Professional Documents

Culture Documents

3.2. OES-TD-INT-005-FS-MM01 Rev1

3.2. OES-TD-INT-005-FS-MM01 Rev1

Uploaded by

sumit kumarCopyright:

Available Formats

You might also like

- Method Statement For Installation of Diesel Generator SetDocument3 pagesMethod Statement For Installation of Diesel Generator SetIngersol Duraikannu100% (2)

- AMS2411Document9 pagesAMS2411Pankaj Shah100% (1)

- Bogie Technical RequirementsDocument8 pagesBogie Technical RequirementsAmit shahNo ratings yet

- Turtle Diagram: New ProductDocument15 pagesTurtle Diagram: New ProductDuy Le100% (6)

- CoversDocument32 pagesCoversJhon Benedick Pando Taja100% (3)

- 3.3. Oes-Td-Int-005-Fs-Mm02Document6 pages3.3. Oes-Td-Int-005-Fs-Mm02sumit kumarNo ratings yet

- Engineering Standards: 1. ScopeDocument3 pagesEngineering Standards: 1. Scopergimiranda.engNo ratings yet

- For Comments OnlyDocument8 pagesFor Comments Onlybidhan012No ratings yet

- HC-49 Engineering SpecificationDocument6 pagesHC-49 Engineering SpecificationarunrathikaNo ratings yet

- 16tech Spec RSJ Pole 10.07.2019 Revised Dt. 10.11.2020 1Document7 pages16tech Spec RSJ Pole 10.07.2019 Revised Dt. 10.11.2020 1Anonymous cj7JdRbDbNo ratings yet

- Astm A537 - A537m-13 (R2019)Document3 pagesAstm A537 - A537m-13 (R2019)1965karanfil6No ratings yet

- TS - LR BendDocument9 pagesTS - LR BendMecon LtdNo ratings yet

- LR BendDocument9 pagesLR BendGiridharan GanesanNo ratings yet

- Plates Spec.Document8 pagesPlates Spec.Shreenivas ThakurNo ratings yet

- Is 1030-1998Document8 pagesIs 1030-1998Sumit ShyamalNo ratings yet

- Engineering Standards: 1. ScopeDocument2 pagesEngineering Standards: 1. ScopepathinathanNo ratings yet

- Asme Sa 517 Astm A517 PDFDocument5 pagesAsme Sa 517 Astm A517 PDFBernathTurnipNo ratings yet

- B587-000-06-41-PLS-03 - Rev 0Document14 pagesB587-000-06-41-PLS-03 - Rev 0SAUGAT DUTTANo ratings yet

- MIL-C-26074E Electroless Nickel CoatingsDocument11 pagesMIL-C-26074E Electroless Nickel CoatingsAbdelhamied ElkadyNo ratings yet

- Scope: Name Engineering Standard NumberDocument2 pagesScope: Name Engineering Standard NumberpathinathanNo ratings yet

- ME 205 - 432 - Assignment 1Document6 pagesME 205 - 432 - Assignment 1سلمان العتيبيNo ratings yet

- Kuwait Oil Company (K.S.C.) : Engineering GroupDocument14 pagesKuwait Oil Company (K.S.C.) : Engineering GroupRELLA ROSHAN KUMARNo ratings yet

- TDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Document1 pageTDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Tanpreet SinghNo ratings yet

- Sa 352Document8 pagesSa 352Raju SkNo ratings yet

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument4 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsSriniramu SriniramuNo ratings yet

- 44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESDocument5 pages44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESAvinash ShuklaNo ratings yet

- Ceramic SpecDocument8 pagesCeramic SpecpujadagaNo ratings yet

- Indian Standard - 2644Document8 pagesIndian Standard - 2644Biswajit DasNo ratings yet

- B. Specifications For FR TankDocument32 pagesB. Specifications For FR TankRoshin99No ratings yet

- Astm A 515 - A 515M PDFDocument3 pagesAstm A 515 - A 515M PDFJosé de Paula MoreiraNo ratings yet

- Scope: Name Engineering Standard NumberDocument4 pagesScope: Name Engineering Standard Numbernethaji nethajiNo ratings yet

- Lloyds Rules For Manufacture Testing and Certification of MaterialsDocument4 pagesLloyds Rules For Manufacture Testing and Certification of MaterialskatchaniNo ratings yet

- A 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFDocument8 pagesA 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFMung Duong XuanNo ratings yet

- Excel SC 1018-1020Document5 pagesExcel SC 1018-1020Nabil MaksudNo ratings yet

- 1 SS MT 007Document34 pages1 SS MT 007SURAJ PRSADNo ratings yet

- Mar2014/zip/10462990 TD Technical SpecificationDocument6 pagesMar2014/zip/10462990 TD Technical SpecificationNaresh Ch MahapatraNo ratings yet

- A516A516M-17 Standard Specification Pressure Vessel PlatesDocument2 pagesA516A516M-17 Standard Specification Pressure Vessel PlatesYilia Wang100% (2)

- Part A: Basic Information: Ref: Current Spec. NoDocument17 pagesPart A: Basic Information: Ref: Current Spec. NoAbhey DograNo ratings yet

- Husky Engineering SpecsDocument89 pagesHusky Engineering Specsntrkulja@hotmail.comNo ratings yet

- Is - 1030Document8 pagesIs - 1030Aaditya SharmaNo ratings yet

- Spec EarthingDocument9 pagesSpec EarthingsbpathiNo ratings yet

- Hy 19580Document6 pagesHy 19580kompany_dNo ratings yet

- Materials Technical Specification.: Stainless SteelDocument6 pagesMaterials Technical Specification.: Stainless SteelMario TirabassiNo ratings yet

- Is 513 - 1994 - r2003 - Cold Rolled Low Carbon Steel SheetsDocument11 pagesIs 513 - 1994 - r2003 - Cold Rolled Low Carbon Steel SheetsRam Niwas100% (3)

- Is 1030 1998 PDFDocument8 pagesIs 1030 1998 PDFRitesh AnandNo ratings yet

- Astm A537Document4 pagesAstm A537mtNo ratings yet

- Seamless Cold-Drawn Carbon Steel Tubing For Hydraulic System ServiceDocument3 pagesSeamless Cold-Drawn Carbon Steel Tubing For Hydraulic System ServiceDarwin DarmawanNo ratings yet

- EGP3-01.16 Welding For Skids and Miscellaneous SteelDocument10 pagesEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodeNo ratings yet

- Austenitic Ductile Iron Castings: Standard Specification ForDocument6 pagesAustenitic Ductile Iron Castings: Standard Specification ForDarwin DarmawanNo ratings yet

- Technical Spec. HRC Procurement API 5L Gr. L450MO PSL 2 Rev. 0Document9 pagesTechnical Spec. HRC Procurement API 5L Gr. L450MO PSL 2 Rev. 0FerryNo ratings yet

- A1021Document4 pagesA1021Aleksei AvilaNo ratings yet

- TDC QapDocument69 pagesTDC QapKuppuraj ParamsivamNo ratings yet

- Is 2707Document6 pagesIs 2707RSP1234No ratings yet

- 2006-Insulation of Piping & Eqptrev1Document43 pages2006-Insulation of Piping & Eqptrev1Rajkumar ANo ratings yet

- 175 017800Document1 page175 017800Abu Anas M.SalaheldinNo ratings yet

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument3 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsTamil funNo ratings yet

- 20 PC e 00165 R1Document20 pages20 PC e 00165 R1isan.structural TjsvgalavanNo ratings yet

- Technical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsDocument11 pagesTechnical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsMunish100% (1)

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Indra: For ConstructionDocument48 pagesIndra: For Constructionsumit kumarNo ratings yet

- Indra: For ConstructionDocument8 pagesIndra: For Constructionsumit kumarNo ratings yet

- Indra: For ConstructionDocument28 pagesIndra: For Constructionsumit kumarNo ratings yet

- Pveng: Vessel With Large Opening Pve Sample VesselDocument1 pagePveng: Vessel With Large Opening Pve Sample VesselSivateja NallamothuNo ratings yet

- Indra: For ConstructionDocument25 pagesIndra: For Constructionsumit kumarNo ratings yet

- S-000-1222-001 BeddDocument30 pagesS-000-1222-001 Beddsumit kumarNo ratings yet

- 7-12-0015 Rev6 (Standard Bolt Hole Orientation)Document1 page7-12-0015 Rev6 (Standard Bolt Hole Orientation)sumit kumarNo ratings yet

- Appendix 3 - Priliminary PFDDocument1 pageAppendix 3 - Priliminary PFDsumit kumarNo ratings yet

- Indra: For ConstructionDocument25 pagesIndra: For Constructionsumit kumarNo ratings yet

- Appendix 1 - Referenc ProjectsDocument2 pagesAppendix 1 - Referenc Projectssumit kumarNo ratings yet

- Inspection and Test Plan FOR Filter Separator/CoalescerDocument6 pagesInspection and Test Plan FOR Filter Separator/Coalescersumit kumarNo ratings yet

- Appendix 2 - Example 3D Model PDFDocument1 pageAppendix 2 - Example 3D Model PDFsumit kumarNo ratings yet

- Improved Spectrometric Analysis For Positive Material Identification (PMI)Document14 pagesImproved Spectrometric Analysis For Positive Material Identification (PMI)sumit kumarNo ratings yet

- 7-12-0007 Rev6 (Pipe Leg Support)Document1 page7-12-0007 Rev6 (Pipe Leg Support)sumit kumar100% (1)

- Untitled2 PDFDocument1 pageUntitled2 PDFsumit kumarNo ratings yet

- GPRS Line Sizes Velocity Max 25 M-SDocument1 pageGPRS Line Sizes Velocity Max 25 M-Ssumit kumarNo ratings yet

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

- 7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFDocument1 page7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFsumit kumar100% (1)

- 7-12-0006 Rev6 (Angle Leg Support)Document2 pages7-12-0006 Rev6 (Angle Leg Support)sumit kumarNo ratings yet

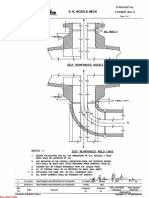

- 7-12-0037 Rev4 (SR Nozzle Neck)Document1 page7-12-0037 Rev4 (SR Nozzle Neck)sumit kumarNo ratings yet

- 7-12-0020 Rev6 (Inlet Deflector Baffles) PDFDocument1 page7-12-0020 Rev6 (Inlet Deflector Baffles) PDFsumit kumarNo ratings yet

- 7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFDocument1 page7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFsumit kumarNo ratings yet

- 134giseers Eb-Nna Limited ... Vessel Tolerances: It WV.L J% 1 "Document2 pages134giseers Eb-Nna Limited ... Vessel Tolerances: It WV.L J% 1 "sumit kumarNo ratings yet

- 7-12-0004 Rev7 (Skirt Base Details)Document1 page7-12-0004 Rev7 (Skirt Base Details)sumit kumarNo ratings yet

- Inter Office Memo: S.NO. Item Offered (SCH/THK) MOC Heat No. & PL No Po/Job No. MRR No. Stock Ref RemarksDocument1 pageInter Office Memo: S.NO. Item Offered (SCH/THK) MOC Heat No. & PL No Po/Job No. MRR No. Stock Ref Remarkssumit kumarNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- 7-12-0005 Rev6 (Skirt Opening Details)Document2 pages7-12-0005 Rev6 (Skirt Opening Details)sumit kumar100% (1)

- KG 98-2-ONT-ME-OGT-DS-00001 - Data Sheet For Gas Separator (V-N78152 AB) Rev.0Document7 pagesKG 98-2-ONT-ME-OGT-DS-00001 - Data Sheet For Gas Separator (V-N78152 AB) Rev.0sumit kumarNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: Pramod KhotDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: Pramod Khotsumit kumarNo ratings yet

- KG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.ADocument5 pagesKG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.Asumit kumarNo ratings yet

- SMOKE CONTROL SYSTEM IN HIGH RISE BUILDINGS Rev1Document57 pagesSMOKE CONTROL SYSTEM IN HIGH RISE BUILDINGS Rev1Joshua FernandezNo ratings yet

- Chapter 5 - Welded Connections: A Beginner's Guide To The Steel Construction Manual, 14 EdDocument10 pagesChapter 5 - Welded Connections: A Beginner's Guide To The Steel Construction Manual, 14 EdINNOBUNo7No ratings yet

- Training and Procedure Manual: Directorate of Airspace and Air Navigation Services StandardsDocument76 pagesTraining and Procedure Manual: Directorate of Airspace and Air Navigation Services StandardsSanchit GoelNo ratings yet

- QuizletDocument39 pagesQuizletbananaNo ratings yet

- Plant Daily Inspection Checklist TemplateDocument2 pagesPlant Daily Inspection Checklist TemplateMuhammad Aiman Mohd SafrizalNo ratings yet

- Third Party Inspection AgencyDocument3 pagesThird Party Inspection Agencyeetcd tilariNo ratings yet

- Nikki AgarwalDocument4 pagesNikki AgarwalNikki AgarwalNo ratings yet

- 25-27a Ewis EzapDocument158 pages25-27a Ewis EzapriversgardenNo ratings yet

- Spedie TheDocument40 pagesSpedie ThedhowardjNo ratings yet

- Installation and Operation: EKL/EMK For Containers and SurfacesDocument23 pagesInstallation and Operation: EKL/EMK For Containers and SurfacesaleksandarlaskovNo ratings yet

- 2.hull Fabrication, Material & TestingDocument68 pages2.hull Fabrication, Material & Testinghailay83100% (1)

- Dam Safety Monitoring Maintenance in MalaysiaDocument64 pagesDam Safety Monitoring Maintenance in MalaysiaNina Aziz100% (1)

- Approved Certification Marks For Electrical Products - Technical Safety BC PDFDocument7 pagesApproved Certification Marks For Electrical Products - Technical Safety BC PDFincobarNo ratings yet

- 1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1Document1 page1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1KirubhakarPooranamNo ratings yet

- Hda Esr 1546Document10 pagesHda Esr 1546Alden CayagaNo ratings yet

- UDC Compilation 2011Document8 pagesUDC Compilation 2011John M. CavoteNo ratings yet

- 3855 ICorr Coating Inspector Assessment Guidelines 0821Document6 pages3855 ICorr Coating Inspector Assessment Guidelines 0821aliNo ratings yet

- Inspection Test Plan Rev 1Document2 pagesInspection Test Plan Rev 1Mohd KhairiNo ratings yet

- 149 Handover Inspection ChecklistDocument10 pages149 Handover Inspection Checklistsudeepjm100% (1)

- Project Execution Plan BTSDocument28 pagesProject Execution Plan BTSAnyanime WilliamsNo ratings yet

- PCBA Quality ControlDocument6 pagesPCBA Quality ControljackNo ratings yet

- Viro Wsi Brochure enDocument8 pagesViro Wsi Brochure enMerced HernandezNo ratings yet

- IPLEX RX - IPLEX RT - Olympus High Image Quality Industrial Videoscopes IPLEX RX Turbine Blade IPLEX Stereo MeasurementDocument10 pagesIPLEX RX - IPLEX RT - Olympus High Image Quality Industrial Videoscopes IPLEX RX Turbine Blade IPLEX Stereo MeasurementHANIF AKBARNo ratings yet

- Transmittal Document Review Notice: D K C Uba A Y'Document32 pagesTransmittal Document Review Notice: D K C Uba A Y'sinijith devNo ratings yet

- OPGWDocument69 pagesOPGWmanoj_ujvnlNo ratings yet

- Mil B 24480a (SH)Document8 pagesMil B 24480a (SH)Jeff95TANo ratings yet

- Control of Monitoring, Inspection, and Measuring Equipment - Rev. 01Document11 pagesControl of Monitoring, Inspection, and Measuring Equipment - Rev. 01moytabura96100% (1)

3.2. OES-TD-INT-005-FS-MM01 Rev1

3.2. OES-TD-INT-005-FS-MM01 Rev1

Uploaded by

sumit kumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.2. OES-TD-INT-005-FS-MM01 Rev1

3.2. OES-TD-INT-005-FS-MM01 Rev1

Uploaded by

sumit kumarCopyright:

Available Formats

FUNCTIONAL SPECIFICATION Spec No OES/TD/INT/005/FS/MM01

FOR Rev. No 1

ONSHORE

Discipline MECHANICAL

ENGINEERING WELDABLE STRUCTRURAL

SERVICES, QUALITY STEEL PLATES FOR

DELHI STORAGE TANKS AND SHEET 1 OF 4

VESSELS

FUNCTIONAL SPECIFICATION

FOR

WELDABLE STRUCTRURAL QUALITY STEEL

PLATES FOR STORAGE TANKS AND VESSELS

* Reproduced from SPECIFICATION NO: BDA/ODG/M/045 REV-1

FUNCTIONAL SPECIFICATION Spec No OES/TD/INT/005/FS/MM01

FOR Rev. No 1

ONSHORE

Discipline MECHANICAL

ENGINEERING WELDABLE STRUCTRURAL

SERVICES, QUALITY STEEL PLATES FOR

DELHI STORAGE TANKS AND SHEET 2 OF 4

VESSELS

CONTENTS

1.0 SCOPE

2.0 GENERAL

3.0 SUPPLEMENTARY TECHNICAL REQUIREMENTS

4.0 CERTIFIED DOCUMENTS

5.0 PAINTING AND COATING

6.0 INSPECTION AUTHORITY

FUNCTIONAL SPECIFICATION Spec No OES/TD/INT/005/FS/MM01

FOR Rev. No 1

ONSHORE

Discipline MECHANICAL

ENGINEERING WELDABLE STRUCTRURAL

SERVICES, QUALITY STEEL PLATES FOR

DELHI STORAGE TANKS AND SHEET 3 OF 4

VESSELS

1.0 SCOPE

This specification covers additional and supplementary requirements for weld-

able structural quality steel pates to IS:2062 ( latest ), intended primarily for

storage tanks and vessels.

2.0 GENERAL

2.1 The maximum under tolerance permissible on the thickness of the plate shall be

0.25 mm. Tolerances on other dimensions of plates shall be as per IS: 1852.

2.2 Direction of final rolling shall be lengthwise.

2.3 Reconditioning / repair of plates by welding shall not be permitted. Surface

condition shall meet requirements of EN 10163 ( Part 2 ) Class A Subclass 3.

2.4 Theoretical mass shall be calculated on the basis of density of 7.85 gm

/ cm3.

3.0 SUPPLEMTARY TECHNICAL REQUIREMENTS

3.1 Heat analysis and product analysis shall be carried out for each heat and

chemical composition shall meet the limits as specified in IS: 2062.

3.2 Y-groove weld crack-ability test as per IS: 10842 shall be carried out for plates

conforming to IS: 2062 Gr. C having thickness 12 mm and above.

3.3 Charpy impact test shall be carried out on the plates conforming to IS:

2062Gr. B and Gr. C. Test temperature shall be as specified in the material

requisition and acceptance criteria for energy absorption shall be as mentioned in

Table - 2 of the specification IS: 2062.

3.4 Simulation Heat Treatment of Test Coupons

3.4.1 Simulation heat treatment of test coupons is required for plates above 25 mm

thick. For plates of thickness 25 mm and below, simulation heat treatment is not

required unless otherwise specified in material requisition.

3.4.2 The heat treatment shall be carried out on test coupons before mechanical testing

like bend, tensile, impact, etc. The test coupons shall be drawn from one plate ( in

each thickness ) per heat. Results shall be reported on test certificate along with

the simulated heat treatment cycle.

Recommended heat treatment cycle :

No. of Cycle : One

Holding Temperature : 6000 C to 6500 C

FUNCTIONAL SPECIFICATION Spec No OES/TD/INT/005/FS/MM01

FOR Rev. No 1

ONSHORE

Discipline MECHANICAL

ENGINEERING WELDABLE STRUCTRURAL

SERVICES, QUALITY STEEL PLATES FOR

DELHI STORAGE TANKS AND SHEET 4 OF 4

VESSELS

Holding Time : Minimum one hour per 25 mm of

thickness but in no case less than

half an hour.

Furnace Temperature at : Not to exceed 4000 C

the Time of Loading

Rate of Heating : 2000 C max. / hr.

Rate of Cooling : 2500 C max. / hr

4.0 CERTIFIED DOCUMENTS

Contractor shall furnish 6 copies of the following certificates / documents inclusive

of results of all tests required as per specification, duly certified by the inspection

authority before shipment of plates. The actual values obtained during tests shall

be recorded in the test certificates / documents. Material certificates shall conform

to DIN 50049 Type 3. 1B / EN 10204 Type 3. 1B.

a. Chemical Analysis

b. Mechanical Test

c. Details of simulation heat treatment

d. Data of heat treatment

e. Charpy V-notch impact tests

f. Y-groove crack-ability test

g. Data of manufacture ( final rolling )

5.0 PAINTING AND COATING

No painting / coating of any kind is permitted on the steel plates except stencil

marking.

6.0 INSPECTION AUTHORITY

6.1 Unless otherwise stated in requisition, no third party inspection is required.

Material test certificate duly certified by Mill’s quality assurance / quality control

department is acceptable. However, Company reserves the right to ask

Contractor to depute the third party inspection agency at Contractor’s cost.

6.2 If third party inspection is required / specified in requisition, all the plates shall be

tested and witnessed in the presence of third party inspector and laboratory test

certificates and documents shall be duly certified by the third party inspection

agency.

You might also like

- Method Statement For Installation of Diesel Generator SetDocument3 pagesMethod Statement For Installation of Diesel Generator SetIngersol Duraikannu100% (2)

- AMS2411Document9 pagesAMS2411Pankaj Shah100% (1)

- Bogie Technical RequirementsDocument8 pagesBogie Technical RequirementsAmit shahNo ratings yet

- Turtle Diagram: New ProductDocument15 pagesTurtle Diagram: New ProductDuy Le100% (6)

- CoversDocument32 pagesCoversJhon Benedick Pando Taja100% (3)

- 3.3. Oes-Td-Int-005-Fs-Mm02Document6 pages3.3. Oes-Td-Int-005-Fs-Mm02sumit kumarNo ratings yet

- Engineering Standards: 1. ScopeDocument3 pagesEngineering Standards: 1. Scopergimiranda.engNo ratings yet

- For Comments OnlyDocument8 pagesFor Comments Onlybidhan012No ratings yet

- HC-49 Engineering SpecificationDocument6 pagesHC-49 Engineering SpecificationarunrathikaNo ratings yet

- 16tech Spec RSJ Pole 10.07.2019 Revised Dt. 10.11.2020 1Document7 pages16tech Spec RSJ Pole 10.07.2019 Revised Dt. 10.11.2020 1Anonymous cj7JdRbDbNo ratings yet

- Astm A537 - A537m-13 (R2019)Document3 pagesAstm A537 - A537m-13 (R2019)1965karanfil6No ratings yet

- TS - LR BendDocument9 pagesTS - LR BendMecon LtdNo ratings yet

- LR BendDocument9 pagesLR BendGiridharan GanesanNo ratings yet

- Plates Spec.Document8 pagesPlates Spec.Shreenivas ThakurNo ratings yet

- Is 1030-1998Document8 pagesIs 1030-1998Sumit ShyamalNo ratings yet

- Engineering Standards: 1. ScopeDocument2 pagesEngineering Standards: 1. ScopepathinathanNo ratings yet

- Asme Sa 517 Astm A517 PDFDocument5 pagesAsme Sa 517 Astm A517 PDFBernathTurnipNo ratings yet

- B587-000-06-41-PLS-03 - Rev 0Document14 pagesB587-000-06-41-PLS-03 - Rev 0SAUGAT DUTTANo ratings yet

- MIL-C-26074E Electroless Nickel CoatingsDocument11 pagesMIL-C-26074E Electroless Nickel CoatingsAbdelhamied ElkadyNo ratings yet

- Scope: Name Engineering Standard NumberDocument2 pagesScope: Name Engineering Standard NumberpathinathanNo ratings yet

- ME 205 - 432 - Assignment 1Document6 pagesME 205 - 432 - Assignment 1سلمان العتيبيNo ratings yet

- Kuwait Oil Company (K.S.C.) : Engineering GroupDocument14 pagesKuwait Oil Company (K.S.C.) : Engineering GroupRELLA ROSHAN KUMARNo ratings yet

- TDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Document1 pageTDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Tanpreet SinghNo ratings yet

- Sa 352Document8 pagesSa 352Raju SkNo ratings yet

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument4 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsSriniramu SriniramuNo ratings yet

- 44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESDocument5 pages44AC9100-000-V.02-0113-A4 - Rev B - GENERAL SPECIFICATION FOR BQ PLATESAvinash ShuklaNo ratings yet

- Ceramic SpecDocument8 pagesCeramic SpecpujadagaNo ratings yet

- Indian Standard - 2644Document8 pagesIndian Standard - 2644Biswajit DasNo ratings yet

- B. Specifications For FR TankDocument32 pagesB. Specifications For FR TankRoshin99No ratings yet

- Astm A 515 - A 515M PDFDocument3 pagesAstm A 515 - A 515M PDFJosé de Paula MoreiraNo ratings yet

- Scope: Name Engineering Standard NumberDocument4 pagesScope: Name Engineering Standard Numbernethaji nethajiNo ratings yet

- Lloyds Rules For Manufacture Testing and Certification of MaterialsDocument4 pagesLloyds Rules For Manufacture Testing and Certification of MaterialskatchaniNo ratings yet

- A 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFDocument8 pagesA 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFMung Duong XuanNo ratings yet

- Excel SC 1018-1020Document5 pagesExcel SC 1018-1020Nabil MaksudNo ratings yet

- 1 SS MT 007Document34 pages1 SS MT 007SURAJ PRSADNo ratings yet

- Mar2014/zip/10462990 TD Technical SpecificationDocument6 pagesMar2014/zip/10462990 TD Technical SpecificationNaresh Ch MahapatraNo ratings yet

- A516A516M-17 Standard Specification Pressure Vessel PlatesDocument2 pagesA516A516M-17 Standard Specification Pressure Vessel PlatesYilia Wang100% (2)

- Part A: Basic Information: Ref: Current Spec. NoDocument17 pagesPart A: Basic Information: Ref: Current Spec. NoAbhey DograNo ratings yet

- Husky Engineering SpecsDocument89 pagesHusky Engineering Specsntrkulja@hotmail.comNo ratings yet

- Is - 1030Document8 pagesIs - 1030Aaditya SharmaNo ratings yet

- Spec EarthingDocument9 pagesSpec EarthingsbpathiNo ratings yet

- Hy 19580Document6 pagesHy 19580kompany_dNo ratings yet

- Materials Technical Specification.: Stainless SteelDocument6 pagesMaterials Technical Specification.: Stainless SteelMario TirabassiNo ratings yet

- Is 513 - 1994 - r2003 - Cold Rolled Low Carbon Steel SheetsDocument11 pagesIs 513 - 1994 - r2003 - Cold Rolled Low Carbon Steel SheetsRam Niwas100% (3)

- Is 1030 1998 PDFDocument8 pagesIs 1030 1998 PDFRitesh AnandNo ratings yet

- Astm A537Document4 pagesAstm A537mtNo ratings yet

- Seamless Cold-Drawn Carbon Steel Tubing For Hydraulic System ServiceDocument3 pagesSeamless Cold-Drawn Carbon Steel Tubing For Hydraulic System ServiceDarwin DarmawanNo ratings yet

- EGP3-01.16 Welding For Skids and Miscellaneous SteelDocument10 pagesEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodeNo ratings yet

- Austenitic Ductile Iron Castings: Standard Specification ForDocument6 pagesAustenitic Ductile Iron Castings: Standard Specification ForDarwin DarmawanNo ratings yet

- Technical Spec. HRC Procurement API 5L Gr. L450MO PSL 2 Rev. 0Document9 pagesTechnical Spec. HRC Procurement API 5L Gr. L450MO PSL 2 Rev. 0FerryNo ratings yet

- A1021Document4 pagesA1021Aleksei AvilaNo ratings yet

- TDC QapDocument69 pagesTDC QapKuppuraj ParamsivamNo ratings yet

- Is 2707Document6 pagesIs 2707RSP1234No ratings yet

- 2006-Insulation of Piping & Eqptrev1Document43 pages2006-Insulation of Piping & Eqptrev1Rajkumar ANo ratings yet

- 175 017800Document1 page175 017800Abu Anas M.SalaheldinNo ratings yet

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument3 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsTamil funNo ratings yet

- 20 PC e 00165 R1Document20 pages20 PC e 00165 R1isan.structural TjsvgalavanNo ratings yet

- Technical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsDocument11 pagesTechnical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsMunish100% (1)

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Indra: For ConstructionDocument48 pagesIndra: For Constructionsumit kumarNo ratings yet

- Indra: For ConstructionDocument8 pagesIndra: For Constructionsumit kumarNo ratings yet

- Indra: For ConstructionDocument28 pagesIndra: For Constructionsumit kumarNo ratings yet

- Pveng: Vessel With Large Opening Pve Sample VesselDocument1 pagePveng: Vessel With Large Opening Pve Sample VesselSivateja NallamothuNo ratings yet

- Indra: For ConstructionDocument25 pagesIndra: For Constructionsumit kumarNo ratings yet

- S-000-1222-001 BeddDocument30 pagesS-000-1222-001 Beddsumit kumarNo ratings yet

- 7-12-0015 Rev6 (Standard Bolt Hole Orientation)Document1 page7-12-0015 Rev6 (Standard Bolt Hole Orientation)sumit kumarNo ratings yet

- Appendix 3 - Priliminary PFDDocument1 pageAppendix 3 - Priliminary PFDsumit kumarNo ratings yet

- Indra: For ConstructionDocument25 pagesIndra: For Constructionsumit kumarNo ratings yet

- Appendix 1 - Referenc ProjectsDocument2 pagesAppendix 1 - Referenc Projectssumit kumarNo ratings yet

- Inspection and Test Plan FOR Filter Separator/CoalescerDocument6 pagesInspection and Test Plan FOR Filter Separator/Coalescersumit kumarNo ratings yet

- Appendix 2 - Example 3D Model PDFDocument1 pageAppendix 2 - Example 3D Model PDFsumit kumarNo ratings yet

- Improved Spectrometric Analysis For Positive Material Identification (PMI)Document14 pagesImproved Spectrometric Analysis For Positive Material Identification (PMI)sumit kumarNo ratings yet

- 7-12-0007 Rev6 (Pipe Leg Support)Document1 page7-12-0007 Rev6 (Pipe Leg Support)sumit kumar100% (1)

- Untitled2 PDFDocument1 pageUntitled2 PDFsumit kumarNo ratings yet

- GPRS Line Sizes Velocity Max 25 M-SDocument1 pageGPRS Line Sizes Velocity Max 25 M-Ssumit kumarNo ratings yet

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

- 7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFDocument1 page7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFsumit kumar100% (1)

- 7-12-0006 Rev6 (Angle Leg Support)Document2 pages7-12-0006 Rev6 (Angle Leg Support)sumit kumarNo ratings yet

- 7-12-0037 Rev4 (SR Nozzle Neck)Document1 page7-12-0037 Rev4 (SR Nozzle Neck)sumit kumarNo ratings yet

- 7-12-0020 Rev6 (Inlet Deflector Baffles) PDFDocument1 page7-12-0020 Rev6 (Inlet Deflector Baffles) PDFsumit kumarNo ratings yet

- 7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFDocument1 page7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFsumit kumarNo ratings yet

- 134giseers Eb-Nna Limited ... Vessel Tolerances: It WV.L J% 1 "Document2 pages134giseers Eb-Nna Limited ... Vessel Tolerances: It WV.L J% 1 "sumit kumarNo ratings yet

- 7-12-0004 Rev7 (Skirt Base Details)Document1 page7-12-0004 Rev7 (Skirt Base Details)sumit kumarNo ratings yet

- Inter Office Memo: S.NO. Item Offered (SCH/THK) MOC Heat No. & PL No Po/Job No. MRR No. Stock Ref RemarksDocument1 pageInter Office Memo: S.NO. Item Offered (SCH/THK) MOC Heat No. & PL No Po/Job No. MRR No. Stock Ref Remarkssumit kumarNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- 7-12-0005 Rev6 (Skirt Opening Details)Document2 pages7-12-0005 Rev6 (Skirt Opening Details)sumit kumar100% (1)

- KG 98-2-ONT-ME-OGT-DS-00001 - Data Sheet For Gas Separator (V-N78152 AB) Rev.0Document7 pagesKG 98-2-ONT-ME-OGT-DS-00001 - Data Sheet For Gas Separator (V-N78152 AB) Rev.0sumit kumarNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: Pramod KhotDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: Pramod Khotsumit kumarNo ratings yet

- KG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.ADocument5 pagesKG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.Asumit kumarNo ratings yet

- SMOKE CONTROL SYSTEM IN HIGH RISE BUILDINGS Rev1Document57 pagesSMOKE CONTROL SYSTEM IN HIGH RISE BUILDINGS Rev1Joshua FernandezNo ratings yet

- Chapter 5 - Welded Connections: A Beginner's Guide To The Steel Construction Manual, 14 EdDocument10 pagesChapter 5 - Welded Connections: A Beginner's Guide To The Steel Construction Manual, 14 EdINNOBUNo7No ratings yet

- Training and Procedure Manual: Directorate of Airspace and Air Navigation Services StandardsDocument76 pagesTraining and Procedure Manual: Directorate of Airspace and Air Navigation Services StandardsSanchit GoelNo ratings yet

- QuizletDocument39 pagesQuizletbananaNo ratings yet

- Plant Daily Inspection Checklist TemplateDocument2 pagesPlant Daily Inspection Checklist TemplateMuhammad Aiman Mohd SafrizalNo ratings yet

- Third Party Inspection AgencyDocument3 pagesThird Party Inspection Agencyeetcd tilariNo ratings yet

- Nikki AgarwalDocument4 pagesNikki AgarwalNikki AgarwalNo ratings yet

- 25-27a Ewis EzapDocument158 pages25-27a Ewis EzapriversgardenNo ratings yet

- Spedie TheDocument40 pagesSpedie ThedhowardjNo ratings yet

- Installation and Operation: EKL/EMK For Containers and SurfacesDocument23 pagesInstallation and Operation: EKL/EMK For Containers and SurfacesaleksandarlaskovNo ratings yet

- 2.hull Fabrication, Material & TestingDocument68 pages2.hull Fabrication, Material & Testinghailay83100% (1)

- Dam Safety Monitoring Maintenance in MalaysiaDocument64 pagesDam Safety Monitoring Maintenance in MalaysiaNina Aziz100% (1)

- Approved Certification Marks For Electrical Products - Technical Safety BC PDFDocument7 pagesApproved Certification Marks For Electrical Products - Technical Safety BC PDFincobarNo ratings yet

- 1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1Document1 page1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1KirubhakarPooranamNo ratings yet

- Hda Esr 1546Document10 pagesHda Esr 1546Alden CayagaNo ratings yet

- UDC Compilation 2011Document8 pagesUDC Compilation 2011John M. CavoteNo ratings yet

- 3855 ICorr Coating Inspector Assessment Guidelines 0821Document6 pages3855 ICorr Coating Inspector Assessment Guidelines 0821aliNo ratings yet

- Inspection Test Plan Rev 1Document2 pagesInspection Test Plan Rev 1Mohd KhairiNo ratings yet

- 149 Handover Inspection ChecklistDocument10 pages149 Handover Inspection Checklistsudeepjm100% (1)

- Project Execution Plan BTSDocument28 pagesProject Execution Plan BTSAnyanime WilliamsNo ratings yet

- PCBA Quality ControlDocument6 pagesPCBA Quality ControljackNo ratings yet

- Viro Wsi Brochure enDocument8 pagesViro Wsi Brochure enMerced HernandezNo ratings yet

- IPLEX RX - IPLEX RT - Olympus High Image Quality Industrial Videoscopes IPLEX RX Turbine Blade IPLEX Stereo MeasurementDocument10 pagesIPLEX RX - IPLEX RT - Olympus High Image Quality Industrial Videoscopes IPLEX RX Turbine Blade IPLEX Stereo MeasurementHANIF AKBARNo ratings yet

- Transmittal Document Review Notice: D K C Uba A Y'Document32 pagesTransmittal Document Review Notice: D K C Uba A Y'sinijith devNo ratings yet

- OPGWDocument69 pagesOPGWmanoj_ujvnlNo ratings yet

- Mil B 24480a (SH)Document8 pagesMil B 24480a (SH)Jeff95TANo ratings yet

- Control of Monitoring, Inspection, and Measuring Equipment - Rev. 01Document11 pagesControl of Monitoring, Inspection, and Measuring Equipment - Rev. 01moytabura96100% (1)