

Simulation Assignment: Farah Naz ERP ID: 18535

Simulation Assignment: Farah Naz ERP ID: 18535

Uploaded by

Adnan SiddiqiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simulation Assignment: Farah Naz ERP ID: 18535

Simulation Assignment: Farah Naz ERP ID: 18535

Uploaded by

Adnan SiddiqiCopyright:

Available Formats

FARAH NAZ

ERP ID: 18535

SIMULATION ASSIGNMENT

INTRODUCTION:

I have been hired as a Supply Chain Manager responsible for production of two new lines of

mobile phones; Model A and Model B. Model A is a base model and Model B is a high end

model. My task is to make key decisions on which features to include and to whom to

outsource the work by keeping in mind the sales season i.e; May through December.

Ultimately, the final objective is to forecast sales and profitability for the next four years.

IMPORTANT QUESTIONS:

Following questions were kept in mind before making the decision.

Q1. What will be the demand for reach year?

Q2. How much production is needed?

Q3. Which supplier should be selected for outsourcing?

Q4. Which features to include in the mobile phone?

Q5. Should we invest in marketing activities?

IMPORTANT FACTORS FOR DECISION MAKING:

Decisions were made on the basis of two factors.

- Profitability.

- Number of votes from board members.

DECISION MAKING PROCESS:

FEATURES DEMAND SUPPLIER MARKETING ANY CHANGE

SELECTION IN

ACTIVITY

AND PRODUCTION

PRODUCTION

ORDER

1. FEATURES:

Several features were added and eliminated on the basis of their impact on the demand of

phones. Each feature alone or in combination led to forecasted demand and profit per unit.

The features with the highest profit per unit and most votes were selected.

2. DEMAND:

Consensus demand was forecasted by taking into consideration the standard deviation to

see if there is any outlier that is causing average demand to deviate. Also, each board

member gave their respective opinions on demand which really helped in forecasting the

actual demand.

3. SUPPLIER SELECTION AND PRODUCTION ORDER:

Two suppliers were selected; one was far-away supplier with a relatively larger lead time

than the local supplier with zero lead time. This combination was selected on the basis of

two factors; Cost per unit and zero lead time.

4. MARKETING ACTIVITY:

We invested in marketing for three years because we considered it to be important for our

supplier decision making and also for creating demand.

5. CHANGE IN PRODUCTION:

We had a simple strategy, each year we planned to pay $2,000,000 for change in production

because fluctuations could cost us more than $2 million if not addressed.

You might also like

- Operations and Supply Management Simulation Anita Souza Davenport University MGMT757Document22 pagesOperations and Supply Management Simulation Anita Souza Davenport University MGMT757Andrew Neuber90% (10)

- Gillette vs. EnergizerDocument5 pagesGillette vs. EnergizerAshish Singh RainuNo ratings yet

- MCQ Law MidtermDocument81 pagesMCQ Law MidtermkaksdvoNo ratings yet

- Vodites - Mds and SemanticDocument5 pagesVodites - Mds and SemanticAnyone SomeoneNo ratings yet

- Lisa BentonDocument8 pagesLisa BentonShrikant JirapureNo ratings yet

- Payload CIGTC-46639 INVDocument4 pagesPayload CIGTC-46639 INVmbraghumb9019No ratings yet

- IMT - OCEAN ActivityDocument4 pagesIMT - OCEAN ActivityViren BansalNo ratings yet

- Chapter 1 Management and Personnel FeasibilityDocument25 pagesChapter 1 Management and Personnel Feasibility버니 모지코50% (2)

- TechCoop Deck - Short ENG 11.9.22Document10 pagesTechCoop Deck - Short ENG 11.9.22Minh LeNo ratings yet

- BAFI3182-FINANCIAL MARKETS Assignment 3 Research PaperDocument16 pagesBAFI3182-FINANCIAL MARKETS Assignment 3 Research PaperChu Ngoc AnhNo ratings yet

- Global Supply Chain M11207Document4 pagesGlobal Supply Chain M11207Anonymous VVSLkDOAC133% (3)

- Case-3 Vinay Kalra PGFC1948Document5 pagesCase-3 Vinay Kalra PGFC1948Vinay KalraNo ratings yet

- Case Study 27 V2Document10 pagesCase Study 27 V2mrchardNo ratings yet

- Stability, Conglomerate Strategy and VariantsDocument13 pagesStability, Conglomerate Strategy and VariantssukruthiNo ratings yet

- GSCM Sim ManualDocument9 pagesGSCM Sim ManualSana BhittaniNo ratings yet

- Imt 69Document4 pagesImt 69arun1974No ratings yet

- GSCMS PlayermanualDocument15 pagesGSCMS Playermanualhemanthsoni16No ratings yet

- Record Sheet, Year 1 NameDocument5 pagesRecord Sheet, Year 1 NameAbirami AsokkumarNo ratings yet

- GSCMRecord SheetsDocument5 pagesGSCMRecord SheetsJoe HigginsNo ratings yet

- IMT-01 Dec 09Document2 pagesIMT-01 Dec 09Fin CorpNo ratings yet

- Digital Business Innovation - Mannam SreedeviDocument4 pagesDigital Business Innovation - Mannam SreedeviSreedevi MannamNo ratings yet

- Solutions Balancing Process Capacity Simulation Challenge 1 and Challange 2Document29 pagesSolutions Balancing Process Capacity Simulation Challenge 1 and Challange 2Mariam AlraeesiNo ratings yet

- Operations Strategy - Simulation NotesDocument4 pagesOperations Strategy - Simulation NotesOlle Green0% (1)

- A Case Study On JioDocument9 pagesA Case Study On JioAnonymous CwJeBCAXpNo ratings yet

- Simulacion GSCMV2 Instrucciones de JuegoDocument8 pagesSimulacion GSCMV2 Instrucciones de Juegodiego jNo ratings yet

- IMT EverestDocument2 pagesIMT EverestDebasish PattanaikNo ratings yet

- Chapter Ten: ForecastingDocument49 pagesChapter Ten: ForecastingK59 Tran Gia KhanhNo ratings yet

- M4W6 GSCM SoloAssignment RecordSheetsDocument8 pagesM4W6 GSCM SoloAssignment RecordSheetsKai DooeNo ratings yet

- Quality Analytics SimulationDocument2 pagesQuality Analytics SimulationNehir AltıparmakNo ratings yet

- Case Study 20202712Document4 pagesCase Study 20202712rabbi sodhiNo ratings yet

- Random Motors Project Submission: Name - Rohith MuralidharanDocument10 pagesRandom Motors Project Submission: Name - Rohith MuralidharanRohith muralidharanNo ratings yet

- OPSCMProject AnirudhaChakrabortyDocument5 pagesOPSCMProject AnirudhaChakrabortyAnirudha ChakrabortyNo ratings yet

- OPSCMProject AniDocument6 pagesOPSCMProject Anianiket.negi1996No ratings yet

- Global Supply Chain Management SimulationDocument9 pagesGlobal Supply Chain Management SimulationJawadNo ratings yet

- Section D - OSD - Group 5Document6 pagesSection D - OSD - Group 5Chidananda PuriNo ratings yet

- Grid OD: Pramod DhawanDocument13 pagesGrid OD: Pramod DhawanPrabhakar DhavanNo ratings yet

- Quality Talk May 2019Document13 pagesQuality Talk May 2019AnkurNo ratings yet

- Project Management-Case Presentation 1 Assignment Questions: Vertex Pharmaceuticals: R& D Portfolio ManagementDocument1 pageProject Management-Case Presentation 1 Assignment Questions: Vertex Pharmaceuticals: R& D Portfolio ManagementAnubhav JainNo ratings yet

- Imt 24Document3 pagesImt 24subhadipsen52100% (1)

- Group Work 4 Reinventing Performance MGMT DelloiteDocument1 pageGroup Work 4 Reinventing Performance MGMT DelloiteVijay RNo ratings yet

- Assignment 1 Back Bay Battery Simulation Shreya Gupta Final PDFDocument10 pagesAssignment 1 Back Bay Battery Simulation Shreya Gupta Final PDFAditya MohamadNo ratings yet

- Pitch Deck Upgrad UpdatedDocument14 pagesPitch Deck Upgrad UpdatedShivam GuptaNo ratings yet

- Rocinante 36 Marengo 32 Mileage (KM/LTR) Top Speed (KM/HR) Mileage (KM/LTR) Top Speed (KM/HR)Document5 pagesRocinante 36 Marengo 32 Mileage (KM/LTR) Top Speed (KM/HR) Mileage (KM/LTR) Top Speed (KM/HR)dharmendra2271993No ratings yet

- Digital Business InnovationDocument5 pagesDigital Business Innovationanju antonyNo ratings yet

- Sineflex Solutions Partnering For Healthcare InnovationDocument9 pagesSineflex Solutions Partnering For Healthcare InnovationDeblina MitraNo ratings yet

- Leading-Change SU08Document8 pagesLeading-Change SU08harshnvicky123No ratings yet

- HBSP Global SC Decision Record TemplateDocument4 pagesHBSP Global SC Decision Record TemplateIman Christin Wirawan0% (1)

- Assignment 2 Group 4BDocument5 pagesAssignment 2 Group 4BBhumika VishnoiNo ratings yet

- PGP MAJVCG 2019-20 S3 Unrelated Diversification PDFDocument22 pagesPGP MAJVCG 2019-20 S3 Unrelated Diversification PDFBschool caseNo ratings yet

- Random Motors Project Submission: Name - Annapoorneshwari.S.UDocument10 pagesRandom Motors Project Submission: Name - Annapoorneshwari.S.Uannapoorneshwari suNo ratings yet

- IMT - Project Submission - Change ManagementDocument7 pagesIMT - Project Submission - Change ManagementRajesh KommineniNo ratings yet

- Case Study On Blue Ocean StrategyDocument6 pagesCase Study On Blue Ocean Strategyarvind sharmaNo ratings yet

- Ceres Gardening Company Submission TemplateDocument2 pagesCeres Gardening Company Submission TemplateSreyashi GhoshNo ratings yet

- RamkrishnaBhandare Project Submission LeadershipDocument14 pagesRamkrishnaBhandare Project Submission LeadershipAarya BhandareNo ratings yet

- Business Model CanvasDocument1 pageBusiness Model CanvasKiran Kumar MallickNo ratings yet

- Small PDFDocument41 pagesSmall PDFNimisha Palawat100% (1)

- Karandeep - Random MotorDocument10 pagesKarandeep - Random MotorRishabh TiwariNo ratings yet

- OPSCMProject SssDocument3 pagesOPSCMProject SssSudhansu Sekhar SinghNo ratings yet

- Swot AnalysisDocument3 pagesSwot AnalysisYashashvi RastogiNo ratings yet

- Shyam.B RandomMotorsDocument10 pagesShyam.B RandomMotorsShyam StarcNo ratings yet

- OPSCMProjectDocument4 pagesOPSCMProjectRinku SinghNo ratings yet

- Assignment 1 - TerraCogDocument6 pagesAssignment 1 - TerraCogEina GuptaNo ratings yet

- Exercise 3Document5 pagesExercise 3Mikhail Aron GorreNo ratings yet

- Developing A Competitive Strategy 1 CompressedDocument55 pagesDeveloping A Competitive Strategy 1 CompressedneffhbaculodmzNo ratings yet

- Nitin Gupta Synopsis)Document12 pagesNitin Gupta Synopsis)tanishka1981No ratings yet

- REKO DIQ Case (Write-Up)Document1 pageREKO DIQ Case (Write-Up)Adnan SiddiqiNo ratings yet

- The Control of Decision and Liability of The CompanyDocument1 pageThe Control of Decision and Liability of The CompanyAdnan SiddiqiNo ratings yet

- IPE - Adnan - 18508Document7 pagesIPE - Adnan - 18508Adnan SiddiqiNo ratings yet

- Case Brief - Adnan - 18508Document2 pagesCase Brief - Adnan - 18508Adnan Siddiqi0% (1)

- OPM ProjectDocument4 pagesOPM ProjectAdnan SiddiqiNo ratings yet

- Visual Merchandising and DisplayDocument45 pagesVisual Merchandising and Displayrakadimass17No ratings yet

- E-Commerce Manager ResumeDocument3 pagesE-Commerce Manager Resumemuhammed SabryNo ratings yet

- At 31 May 20X7 RobertaDocument6 pagesAt 31 May 20X7 RobertaTrung Anh NguyenNo ratings yet

- Dissertation Final Proposal Patricia ChabataDocument19 pagesDissertation Final Proposal Patricia ChabataPaul Bunhu100% (2)

- A Study On Ratio Analysis at Leading Commercial Banks in IndiaDocument19 pagesA Study On Ratio Analysis at Leading Commercial Banks in IndiaCentral Asian StudiesNo ratings yet

- ĐHTMDocument3 pagesĐHTMNgọc MaiNo ratings yet

- Marris Theory: AssumptionsDocument3 pagesMarris Theory: Assumptionssara100% (1)

- Question 1&2Document21 pagesQuestion 1&2May MansiaNo ratings yet

- Ud, BuanaDocument9 pagesUd, Buanafitrianura04No ratings yet

- Rev v01 Genzyme and Relational Investors - Science and Business CollideDocument5 pagesRev v01 Genzyme and Relational Investors - Science and Business CollideEffendi AndokoNo ratings yet

- Color-Coding:: Step 1 - Enter Info About Your Company in Yellow Shaded Boxes BelowDocument26 pagesColor-Coding:: Step 1 - Enter Info About Your Company in Yellow Shaded Boxes BelowBangesweNo ratings yet

- EMT 301 Lecture 4 - Copy - Copy-1Document31 pagesEMT 301 Lecture 4 - Copy - Copy-1Abraham Temitope AkinnurojuNo ratings yet

- Campus Proposition 2024 ICICI BankDocument31 pagesCampus Proposition 2024 ICICI Bankajith vNo ratings yet

- BTS - Design Thinking Canvasses For Student ProgramsDocument18 pagesBTS - Design Thinking Canvasses For Student ProgramsJoseph CadelinaNo ratings yet

- Business LetterDocument5 pagesBusiness Lettermjpason0425No ratings yet

- 3.3.2 Brand Extension - Brand Reinforcement, Brand RevitalizationDocument12 pages3.3.2 Brand Extension - Brand Reinforcement, Brand RevitalizationKetan MahajanNo ratings yet

- Business Plan Sandwich Queens1Document10 pagesBusiness Plan Sandwich Queens1Alyzza CasinoNo ratings yet

- Adjustments To Reconcile Net Income To Net Cash Provided by Operating ActivitiesDocument4 pagesAdjustments To Reconcile Net Income To Net Cash Provided by Operating ActivitiesTasim IshraqueNo ratings yet

- Year Examination Institution Marks ObtainedDocument2 pagesYear Examination Institution Marks ObtainedTanya SinghNo ratings yet

- Econ2113 PS2Document5 pagesEcon2113 PS2jacky114aaNo ratings yet

- Test Bank For Supply Management 8th Edition David N BurtDocument10 pagesTest Bank For Supply Management 8th Edition David N BurtShamika Bejaran100% (27)

- The B2B Executive Playbook: Achieving Sustainable, Predictable, Profitable GrowthDocument21 pagesThe B2B Executive Playbook: Achieving Sustainable, Predictable, Profitable GrowthSasi KumarNo ratings yet

- Types of Media: Lecture - 3Document21 pagesTypes of Media: Lecture - 3MUHAMMAD ZAINNo ratings yet

- Third Quarter ExamDocument6 pagesThird Quarter ExamRaul Soriano Cabanting100% (4)

- Hfsafety 1 SEM 22-23: Click To Add Text Click To Add TextDocument70 pagesHfsafety 1 SEM 22-23: Click To Add Text Click To Add TextAdrienne CoNo ratings yet